Thank you Ken, I don't know what to say other than happy accident

I was thinking of using the gravel to cover the damp areas that I soak for digging, make for a dry surface to keep the tracks out of the muddy clay.

The last time I posted was the morning before I went to the city to take in a seminar from a prairie marketing analyst; about 200 ppl attending & no doubt a few sickies in the group too, I just started feeling better this wkend.

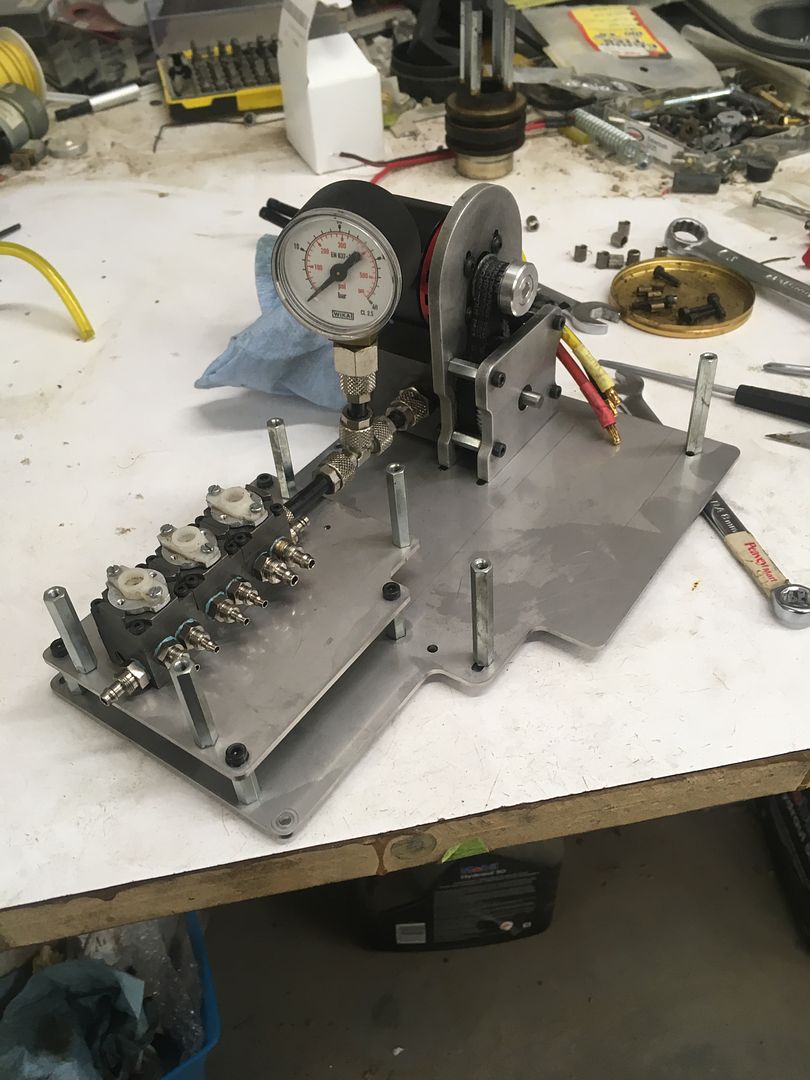

Getting some work done on the old JD850 last few days... pulled the boom off to get a better unobstructed view of the boom lines to look for a leak.

I capped the lines of the stick & bucket with Tamiya sized screws that fit snuggly to keep the oil from dripping everywhere... when I turned on the pump to pressure up boom cyls in both directions to see if a neoprene line had a pin hole, oil was coming out the other 4 lines past the screws

