|

|

|||||||

| Construction Equipment If it digs, pushes, hauls dirt "off road" post it here. |

|

|

|

Thread Tools | Display Modes |

|

#1

|

|||

|

|||

|

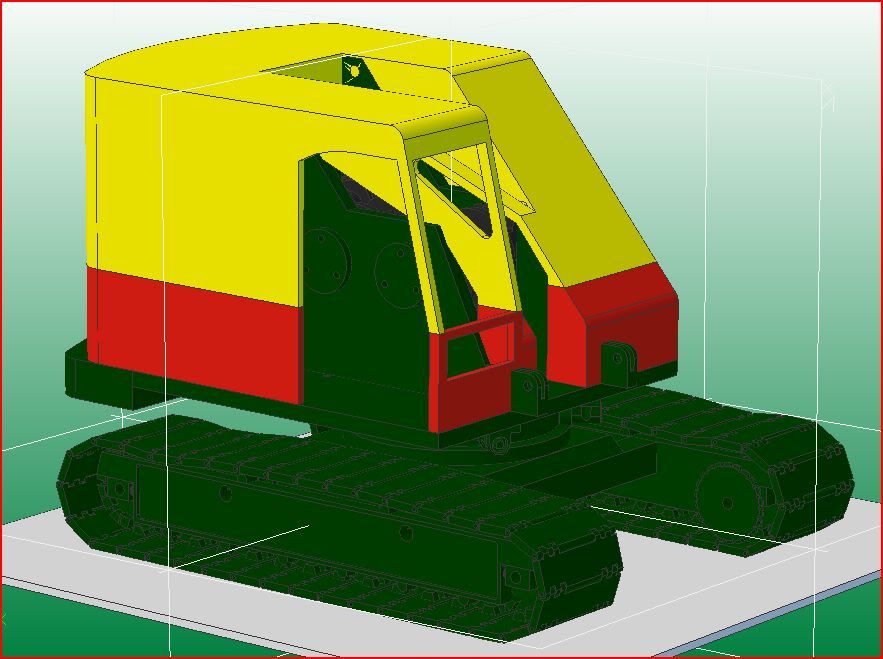

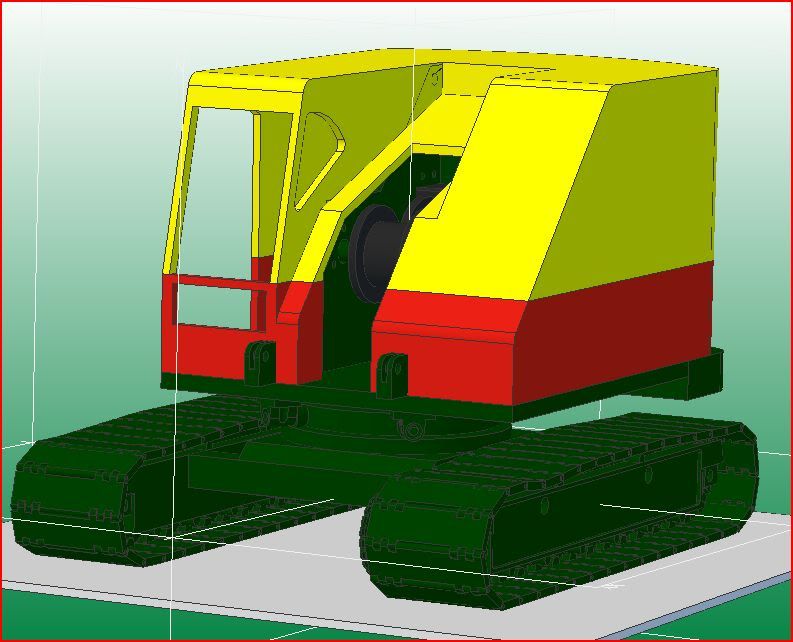

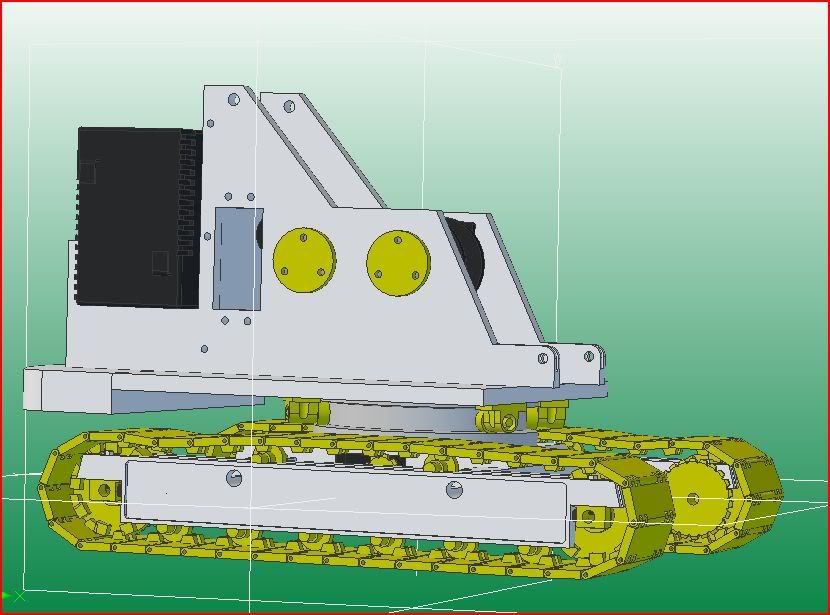

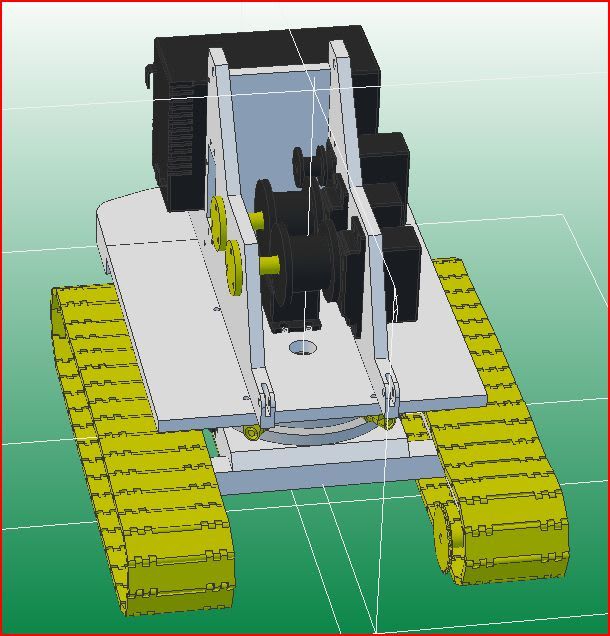

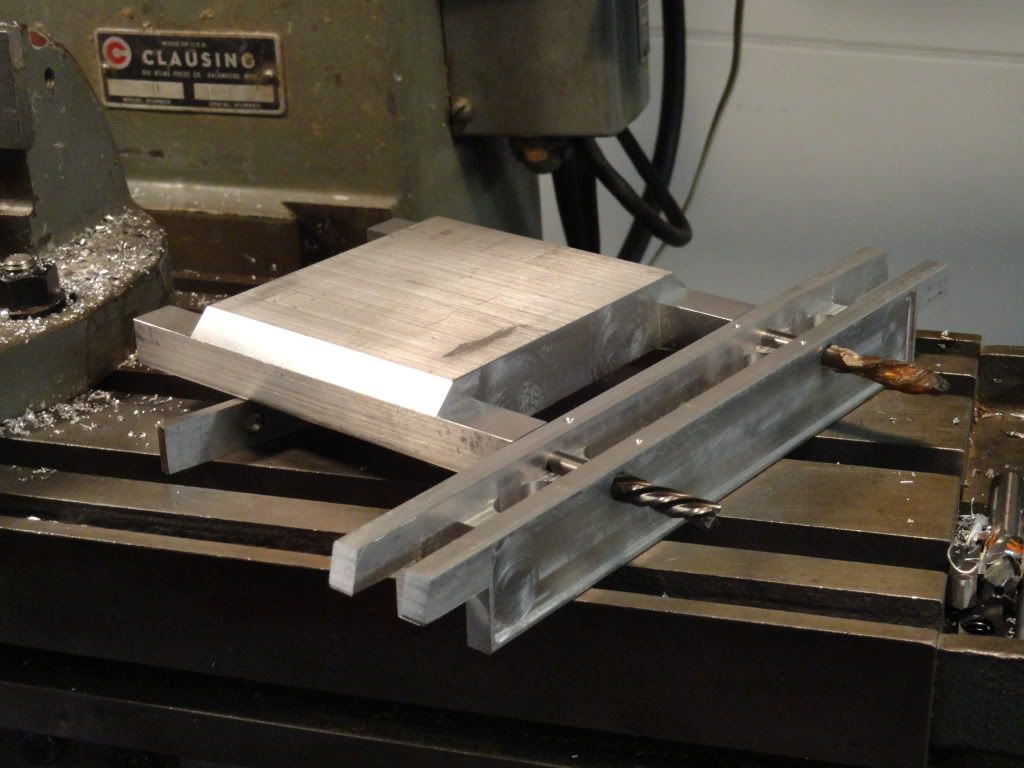

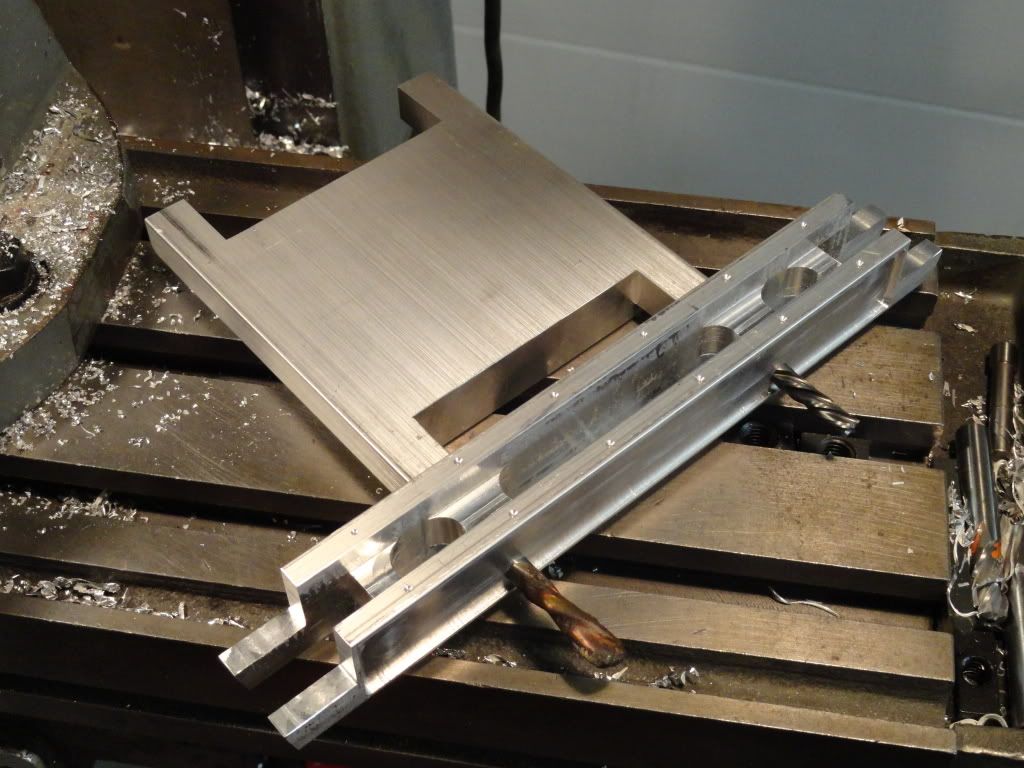

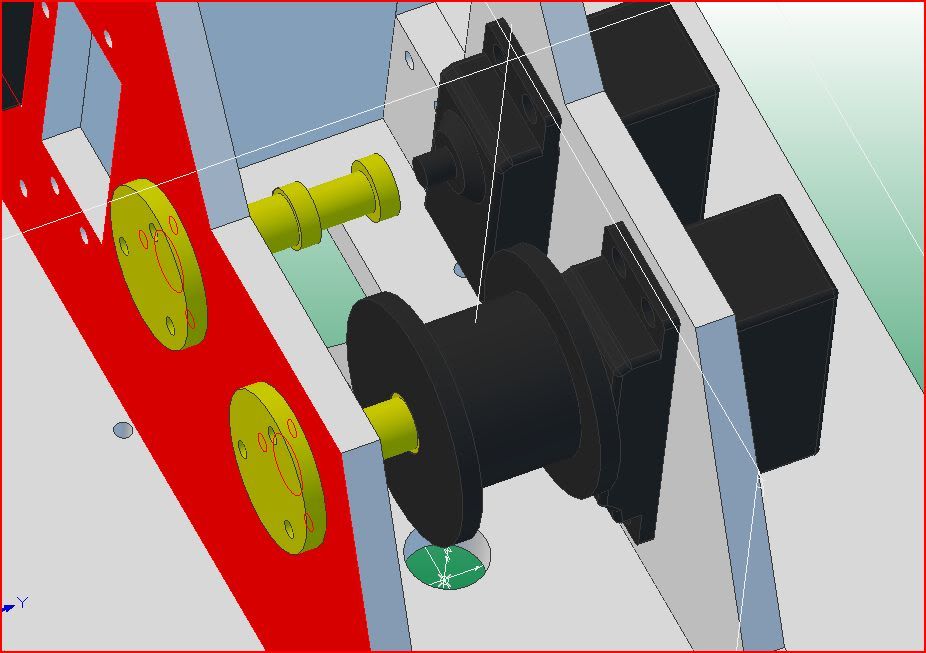

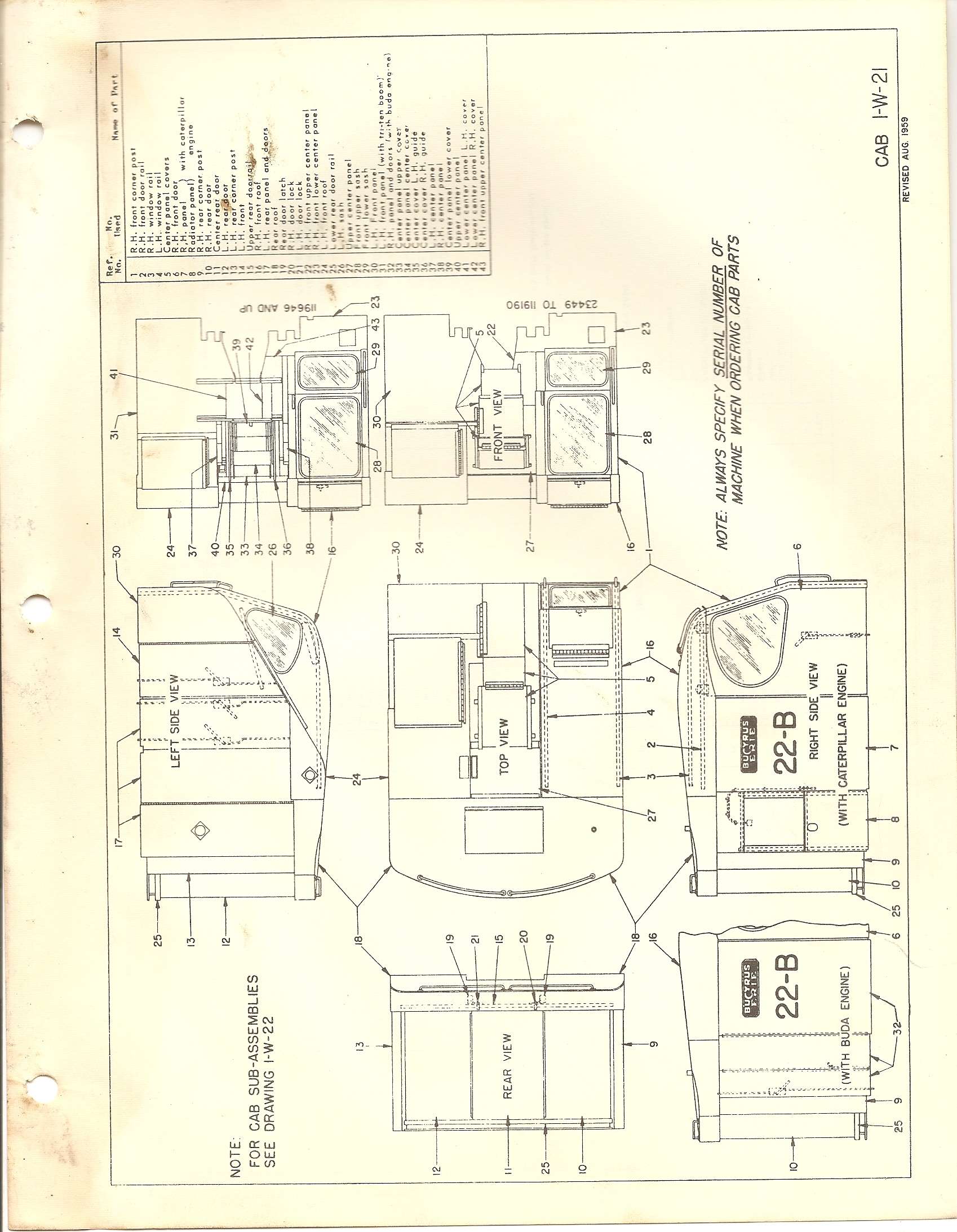

After a year of drawing, losing files, drawing again, modifying, tweaking, jiggering, improving, and generally not leaving well enough alone, I'm finally cutting metal. I bought a "new" Clausing 8530 mill a couple months ago and after throwing some money at it I've got it running now, so my first project with it is a B-E 22B. I started cutting metal a couple of weeks ago but didn't have much to show until now.

This is an almost-scale model. I took a few liberties with dimensions and shapes to make machining and buying metal stock easier but on the whole it's pretty close. I don't have a real machine to measure, just a spec sheet with the major dimensions on it. Everything else I've had to guess by looking at pictures. I haven't designed a boom and fairlead for it yet but it eventually it will be set up as a dragline and clam bucket. So here goes...     All functions are modified servos. Makes it clean and easy that way. We'll see how they hold up.  Did a bunch of puttering around in the garage and I found these on the mill.  Neither the track frame or carbody is finished yet. Got a bunch of 2-56 holes to drill and tap yet in the track frame and the carbody still needs to be hollowed out underneath to make room for the servos that will drive the tracks.  Hopefully I can keep things going and get this done before summer. It looks like I'll be working a few hours from home for a while so progress updates may be sporadic. |

