|

|

|||||||

| Construction Equipment Tech Hydraulics, Electronics, General Engineering, ect in constr equip |

|

|

|

Thread Tools | Display Modes |

|

#61

|

|||

|

|||

|

Could you put a drawing where I could see the dimensions for reference?

|

|

#62

|

||||

|

||||

|

Madda - oops forgot to post that! Ill post some blue prints asap!

Also wanted to mention that all pieces come in a Black hard anodizing  no extra cost! no extra cost!Chris |

|

#63

|

|||

|

|||

|

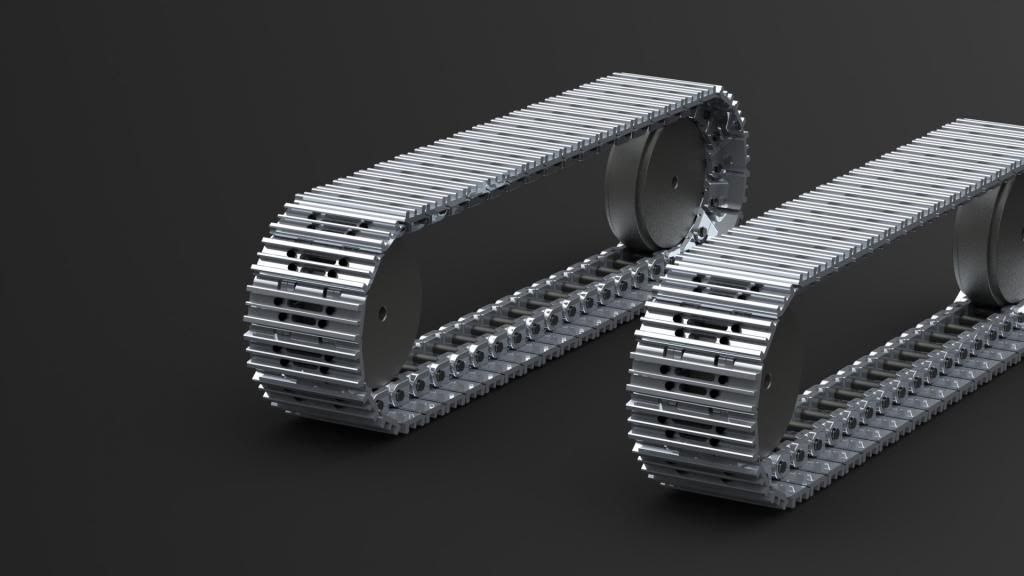

I dont know if its just the rendering/shadows but the grousers look a bit too high or to thick?

Very nice that they are anodized black for the same price!  Im in!

|

|

#64

|

|||

|

|||

|

These grousers look more slim and seem to have thinner grousers and not so thick as the last rendering...

|

|

#65

|

||||

|

||||

|

If I had a Rc construction toy that needed tracks then I would be in but I have no need at the moment.

__________________

Sees no evil, Hears no evil, Speaks no evil To view links or images in signatures your post count must be 10 or greater. You currently have 0 posts. |

|

#66

|

|||

|

|||

|

Chris, the price seems pretty reasonable, they look good, it's certainly an option for some of the people here.

|

|

#67

|

|||

|

|||

|

Chris do you realize that there are 2 inside dimensions for the tracks? On the Vario excavator the old ones or original took a single row sprocket and the revised ones have a double row sprocket. I am not sure but the tracks might be a little bit wider. Ed

|

|

#68

|

||||

|

||||

|

The old ones had a wide inside too. I still have the 2 bar pad on mine. I added a washer to either side of the sprocket to fill the gap.

The older set & newer set come from the same manufacturer. http://www.modellbaudiepold.de/2_steg_kettenglied.html

__________________

Sharing knowledge is one thing that defies basic arithmetic logic --- the more you share, the more you get! Joe |

|

#69

|

||||

|

||||

|

Kingcam2 - Okay, maybe sometime in the future

catmack - Thanks! Jammer - Okay ill talk to azonic and figure out which these are designed to fit on. Lil Giants - how wide is the inside dimension on the wide track? Chris |

|

#70

|

|||

|

|||

|

Chris I have both tracks and the 2 different double row sprockets one from Vario and one I bought somewhere else to fit the old chain. I will try and mike them up by the weekend.. The old chain links are narrower inside were the sprockets ride on the back side of the link than the new ones that is why I have 2 different sprockets. The newer chain is wider inside than the old one.

|

|

#71

|

||||

|

||||

|

You are right Ed, I got a reply from Frank, Vario's new triple bar tracks come from their own self made molds and it's a different pitch too.. he didn't say what the difference was.

