Before I can finish the hydraulics. I need to sort out the oil tank/pump part.

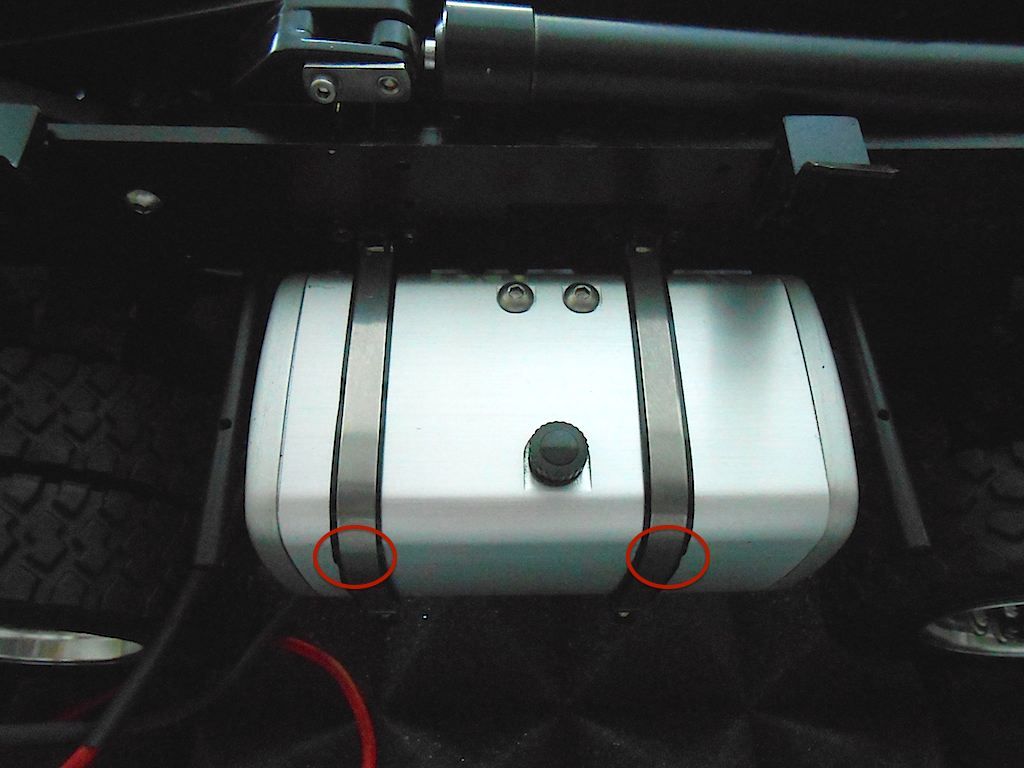

First the straps that hold it to the frame. After removing the bit of shrink tubing that protects the threads, you can see that some of the solder has contaminated them

Lucky I had an M2 thread cutter. So a couple of minutes later

As seen on other people's threads, the tank straps are having black rubber underneath. I could use some rubber from an old bike tire, but scaled up from 1/14.5 to 1.1 that bit of rubber would be way to thick. Ended up glueing two pieces of PVC film to one another and cutting some strips and gluing them to the straps with super glue.

