|

|

#541

|

||||

|

||||

|

There sure are a bunch. I was thinking there were more riveted joints on the exterior but now I can see. I will probably tap most of the holes and then put a nut on some. That would make the joint less likely to come loose. That's easier for me because those tiny nuts are a real pain to screw on a loose bolt. Nuts do show better detail than just a bolt head.

|

|

#542

|

|||

|

|||

|

I have a couple of questions for you steve-The towers on each side-will they have a bearing to actually support the walking shaft or will they be just cosmetic? About all those bolts-do you know how they drilled all those holes back in the 40"s? Did they have electric drills then? I remember using an electric drill in "1962" when working at a marine shop but I don't know when they first came out.

|

|

#543

|

||||

|

||||

|

Quote:

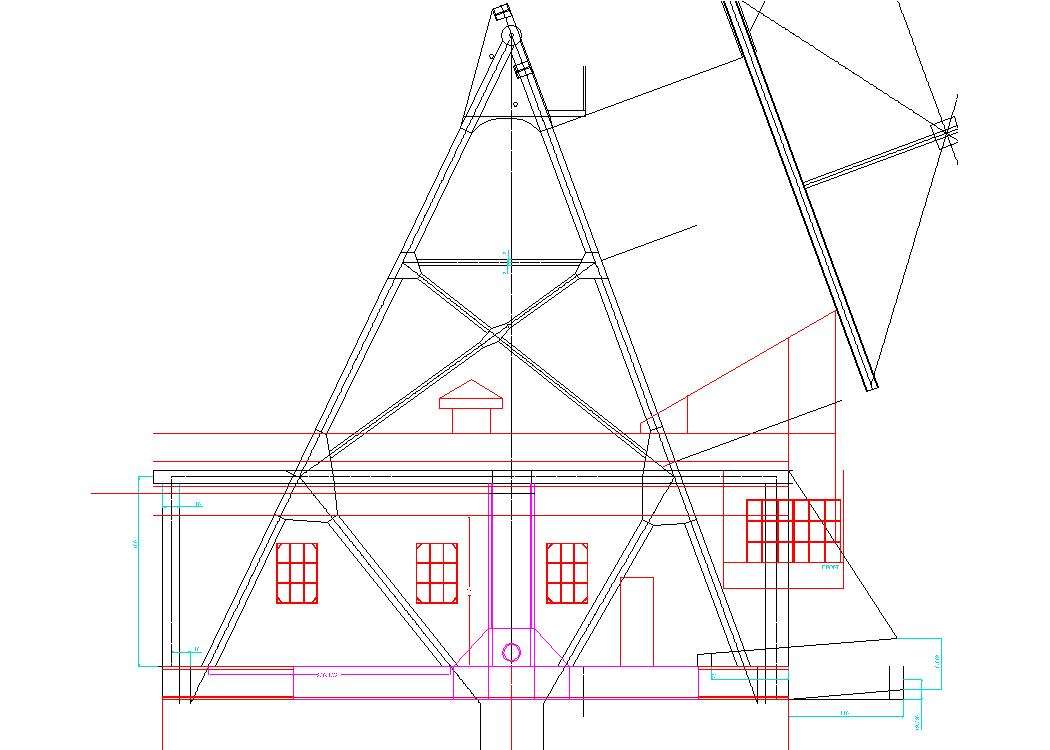

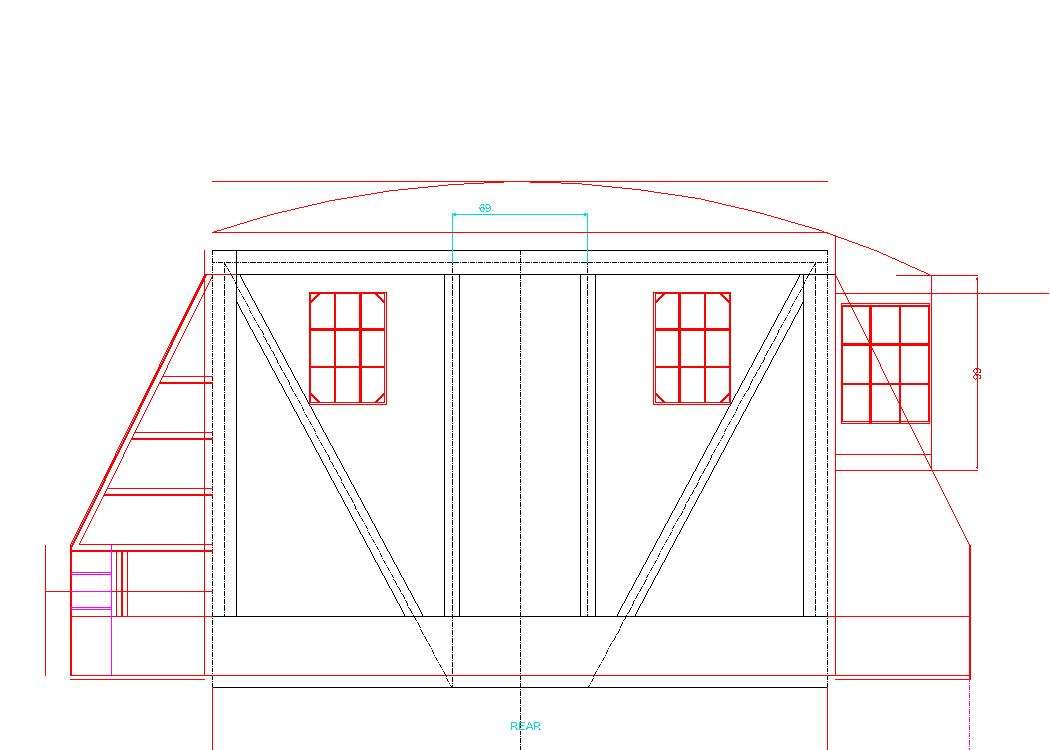

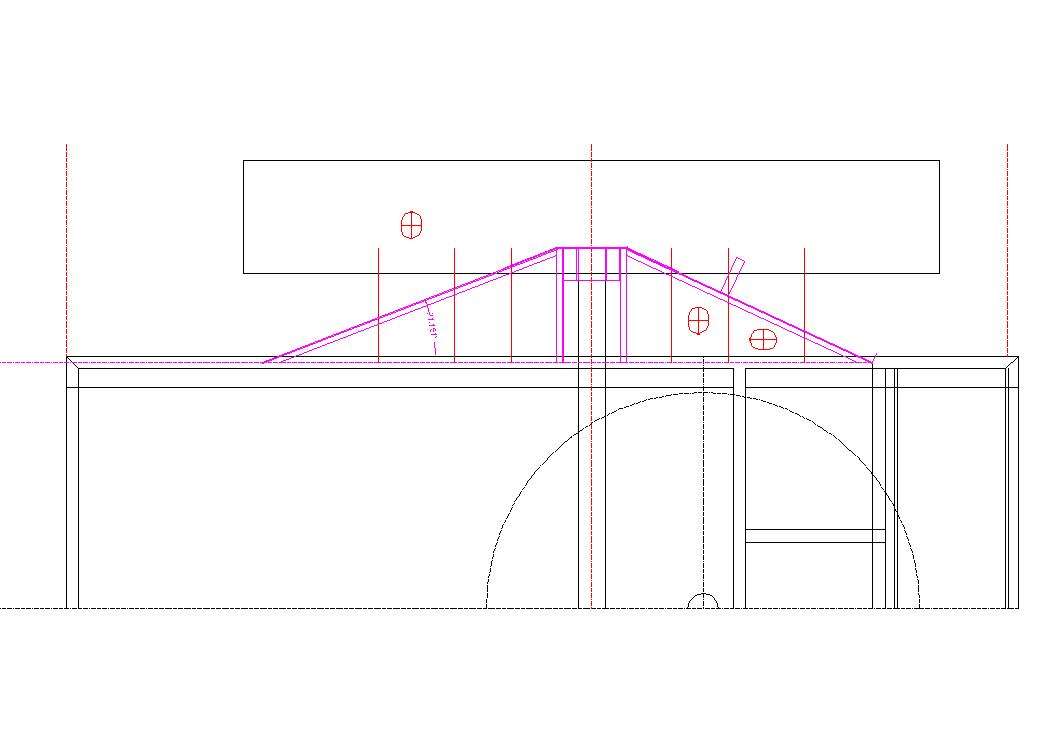

Yes, the towers do support the bearings. Originally I was going to make the towers cosmetic when I started this years ago, I never envisioned being able to get next to the 1:1 machine and acquire all the drawings to boot so I'll be remachining the existing two bearings and inverting then like they're supposed to be but I want to tie it all together with some of the steel channel already in place so the tiny 0-80 bolts aren't stressed too much. 250# may stress them a bit. Here are a couple screen shots of my full size elevations. I don't have the bearing completely detailed and no bolt or rivet holes drawn yet.

