|

|

|||||||

| Construction Equipment If it digs, pushes, hauls dirt "off road" post it here. |

|

|

|

Thread Tools | Display Modes |

|

|

|

#1

|

||||

|

||||

|

Hey everyone,

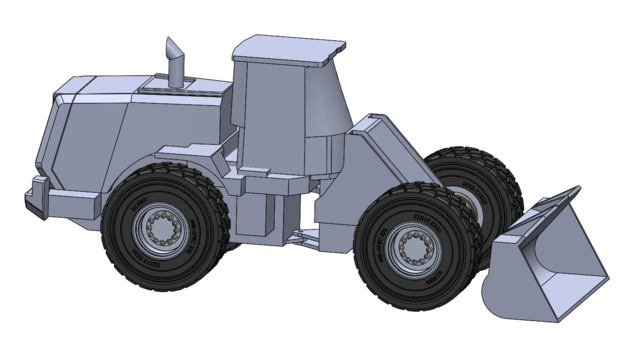

Well after a long hiatus from the RC world due to working and completing post secondary I am finally at a place where I can get back into it. Some of you may know of my build from about 4 years ago that can be found here: http://www.rctruckandconstruction.co...ead.php?t=3260 Decided to use some of the parts from that build in the new one but also I have re-designed almost all of it by the time its done haha. Anyways I am planning to build a 1:14 CAT 996K XE wheel loader. I picked up a 1:50 model and began modelling everything in Solidworks to get the basic geometry down and then Ill be designing all the hydraulics and electronics for the system.  Ill try to keep the thread updated as often as possible with CAD design work and the metal work once I can get a lathe and metal mill   Also here's a picture of my electronics lab where Ill be trying to design all the systems for the loader  By trade I am a Robotics and Mechatronics Technologist By trade I am a Robotics and Mechatronics Technologist   If you have any questions Ill try to help answer them  Thanks!! Chris |

|

#2

|

||||

|

||||

|

Great start. When I look at all the loader threads, everyone is doing CAD all over again. Maybe the best thing would be to make open source version, so we dont spend time on the same design, but spend it to upgrade already made design.

How will you make the rear panels? Mill it from a single block, or use sheet metal? I am searching for the best solution to make 3D surfaces. Right now I am using 3D printer, but I am thinking a lot about milling molds and try to do a real injection molding, or maybe press sheet metal over milled mold.

__________________

To view links or images in signatures your post count must be 10 or greater. You currently have 0 posts. |

|

#3

|

||||

|

||||

|

Well looks who back at 'er... good to see you again Chris... your title is 996, but the one pictured is 966... which is it?

__________________

Sharing knowledge is one thing that defies basic arithmetic logic --- the more you share, the more you get! Joe |

|

#4

|

||||

|

||||

|

Hey Doggy, thanks! Haha that would be nice, the amount of hours I spend on CAD doing simple things, it would be nice to skip it! Currently I am planning to build the chassis from 1/8th sheet steel and weld it all together. Then for the complex surfaces I may have them 3d printed or build them out of sheet steel. Plastic is nice for the ease of use but I want the loader to be heavy so it is more realistic.

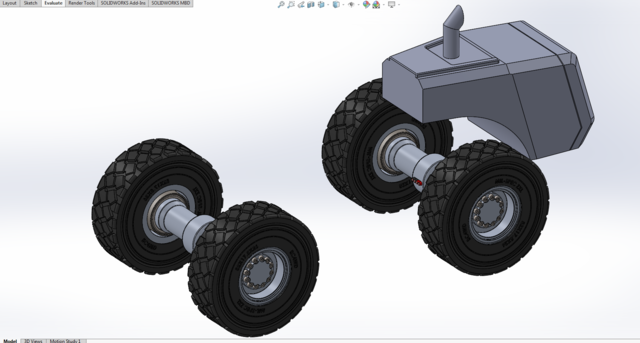

Hahaha yea I am finally back which is nice. You caught me, messed the title. I am planning on building a 966K XE loader. How can I edit the title? Little update here, work has been very busy the last couple weeks so not much progress. I have got some preliminary CAD models done of the outside shape and begun the design of the electrical system. Here a screen capture of the CAD:  -Chris |

|

#5

|

||||

|

||||

|

|

|

#6

|

||||

|

||||

|

welcome back Chris . all fixed

__________________

RIP FreddyGearDrive 2-12-59/12-19-11 To view links or images in signatures your post count must be 10 or greater. You currently have 0 posts. |

|

#7

|

||||

|

||||

|

Thanks ihbuilder.