... that shouldn't do that

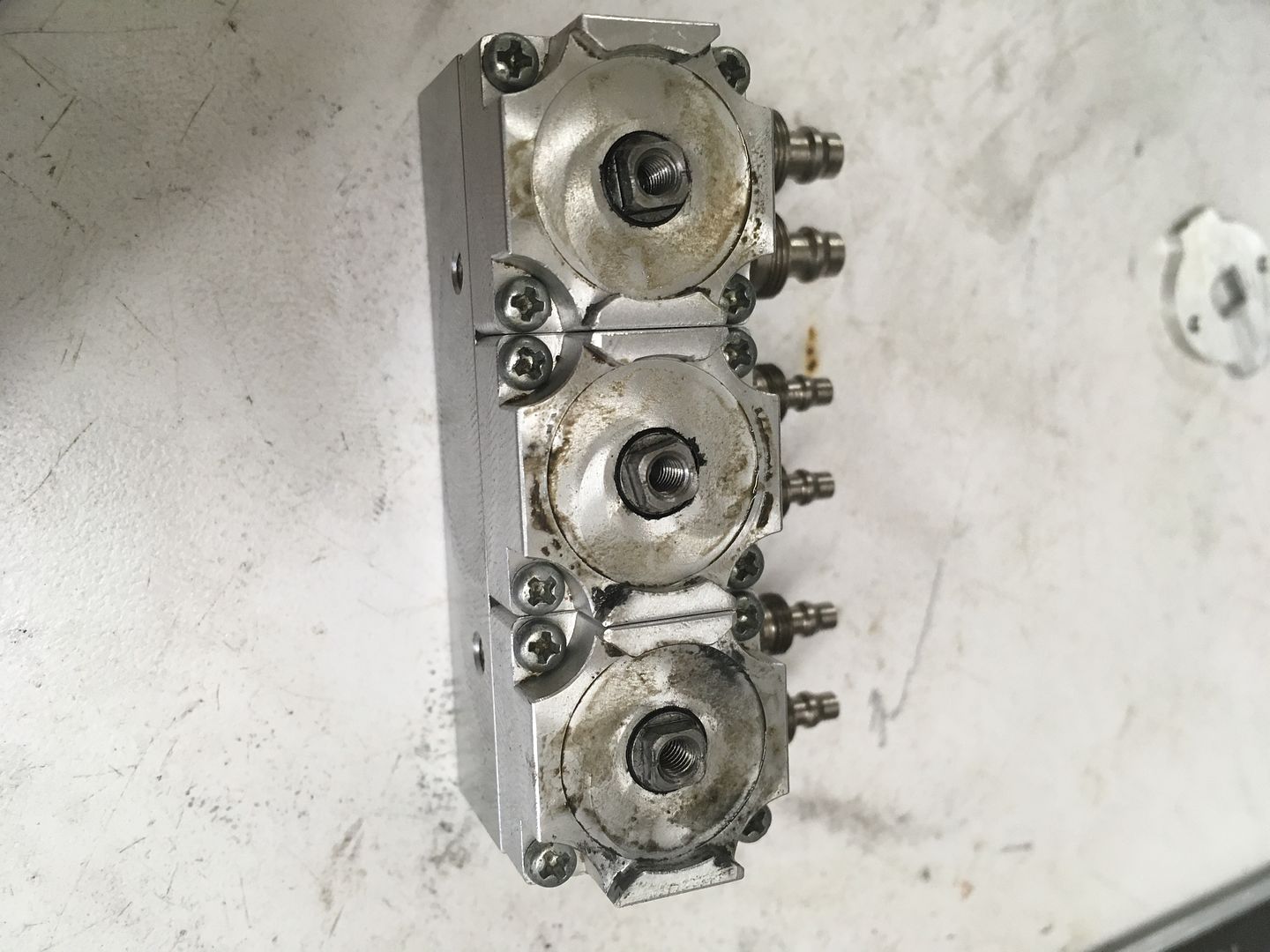

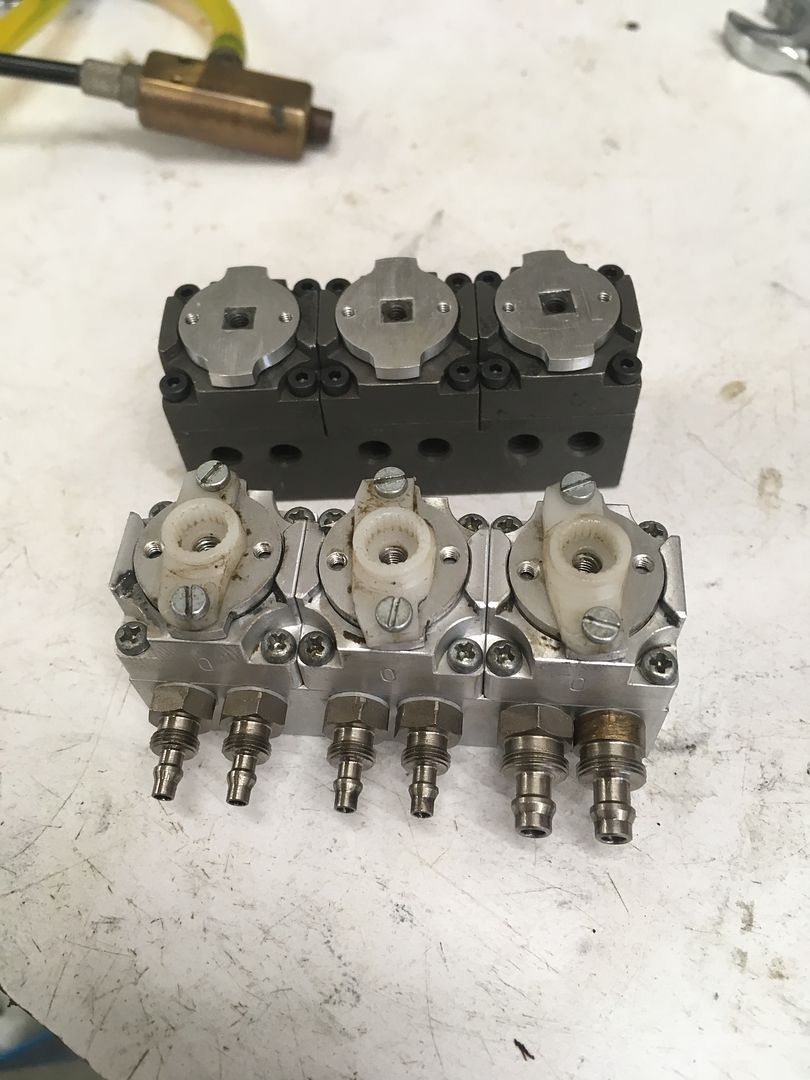

I pulled servos off & tried to hand center the valves, but the oil continued to flow out both sides of each valve... internal sealing issues

And the bucket valve (bottom valve in pic) has noticeably more oil atop it, I think that's where the leak is from. I'm gonna change all neoprene lines to new as well.

Fortunately I got a spare 3 valve on hand & it's a steel one too.

