compare

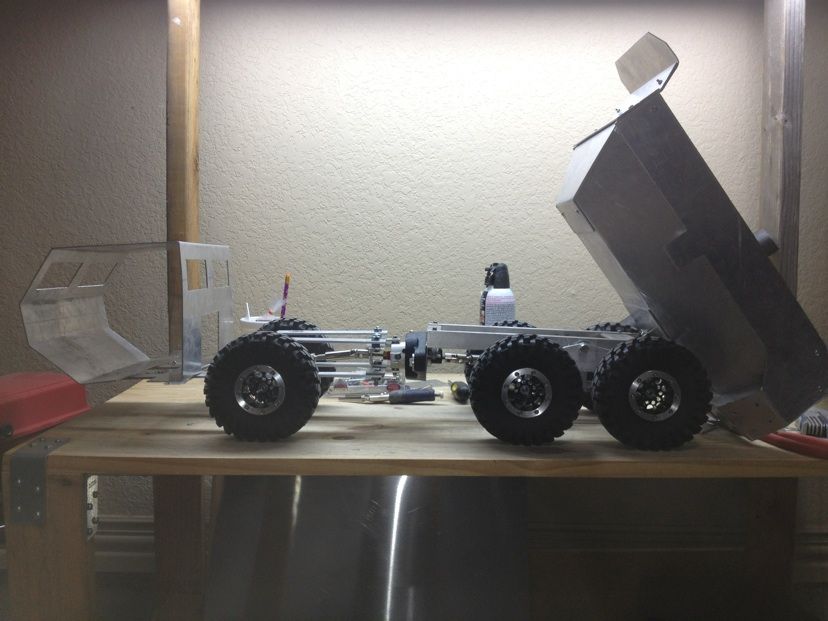

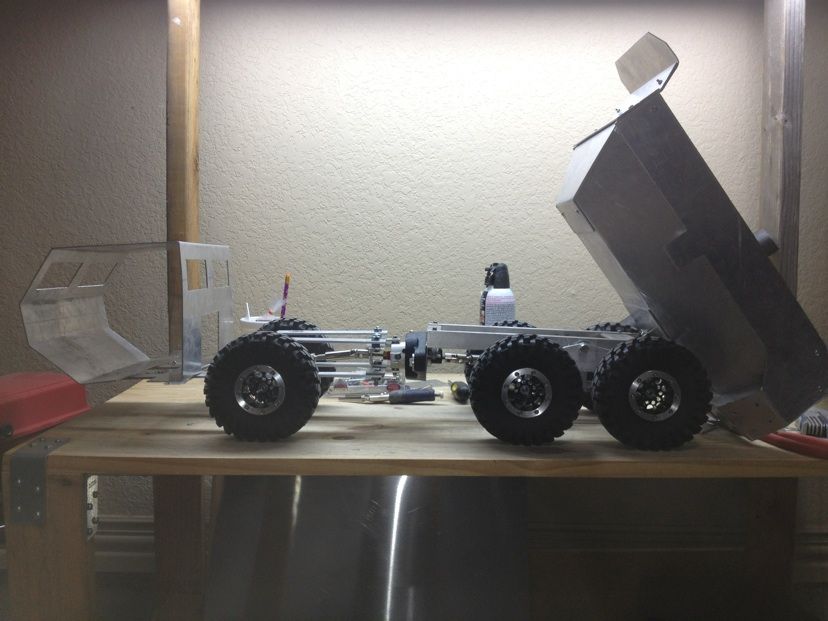

Thanks Lil Giants for taking a look at the pics and tell me the problem about the hinge point. I noticed there was something wrong too before I read your message. I did remarked it and it works whole lot of better.

I like to show y'all the geared motor that I bought n this is what I want to connect it to the 1st axle. I think it looks better too!! The dia of the tires r almost 5.5" n the Final drive ratio 3.75:1 of the axle (from rc4wd n I have no idea what the number means) So, Do you think the 30rpm will work?

Thanks,

Leon

I like to show y'all the geared motor that I bought n this is what I want to connect it to the 1st axle. I think it looks better too!! The dia of the tires r almost 5.5" n the Final drive ratio 3.75:1 of the axle (from rc4wd n I have no idea what the number means) So, Do you think the 30rpm will work?

I like to show y'all the geared motor that I bought n this is what I want to connect it to the 1st axle. I think it looks better too!! The dia of the tires r almost 5.5" n the Final drive ratio 3.75:1 of the axle (from rc4wd n I have no idea what the number means) So, Do you think the 30rpm will work?