Building a 'heavy haul' King Hauler. Body will be mostly standard, mainly changes to the drive line to give some real grunt. Work in progress....I'll point out some mods on the way....

Chose 'British Racing Green' for colour. It's a bit of a joke for this build 'cos 1) I'm a brit and 2) this truck will only be crawling, even in top gear :-D

The flash on the camera makes the colour look MUCH lighter than it really is, I'll see if pics without flash work better.

front arches modified for twin lights

I cut up the rear bumper to make these as twin headlights. They fit really well but have decided to get some in polished Aluminium to match the grill and front bumper from same material.

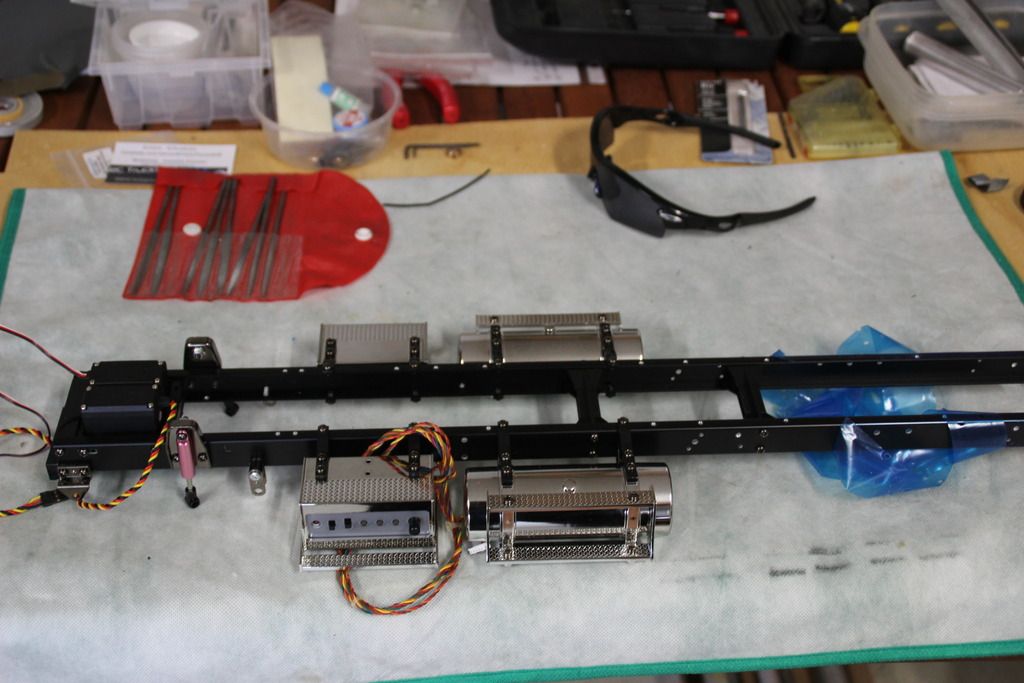

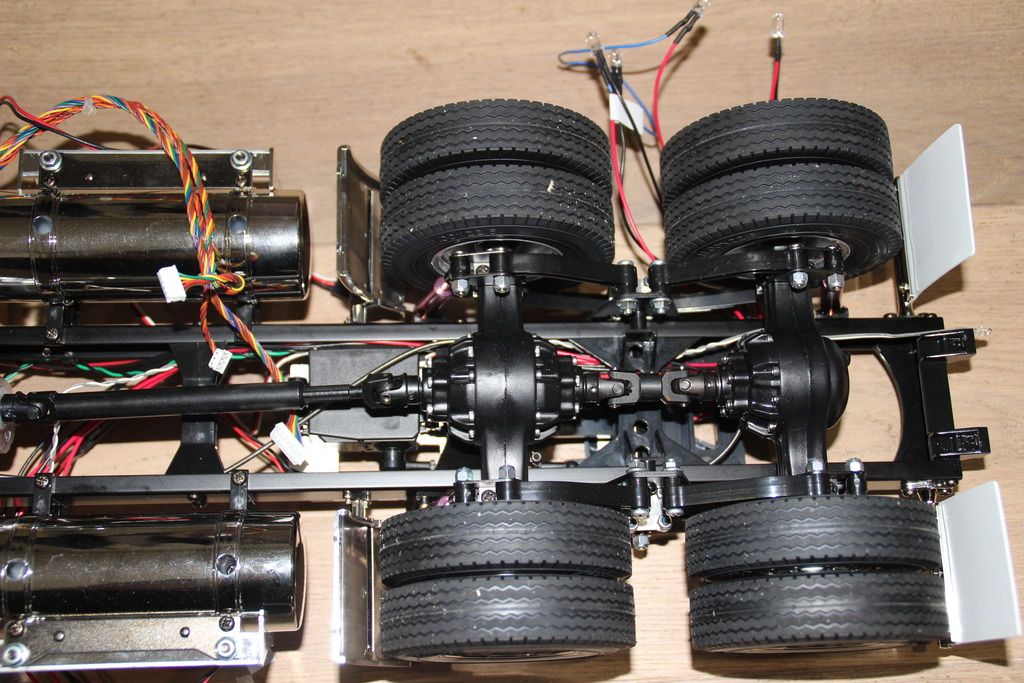

drilled holes in chassis cross members to route the wiring and diff lock cables on the other side

machined the outside edge of the front shock brackets to get better steering lock

