|

|

|||||||

| Construction Equipment If it digs, pushes, hauls dirt "off road" post it here. |

|

|

|

Thread Tools | Display Modes |

|

#41

|

|||

|

|||

|

Looking great Jim! I like the progress and constant updates. Keeps the interest up!

__________________

Life: it's all about the ride! |

|

#42

|

|||

|

|||

|

Those pads look great, Jim! Keep it up. You're getting me thinking about finishing out the back half of my 40' container so I can set up a my stuff and get working. Be a great winter project.

|

|

#43

|

||||

|

||||

|

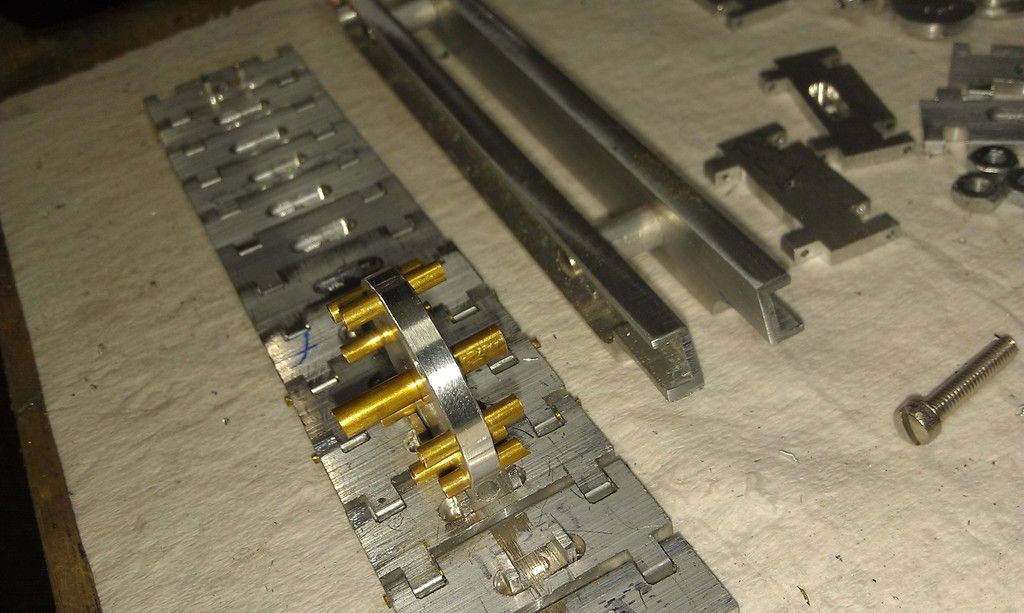

Got four side frame rails made and bolted two of them together. Oh, and if I counted correctly, I got all the pads drilled yesterday. Now all I have left on the pads is riveting the drive dogs into the slots. The pads detail never ends!

