|

|

|||||||

| Construction Equipment If it digs, pushes, hauls dirt "off road" post it here. |

|

|

|

Thread Tools | Display Modes |

|

#21

|

||||

|

||||

|

Excellent machining on the wheels and frame work. Question for you- how are you fastening the wheel centers to the rims on the front 3 axles? Are the center bolts and nuts gripping on the rim?

__________________

LYNN |

|

#22

|

||||

|

||||

|

Quote:

Kerst |

|

#23

|

||||

|

||||

|

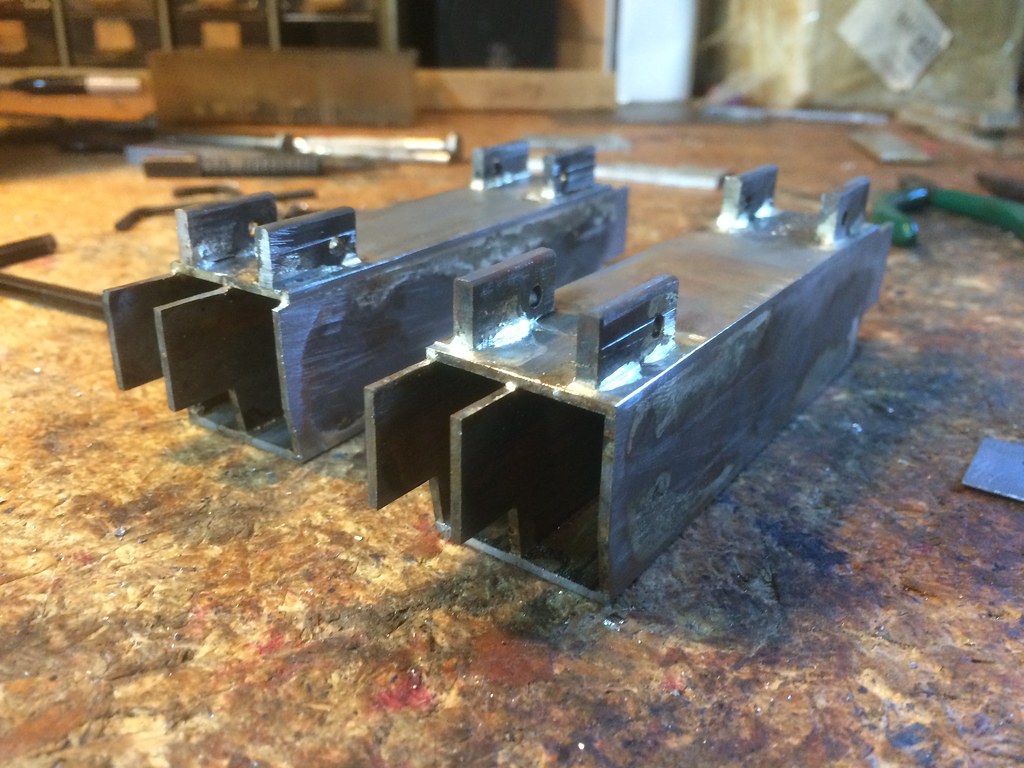

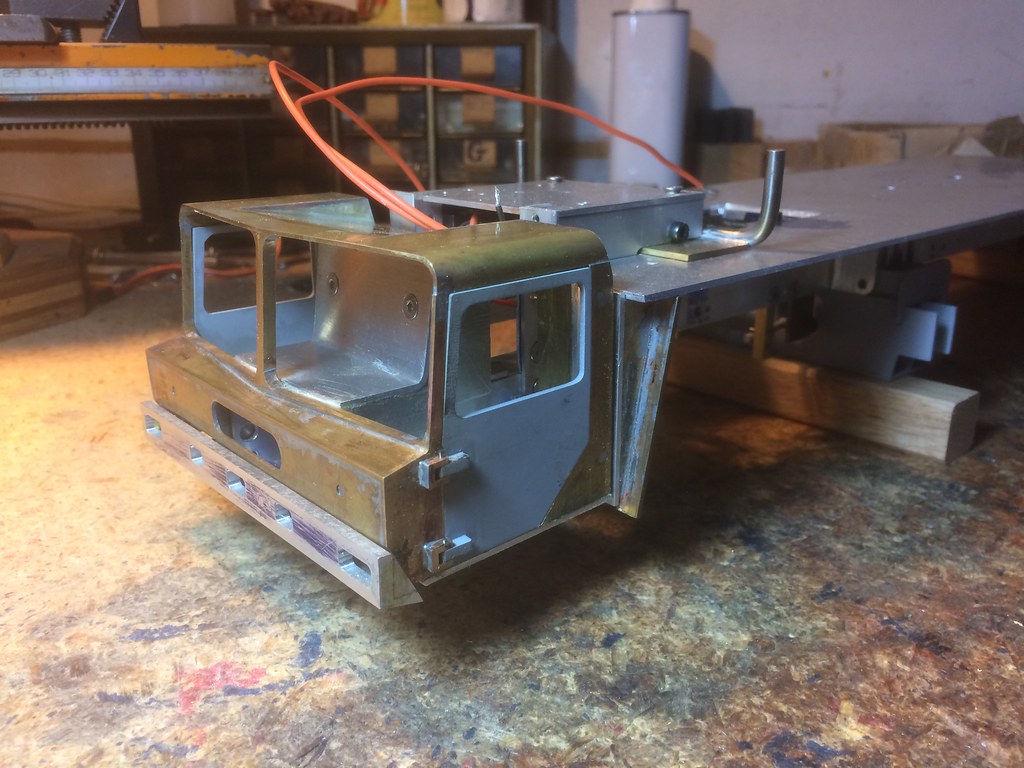

The beginnings of the cab are here:

I also started on the outrigger boxes. They are pretty straightforward. I decided on Steel and I brazed them together. Now they are definitely strong enough. The second picture shows some parts added using solder. They need to be cleaned up a bit and they are ready. Next are the outrigger beams.   Kerst |

|

#24

|

||||

|

||||

|

Faun carrier

The outrigger boxes are ready and bolted to the carrier. Next will be the outrigger beams. I am also thinking how to build the gearbox and transfer case and which motor to use. There is not a lot of space, so they need to be designed carefully.   Note: The third axle is missing. Kerst |