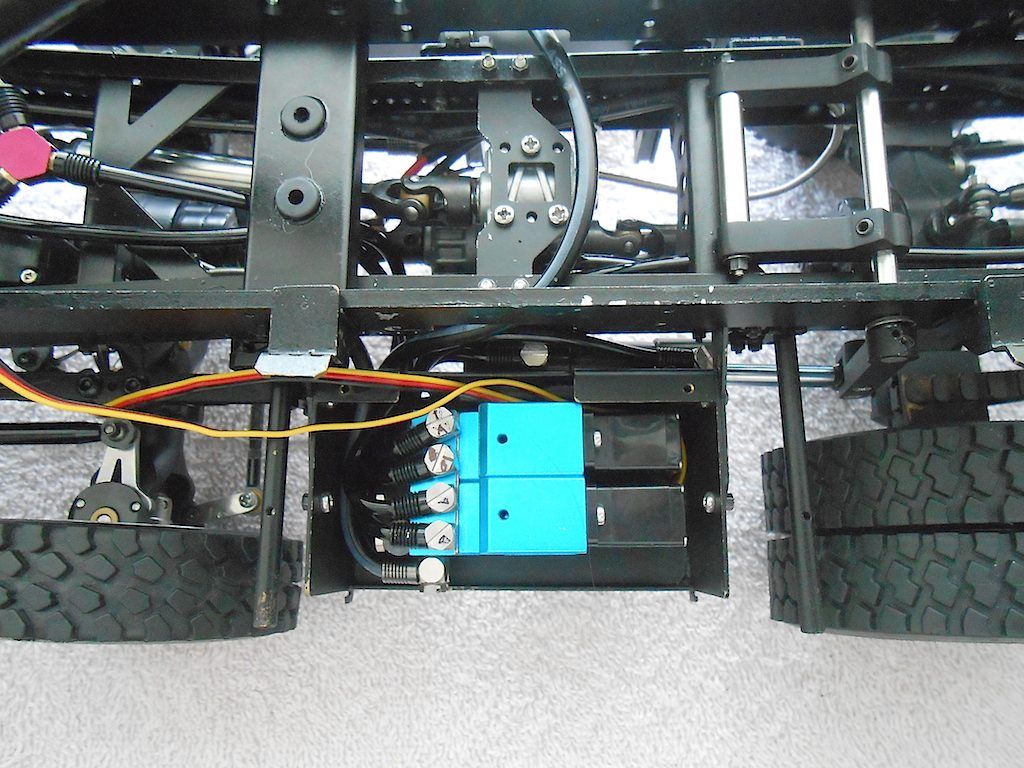

Installed the tank. The PVC - stainless and Super Glue didn't work. PVC film buckled. Something to deal with later.