Ya, I need to find some better looking hardware to bolt them together...  Jim |

|

#44

|

|||

|

|||

|

looking good

__________________

Steve |

|

#45

|

|||

|

|||

|

Very good Jim, those high production parts sure do get monotonous

__________________

Life: it's all about the ride! |

|

#46

|

||||

|

||||

|

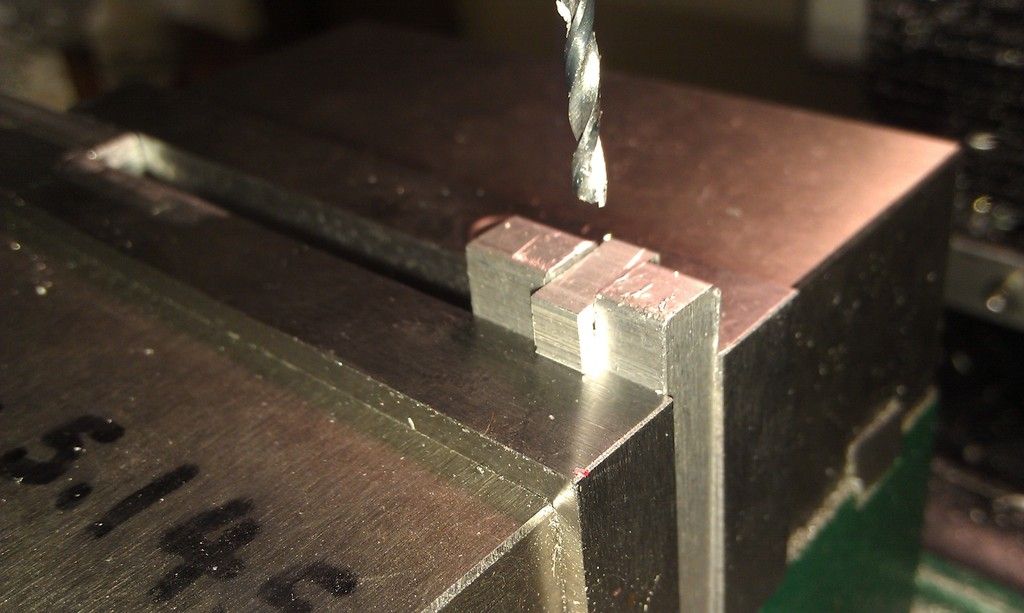

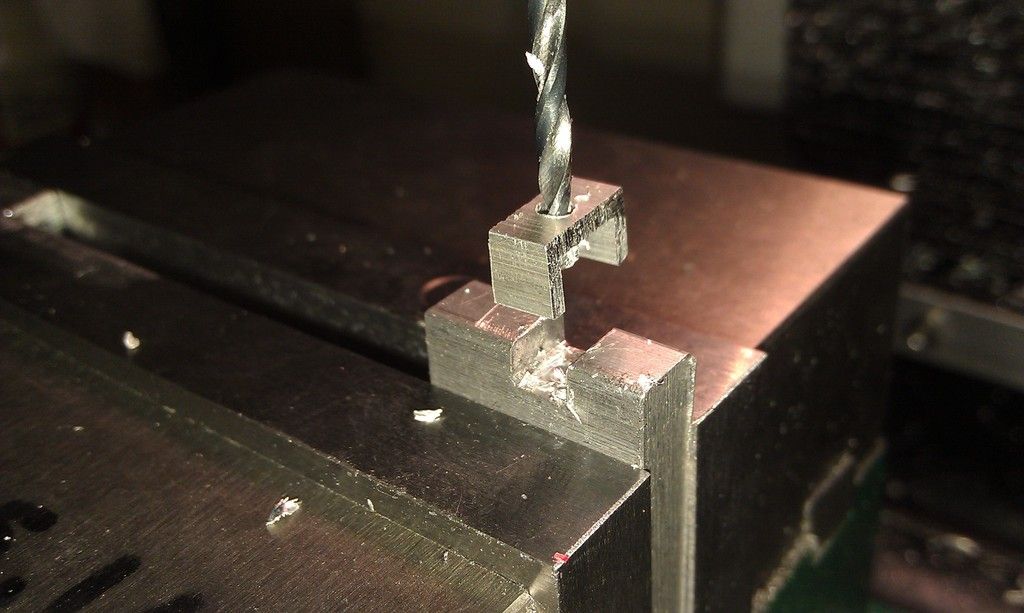

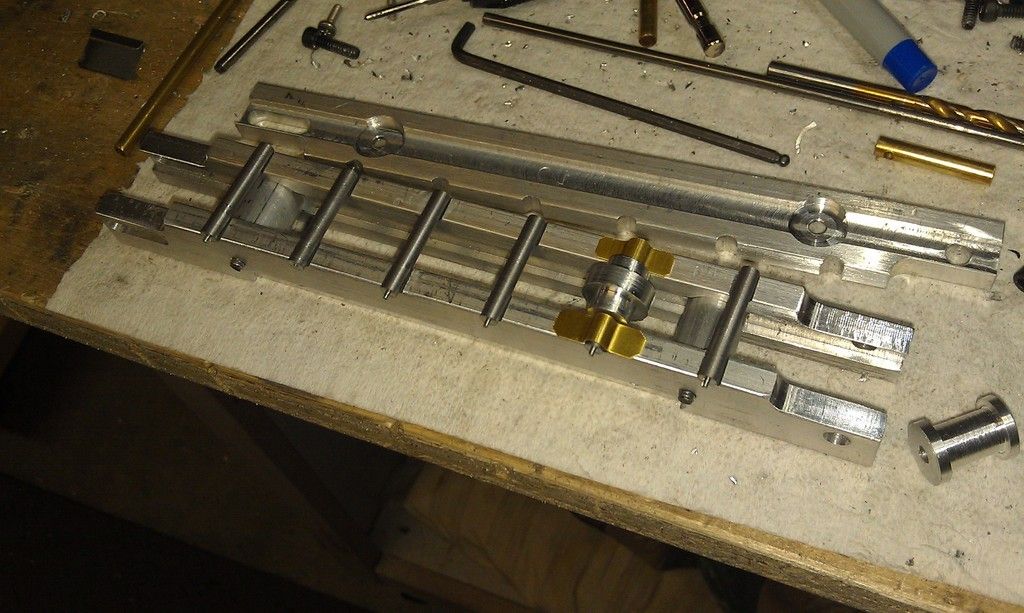

Here is my simple fixture to drill the little sections of channel that get riveted into the pocket in each pad.

