|

|

|||||||

| Highway Trucks and Trailers On road trucks and trailers single and twin axle trucks. |

|

|

|

Thread Tools | Display Modes |

|

|

|

#1

|

||||

|

||||

|

Thanks for the kind words, guys. I appreciate it! It keeps me going. So how about an update?

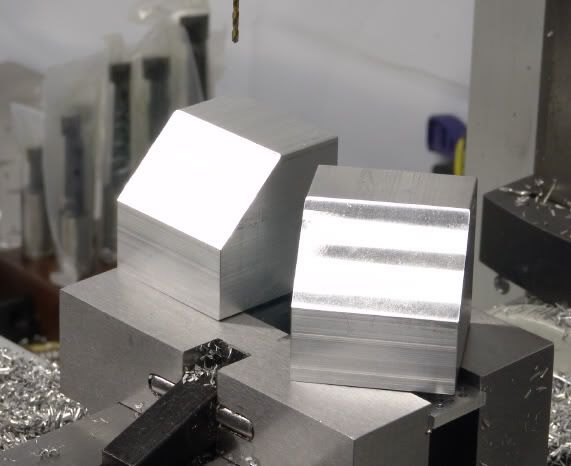

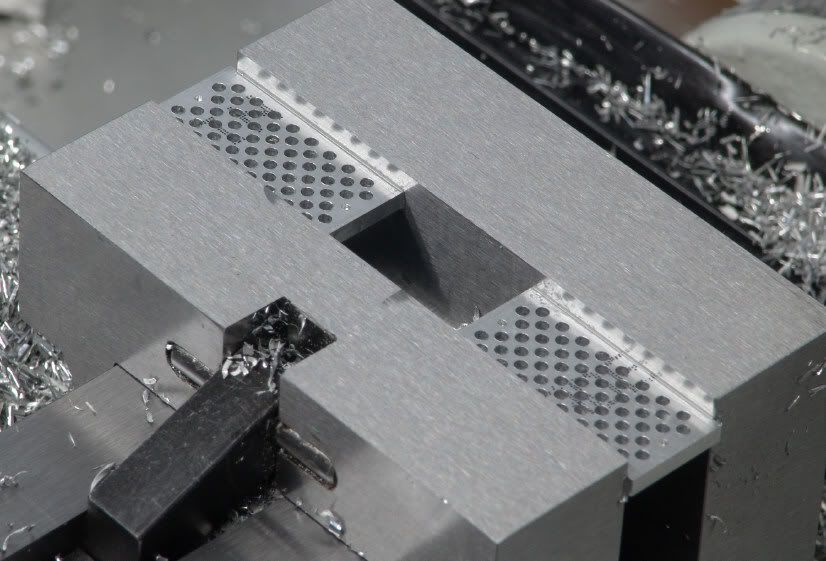

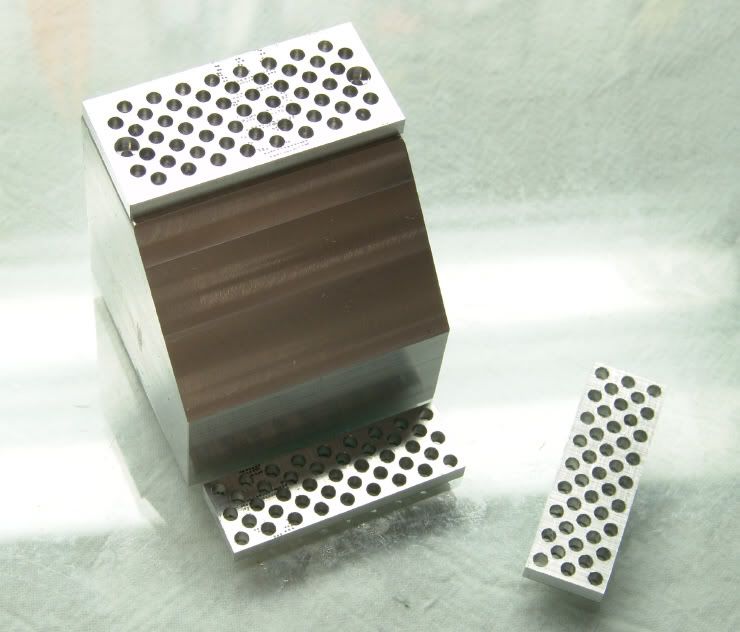

The weather has been unusually warm, so it's hard to spend time inside, working on the Wedico. We hit 79 degrees today, and it's not even April yet. Normally, even in April, there is still snow on the ground, with some 30 degree temps, but it already feels like summer. Anyhow, I was having a hard time finding the movitation to work on the Wedico, but I pushed on, and got some back. Nothing like machining up some parts, and seeing some form of progress take shape. That was enough to get me going again, and I really hope to get this truck finished by the end of the year?!? Ha, we'll see. So one thing I have been wanting to do is build some aluminum tool box steps for the truck, like these -  Here is what I've got so far -  There going to go on the truck something like this -   I intend to run the fuel tanks under the cab, instead of the more typical place, behind the cab. I've got a plan for making some nice tank saddles and tank steps, but first, I want to finish these tool boxes.  