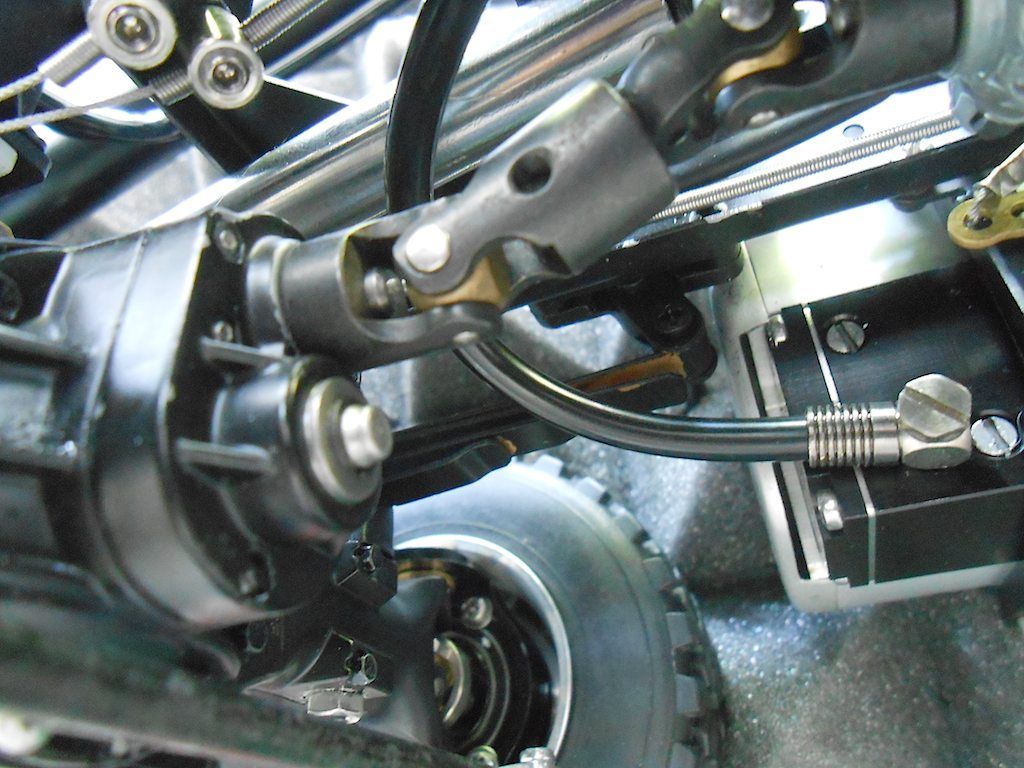

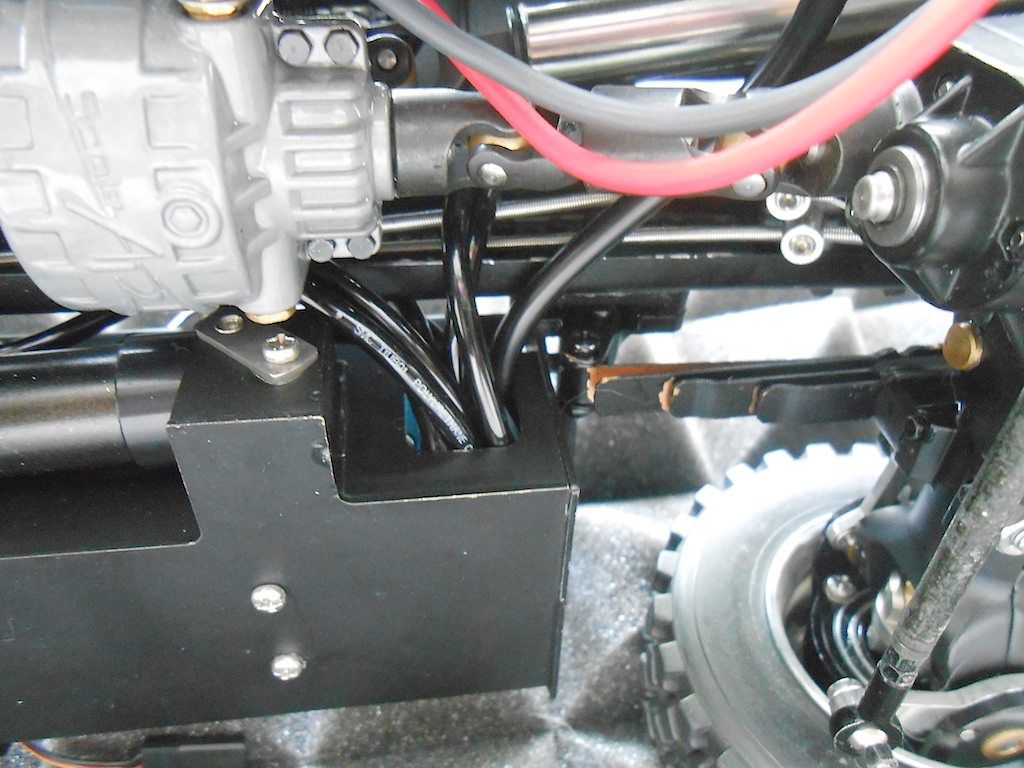

After trying different paths for the hose to go from pump to valve body ended up with this. Looks close to both props hafts, but plenty of room really. Very hard to get a picture of it. And those 4mm clamps that go on the nipple are absolutely impossible to get on. Used a 4.5 mm wrench as aid. (As seen in one of Newcomer_2's threads)

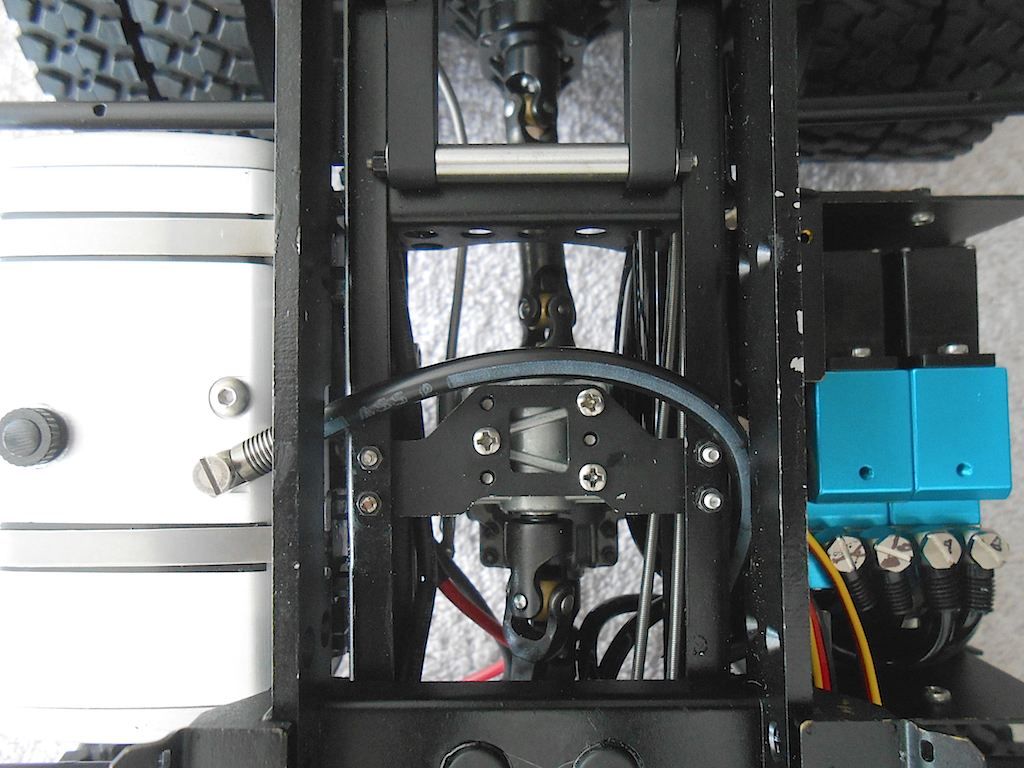

After sorting how to run both 4mm hoses. Have to connect the 2 hoses from the small kicker cylinder.