Jim |

|

#47

|

|||

|

|||

|

Looking good jim- to me the pads are the most tedious and time consuming job on these types of projects. Once you get those finished you can have some fun milling all the other parts. Are you using a center drill to spot each hole?

Last edited by modelman; 06-07-2015 at 04:58 PM. Reason: adding |

|

#48

|

||||

|

||||

|

Here is a shot of the micro stop counter sink tool and pneumatic rivet squeezer. I have a bit of aluminum metal work experience and already had these tools, or I would have NOT attempted to do the pads like it did. I countersink the hole in the bottom of the pads to accept the rivet flush.

The micro stop is fine threaded and allows adjustment so you can get a perfect depth on the countersink to fit the rivet head. I left them a bit high because I didn't want any extra rivet on the inside to get in the way of the tumblers. And, the little channel parts are so small and the hole clearance is way less than it should be so setting the rivet to standards can split or crack the part. I could have used a soft rivet here but had a bunch of standard.  Here is the rivet squeezer, really handy of you have a lot of rivets to squeeze.  Closeup of the dirt side of one of the pads with the rivet set.  Jim |

|

#49

|

|||

|

|||

|

Nice work jim-it's good to have the tools you need.

|

|

#50

|

||||

|

||||

|

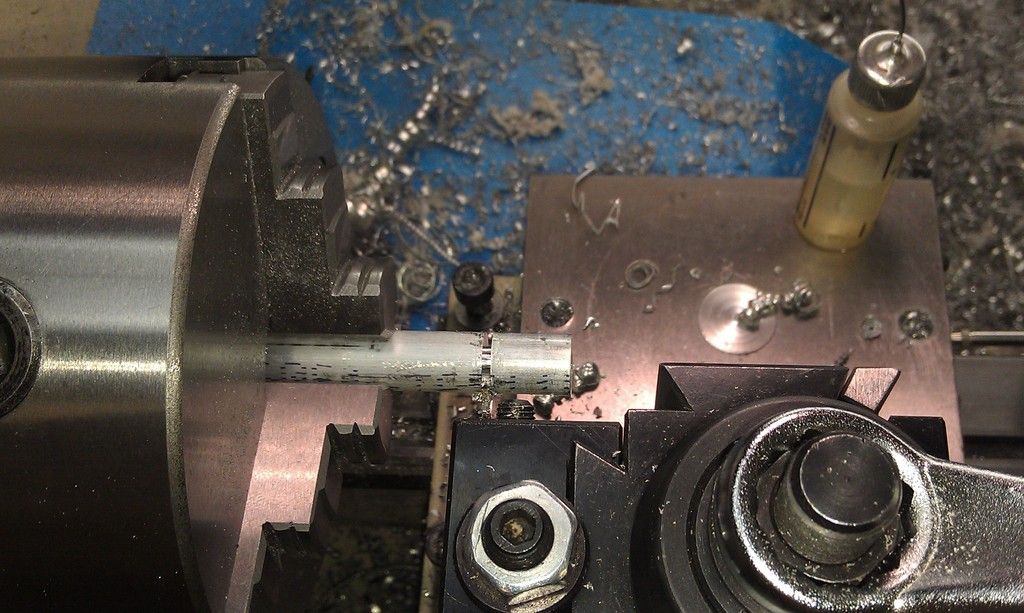

Parting off one of the spacers for the pairs of side frame rails.

I changed my side rail design a bit, should have one set finished tonight...  Jim |

|

#51

|

||||

|

||||

|

Got enough finished to do a first check of the "scale" of my undercarriage to the crane.