Now the really fun part is I intend to make the steps and tread plates for these tool boxes, and see through. I had fun drilling out 57 holes, per top tread plate. I haven't even gotten to the actual steps yet! I am in need of some small screws, to bolt it all together. I'm thinking 0-80 screws. They are a little smaller then the 2mm screws I have been using. Bolting everything together will be a little tedious, but it's the only way I'll have the detail of individual pieces, made into a complete tool box. It should be fun!

__________________

Nathan |

|

#2

|

||||

|

||||

|

looks good Nate

I don't think you have enough chips laying around yet I don't think you have enough chips laying around yet

__________________

RIP FreddyGearDrive 2-12-59/12-19-11 To view links or images in signatures your post count must be 10 or greater. You currently have 0 posts. |

|

#3

|

||||

|

||||

|

very nice machining indeed. well thought out and good planning too i'd say.

Chris |

|

#4

|

||||

|

||||

|

Them are going to be very nice finished.. First class work as always nice job.

__________________

Paul W. "Tamiya Cowboy" HI.. My name is Paul.. And.. I.. Have a Cabover Addiction. RIP FreddyGearDrive 2-12-59/12-19-11 "LET IT EAT" Like Us on Facebook "Corn Field Mafia" To view links or images in signatures your post count must be 10 or greater. You currently have 0 posts. |

|

#5

|

||||

|

||||

|

Quote:

Quote:

Quote:

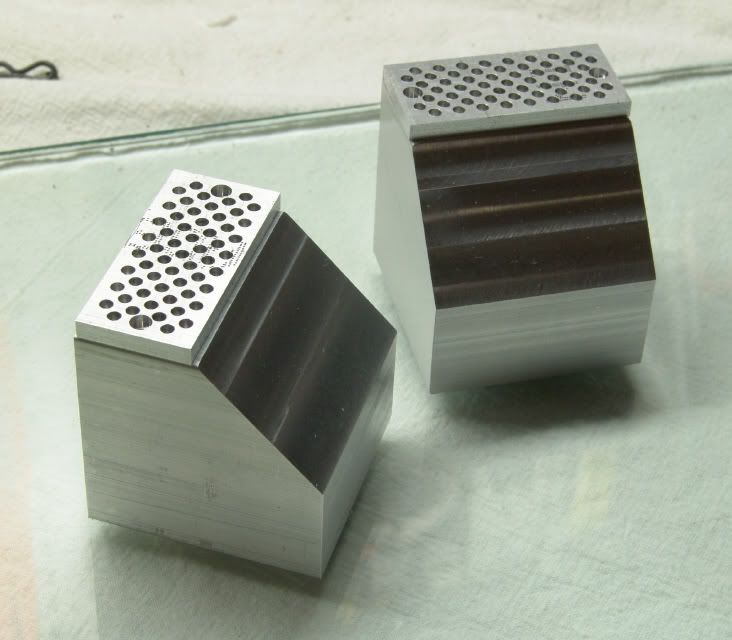

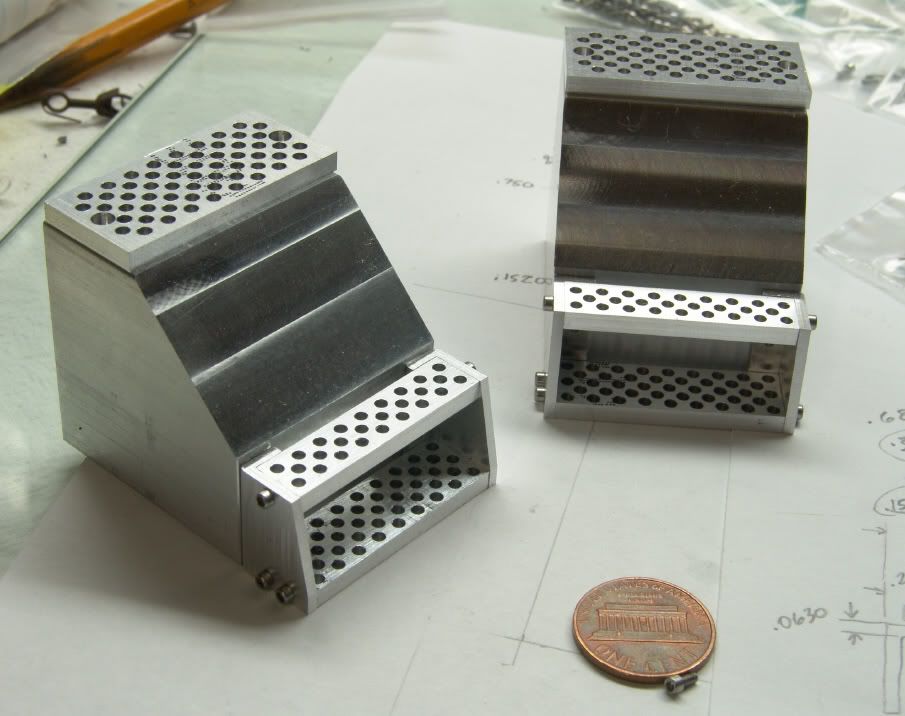

Here are a couple more photos. I finished off the top tread plates tonight. I ordered some 0-80 screws, and thought I'd have to wait till I got them, so I could drill the last two holes and counter sunk relief for the screw heads to size. Instead, I found the specs for the head diameter and height online. I was able to go ahead and punch the last couple holes into the plates. The heads of the screws should sit flush or slightly below the tread plates, so it will look clean.   Definitely a labor of love! 59 holes a piece. Now to get the steps on the front, which thankfully will have a few less holes. The tread plates are going to be narrower, but scale. Hmmm, wonder if I should make a deck plate for my truck, and drill all the holes for them too?

__________________

Nathan Last edited by Espeefan; 03-19-2012 at 01:30 AM. Reason: Fixin' messed up quotes! |

|

#6

|

||||

|

||||

|

those are sweet Nate . careful now

machining can get addictive . I have more then most here machining can get addictive . I have more then most here  , but it's not enough , but it's not enough  I need a good BP for the stuff I don't need to put in the VMC . I dislike electronic hand wheels , no feel I need a good BP for the stuff I don't need to put in the VMC . I dislike electronic hand wheels , no feel

__________________

RIP FreddyGearDrive 2-12-59/12-19-11 To view links or images in signatures your post count must be 10 or greater. You currently have 0 posts. |

|

#7

|

||||

|

||||

|

Lookin SWEET Nate

__________________

To view links or images in signatures your post count must be 10 or greater. You currently have 0 posts. Mike "DREAMWEAVER" Johnson To view links or images in signatures your post count must be 10 or greater. You currently have 0 posts. RIP FreddyGearDrive 2-12-59/12-19-11 Rims and Tanks by ihbuilder / Grill and Visor by Brian in PA / Mirrors, Front and Rear Bumper, Back of Cab Lights, and Steering Arms by tc1cat / Fenders by Stylin n Profilin / Frame Rails by The Late Freddy Gear Drive |

|

#8

|

||||

|

||||

|

Unbelievable Nathan! Looks like you drilled all of those holes perfectly without the use of a jig?

|

|

#9

|

||||

|

||||

|

Incredible as always.Those boxes are the real deal. great job!!!

|

|

#10

|

||||

|

||||

|

Quote:

Quote:

Thank you Mike. Quote:

It's snowballed a little, Steve. I find it very easy to keep spending money on tooling, but I won't be getting a new machine until I wear this one out, or until I build a workshop for something bigger. Still, I'm very pleased with this machine. It wasn't perfect out of the crate, and took me a while to dial in, but it's totally worth it. Thanks for watching the progress.

