|

|

#721

|

||||

|

||||

|

13" high at the cab shield heaped 18.9 litters or 5 USG . Which is good till you get over 8% grade then it starts to roll out the back . The tires are crap for sure

was wondering how the 1's on the stal equipment would work ). I got stuff to fill them , but it requires a special application gun was wondering how the 1's on the stal equipment would work ). I got stuff to fill them , but it requires a special application gun  . The jerkiness happens when loaded turning in tight spaces ( ithink I still have the glitching issue that Ken has/had on his payhauler . The jerkiness happens when loaded turning in tight spaces ( ithink I still have the glitching issue that Ken has/had on his payhauler  . From the looks of all your basement pics , It really wouldn't be efficient as your combos . A guy I talked to at cabin fever last year , told me the real 1's never turned well in tight spaces loaded . They always wanted to plow straight . I was working it in my craw space I moved at least 2 cubic yards of #57 (3/4") stone so far when I had a little time a month or so back . . From the looks of all your basement pics , It really wouldn't be efficient as your combos . A guy I talked to at cabin fever last year , told me the real 1's never turned well in tight spaces loaded . They always wanted to plow straight . I was working it in my craw space I moved at least 2 cubic yards of #57 (3/4") stone so far when I had a little time a month or so back . Who knows , I may build 1 as a tractor with a bottom dump that would double capacity

__________________

RIP FreddyGearDrive 2-12-59/12-19-11 To view links or images in signatures your post count must be 10 or greater. You currently have 0 posts. |

|

#722

|

||||

|

||||

|

I measured the Mammoth @11.75", if memory serves me correctly, it wouldn't be a half inch clearance... you'd need a different box.

Even @15L load, I'd get a lot out in a few hrs every day!  Tandem & tri pup should do pretty well (maybe close to 10L) if the corners aren't too much trouble to navigate. Tandem & tri pup should do pretty well (maybe close to 10L) if the corners aren't too much trouble to navigate.Your series of Mack, did they ever make 6wd? That makes a huge difference for steering control, especially when carrying alot weight on the front axle. I have 3 Stahl models & now the 850 with a 4.8v rx battery installed with the BEC coming from the Sabertooth esc as well. I never have to recharge that rx batt b/c the BEC from esc is keeping it charged & the batt takes care of the current spikes when they happen so no glitches or time outs.  Here's some pics of tires... I did some horse trading with PFB, got his excavator dollies, so I think they're the same tires you're using? 1st pic - tires from the wheel loader & the other is from the adt.    Nathan used that foam wrap to fill the tires, which created a flat spot where ever it ended... I tried to redo it, butting the ends together with each wrap, but still had a bit of a flat spot where it met. I tried a few other tires I have on hand, but they don't fit the Mil-Spec rims.,..  Then it occured to me today (while taking the pics) that I should turn out some tire fillers from oak!  Make the donuts, cut each one in half so I can get them inside the tires for a true round smooth rolling tire... then maybe I can use them without pulling the track hoe out of the dollies b/c of skidding wheels while on the move?! Make the donuts, cut each one in half so I can get them inside the tires for a true round smooth rolling tire... then maybe I can use them without pulling the track hoe out of the dollies b/c of skidding wheels while on the move?!

__________________

Sharing knowledge is one thing that defies basic arithmetic logic --- the more you share, the more you get! Joe |

|

#723

|

||||

|

||||

|

They never made a 6WD to my knowledge . I think Nate used the 1.9 which are smaller then what I have . mine are 5" dia . I found some on RC machines in Germany I'm just hesitant to buy . they also have nice 1's that get me closer to the size I need on the 990 . I have foundation sill seal wrapped in the fronts . no matter how hard I tried to keep it from over lapping , It bounces . I gotta find the stuff Reg uses . All the furniture co's are gone in my area from when I was a kid

. .

__________________

RIP FreddyGearDrive 2-12-59/12-19-11 To view links or images in signatures your post count must be 10 or greater. You currently have 0 posts. |

|

#724

|

||||

|

||||

|

The foam I use comes from an automotive upholstery shop. I did the 850KW's fronts the other day and they now work great. I have a home for those mil specs Joe....

|

|

#725

|

||||

|

||||

|

Joe, does your WA500 notice the bigger, and heavier bucket much? Any guesses on the max wieght that the hydraulics can lift on the loader? I am sure it's somewhat dependant on the hydraulic pressure, and there is probably a point of diminishing returns, if you try to raise the pressure much more.