|

#2

|

||||

|

||||

|

Look's like a fun project, Thank's for sharing the progress!

Cheer's, Neil. |

|

#3

|

||||

|

||||

|

Cool build. It will be fun to watch it come together.

__________________

Scott "No load is too Small" |

|

#4

|

||||

|

||||

|

Looks like your off to a good start. If you need details of the machine,I can help. I have owners manuals and parts books for the 22B in my vast collection of Bucyrus-Erie memorabilia.

|

|

#5

|

||||

|

||||

|

Jared, good to see a new project started. will be fun to watch it grow. Fred

|

|

#6

|

||||

|

||||

|

this looks like it is going to be a very interesting build to watch

|

|

#7

|

||||

|

||||

|

This going to be an AWESOME design and build!! Keep us all posted with updates.

Thanks for sharing. -Terry

__________________

FabOne NW Ohio |

|

#8

|

|||

|

|||

|

Thanks, guys! Steve, the only thing I really need is the outside diameter of the swing circle hook roller path. I have a sneaking suspicion mine is too big but I hope not; I have it drawn for 90 teeth on the swing gear which will be really easy to cut on the rotary table without dividing plates. Probably your manuals don't give that, though. Do they have detailed drawings in them with dimensions? If they do I'll just get one.

Hi Fred, good to meet you at the Threshing Bee. Don't let me go too long between updates. Last edited by Jared; 01-22-2012 at 11:40 PM. |

|

#9

|

||||

|

||||

|

This is going to be an exciting build to follow.

__________________

Giving up is not an option!!! Rob |

|

#10

|

|||

|

|||

|

Don't worry about it, Steve. D8R Dan fixed me up with a drawing.

