Drivetrain - Part 1

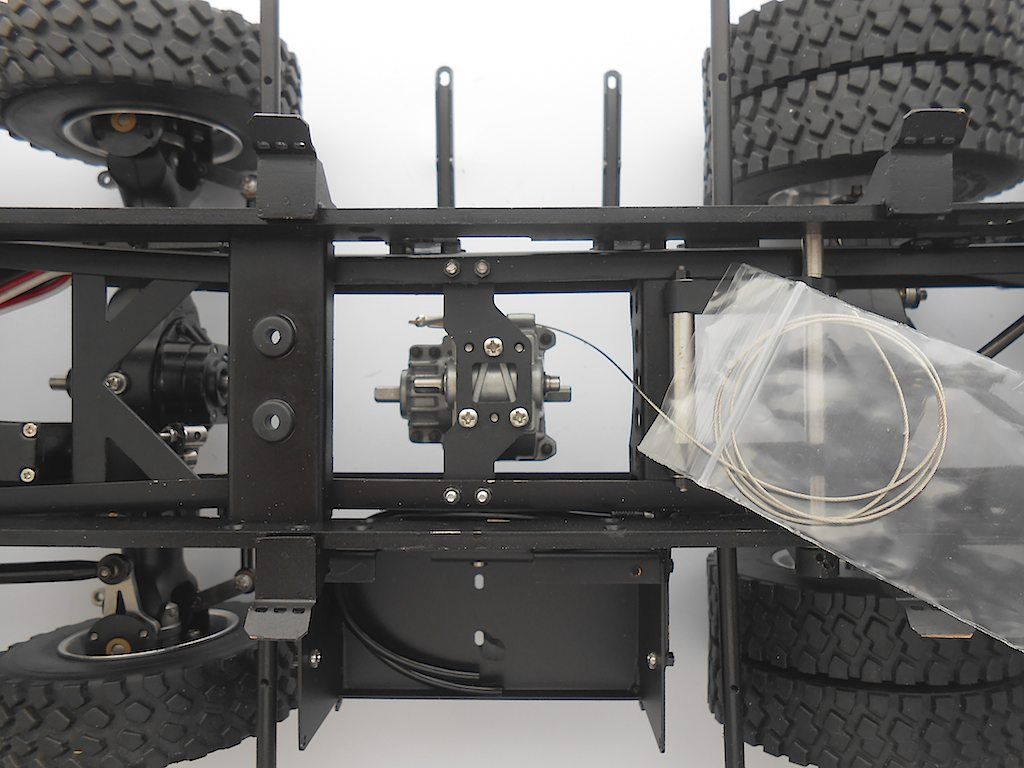

Started with the transfer case.