__________________

Nathan |

|

#726

|

|||

|

|||

|

would cutting the foam at a sharper angle work ?

just like a sanding belt is cut and glued, or even cut it at an angle 90 degrees to the rim never have tryed what you are doing so may not work but it is 5:08 am and can't sleep so sit and think lol |

|

#727

|

||||

|

||||

|

5" dia? The tractor lug for the wheel loader is solid rubber & the other has thick sidewalls, both 5" outer dia. Inner diameters for both wheels are 60mm or 2.4"

This foam Reg, would it carry 80lbs on four tires without excessive squat? ...basement floor is anything but flat! I think the oak donut might work famously... if not, then I'll have to start from scratch to make something else entirely to use these solid rubber wheel loader tires... maybe we make a trade?  You betcha Nathan, that steel bucket is very noticeable with its additional steel weight, but even moreso with its 2.25" longer depth (@5" total), add to that the BB's in the tires and jacking up the pressure from 12bar to 17 bar, tilting the bucket down won't lift the front tires off the ground anymore!  Chances are the bucket cyl needs to be replaced, the oil might be slipping by the piston; the seal drips a bit too... I need to change all 5cyls on this loader, as they all seep a bit... what a mess it all makes!!! However, the twin loader arm cyls have zero trouble lifting a bucket full quickly with the higher pressure. Chances are the bucket cyl needs to be replaced, the oil might be slipping by the piston; the seal drips a bit too... I need to change all 5cyls on this loader, as they all seep a bit... what a mess it all makes!!! However, the twin loader arm cyls have zero trouble lifting a bucket full quickly with the higher pressure.I understand exactly what you're saying Grady, a 45* splice would definitely be better than a 90* butt joint for a smoother roll... but I don't have any extra to redo the job. Although, after wrapping the rim with each layer - I think 5 layers, then removing it from the rim to scrunch & stuff into the tire, I think I distorted the true shape I previously had & probably didn't gain much... these are crawler tires for lightweight scalers, not meant at all for what I'm trying to do. But I'm gonna try the oak donut before giving up on them totally.

__________________

Sharing knowledge is one thing that defies basic arithmetic logic --- the more you share, the more you get! Joe |

|

#728

|

||||

|

||||

|

I thought I would see what kind of weight could be put on these homemade foams. I put a 40lbs battery in the back of my R18 for a combined weight on the rear axle of 50lbs. I don't know how much more weight these would take but probably not 80lbs. Something tells me that if I put 80lbs+ in my Euc the tires would be the least of my worries though.

|

|

#729

|

||||

|

||||

|

Reg, I'd say the tire squat is about as scale perfect as can be!

__________________

Nathan |

|

#730

|

||||

|

||||

|

Quote:

__________________

Nathan |

|

#731

|

||||

|

||||

|

Thanx for the experiment test Reg.

No idea Nathan.. intermittent use since 2007... 2 - 300 or more. Always scooped loose soil. I don't have a scale to weigh it (can't buy a scale locally, and never remember it when in the city  ), it's definitely 20-25% heavier. No, the motors have tons of power, I could spin all four & sink it to the frame in an instant, if I'd let it. ), it's definitely 20-25% heavier. No, the motors have tons of power, I could spin all four & sink it to the frame in an instant, if I'd let it. Why haven't you snapped up Ed's loader yet Nathan?! Somebody else is gonna get it again & then you're gonna whine again you missed out!  Buy it! The guilt of the cost of the 1st one stings a little momentarily, but once you discover the enjoyment it brings to use 'em... the cost is a distant thought! Buy it! The guilt of the cost of the 1st one stings a little momentarily, but once you discover the enjoyment it brings to use 'em... the cost is a distant thought!It crossed my mind to buy it - trade up, so to speak - but all that mine needs is cyls @<$400, nothing else. And I sure as he77 wouldn't give mine away for much cheaper just to get rid of it.