|

|

#11

|

||||

|

||||

|

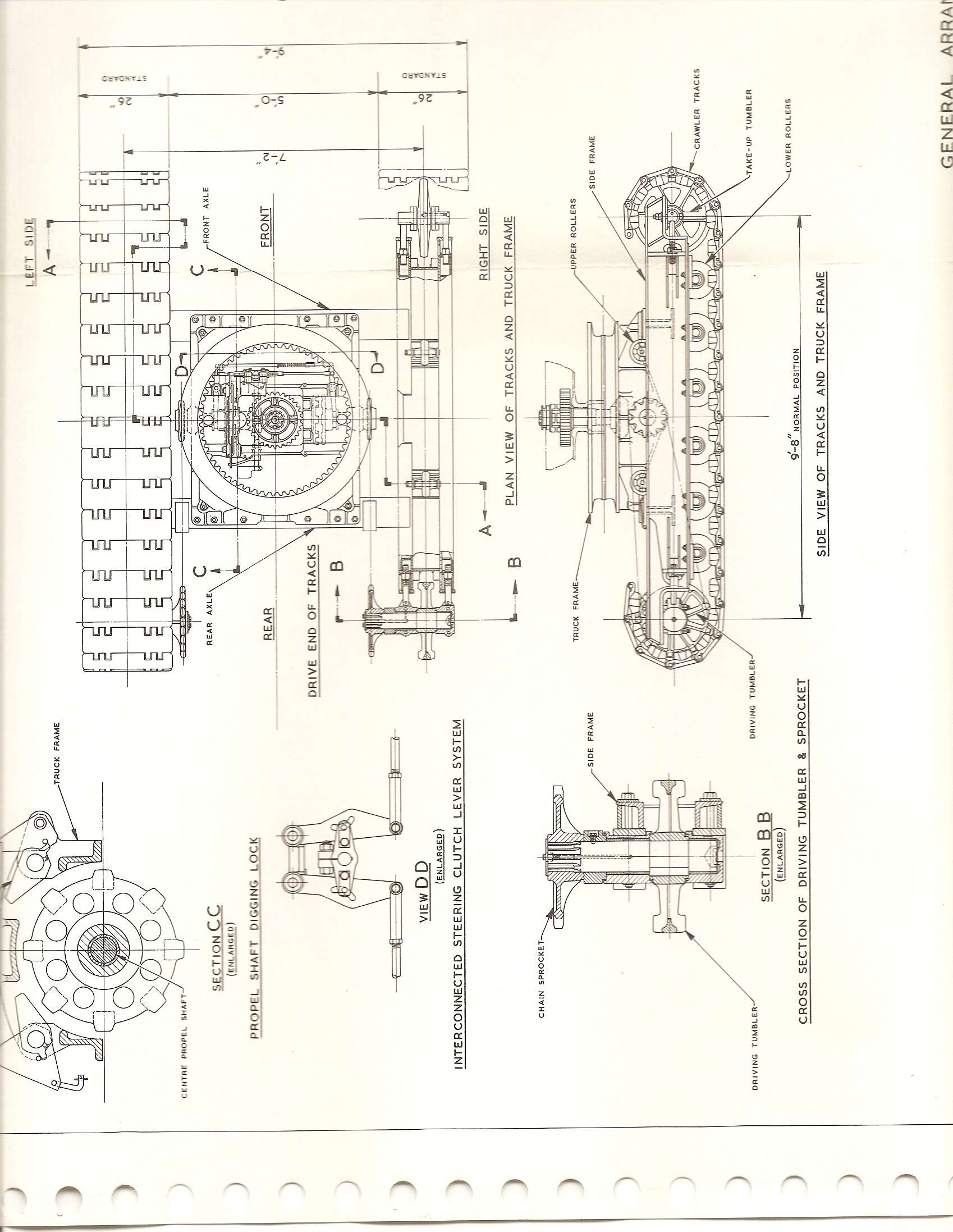

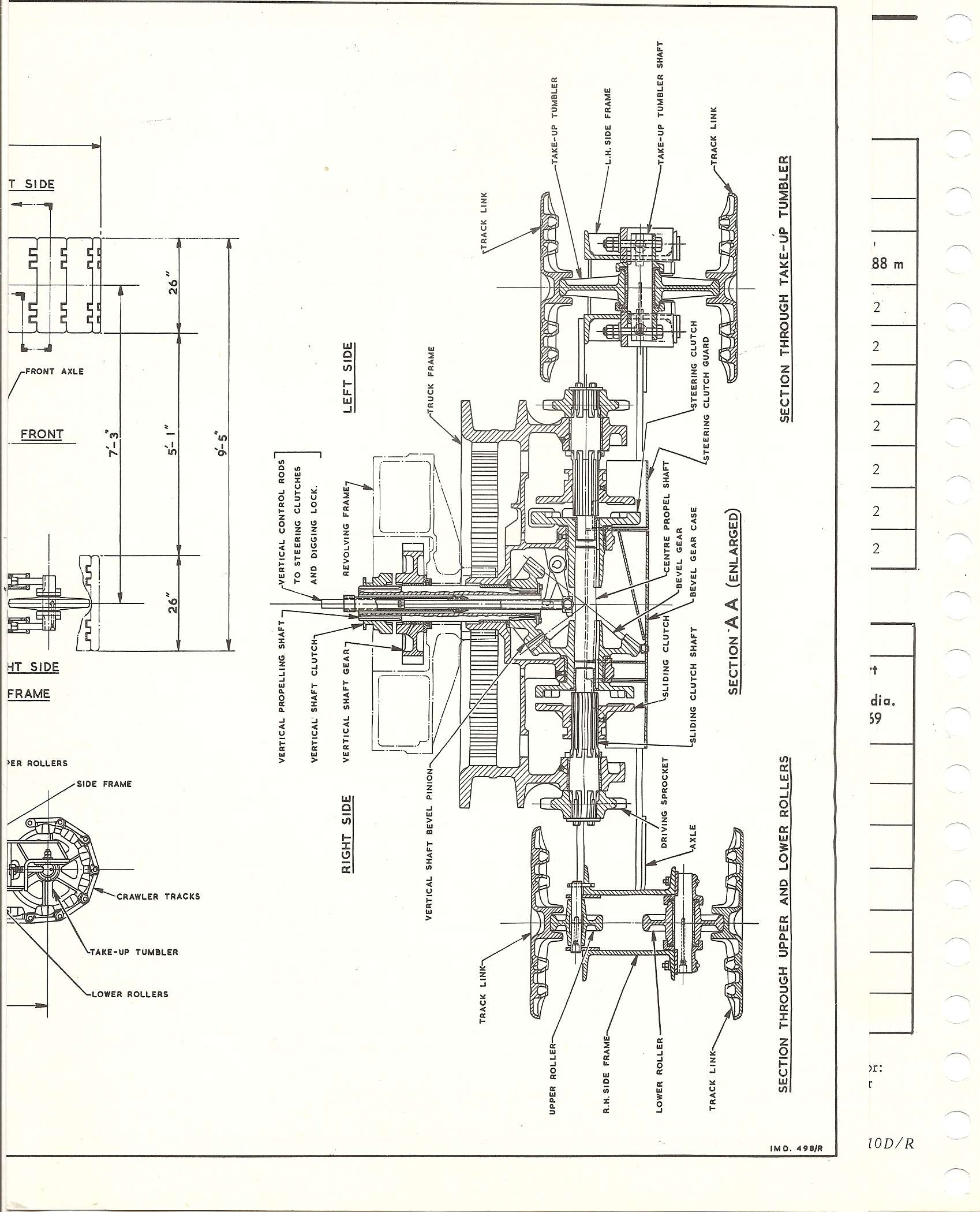

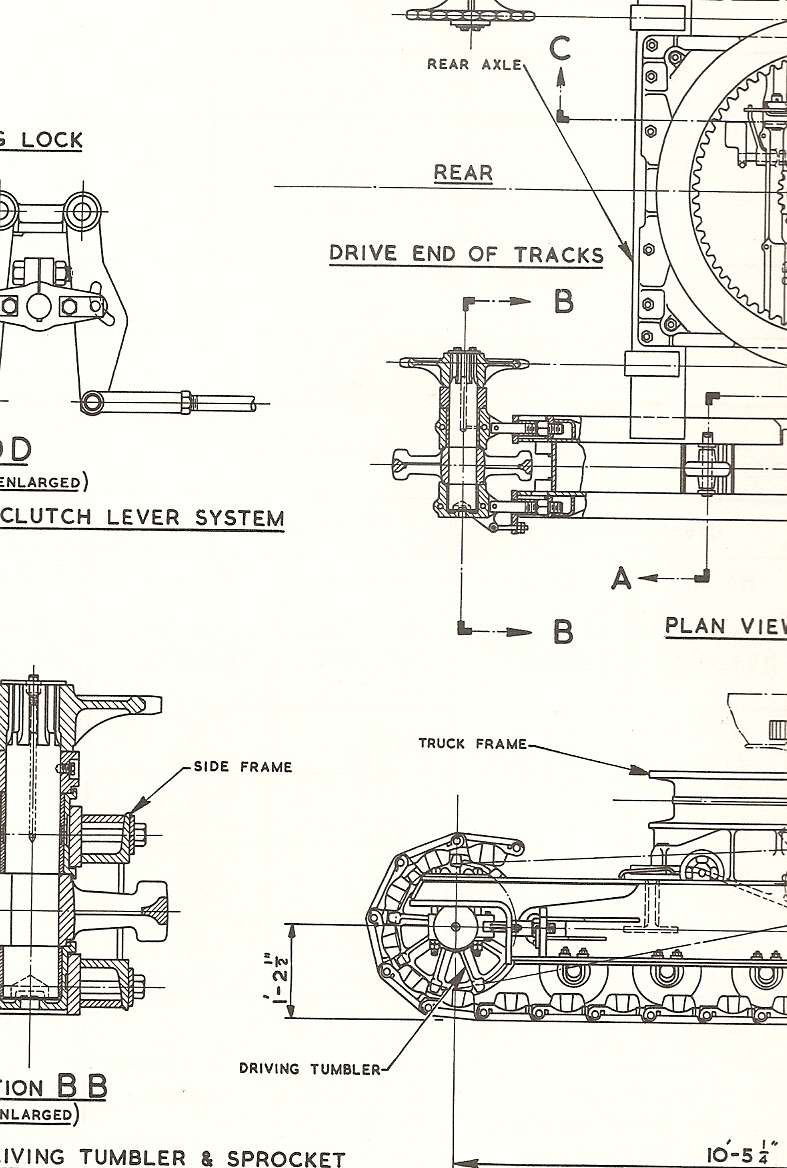

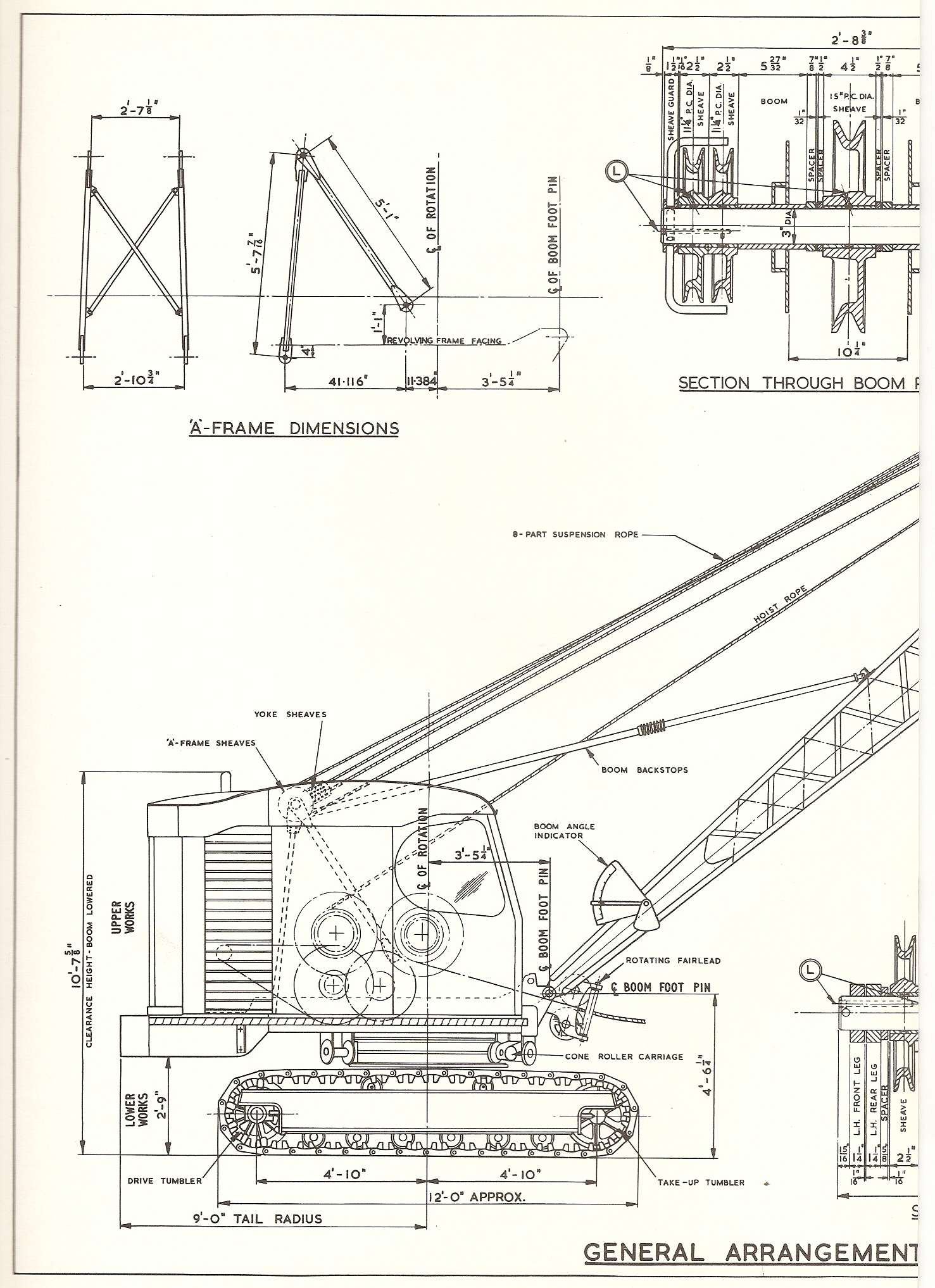

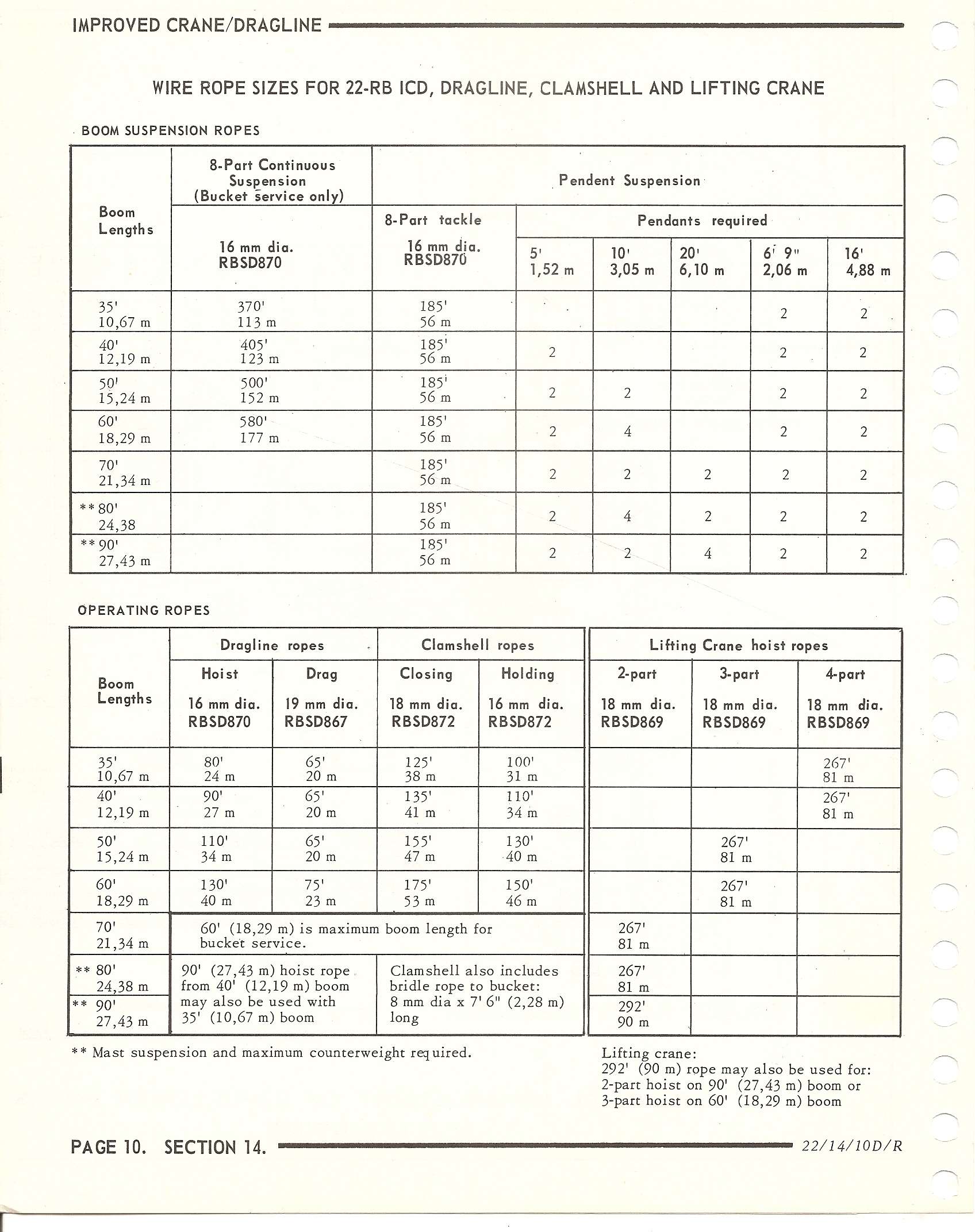

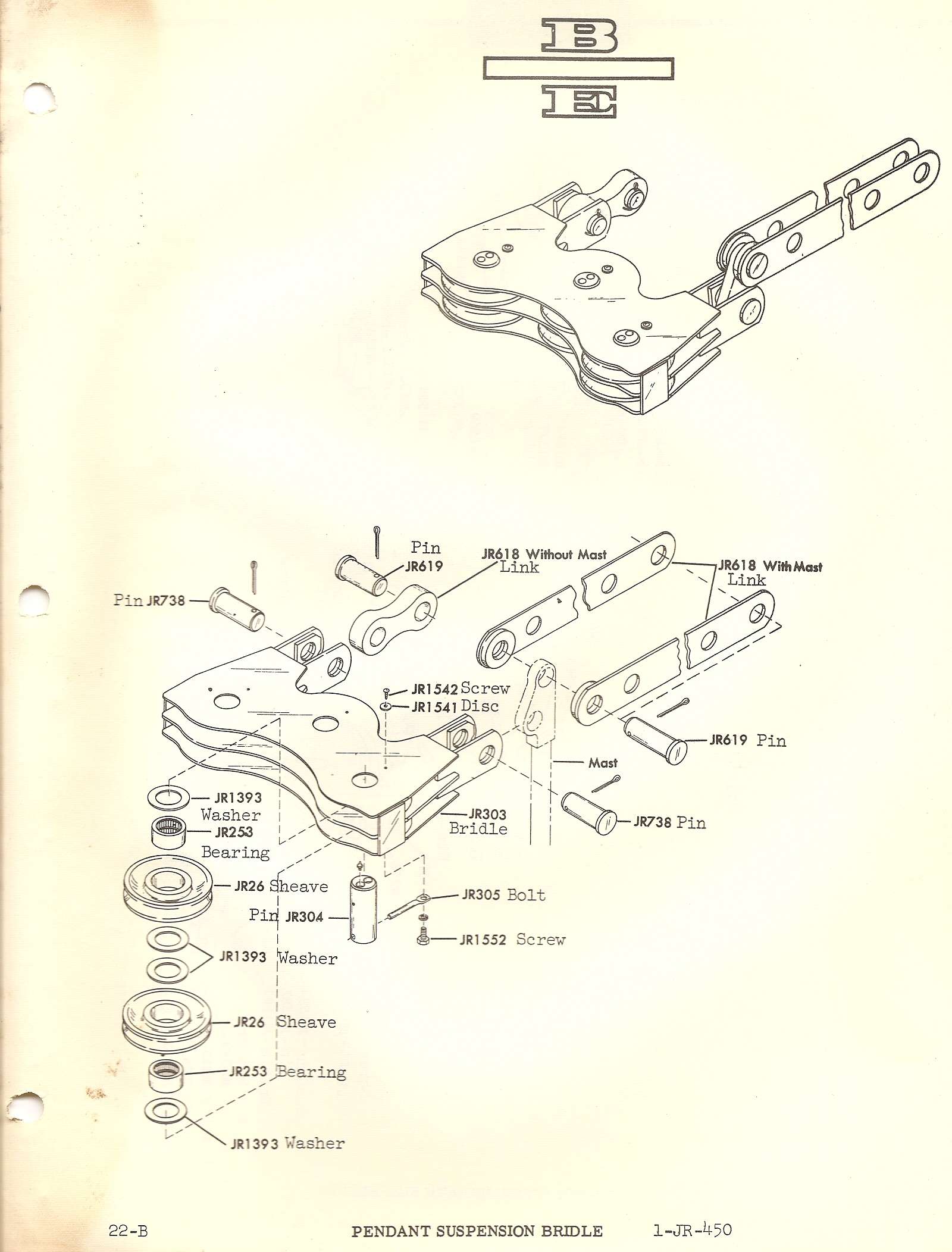

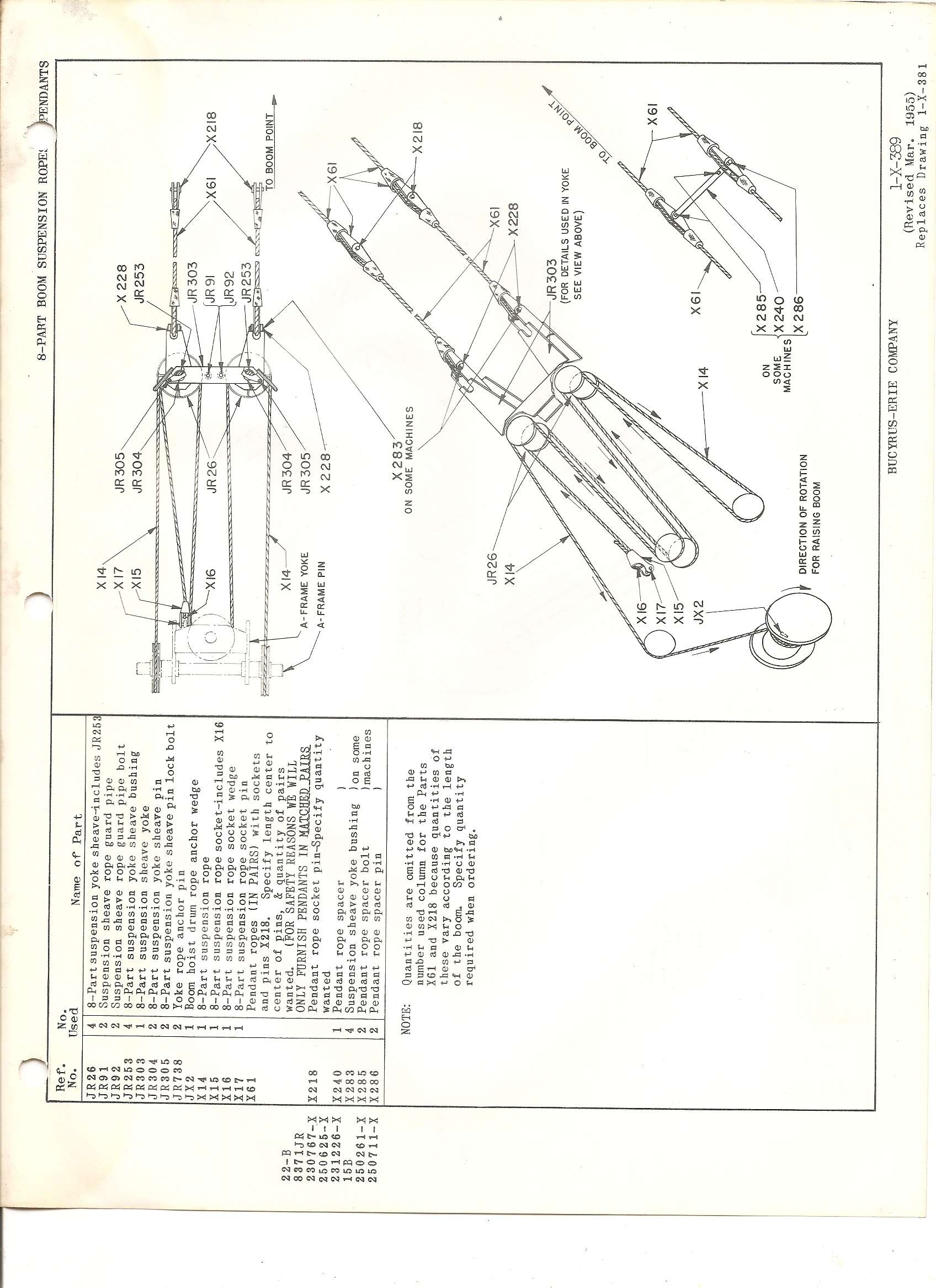

The slewing ring measures 60''dia X 47''dia in the hook roller grooves X 9''thick.I count 64T on the internal ring and it looks to be about a 42'' PD. The pinion appears to be 16T. I don't know how you're going to cut the internal ring though. I have measurements for the A frame and the correct wire rope sizes and lengths. This IS going to be a dragline ,Correct? I can also get you some pictures and sizes of the fairlead in the spring when we have our outdoor show. The books I have show alot of details. Especially the 22-RB books.

|

|

#12

|

|||

|

|||

|

A scratch build and a cable machine! My-2-favorite things! I will follow this closely. I'm sure you will put a lot of work and $$ in this project but I am not sure about your decision to use servos for your drums. I don't think they will last. Gearmotors would be a better choice in my opinion but maybe you have thought this thru. Sometimes taking the easy way out will cost you in the end but I wish you luck and keep the pictures coming.

|

|

#13

|

|||

|

|||

|

Quote:

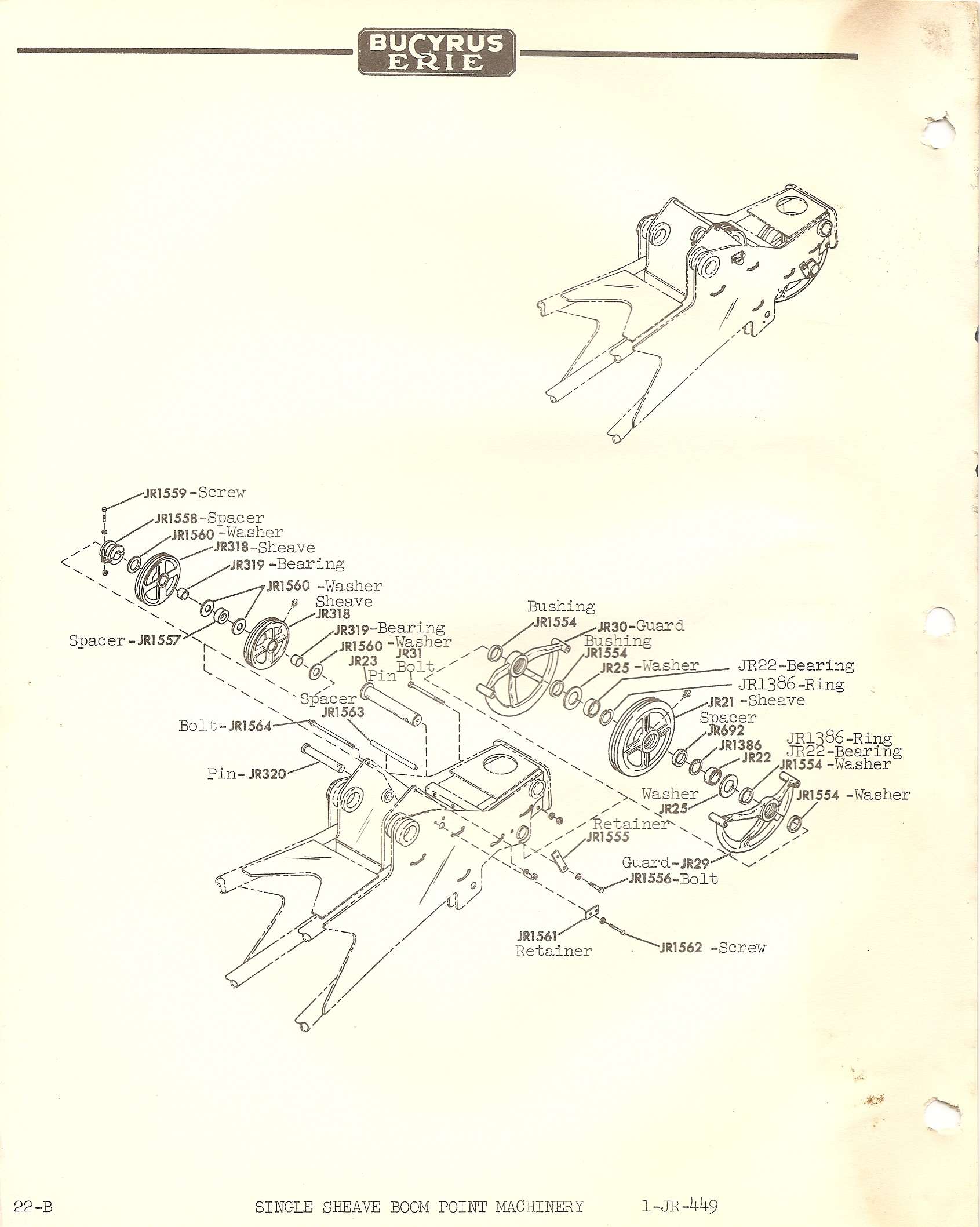

I've got a shaper that once I make a new gib for the table it should be good to go. I traded 20 hours of labor for it. A friend of mine was going to tear it apart to shake his gold separating table and I talked him out of it. The real trick will be to grind the tool to the proper profile. I think I'm going to stick with the 32 pitch 90 tooth gear, even though 24P 60-something teeth would be more scale simply because the bigger the teeth get, the higher the gear ratio gets and the harder the swing servo will have to work. The one I'm using is the slowest low-profile servo I could find and I'll still have to slow it down some. The A-frame mesurements would be good, too. I just eyeballed it and I think I'm close but measurements can't be beat. Basically I just need to know how far it is from something like the center of rotation or the boom pins, and how high. It will be a dragline and fairlead details would be excellent. I haven't been able to find any good pictures that show how it mounts to the deck. I know it pins to the boom foot. Quote:

|

|

#14

|

||||

|

||||

|

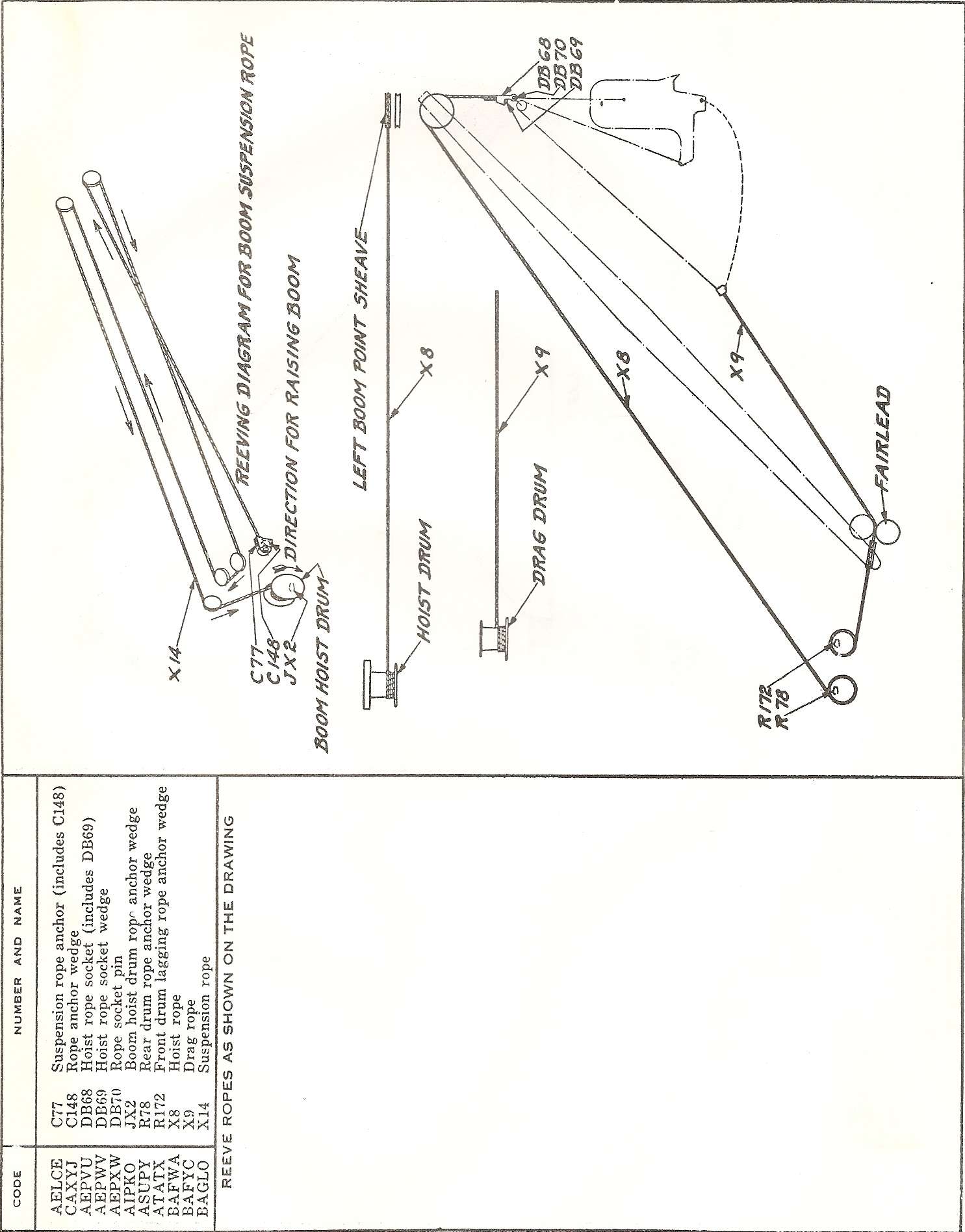

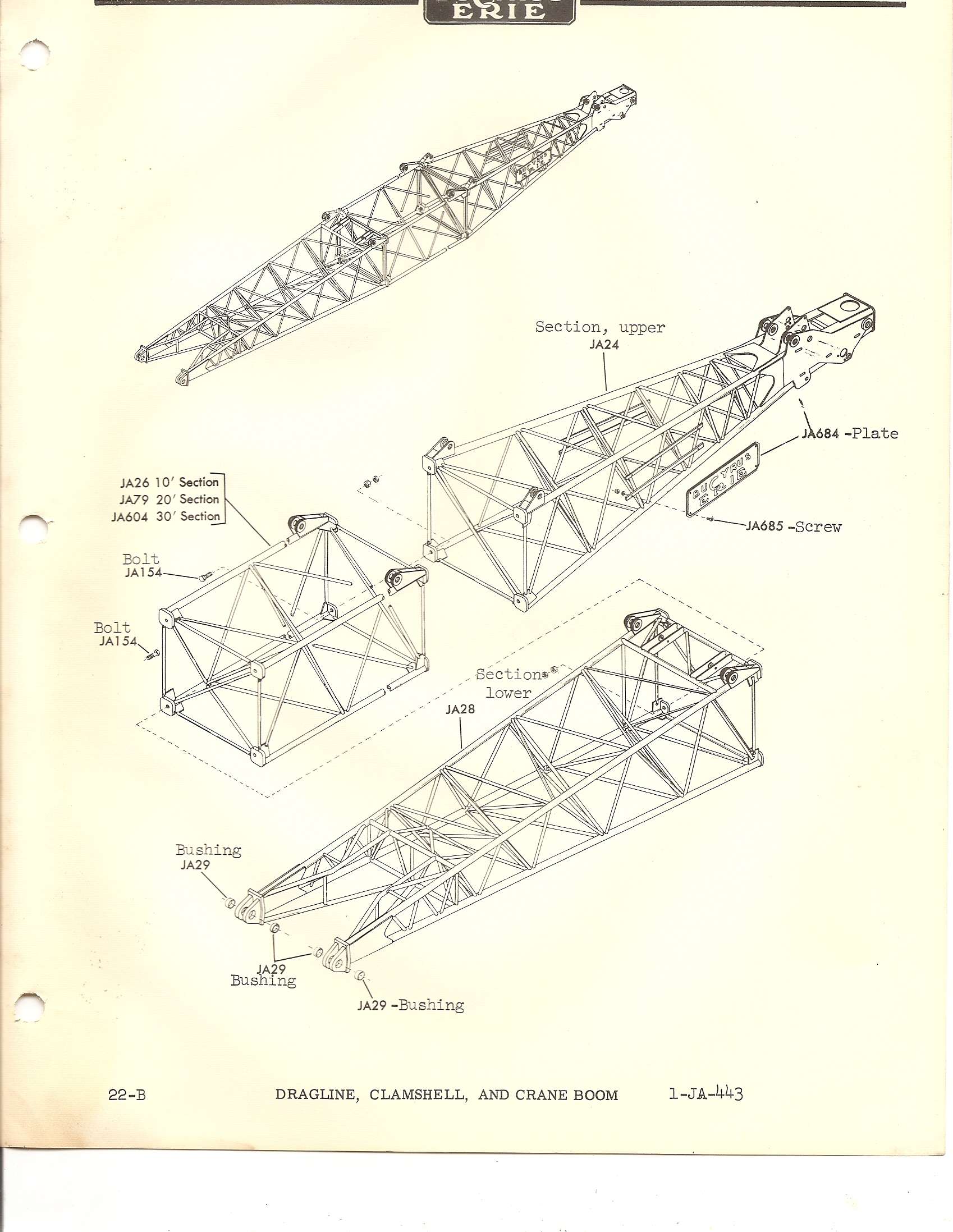

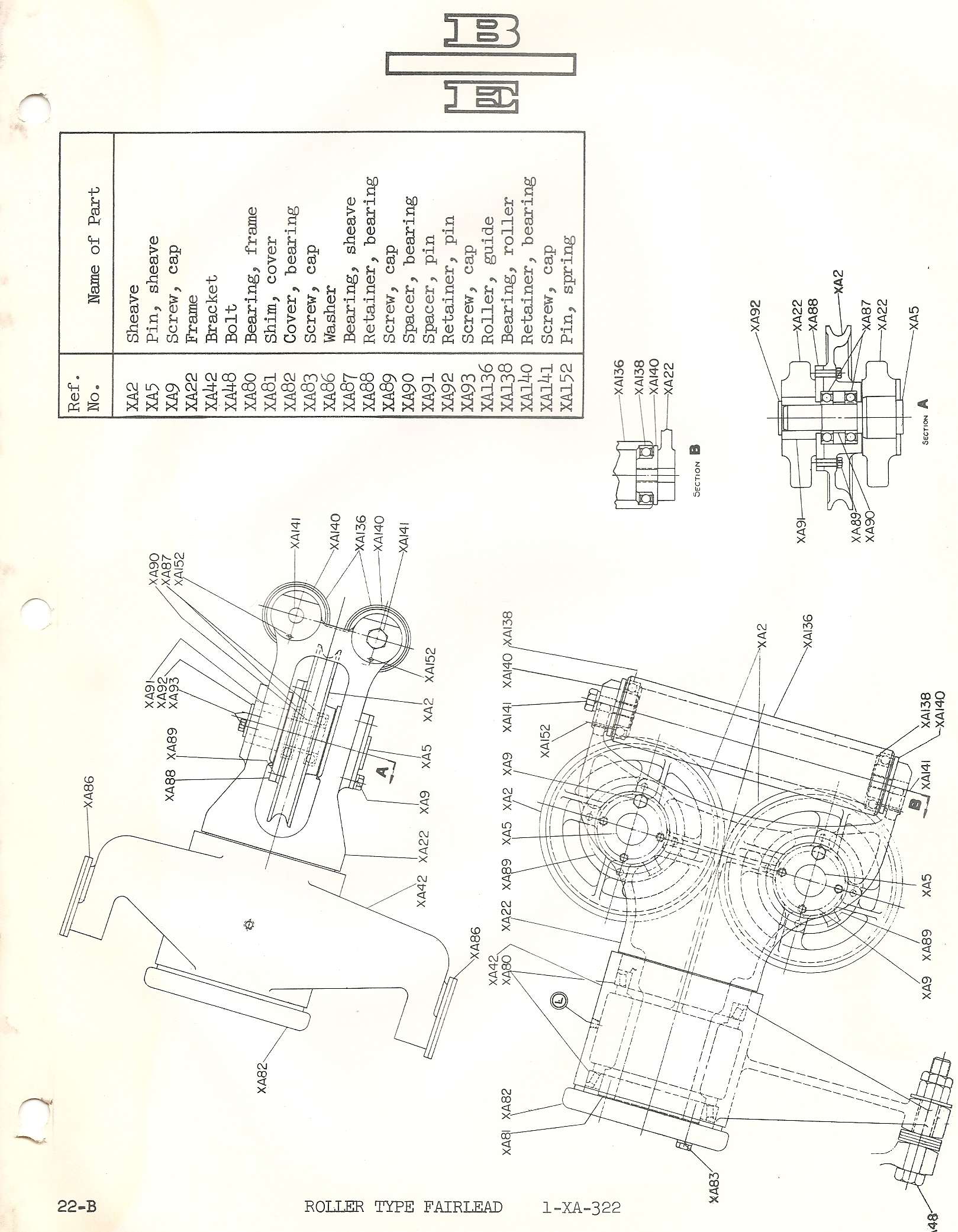

This should steer you in the right direction.

Not sure if I have the correct rigging for the boom.      There are several fairlead arrangements. This one looks cool because of the side rollers.

Last edited by 9W Monighan; 01-24-2012 at 09:59 AM. |

|

#15

|

|||

|

|||

|

I think that converted servos are really useful and they are basically nothing else than gear motors in a different form factor and packaging anyway?

As long as their gear ratio matches the application - if not then gear motors usually offer a wider range of gear ratios. I'd love to buy a gear motor with comparable power and double ball bearings that does not cost an arm and a leg. I'd be honestly interested, as I couldn't find one and went with the popular RB35. But these motors only have bushings and these do not take radial loads well, in my experience. Looks like a great project and the drawings Steve posted are fantastic! |

|

#16

|

|||

|

|||

|

Here´s the front of my friend 22-RB´s

The boom is made of L-profile, maybee this was unique to machines built in England  Dan |

|

#17

|

||||

|

||||

|

Always nice to see the scratch builds and this one will be another good one. Don't forget lots of pics.

__________________

Joe |

|

#18

|

|||

|

|||

|

Wow!!!! Thank you so much, Steve and Dan! Steve, you just saved me $60 on a manual I was looking at. I'm not sure how I can repay the favors, but if I see something I can help with, I'll make extra sure I will!

|

|

#19

|

|||

|

|||

|

Hi Jared, Welcome to the elite 'Cable Digger Builders' club

. We are few in number but we are growing. I knew that machine well. I built them in the erecting shops in Lincoln 50 years ago. One of the classiest excavators ever built. . We are few in number but we are growing. I knew that machine well. I built them in the erecting shops in Lincoln 50 years ago. One of the classiest excavators ever built.

|

|

#20

|

|||

|

|||

|

Another Bucyrus on this forum !!! great idea ! Congrat's for the CAD design : this will allow you to build it faster

I know an old man in my area that has at least 2 of them in perfect condition, including lattice boom/shovel/backhoe equipments.....too bad the guy is over 80 and his son is just waiting he's gone to scrap all this old iron

|

|

| Currently Active Users Viewing This Thread: 1 (0 members and 1 guests) | |

|

|