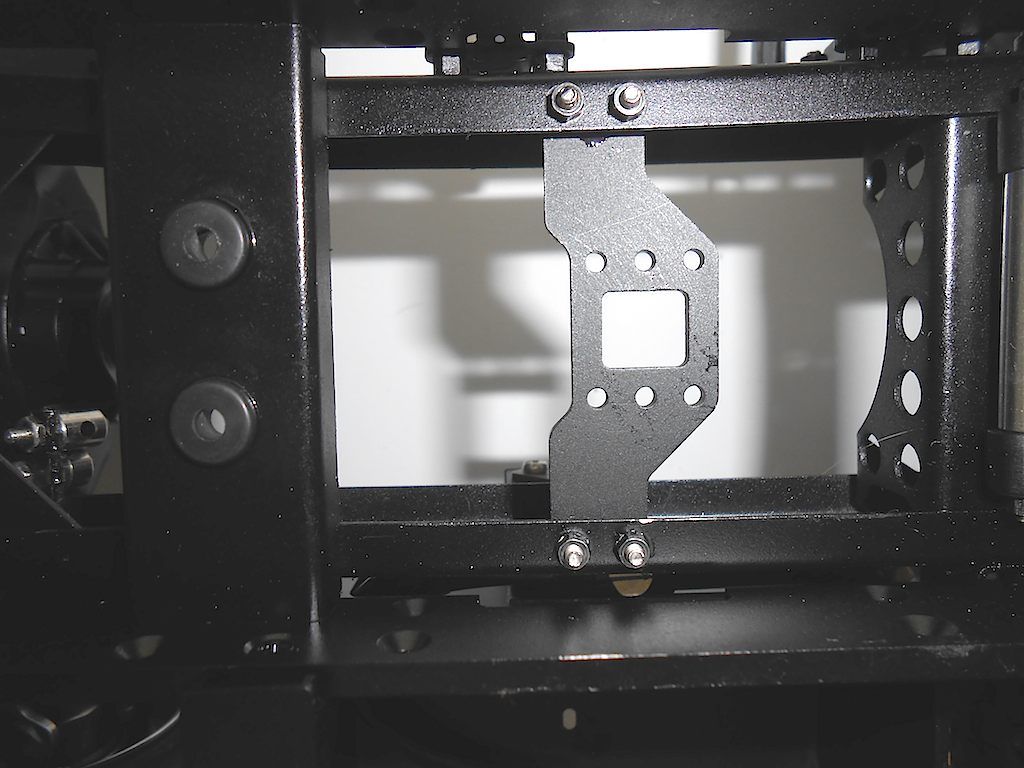

The support gets M2 nuts as spacers to the frame.