Jim |

|

#52

|

|||

|

|||

|

Just about ready to take a walk

__________________

Life: it's all about the ride! |

|

#53

|

|||

|

|||

|

Your scale looks good to me jim. Are you happy with it? I like the new frame rails you made. Adds strength, which you probably don't need but it helps the appearance. Are you about ready to make a tumbler and see if this works? Keep cranking on those handles.

|

|

#54

|

||||

|

||||

|

Thanks Tom! Ya I am pretty happy with it. I did the side over just for a better appearance. I have a hard time visualizing stuff like this so I always end up making something to see how it looks and then usually make one or two more until I am happy with it.

I am hesitating on the tumblers only because I don't want to take the vice off to put the rotary table on and then I know I will be going back to the vice. It really isn't a big deal, but I am trying to do as much as I can before the switch over. Decided to put a .050" groove in the bottom of the rails to "hold" the lower rollers.  Thanks to ALL for watching!  Jim Last edited by Rvjimd; 06-10-2015 at 11:17 AM. Reason: Added picture |

|

#55

|

|||

|

|||

|

I know exactly what you mean about changing set-ups. When I got my 2-in-1 machine several people told me I would regret it but the price was just too good to pass up. However, I thought about what I was told every time I was turning something and needed the mill for 1-simple cut and had to change over again and again. Oh well, live and learn.