__________________

Sharing knowledge is one thing that defies basic arithmetic logic --- the more you share, the more you get! Joe |

|

#732

|

||||

|

||||

|

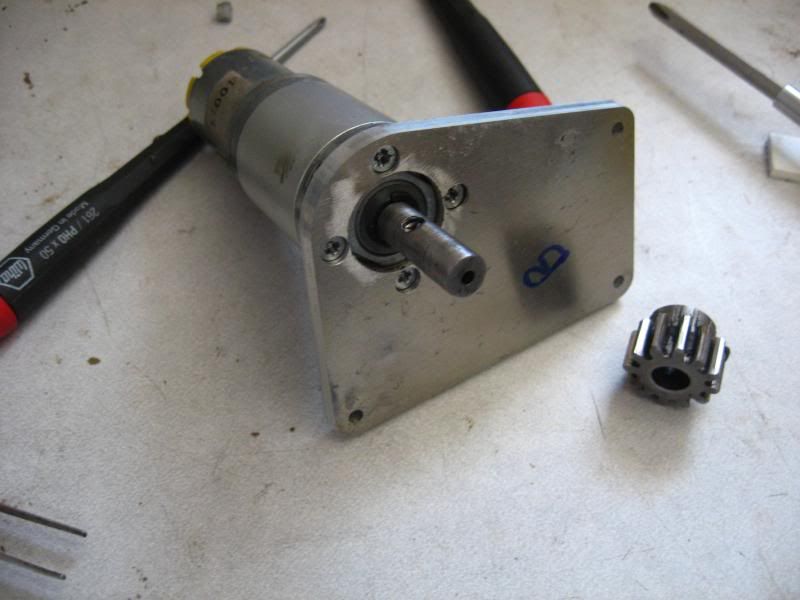

I almost made it the whole winter without putting a wrench to the 850.

I have a spare gearhead & made the repair last night, thread locking the old steel bushing in place on the new output shaft. It'll take an hour this morning to put everything back together & have it running again... it's good to carry inventory.

__________________

Sharing knowledge is one thing that defies basic arithmetic logic --- the more you share, the more you get! Joe |

|

#733

|

|||

|

|||

|

Joe you run a gear reduction on your swing I run it right of the motor shaft. Ed

|

|

#734

|

||||

|

||||

|

Ed, everything pictured, I sent that to you last yr... did you remove the gearhead to run the motor directly on the pinion?

__________________

Sharing knowledge is one thing that defies basic arithmetic logic --- the more you share, the more you get! Joe |

|

#735

|

||||

|

||||

|

wow that 850 held up good!

__________________

Rc's are like pringles. You can't have just one!! my YouTube is - To view links or images in signatures your post count must be 10 or greater. You currently have 0 posts. Subscribe!! My Facebook - To view links or images in signatures your post count must be 10 or greater. You currently have 0 posts. |

|

#736

|

||||

|

||||

|

About how many hours does that take to let go?

|

|

#737

|

|||

|

|||

|

Joe now to tell you I can't really remember if that what you sent that is what I put on it. Ed

|

|

#738

|

|||

|

|||

|

Joe,

Impressive failure, a 4 or 5mm output shaft sheared off? Even with the hole up the middle of the shaft it would have taken some force to shear it .... Possibly need to change to shaft to something more solid or somehow limit the torque output to minimise the chance of it happening again? Cheers, AP |

|

#739

|

||||

|

||||

|

No idea on the hrs Steve... it was Aug or Sept 2011 when installed, 10cy of hard digging would put the most amount of stress on it, and I use the arm occassionally too to lift the front of tracks & turn.

__________________

Sharing knowledge is one thing that defies basic arithmetic logic --- the more you share, the more you get! Joe |

|

#740

|

||||

|

||||

|

The pinion shaft on the gearhead is a solid 4mm, the bore of the pinion gear is 8mm. The hole you see, I just drilled that to pound out the broken pinion shaft from the steel bushing I made to mate the two. I also drilled two holes in the side of the steel bushing so the gear pinion set screws lock onto the output shaft.

__________________

Sharing knowledge is one thing that defies basic arithmetic logic --- the more you share, the more you get! Joe |

|

| Currently Active Users Viewing This Thread: 45 (0 members and 45 guests) | |

|

|