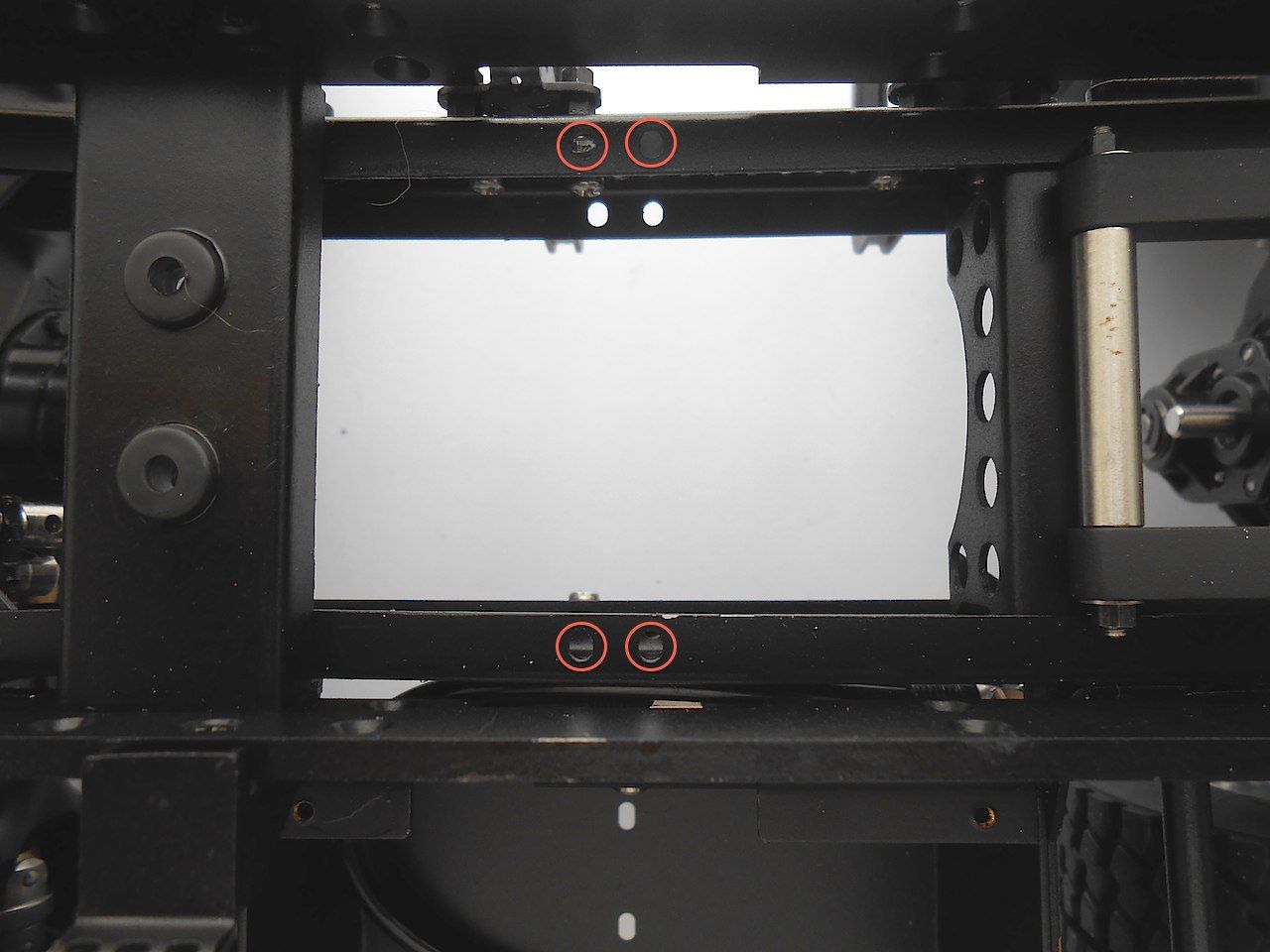

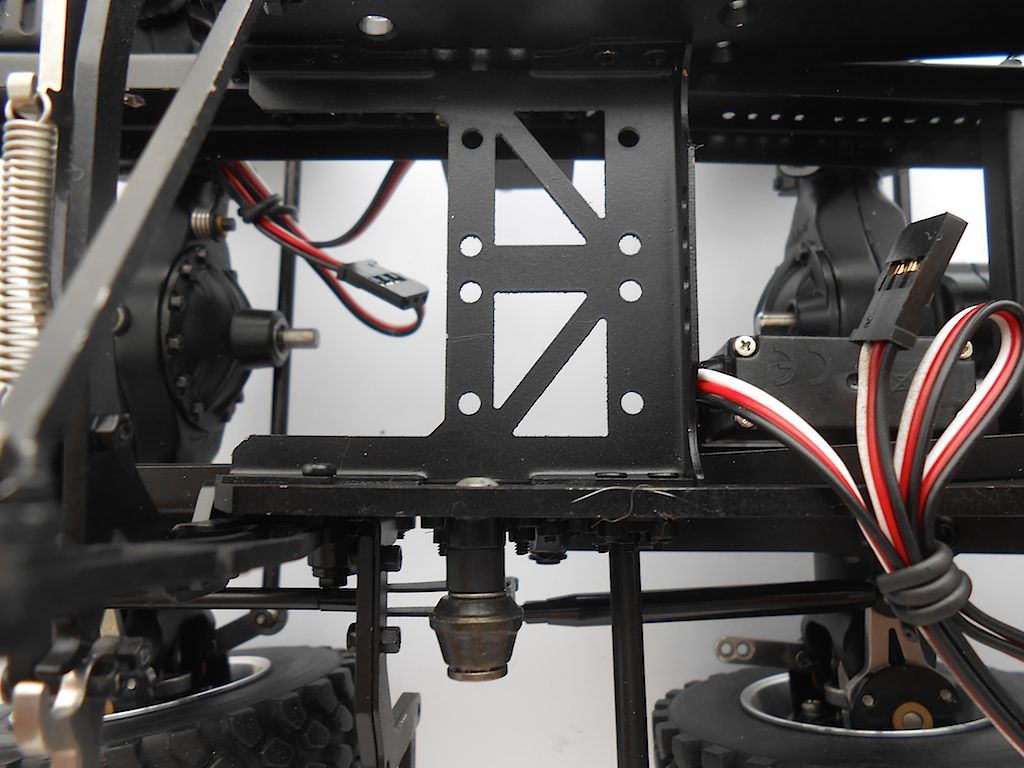

And it attaches here

The transfer case comes with 3 M8 screws in place that need be replaced with M10 ones.