|

|

#56

|

||||

|

||||

|

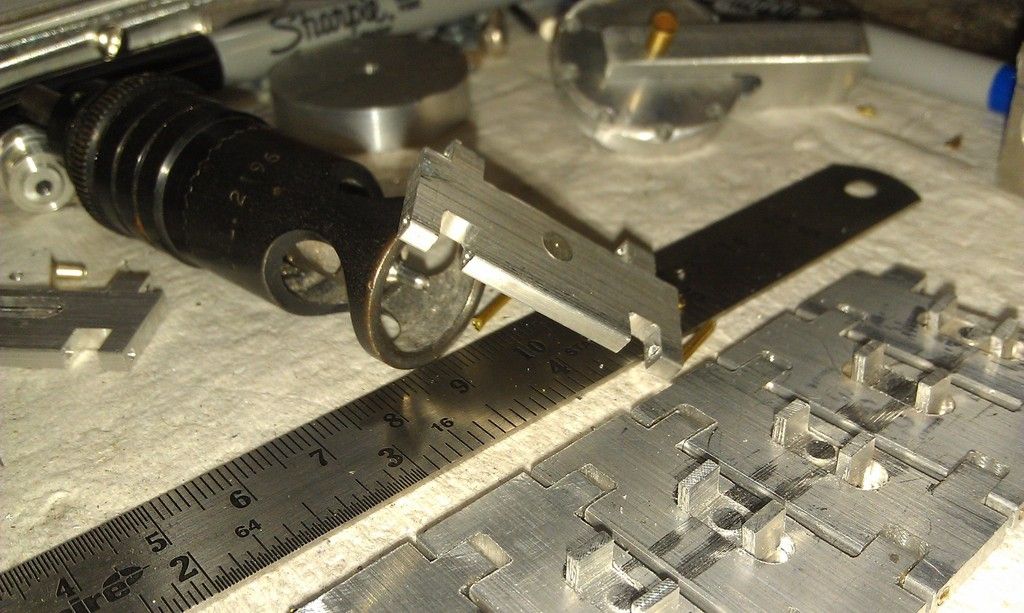

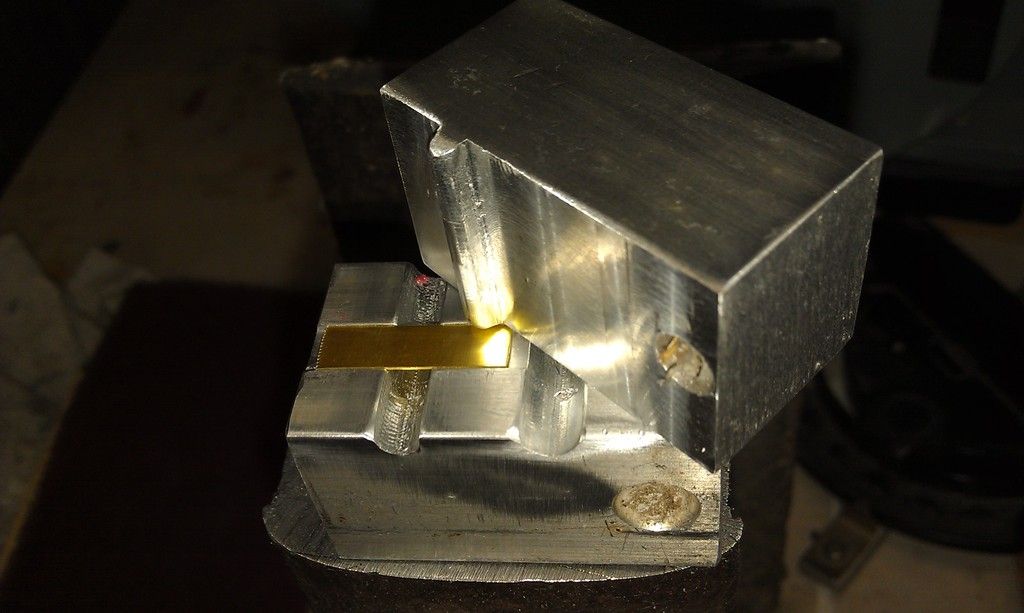

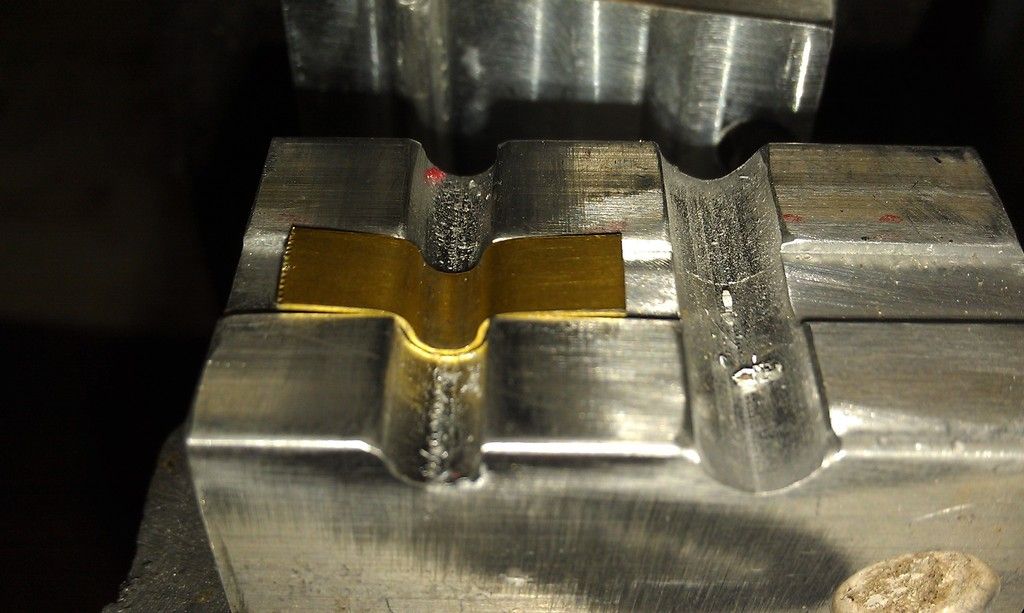

More progress shots! Decided to leave the lower roller shafts round and make little clamps for each end. Will attach them with 2-56 cap screws. Made a little die to form the strap clamps. Turned the 3/16" steel rod down to fit a 3/16" brass bushing to go inside the rollers.

Jim |

|

#57

|

|||

|

|||

|

Looks like that undercarriage will fit real nice underneath the house, Jim. On those rollers, you might want to bevel the edges that will run between the lugs on the track. That way the roller won't be able to catch the edge of the lug, ride up on it and throw the track off.

|

|

#58

|

||||

|

||||

|

Jared,

Good idea on the roller profile. I need to make all of them, the one in the photo is a prototype. I will put a nice big angle on the corner of them. QUESTION: How tight should the rollers and tumblers fit between the dog ears on the pads? Not sure if they should be close or real sloppy narrow? Jim |

|

#59

|

||||

|

||||

|

Very cool! I have always wondered if someone was ever going to build an older track style like this, and it looks like you're knocking it out of the park..

__________________

Jarrett |

|

#60

|

|||

|

|||

|

Looking good jim-that is a nice beefy press you made. I agree with jared on the rollers, just a slight chamfer on the edges should help. I say you need some clearance between tumblers, rollers, etc.. This allows for dirt not jamming the parts. 9W may know something about this.

|

|

| Currently Active Users Viewing This Thread: 2 (0 members and 2 guests) | |

| Thread Tools | |

| Display Modes | |

|

|