|

#25

|

||||

|

||||

|

if this is anything like you had at cabinfever it will be amazing

|

|

#26

|

||||

|

||||

|

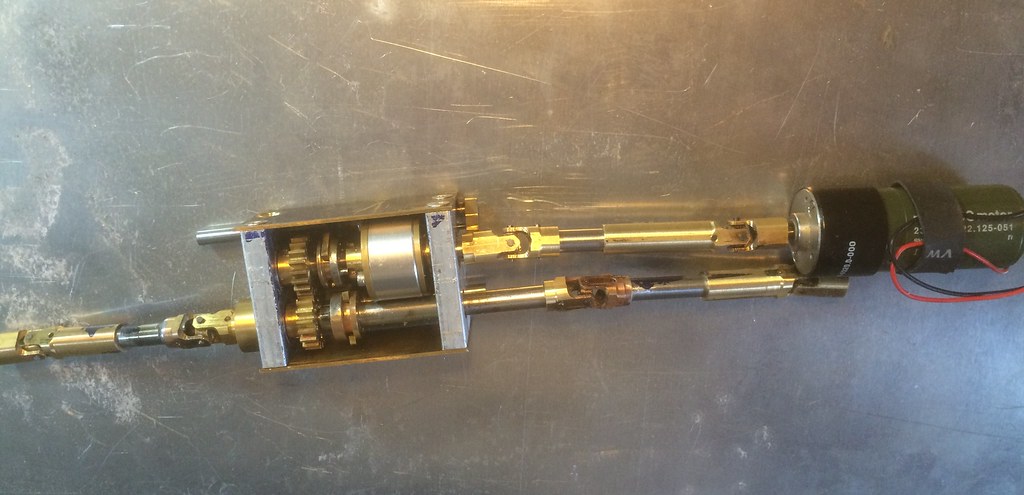

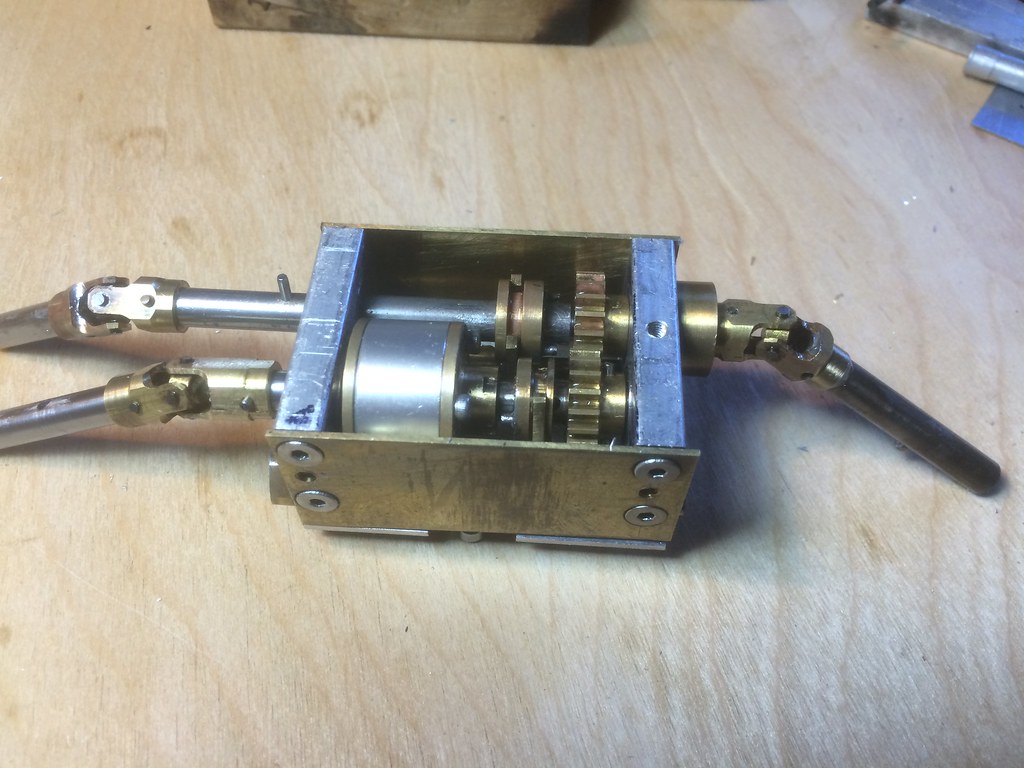

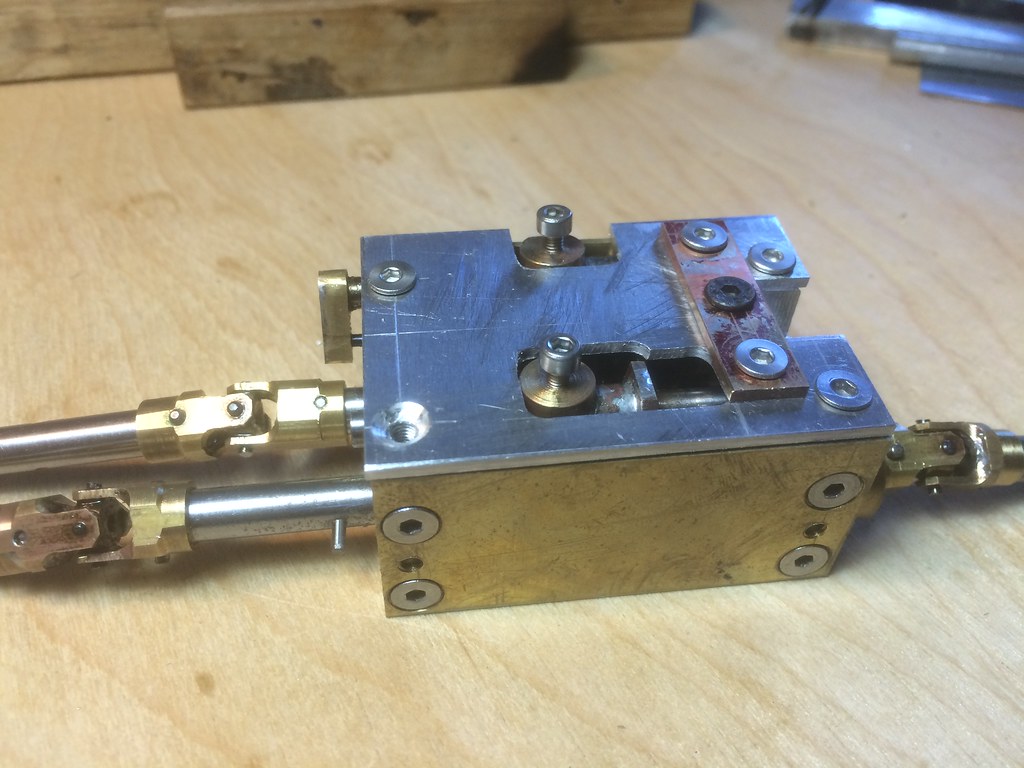

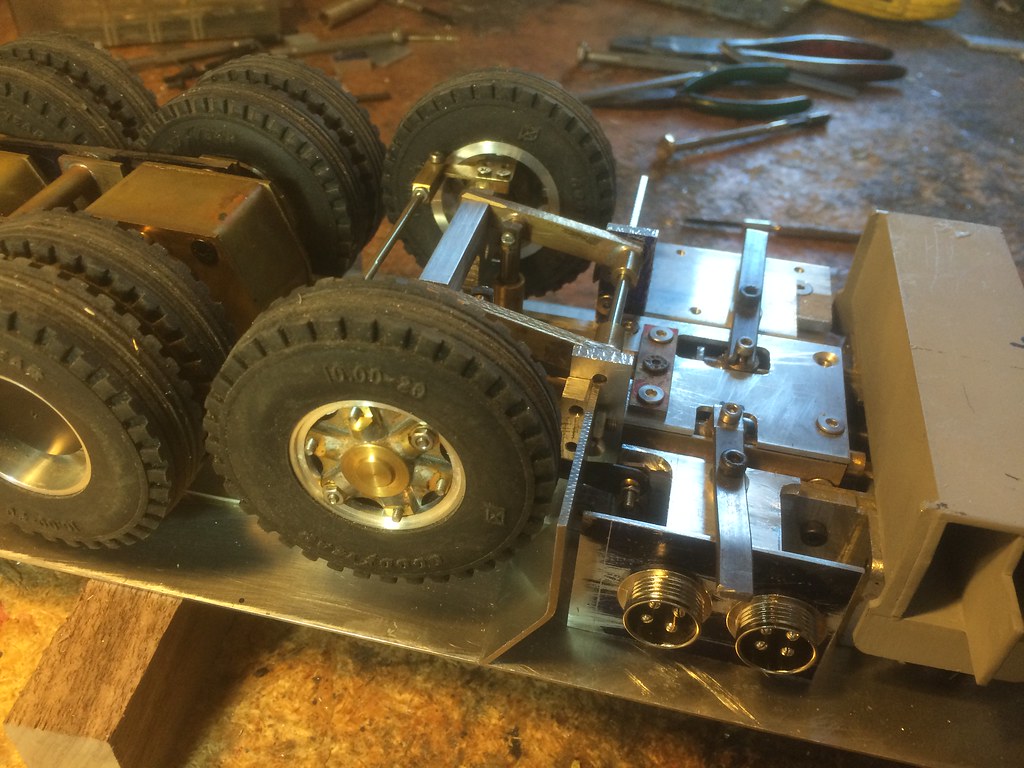

Transfer box

In the last couple of weeks I have been experimenting with a planetary reduction, which I got from a small geared motor. A lot of trial and error! The outside diameter is 22 mm and all the gears are steel. The trick was to incorporate it in the transfer box. I tried a lot of different setups, but I think I found a setup that works. The transfer box will have two speeds (direct and very low) and front wheel drive can be engaged or disengaged. The real one has an inter-axle diff, between the rear axles and the front axle, but I couldn’t find the right planetaries to accomplish that. It would need a 1:2 ratio. It turned out nice and compact. But it hasn’t been tested yet.  Kerst |

|

#27

|

||||

|

||||

|

Love to see gearing!!