Just picked up a refurbished Robo 3D +Plus 3d printer to do some of the plastic work and prototyping as can't afford the metal working tools yet and gotta say it was well worth the money. Did some test prints of the wheel hub, and rear bumper to test it out and the results where pretty dam good. And they have been pretty accurate. -Chris |

|

#8

|

||||

|

||||

|

Looks like a pretty good resolution .

__________________

RIP FreddyGearDrive 2-12-59/12-19-11 To view links or images in signatures your post count must be 10 or greater. You currently have 0 posts. |

|

#9

|

|||

|

|||

|

Looks like a great start) that's the most durable solution, putting a gear motor directly on each wheel, much less trouble than having a standard axle and transmission I would say.

|

|

#10

|

|||

|

|||

|

Fhahfhurhdhdhdhshxheshxhdbshxjd dhhebdvdbdhd

|

|

#11

|

||||

|

||||

|

This looks like what my cat types when I'm not looking.

|

|

#12

|

||||

|

||||

|

His cat 966 is typing now? But it's just a couple pieces. It'll be unstoppable once it's built...

|

|

#13

|

||||

|

||||

|

|

|

#14

|

||||

|

||||

|

|

|

#15

|

|||

|

|||

|

Looks good man! Where did you get the printer???? Iydmma

|

|

#16

|

||||

|

||||

|

Thanks Cat 966c!

|

|

#17

|

||||

|

||||

|

Been slowly working away at the design and getting parts printed. The holidays slowed things down and I have been very busy with doing CAD at work.

Anyways I got the front axle completed and I have been working at the front chassis. Also been doing some very slow design of the controller system using a system of a 2x Xbee Pro's, an MSP432 mCU and a Arduino 2560 Mega.   Thanks, Chris |

|

#18

|

||||

|

||||

|

|

|

#19

|

||||

|

||||

|

Hey Chris. Good to see some parts getting completed. I like the idea of printing the loader. Bigpipespete is over in the LMD and has some nice machines you should check out. Keep us update as the build continues.

Greg |

|

#20

|

||||

|

||||

|

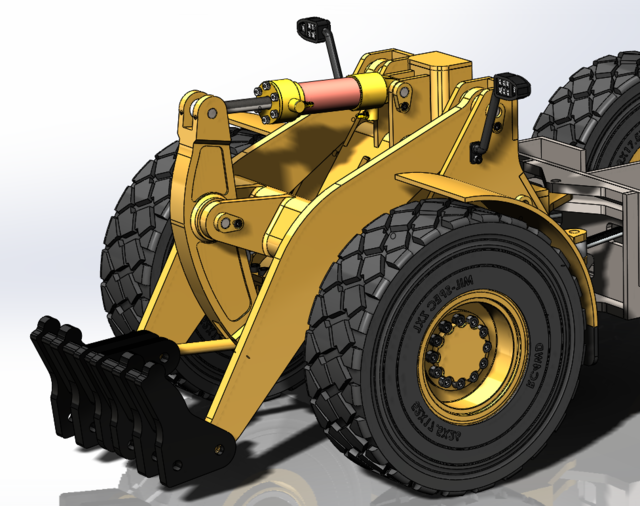

Hey Greg,

Thanks! Glad to be making some progress, trying to enjoy the journey more than the completion  I guess I must be getting older haha. Awesome I should see if I can meet up with him. Definitely will do! I guess I must be getting older haha. Awesome I should see if I can meet up with him. Definitely will do!Decided to try out the Cylinders and hydraulics from Magom HRC in Spain as they offer custom cylinder lengths in a variety of sizing. They had awesome customer service and I received my package in 6 days from Spain for only 16 euro!!  Being a CAD junkie first thing I did was draw it up to get it into the model.  Looks like it is going to be a great fit, now I need to finalise the remaining cylinder lengths and hydraulic system so I can order the rest and test them out!  Check them out at http://www.magomhrc.com/en/ Check them out at http://www.magomhrc.com/en/-Chris |

|

| Currently Active Users Viewing This Thread: 1 (0 members and 1 guests) | |

|

|