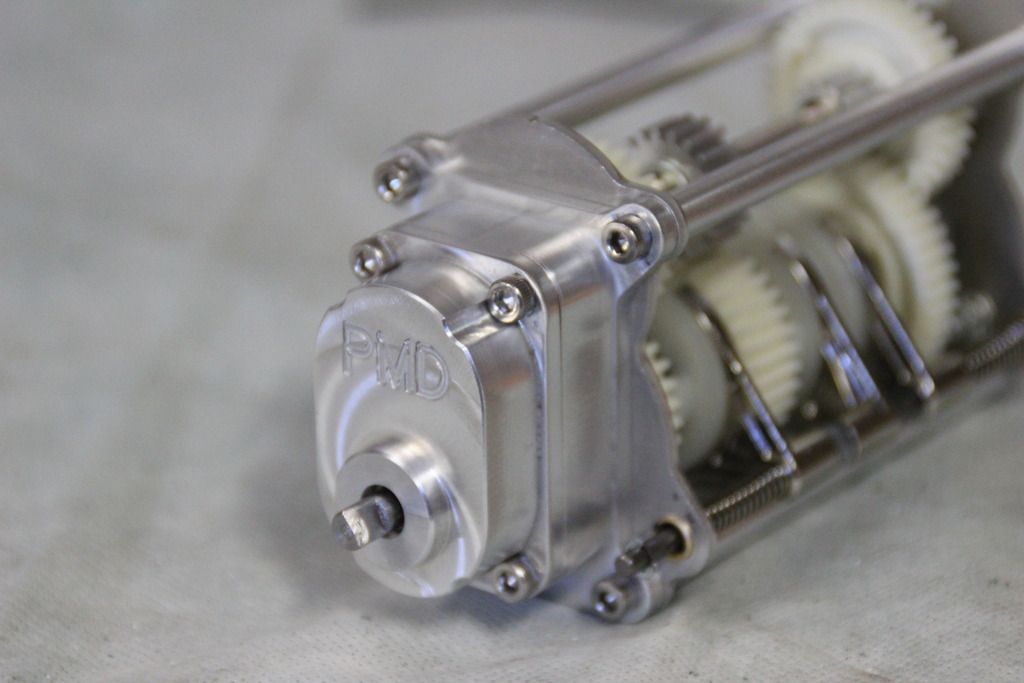

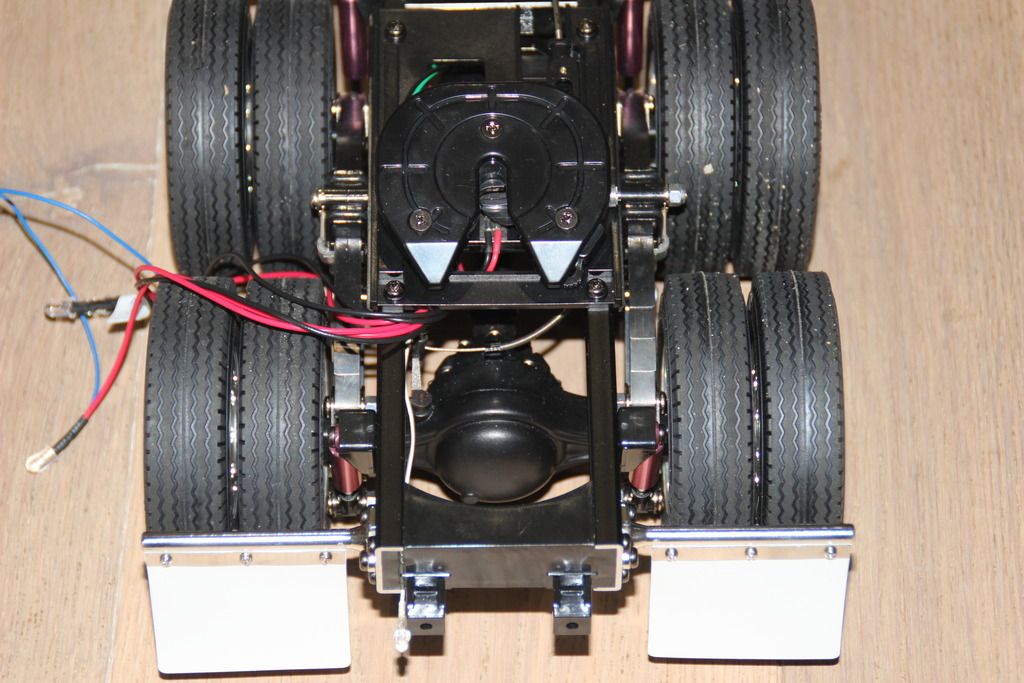

4:1 reduction from Garden Trucking bolts directly onto rear of gearbox. Great quality job, internal gears are hardened steel and comes with ball race bearings throughout