After initialling the spacer nuts on the support, I tried to fit it, but ran into difficulties ... Remember I had moved one of the tank supports one hole to the right. It now interferes with the support.

After replacing the M8 screws on the support with one with a smaller head, and grinding a bit off the one holding the tank support, it fitted. Easy solution.

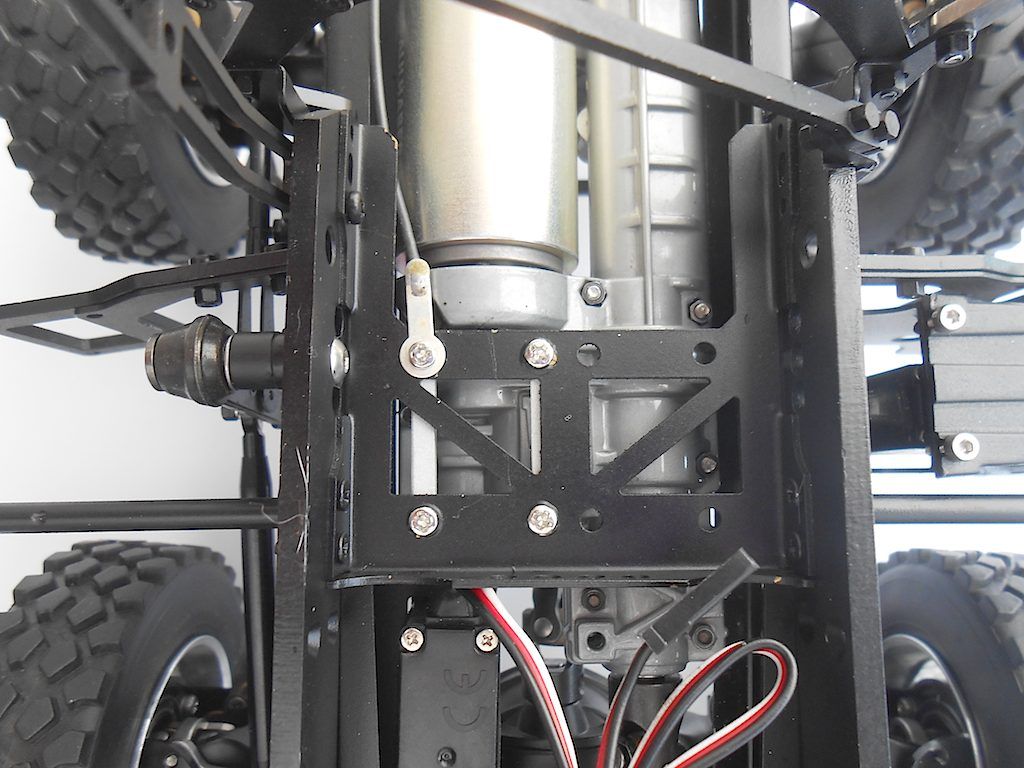

Support in place

Transfer case screwed on.