If Kalle was specing from the old double bar tracks, then you'll need the old double sprocket you sourced from France.

__________________

Sharing knowledge is one thing that defies basic arithmetic logic --- the more you share, the more you get! Joe |

|

#72

|

|||

|

|||

|

OK here we go I went out in the garage an shaking from the cold 27 degrees no heat could not light my heater and got these measurements shaking and still shaking in the house. Old sprocket outside measurement .323 old chain inside measurement .340 new sprocket .609 outside measurement new chain .489 inside measurement both chain measurements are taken from the inside of the chain were the sprocket rider. Joe no I did not get the narrow sprockets from France I got both of them here in the states for $ 75 for the pair I believe if you remember I sent you an email about them. I hope this helps to answers a few questions. Ed

Last edited by JAMMER; 03-16-2013 at 07:53 AM. |

|

#73

|

|||

|

|||

|

I talked to Frank and he said he will be converting his 470 to the new cast tracks with new sprocket, rollers and idler, he was going to get back to me when he has done that to see how it goes.

I think the 490 will be a nice machine, but **** i want to see a Volvo made!

|

|

#74

|

|||

|

|||

|

It sounds like that 490 will be a hole new design and smaller than the ones we have.Ed

|

|

#75

|

||||

|

||||

|

Sorry for the lack of response but I am very busy right now working OT and trying to do tons of other stuff in my personal life.

Anyways it sounds like we wont be able to meet the 700 piece quota and it looks like we have only 450 needed.  So ill see what the machine shop says but ill warn you it may be a bust....  Chris |

|

#76

|

|||

|

|||

|

Are you still looking at having this go forward, or has this completely died?

I am new to the building process, and to the site. I will update my profile when I am not at work. Basically, grew up on a farm where we had a 1955 d8 most my life, and just now have been getting a pull scraper, excavator, and grader on the farm. I just moved away from home though for work as an engineer since finishing school. I think it would be fun to build some models as my great uncle used to do it. thanks, kyle |

|

#77

|

|||

|

|||

|

My tracks on my 4200 xl are carbon 4 steel, if that helps any, I would like to know as well what the best metal would be for tracks. A lot of the euro Models have either brass or aluminium tracks? Not sure what grade of aluminuim though?

|

|

#78

|

|||

|

|||

|

hi have got the 4200 xl my self and am a earthmoving business owner operator I take great pride in excavators and when it comes to scale models the 4200xl is pretty close but it needs a few mods, the steel tracks are great you want to try to keep the weight to the ground, alloy tracks are prob gona be a lot lighter therefor you will not get the traction when digging, I have also replaced the slew motor to a 60rpm motor rather than a 30rpm the digger originally did about 5rpm slewing now does 10rpm where as a 30ton excavator does about 12rpm. so the scaling is closer but you do lose out on a bit of slew power but you can move a **** of a lot more dirt when u slew faster. as far as the tracks go I think the 4200xl needs track chains with holes in the sides and the grousers need the 2 holes in the top because just not enough dirt escapes and it locks up the tracks and you do in the final drive motors all the time, I think ive gone through 4 motors already.

|

|

#79

|

|||

|

|||

|

love your work with the 3D cad drawings not sure if u started to mill these yet but if you havn't the idlers need to be a lot smaller and maybe the grousers a little wider if you want I can give you the dimensions of my digger for reference

|

|

#80

|

|||

|

|||

|

Quote:

The 4200xl is a quite basic machine, where one has kept the level of detailing on a minimum to keep cost down. I think they just want to keep it this way, as a cheap 'starter machine'. They actually haven't any real competition in this price range, so they don't care too much about developing the machine. There should have been added a spring on the idler in order for the tracks not to jam that often, and track engines are under-powered. But hey, one can't expect the same as from machines costing 3 times more. |

|

| Currently Active Users Viewing This Thread: 1 (0 members and 1 guests) | |

|

|