|

|

#28

|

|||

|

|||

|

Kerst,

Very nice build. I hope to learn more about building small controllable transmission like this. Have you done any experimentation with electromagnetic clutches or other types of clutch set ups in any of your work? I have been thinking about how a clutch could be used to precisely control a hoist. |

|

#29

|

||||

|

||||

|

Quote:

I haven't worked with any type of remote controlled clutches yet. I have thought about it, including using pneumatics or servos. This gearbox will have a simple lever. Kerst |

|

#30

|

||||

|

||||

|

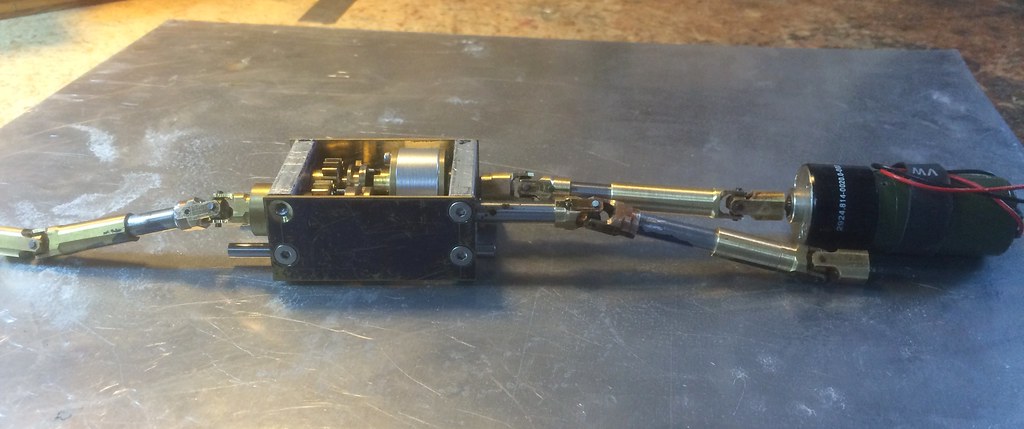

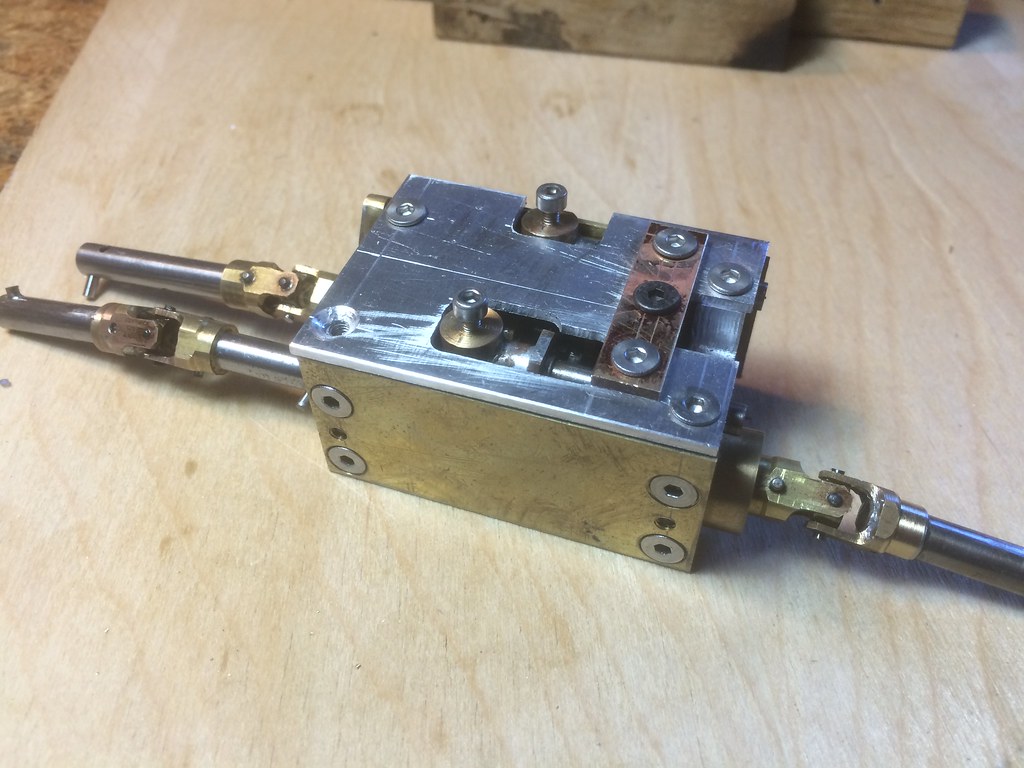

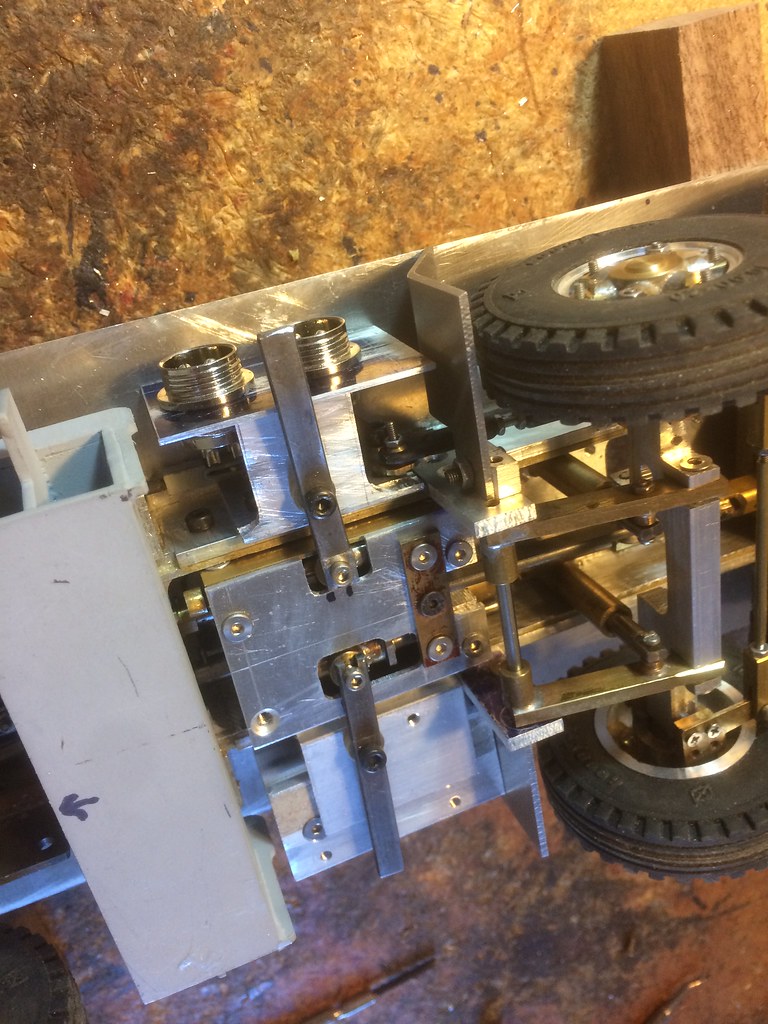

During the past couple of weeks I worked on the universal joints. I always make them myself, mainly because they need to be very specific in size, but also because good quality universal joints are very expensive. The final assembly of the joints is always tricky, because I solder the pins (1/16" diameter) in from the center and the solder easily flows in the wrong spaces. It needs to be heated just enough for the solder to flow, but not too long. I had a cup of water handy to cool it down quick once I thought it was done.

In the pictures the motor is directly connected to the transfer box, but I might add a 2-speed gearbox. I want to first try out the speeds and see if this is the right motor, etc.   Kerst |