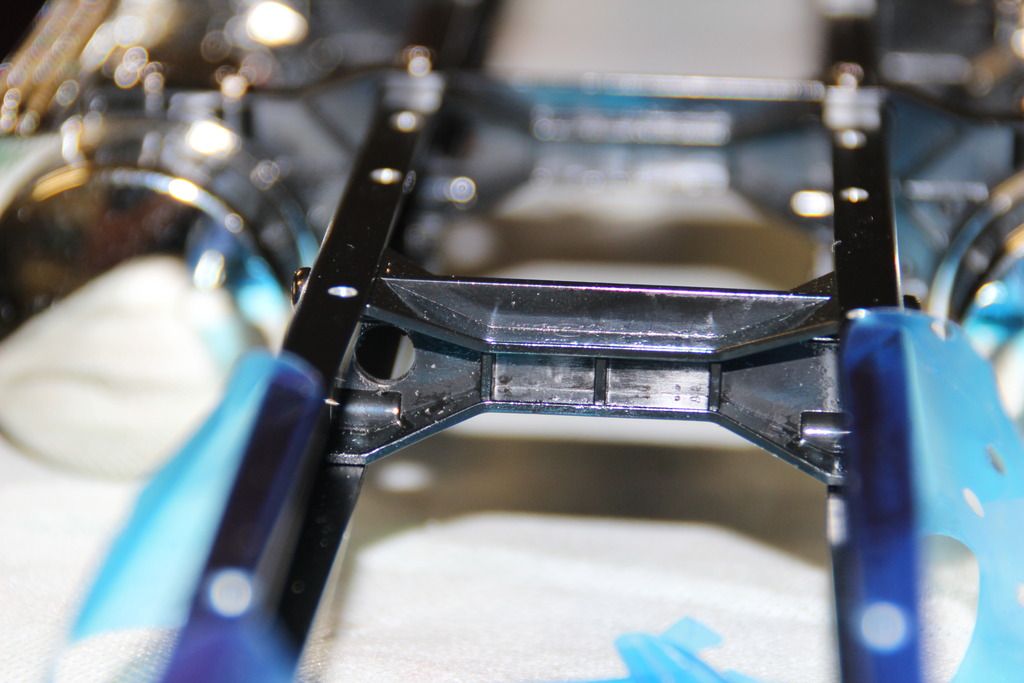

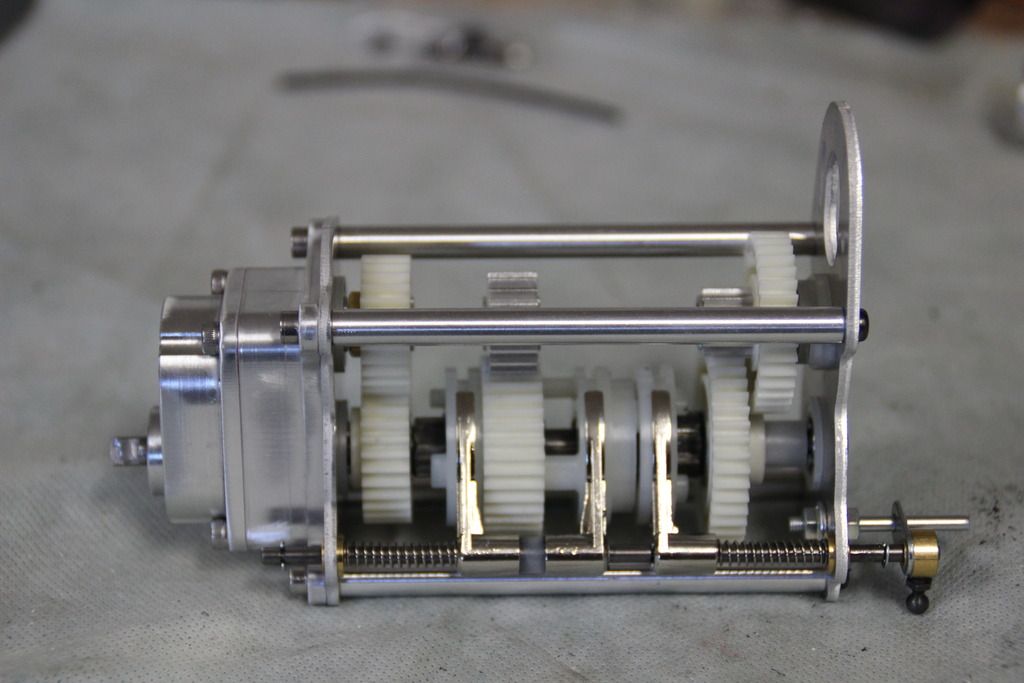

replaced the original KH 2-part selector forks with later single piece cast part. Had to file the web on the front one a bit, to allow clearance to the large gear when in 1st. Also used the ball knuckle from the Euro style trucks, which has the stabilizer rod so the selector shaft can't rotate

