Hi guys,

Inspired by our on-farm 9510RT, I've begun designing a 1/16 scale remote control 9RT. I really wanted to do it the "right" way with real double differential/planetary steering & it is even better than I anticipated. Steering control is very precise.

Features so far:

- True double planetary steering

- Continuous rotation GoBilda Speed servo for precise steering control

- Brushless sensored 540 1800Kv motor for unbelievable torque & smooth control

- All metal Actobotics gears & shafts

- Fully designed and 3D printed, less the hood, cab, and tracks.

Tractor is currently in 9300T form, but I'm working on the components to create a newer 9RT.

I have a sound module on the way also.

The 2700 Ripper has a servo to control up/down movements. I'm hoping to replicate a decent sized Deere 2660VT variable intensite tillage tool to go behind the tractor.

Quick progress video here:

https://youtu.be/CkZ-da93lEI

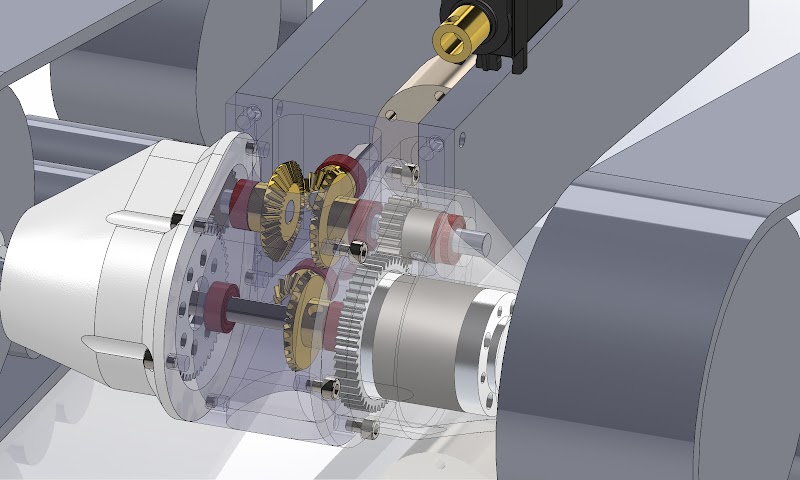

Solidworks design of the differential steering and drive gears:

Some mini-lathe work to create adapters for the planetary sun gear. I found these planetaries on eBay as part of a brushless gear reduction motor.

Early design of the small planetary assemblies, modified to accept a ring gear for the steering.

All parts use M3 fasteners and heat-set inserts. Sealed ball bearings throughout.

Since the base 9300T that I sourced the original cab, hood, and tracks from hasn't been made in 20+ years, I had to soften the tracks in a mixture of boiling water and wintergreen oil. Worked very well!

Final iteration of the track frame assembly. Has functional track tensioner & walking beam articulation.

Cheers!

Dave