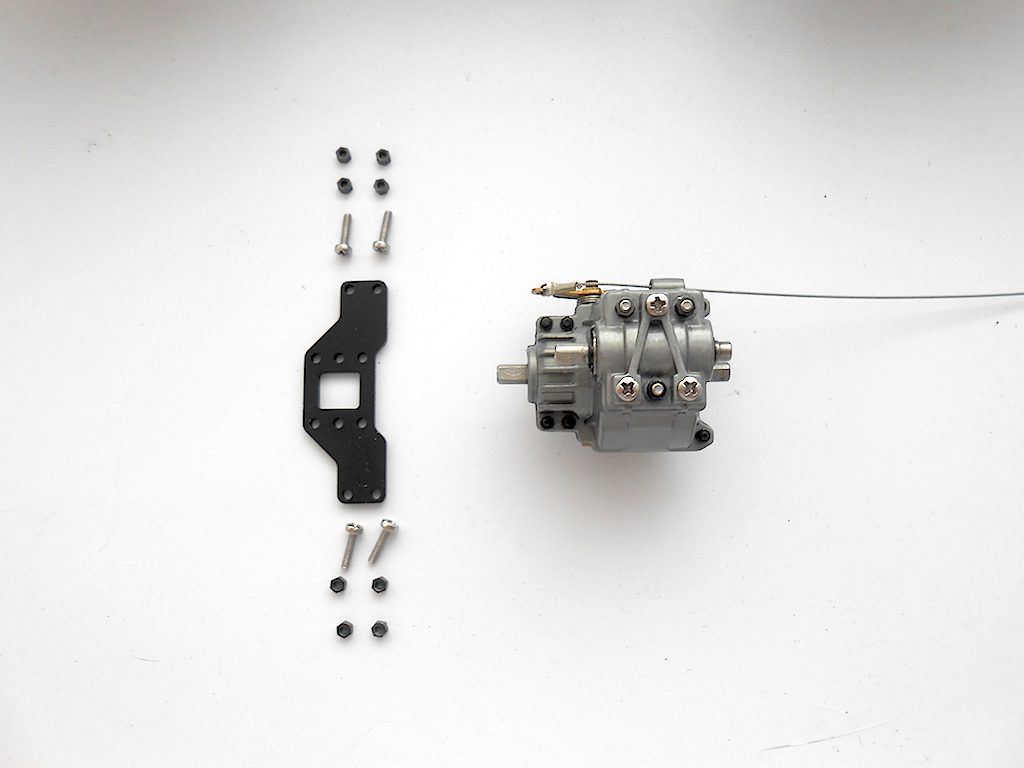

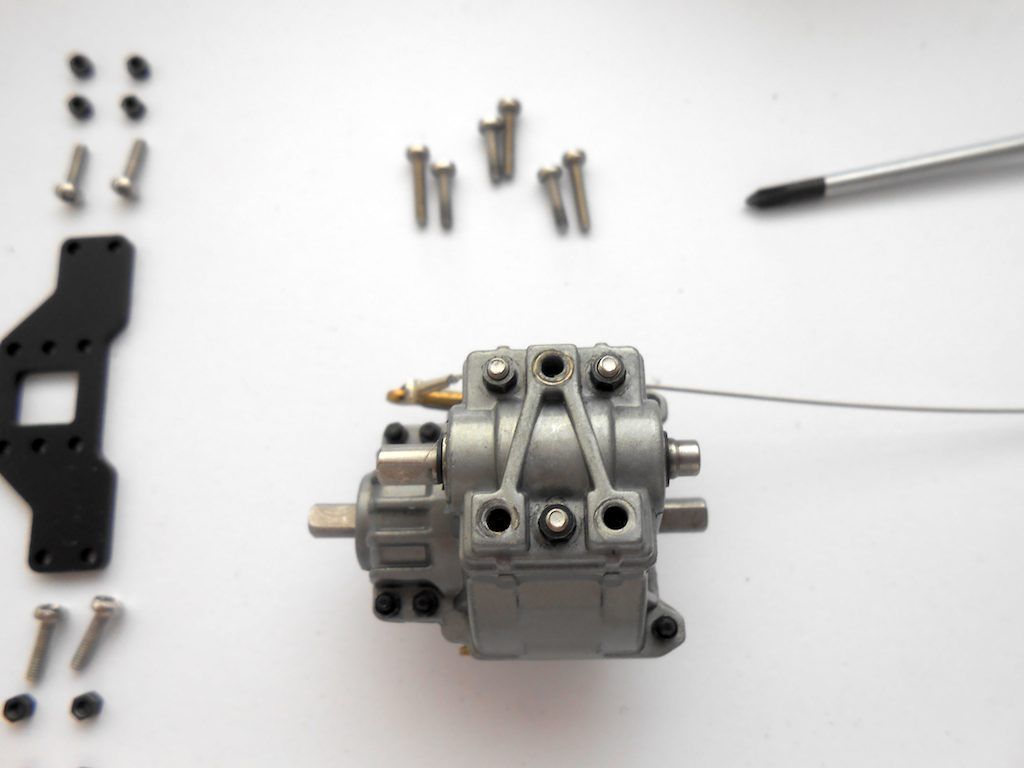

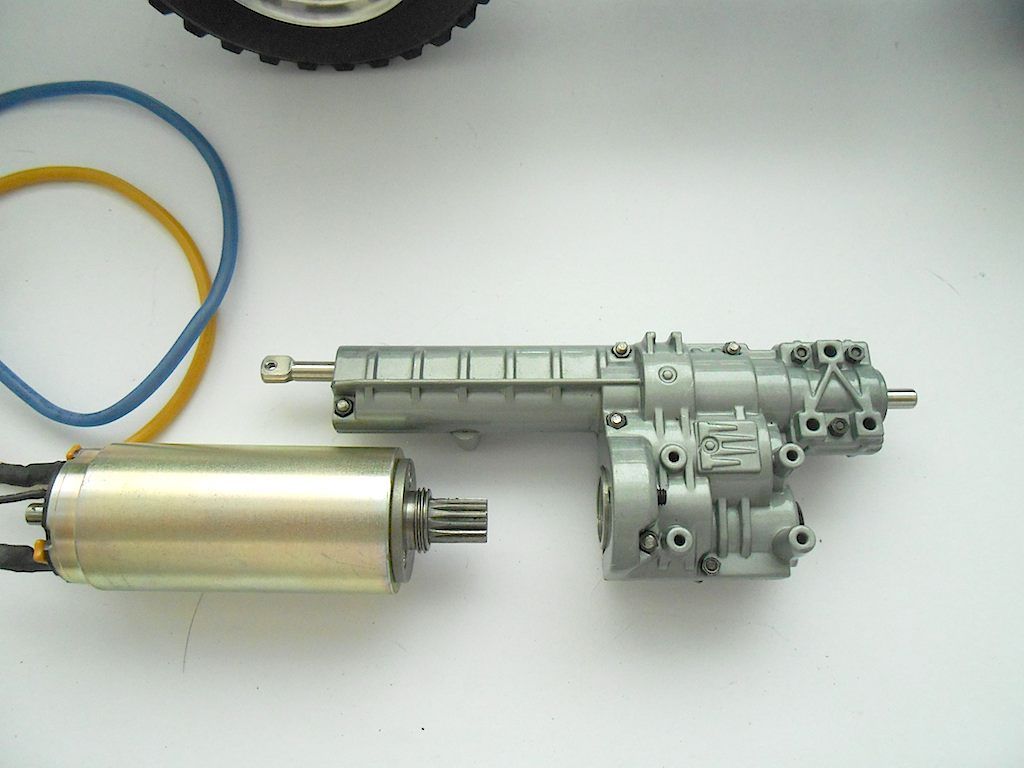

Next the motor/gearbox