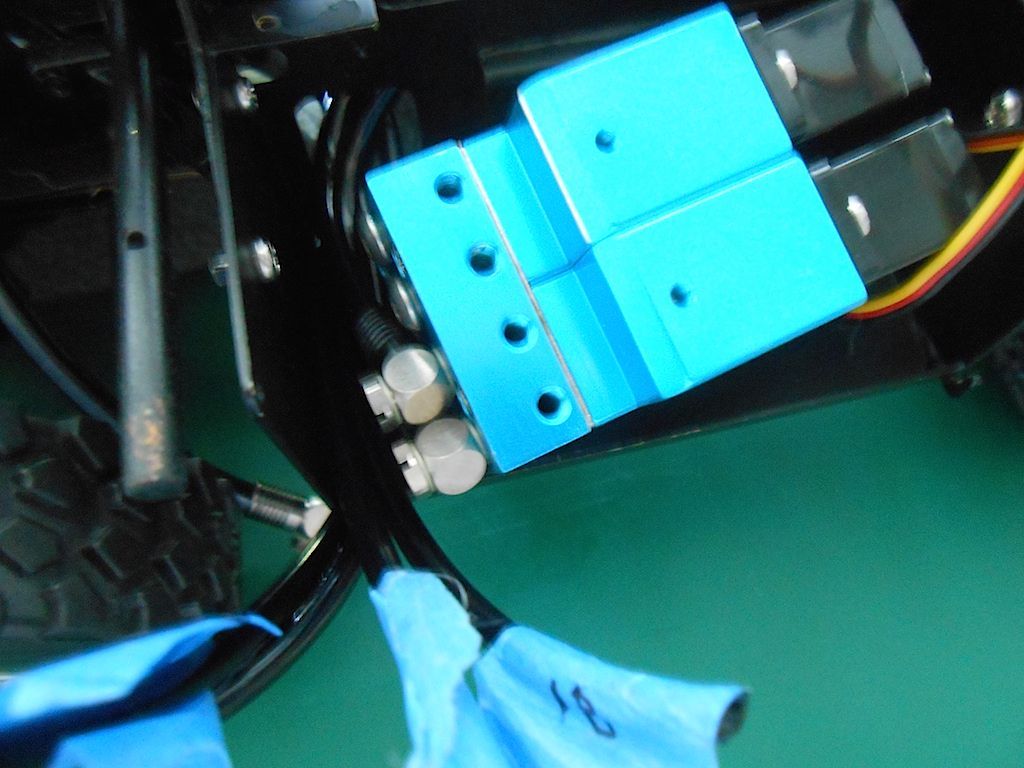

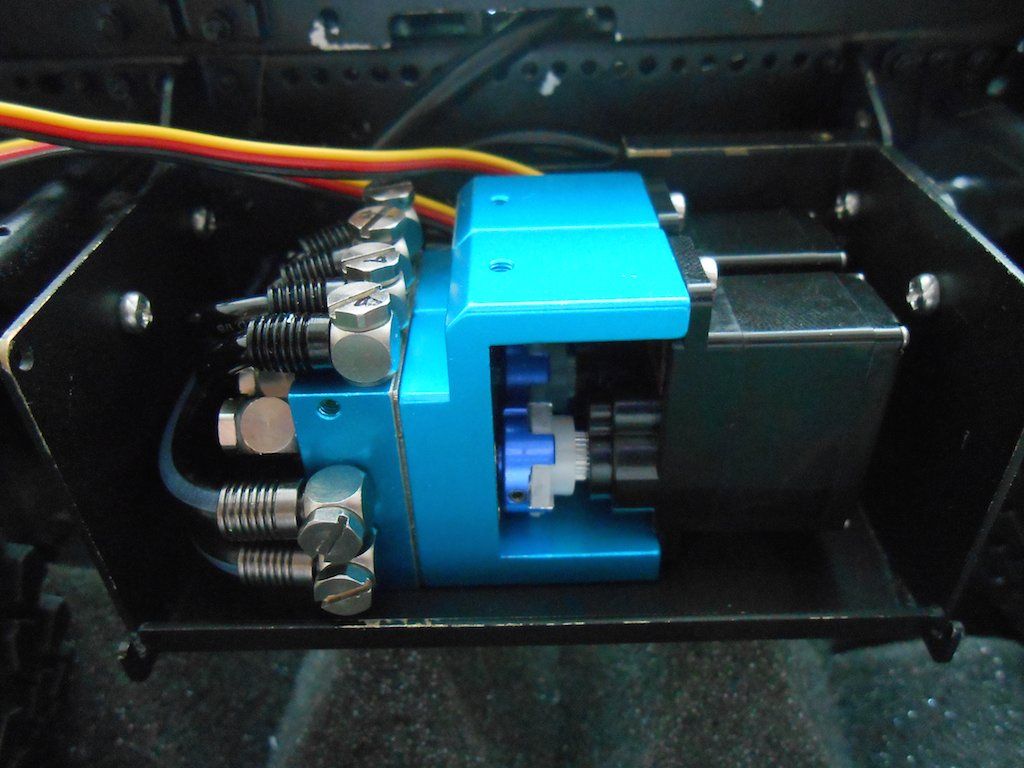

Then attach the 2 4mm hoses, and the rest of the connections. A bit of a job all this. Not really much room the work in. Found it was easier to get the nipples on the hoses and then attach to the valve block. The 4 nipples on top are not tightened yet to allow me to move the hook mechanism up and down. In the picture you can see one 3mm hose underneath the 4mm one at the chassis. I'll get back to that one ...

After this tightened up de straps of the oil pump after cutting 2 new strips from the PVC film. This time I just shoved it under the straps before tightening them. Works fine.

