|

|

#321

|

||||

|

||||

|

Very nice progress Steve the spokes came out real nice.

Are the 19 sheaves for the suspension ropes all the same or a lot of different sizes ? How is the flu ?? ( over here it does not feel very pleasant ) Eef |

|

#322

|

||||

|

||||

|

Quote:

to keep the cable from rubbing the lattace. I noticed some rubbing but nothing major from the Cabin Fever run. As far as the Flu, I'm only in one day with the Amoxicillin. but getting a little better. |

|

#323

|

|||

|

|||

|

ya need to chill out and take care of yourself and get better then start buildin again lol hope you get better soon then back to buildin

__________________

I built this thing and have it working now what do I do with it? |

|

#324

|

||||

|

||||

|

I got the chance to see the boom for this masterpiece in person at the east coast show and it is just unbelievable the detail and craftsmanship are second to none good job Steve.

Travis

__________________

AKA "00" Biddle RIP FreddyGearDrive 2-12-59/12-19-11 |

|

#325

|

||||

|

||||

|

Nice progress Steve. I hope you are feeling better soon.

__________________

Scott "No load is too Small" |

|

#326

|

||||

|

||||

|

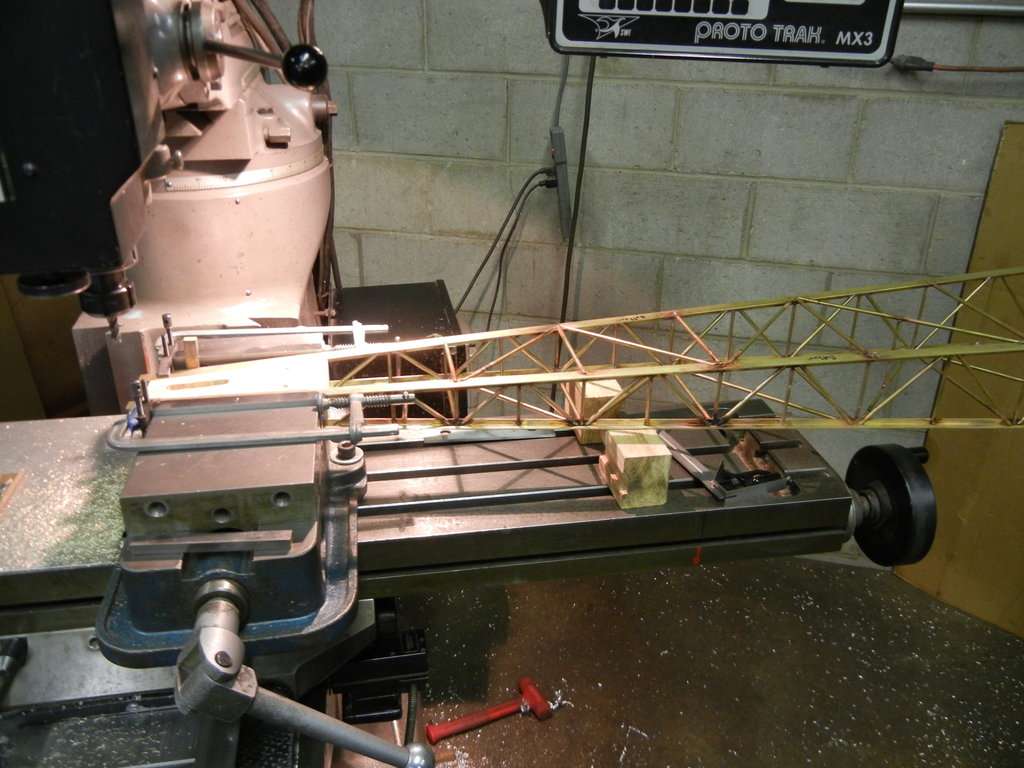

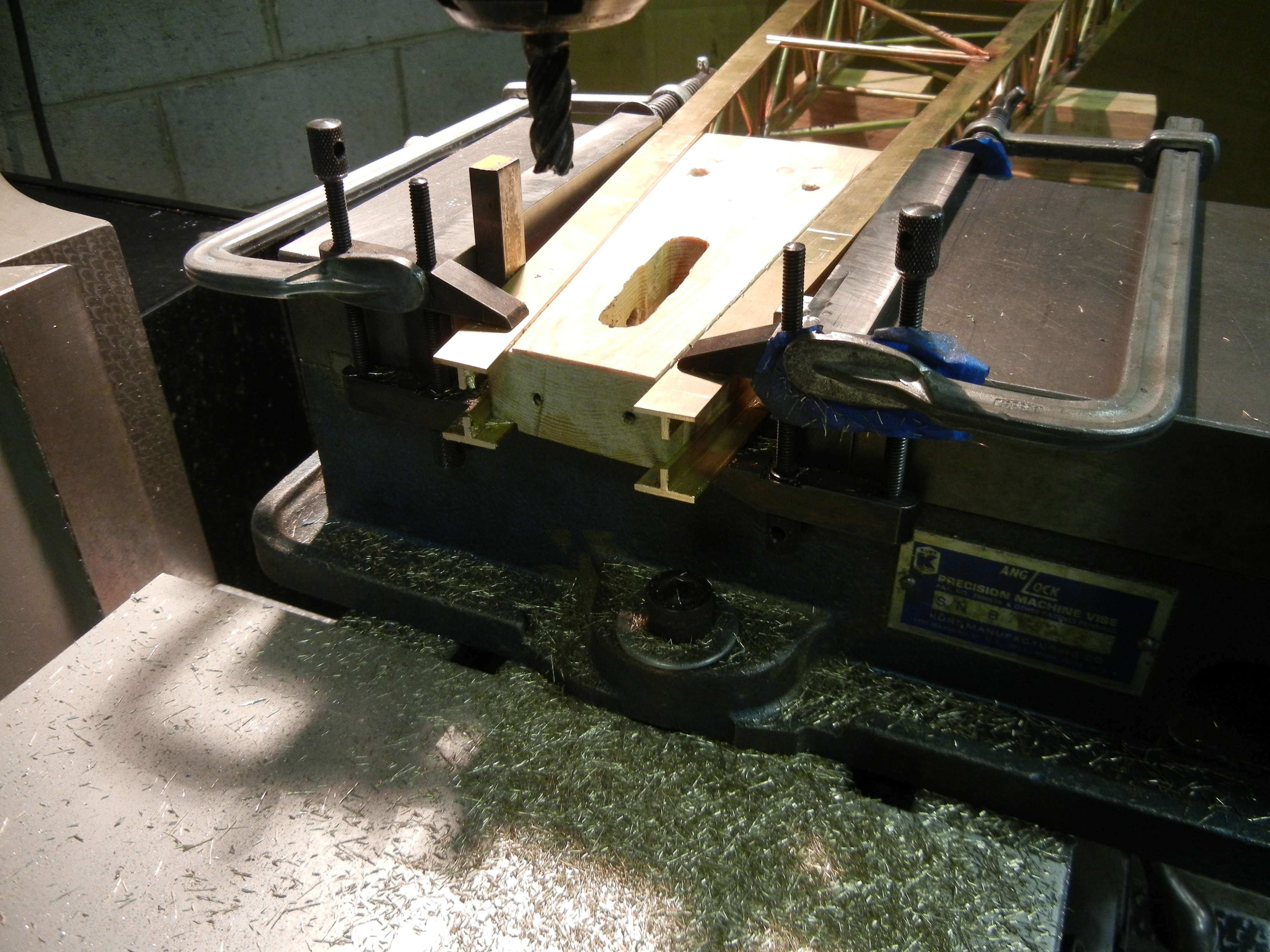

Been working very slow lately. Thought I'd post a couple from this week.

Setting up boom to mill the chords to proper length  Now I need to make plates and attach to the ends so the channel that holds the front pillow block on can be mounted. That wood block I used temporally for the point sheave came in handy to hold everything in alignment.  I miscounted the quantity of 1.25'' sheaves needed. I still need about 5 more and 4- 1''dia. This is the first side then I will flip them over locate to one of the holes and continue milling the pockets.

|

|

#327

|

||||

|

||||

|

Looking good Steve

See that you are running production on the sheaves. You are going fast. Eef |

|

#328

|

|||

|

|||

|

Interesting clamp configuration

. .Did you turn the small sheaves manually or via cnc? BTW: did you get my last pm? |

|

#329

|

||||

|

||||

|

Eef, I want to get these done. I want to move on to other things on the boom. Pretty boring on the milling operation. It takes 9min.ea to drill the 6 holes and pocket the spokes for the 24pcs. This evening I'm going to program the other side.Probably take close to 15min. each. I could probably go faster but risk breaking my 3/32''carbide endmill. I still need 6 more sheaves that are different size.