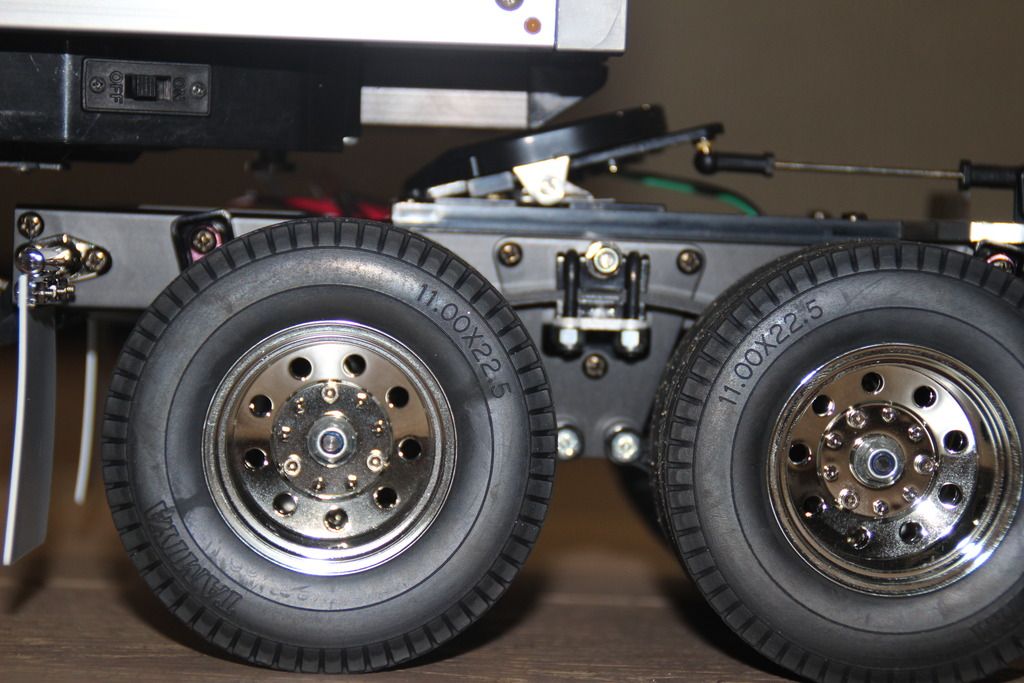

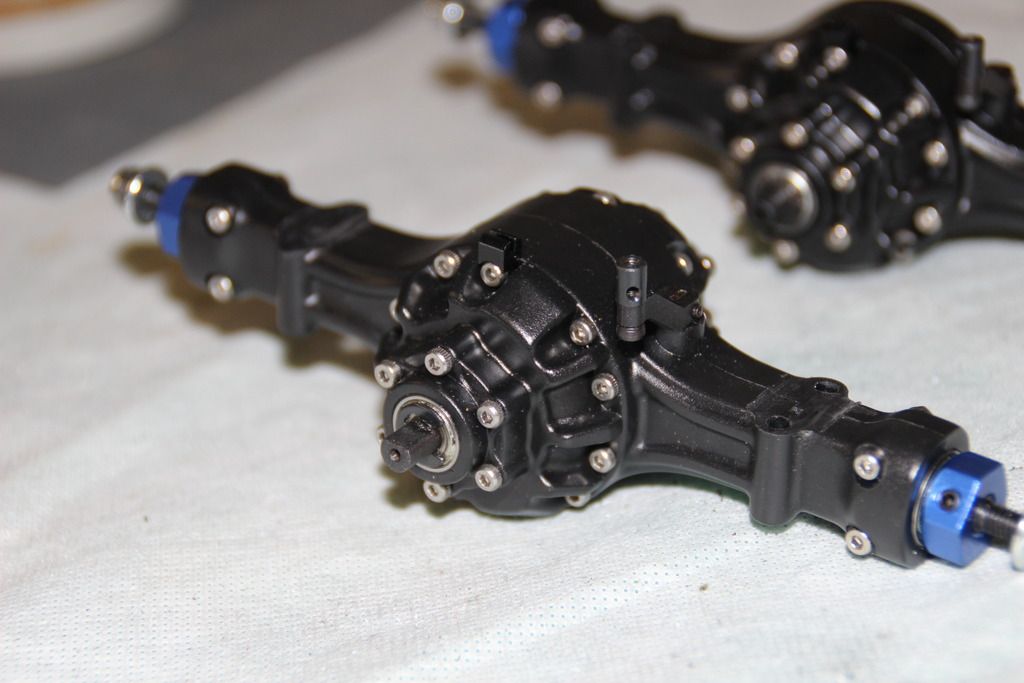

got a pair of RC4WD locking rear axles

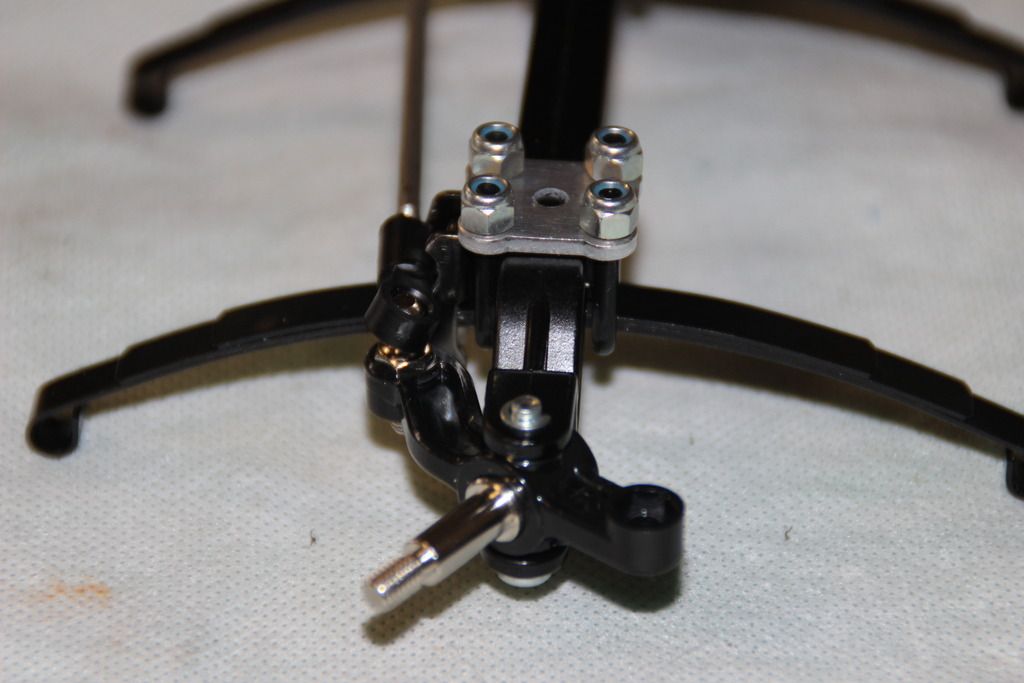

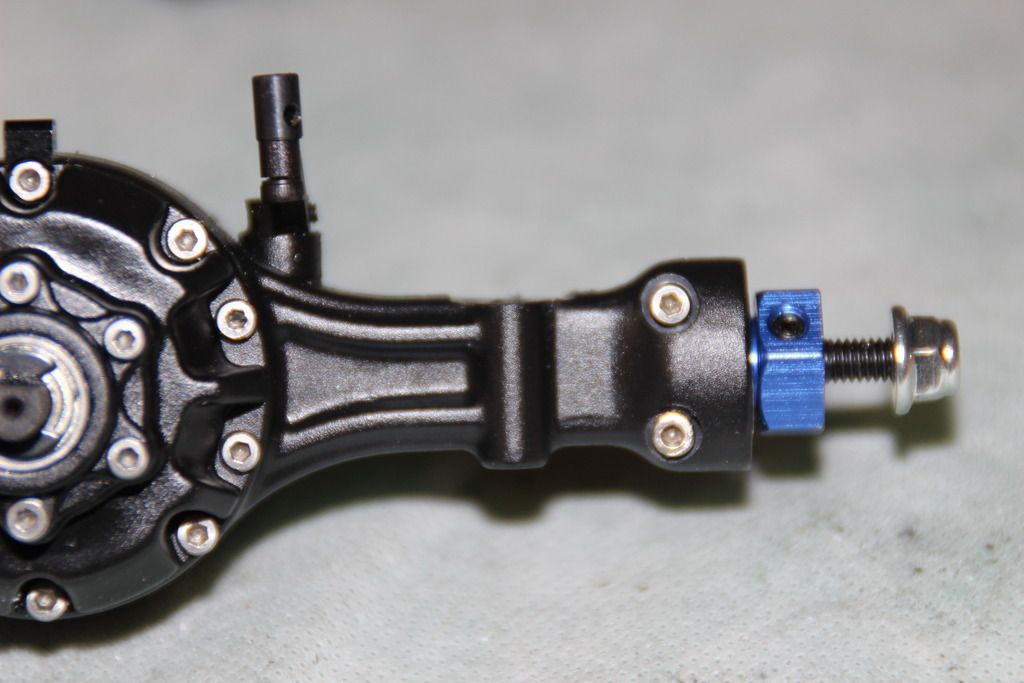

Since all my trailer use motorized support legs, it's critical to get the 5th wheel to sit at the same height as a standard truck otherwise trailer coupling is a shocker. These axle shaft is about 0.5mm lower than the surface where the suspension mounts to the axel, compared to the Tamiya standard, so need to remove 0.5mm of material from this surface for this. Also, I'm using the 4-leaf springs from the Euro 4x2 trucks on the back end, much stiffer than standard 3-leaf version which comes with all 6x4 trucks. But the extra leaf adds another 0.5mm, then the spring itself has slightly more curvature...another 0.5mm. So in total, need to removed 1.5mm from the axle mounting points...

Chassis pretty much finished. Changed motor for 33T 'Torque Tuned' truck motor. I don't really go for cosmetic hop-ups but I did replace the coupler servo plate with Tamiya's Aluminium upgrade. I think it looks really good, glad I got it.

Axles look more realistic, you can see the locking control cable

checked coupler height with a box trailer with motorized legs....the coupler first touches the trailer striker plate directly above the coupler hinge point, exactly how it should be. This means that when the prime mover hits the king pin, there is almost no pressure between the trailer and coupler when the trailer legs are extended....so got the machining on the axles it just right....phew......