__________________

Nathan Last edited by Espeefan; 03-19-2012 at 05:51 AM. |

|

#11

|

||||

|

||||

|

Very nice start on a great project! If you want to go even smaller than the 0-80 machine screws you might want to try www.scalehardware.com He has nuts and bolts down to .5mm. He also has taps for that size. I have only had the nerve to try 1 hole in .5mm. Came out OK but very nerve racking as it was the final detail on the part.

__________________

LYNN |

|

#12

|

||||

|

||||

|

Quote:

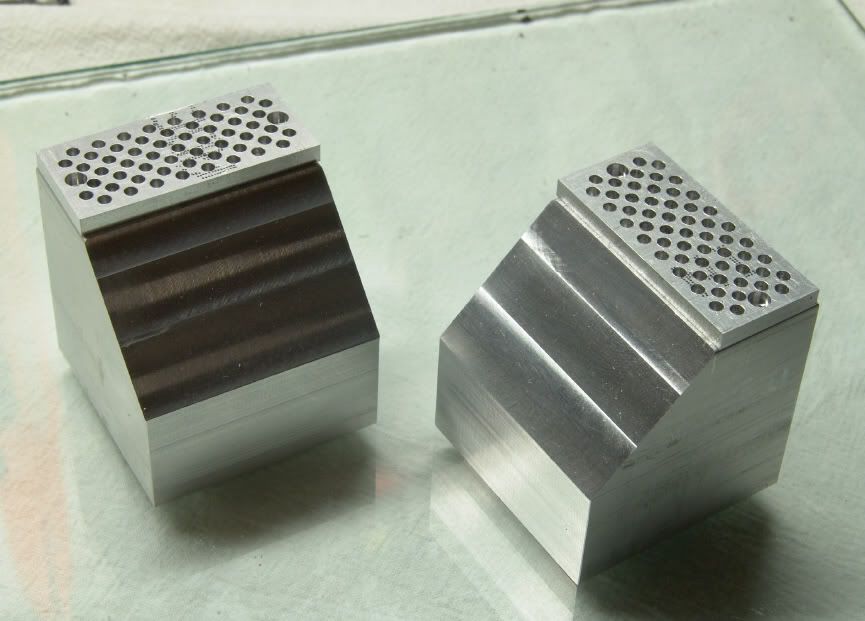

Forging ahead! I got two more tread plates for the steps done this morning.  Here's another photo, that shows how I hope to tie the steps to the boxes. I've got some step side members machined, that will pretty much bolt together, like the 1:1 steps will. These are not finished parts yet. The front edge (lip) will be milled off completely, at an angle, to match the 1:1 steps. In the next stage of machining, they'll be finished. Sometimes you have plan how you are going to hold onto such small parts, for each step of the machining process. They are oversized right now, but will get trimmed down to size soon enough. The top step will be slightly narrower then the bottom step and the side members will be angled to meet the top step. One just has to look at the 1:1 prototype photo I posted to see what I mean.

__________________

Nathan |

|

#13

|

||||

|

||||

|

Nathan, the step plates look really great. A lot of drilling but sure adds a bunch to the detail. If the 0-80 is a bit large, maybe 00-90? I use this size a lot on brass, aluminum and styrene. Not really a problem, in my experience. Just take your time. I've had the best luck by holding both the work and the tap in my hands. Seems that both "move" together, as opposed to having the work stationary in a bench vise. I've never used a tapping block or fixture - perhaps they would be helpful. Keep up the good work!

Ken

__________________

Big iron is awesome! |

|

#14

|

||||

|

||||

|

My head hurts from the coolness of this project..... My GOD what an outstanding looking RIG this is!!

__________________

To view links or images in signatures your post count must be 10 or greater. You currently have 0 posts. If you got it, a Trucker brought it.... |

|

#15

|

||||

|

||||

|

Quote:

Thanks MoRockN. Hopefully I can keep the standard going. I have a lot of other detailed parts to make yet.