The electrical wires from the motor fitted just in between the curvature of the motor and the tank holder

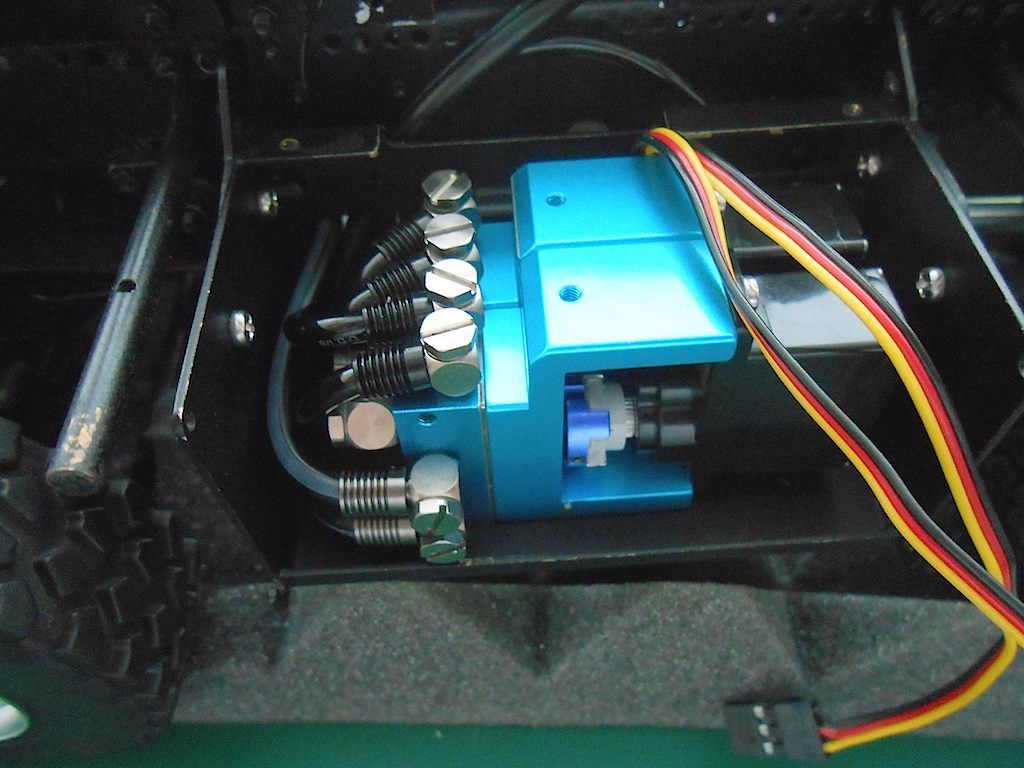

View of the back side of the Valve box

That brings us back to the hose I mentioned before ... Good thing I checked, as it turned out that I had swapped the 2 hoses. So had to take the whole thing out again and move those 2 from place. Of course they had to be the ones I installed first.

Anyway about 15 minutes later... much better.

And since I was at it, here the pictures of the return line I forgot to take

Now I have to figure out how to run the electrical wires to the front and sort it out on that end. This might take me some time.

Stephan