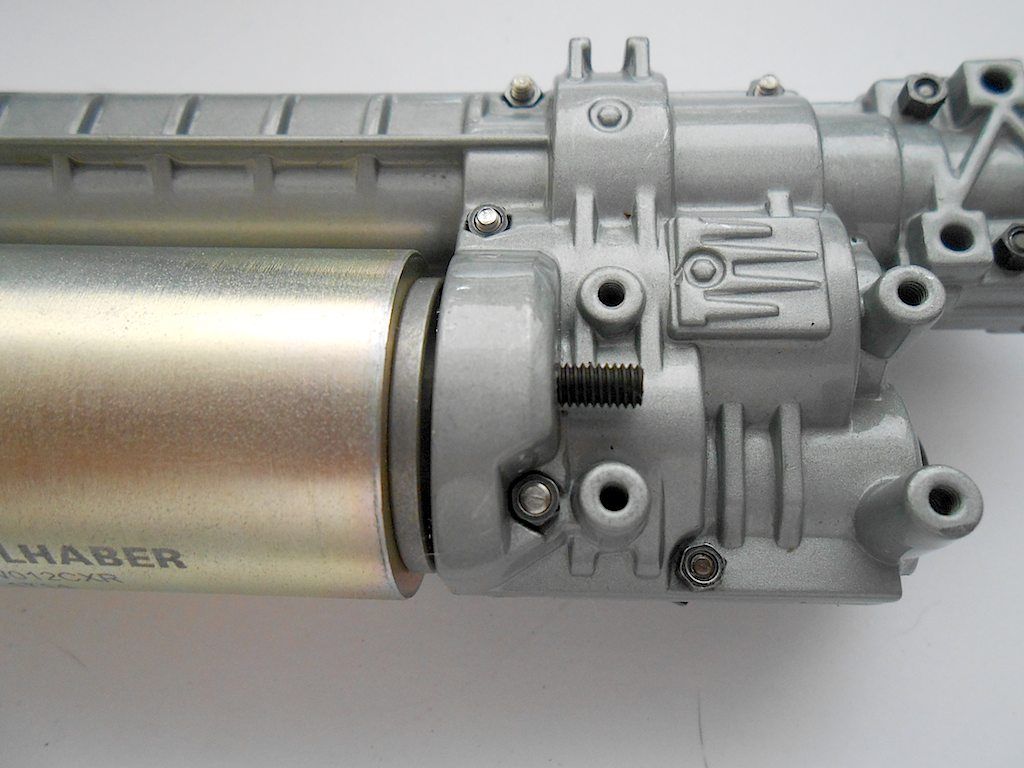

The motor has a thread and screws into the gearbox. It is held in place with a grubscrew.