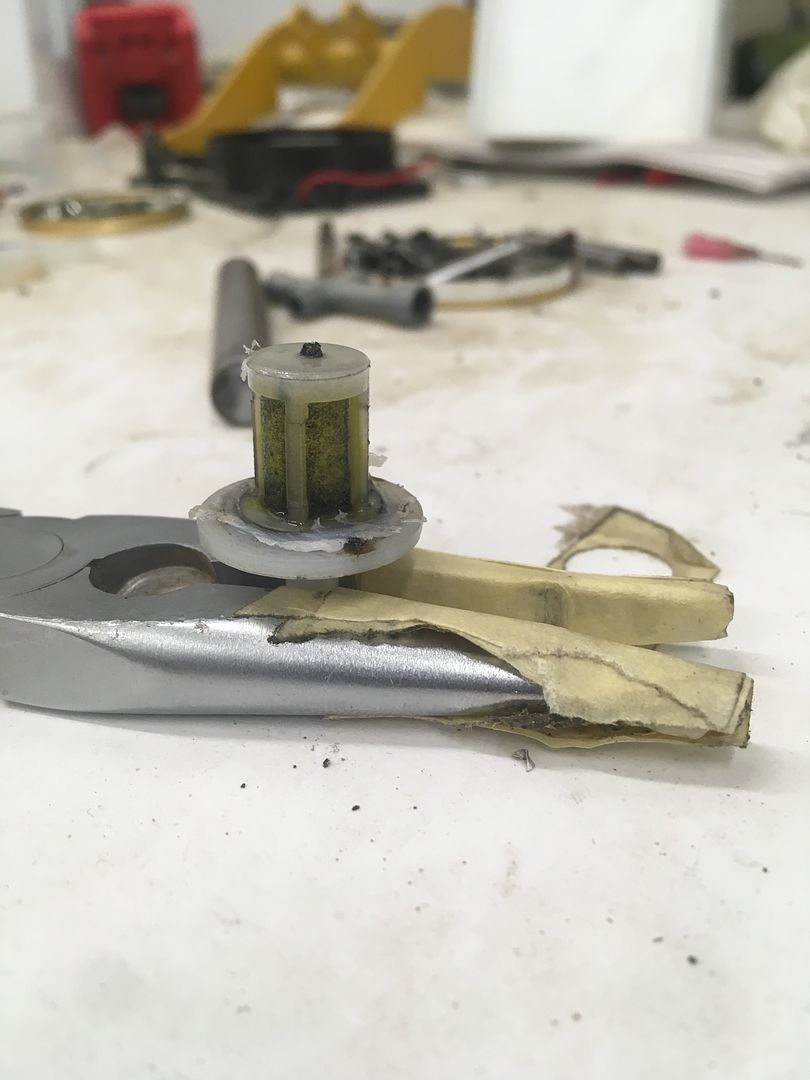

I cut open one of the oil filters, some grit in it

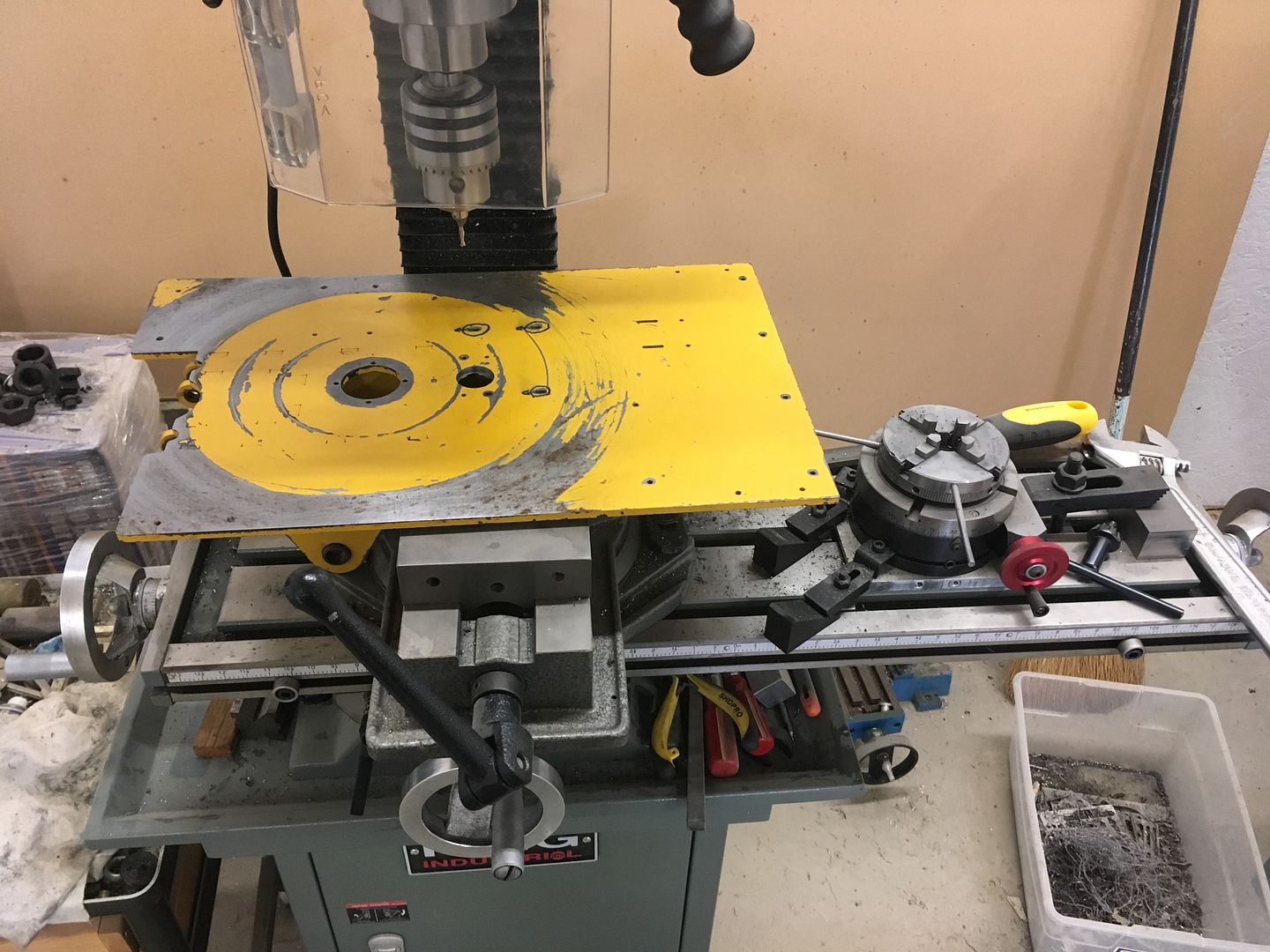

It's so nice to now have a bigger mill to work on some of this stuff... my newer JD850 that I built the summer of '16, I drilled the swing motor hole large enough so the pinion gear would pass through, for the reason if I had any trouble with swing motor/gear I don't have separate the house from the u/c to get it apart... the mini mill I had before with a much smaller vise, the work piece popped out & I broke a very expensive drill bit

...simple job to do this time around

I also slotted the 3mm holes a bit further to get tighter adjustment of pinion to crown gear

Got a new boom a couple yrs ago.. the old boom, upon close inspection, the steel shows very little signs of wear, but rather it's the GFR that is completely broken away from both sides is why the hole is so much bigger. When the kit was new in 2010, the left side of pivot, the GFR was broke out showing the plate steel. I tried to make it as good as new with JB Weld...

Cleaning/repainting all the cylinders

And a quick sand/wash/paint on these two items

I hope my goody box from Germany shows up before the wkend, it's been in transit since last Tuesday... could have the old JD850 running again Sunday.