__________________

Nathan |

|

#16

|

||||

|

||||

|

WOW

Nathan nice router work! Nathan nice router work! , and what? no jigs or templates to boot! Must be that calibrated eye! , and what? no jigs or templates to boot! Must be that calibrated eye!   . All seriouness aside, it looks very good and I can't wait to see it move a little faster, I mean done! Just one thing I'd like to see some one do is put rubber fender extensions on the front fenders when running super singles. Ok enough of my 2 cents. . All seriouness aside, it looks very good and I can't wait to see it move a little faster, I mean done! Just one thing I'd like to see some one do is put rubber fender extensions on the front fenders when running super singles. Ok enough of my 2 cents.  Keep up the great progress! Keep up the great progress!

|

|

#17

|

||||

|

||||

|

Quote:

I don't think anyone wants to see this project done more then I do. I've been working on it for such a long time now, but I've gained some momentum back. I just have to keep it rolling. I'm doing a little every day, when I can, but more so on weekends. That's when I seem to have the most time to play with things. Funny you mention the rubber fender extensions, because it is on the list of things to do, but that list is quite long at the moment! Maybe what I need, to put the pressure on me, is a feline supervisor, like you have! I don't think anyone wants to see this project done more then I do. I've been working on it for such a long time now, but I've gained some momentum back. I just have to keep it rolling. I'm doing a little every day, when I can, but more so on weekends. That's when I seem to have the most time to play with things. Funny you mention the rubber fender extensions, because it is on the list of things to do, but that list is quite long at the moment! Maybe what I need, to put the pressure on me, is a feline supervisor, like you have!

__________________

Nathan |

|

#18

|

||||

|

||||

|

Holy ..........those steps are out of this world!! Watching eagerly.

__________________

Never judge a man until you have walked a mile in his shoes. Then, when you judge him, you are a mile away and you have his shoes! To view links or images in signatures your post count must be 10 or greater. You currently have 0 posts. |

|

#19

|

||||

|

||||

|

Quote:

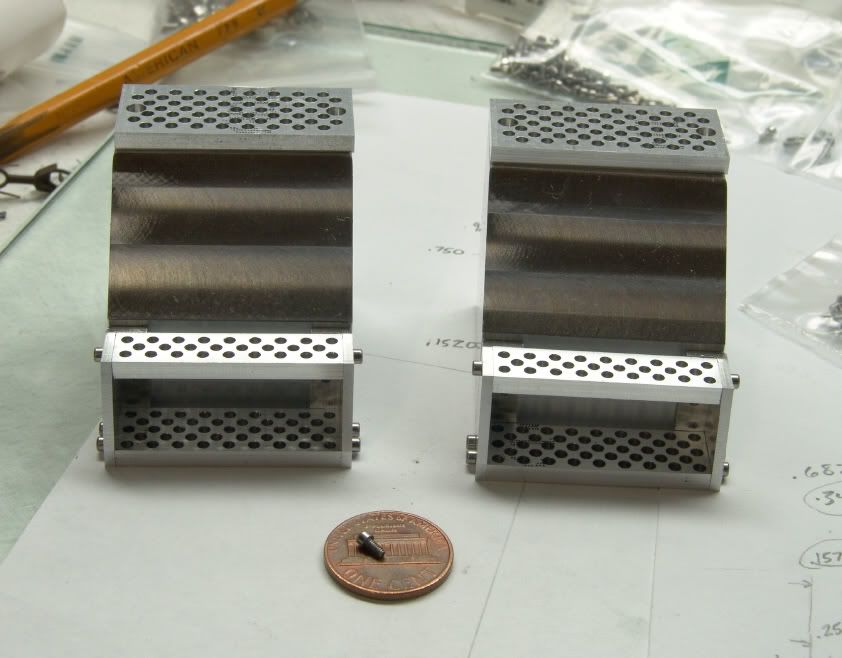

So, a small update. I've been finding the time before work each day to do a little more on the boxes. The last two days I've been working on the steps, which will bolt up to the tool boxes. The side members are all done! It was a tedious process to machine such small parts. I did run with the 0-80 screws, which seem about perfect for the task of holding things together. I'm glad I didn't go smaller. I think these are the smallest I would want to try and use for a build like this. They are so tiny! Drilling and tapping went without a hitch. I also milled the side members and gave them the proper angle on their face, to match the 1:1 boxes. These little buggers are really taking the time to make. I think I have 15 hours of work in them. Pictures of the last couple days of work.   I think I'm on a machining high right now! Still more to do. I need to make the tool box doors themselves, and drill and tap a few more holes to bolt the steps to the boxes. Also, the top tread plate is still not bolted down either. This should be a simple job, after accomplishing today's work.

__________________

Nathan Last edited by Espeefan; 03-22-2012 at 08:34 AM. |

|

#20

|

|||

|

|||

|

Nice work and attention to detail.

|

|

| Currently Active Users Viewing This Thread: 3 (0 members and 3 guests) | |

|

|