|

#31

|

||||

|

||||

|

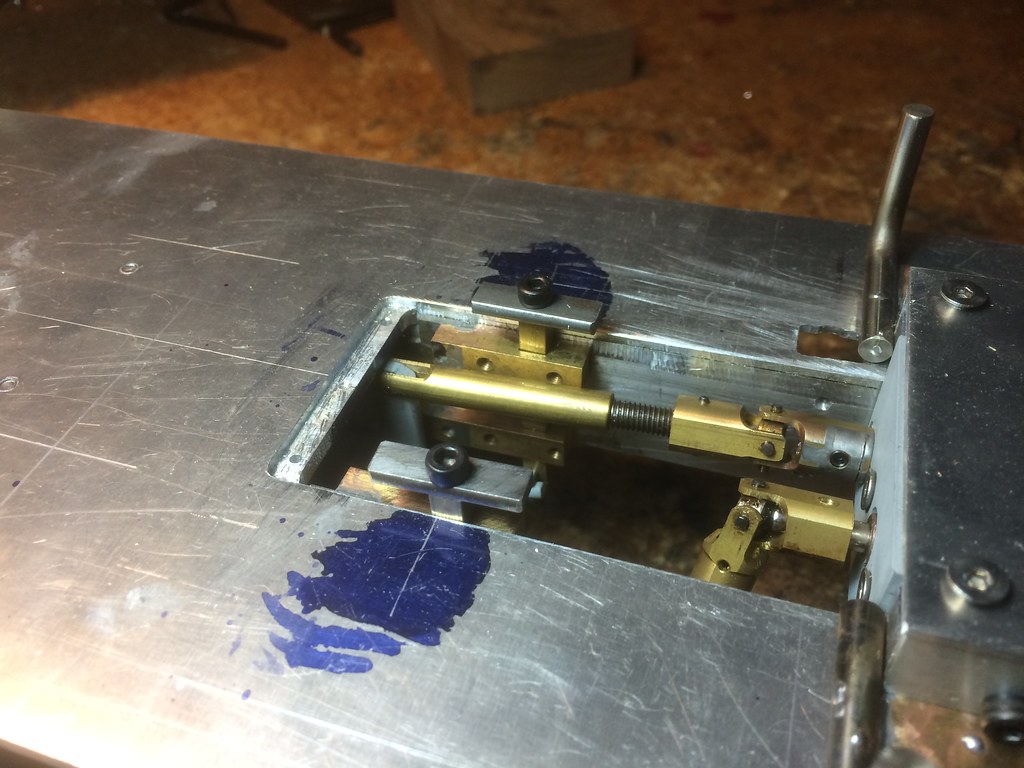

The transfer box is finished:

Kerst |

|

#32

|

|||

|

|||

|

Nice work in a tight space. Very nice build you have started.

|

|

#33

|

|||

|

|||

|

That looks like it should handle a pretty good load. Those U-joints are beautiful! Did you use ball bearings or bushings?

|

|

#34

|

||||

|

||||

|

I've really enjoyed following this build and am very interested in your u-joint fabrication. Would you post a bit more detail on how you make them?

Thanks! Ken

__________________

Big iron is awesome! |

|

#35

|

||||

|

||||

|

Very impressive home made parts! Nice job.

__________________

Jarrett |

|

#36

|

|||

|

|||

|

Mr. Kerst Sir you are are very impressive cant wait to see the final build and here I thought the last crane you built was amazing this will be a masterpiece

__________________

Steve |

|

#37

|

||||

|

||||

|

I did some work on the cab. I added the doors with homemade hinges. They still look clunky, but this was the best I could do.

I also installed the motor and a separate small gear motor to lift the counterweights. This needed a bit of thinking, since room was very limited. The 2 pictures show it both in lowered as in in raised position.   Kerst |

|

#38

|

||||

|

||||

|

In the past couple of months I did all kinds of little things, including optimizing the steering, working on the space in front of the third axle, the levers of the gearbox and some other details.

Here is a short video of the steering in action: https://youtu.be/ObYaSMiSlfU I also made a box for the crane with space for the crane itself and the boom sections.   I wish you all a Happy New year and see you at the Cabin Fever Expo! Kerst |

|

#39

|

||||

|

||||

|

This is a super build! With limited space you have still figured ways to make things work. Love all the mechanisms that make this crane tick and the detail.

Ken

__________________

Big iron is awesome! |

|

#40

|

||||

|

||||

|

I started work on the outriggers. here you can see the structural parts of the outriggers, steel, brazed together. I will use hand operated screw jacks for the vertical movement. there is too little space for a motor.

kerst |

|

| Currently Active Users Viewing This Thread: 1 (0 members and 1 guests) | |

| Thread Tools | |

| Display Modes | |

|

|