Lorenzo, I made each one on my lathe manually:bore,groove,part off, face to thickness. |

|

#330

|

|||

|

|||

|

Oh, very time consuming and boring work. I don't really like those kind of work.

But never the less they look like if they are done by cnc. Keep up the good work. |

|

#331

|

||||

|

||||

|

Finally got this set done. This is enough to reeve the boom but I still need a a couple smaller to run down to the boom hoist.

Collet fixture to hold in mill  view showing groove for 1/16'' cable

|

|

#332

|

||||

|

||||

|

they look beautiful!

Are you going to use ball bearings? kerst |

|

#333

|

|||

|

|||

|

Nice wheels, have to get a CNC machine sometime. Was a little surpriced when visiting the show in Germany last november, there was manufactors showing CNC equipment, had never thought about that modeler should be those machines. Now when looking here at the forum I see more and more modeler using those.

Dan |

|

#334

|

|||

|

|||

|

Nice looking work as always.

__________________

Jeff |

|

#335

|

||||

|

||||

|

Hey Steve, you mentioned a while back, about changing the toggle switch's on your controlbox? Have you seen the joystick controler's in the Automation direct catalog?

http://www.automationdirect.com/adc/...etal/Joysticks I'm planning on using these for my grader project (1:1) And alot less than what Grainger want's for sqaure d or telemechanique Later, Neil#2 aka doodlebug. |

|

#336

|

||||

|

||||

|

Thanks All

No bearings Kerst, These will run on bronze bushings. They don't rotate enough to ever need ball beraings. The deflection sheaves will run on a bushing too. Those are next to machine. |

|

#337

|

||||

|

||||

|

Quote:

|

|

#338

|

|||

|

|||

|

hmmm, for short range and the room you have, what about a pair of Arduino boards with Xbee wireless on their backs. Just set up to to a few analog and digital IO's???

__________________

Jeff |

|

#339

|

||||

|

||||

|

That control setup would be pretty cool Steve! is that a old cat pedal I spy in the background? I got a bunch of old pedal tractors, I'm trying to sell 'em. Keep up the good work!

Brian |

|

#340

|

||||

|

||||

|

Hey Steve, I'll keep my eye's open next week, for pot. style controller's. Let me know if you need info on hall effect or encoder style joystick's.

More idea's http://www.jrmerritt.com/ Later, Neil#2 aka doodlebug. |

|

| Currently Active Users Viewing This Thread: 1 (0 members and 1 guests) | |

|

|