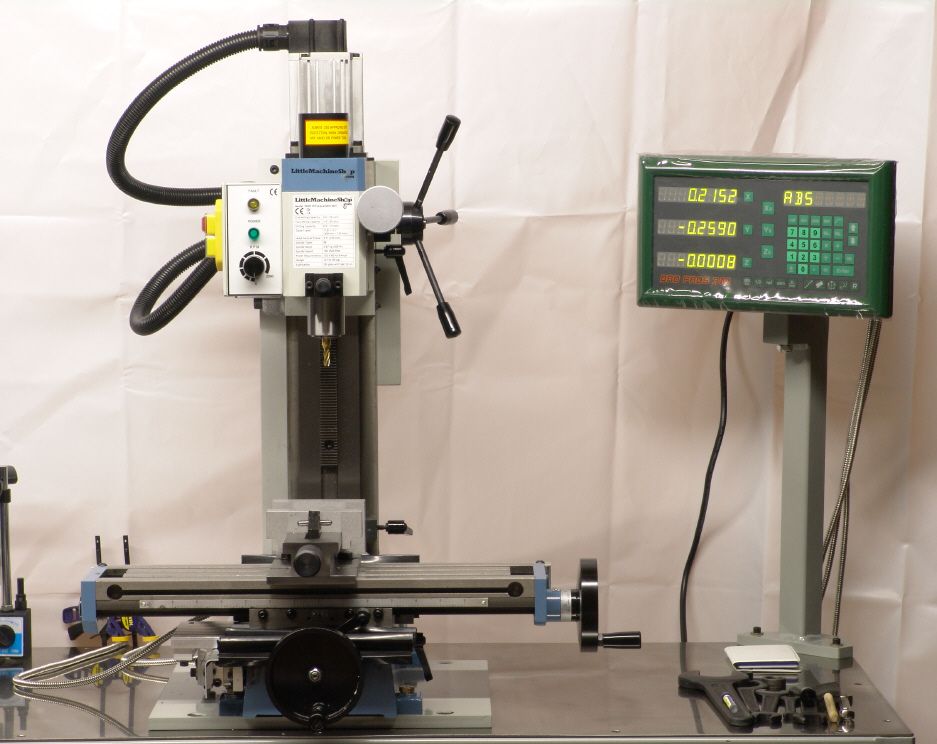

I don't have to much add to the thread, but I thought I'd throw a photo of my mill into the mix. I can only tell you that it's been a great little machine for me, so far. I've been extremely pleased with it's performance, especially after adding the DROs.

When I first got it, there were some issues I had to address, and the spindle bearings started going bad on me within a couple months, but I changed them out for some quality bearings, and it's been smooth sailing ever since. I also added thrust washers to both the X and Y axis screws, and a heavy 1/2" steel plate, which runs, and is bolted to the entire length of the column, to make it more rigid. With these three improvments done, it's become a really great mill, handling everything I've throw at it so far. I've been really happy with the purchase. I would have gone larger, if I could, but I keep the mill in the basement, and I wanted something I could carry down there by myself. It's weighs almost as much as I do, and though not really easy to move around, I can manage, if I have to. The next mill I buy, I hope will be a Bridgeport! I can always dream.

The added mass, bigger tables, and table travel, compared to a little Sherline mill makes me feel I made the right decision. My mill is bigger, but not to big, if you know what I mean. I felt that even a Sieg X3 would have been to much for me. Once the head on my mill is trammed, I really don't change the set-ups. Otherwise, I love how easily the Sherline can be trammed!

This photo is when it was brand spankin' new. That's why everything is so clean! Normally there are chips everywhere!