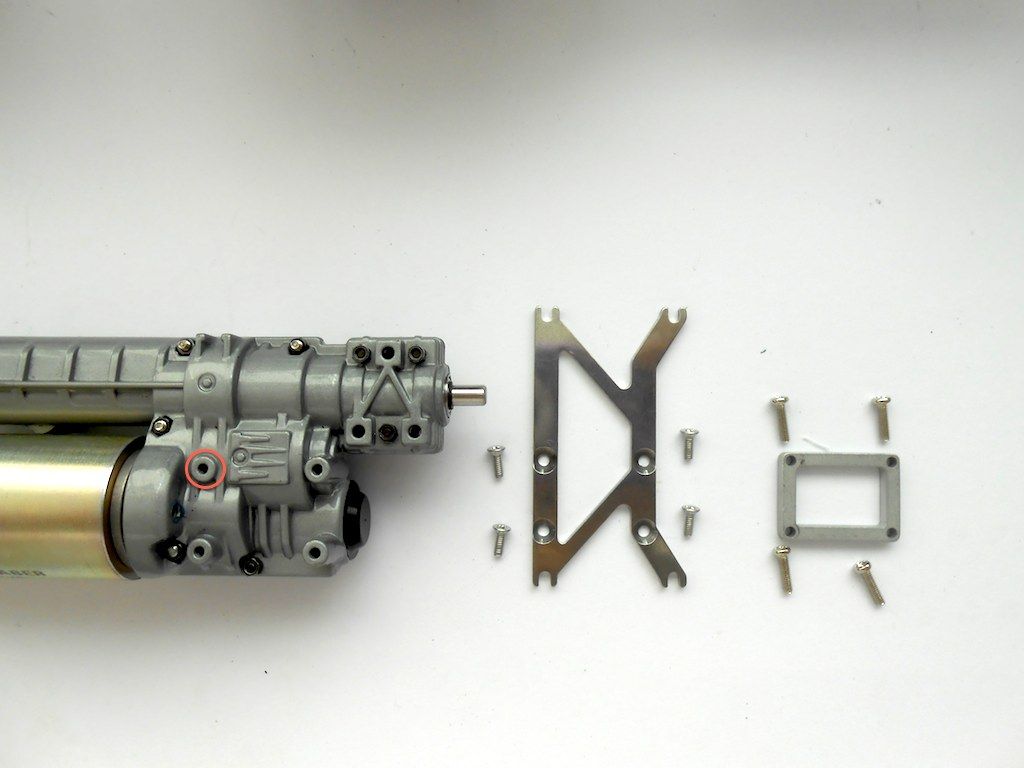

In the kit they supply a support for the motor/gearbox. (the big stainless contraption) This is not needed in this truck since the support is part of the frame of the hook mechanism.

Luckily for me I remembered reading in Christian's (Newcomer_2) thread on the

German forum that for this truck you need to use a special spacer (the small rectangular bit) which comes with the hydraulic parts.

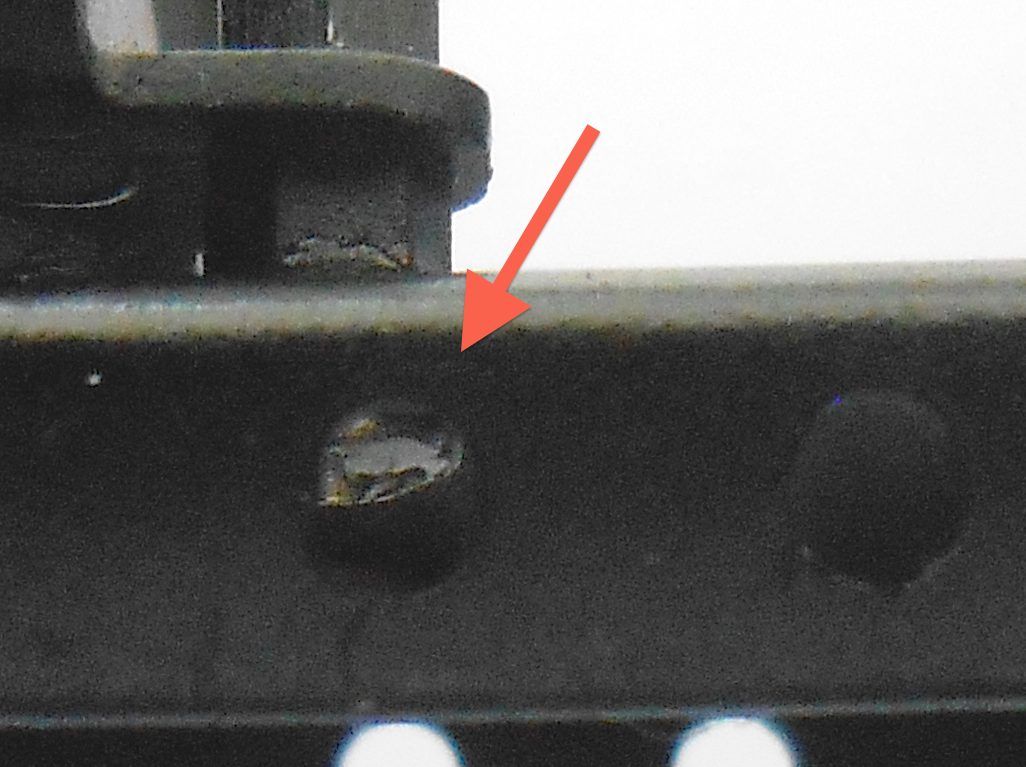

Because this spaces is about 3mm thick, I replaced the recommended M2x6 countersunk screws with M2x8 ones. Have to be careful because the hole circled in red. You can block the gears if you get too long a screw in there.

Because the frame I have is not foreseen for countersunk screws, used regular ones.

Installing this unit with that spacer "floating" around was an absolute pain in the neck ... but eventually I got it sorted. According to the instructions, the motor needs to be grounded to the frame.