Last edited by 9W Monighan; 06-18-2012 at 01:17 PM. |

|

#544

|

||||

|

||||

|

Looks like you draw everything the way I do

3D is a pita 3D is a pita

__________________

RIP FreddyGearDrive 2-12-59/12-19-11 To view links or images in signatures your post count must be 10 or greater. You currently have 0 posts. |

|

#545

|

|||

|

|||

|

Thanks steve-I was thinking that lining those bearings up with the walking shaft would be kinda tricky but I'm guessing you know how to do that. I wouldn't have a clue about that. Judging by your pictures it's gonna look great!!

|

|

#546

|

||||

|

||||

|

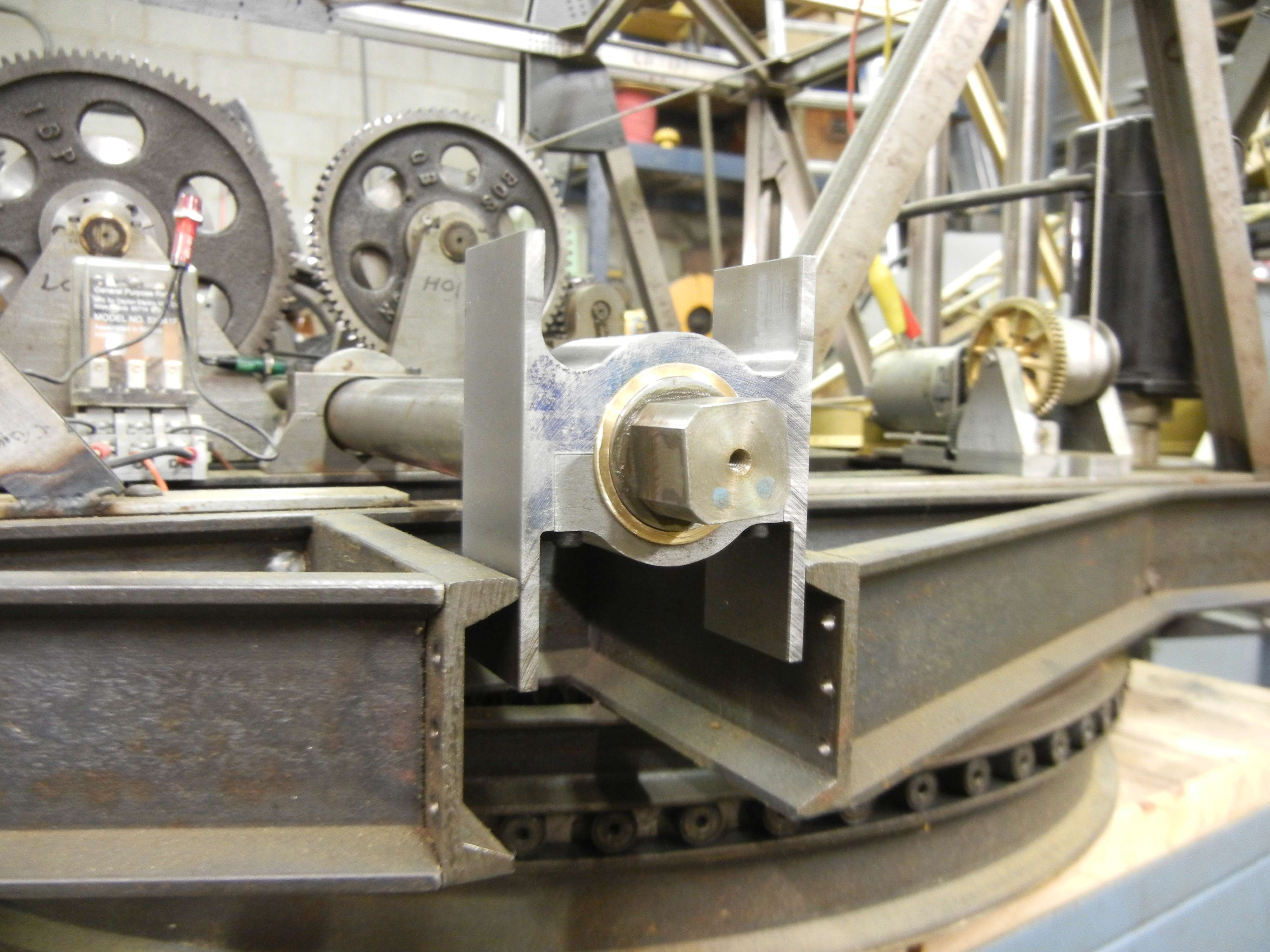

The bearings are not that hard to align. One of the pillow blocks on the interior didn't work so well because the deck flooring has never been cut and installed in that area so I left the bronze insert out. Actually now that a few years have gone by and all the walking it's done, the bearings have wore in up some. The big problem there is I need the make the walking gear parking brake. If you notice in some of my pictures or videos I have a wooden wedge shoved into the big walking bull gear locking it in the "High Cam" position for digging. If I'm not paying attention it comes loose and the shoes fall down and next thing you know the trailing cable is getting rubbed or the whole tub is spinning instead of the house.

|

|

#547

|

|||

|

|||

|

I saw that block of wood in your videos and knew it had to be doing something or it wouldn't be there. Jim Brennan told me about a circuit that will automatically stop the shoes at the correct position after walking. If this would help I'm sure if you gave him a call he would share this with you.

|

|

#548

|

||||

|

||||

|

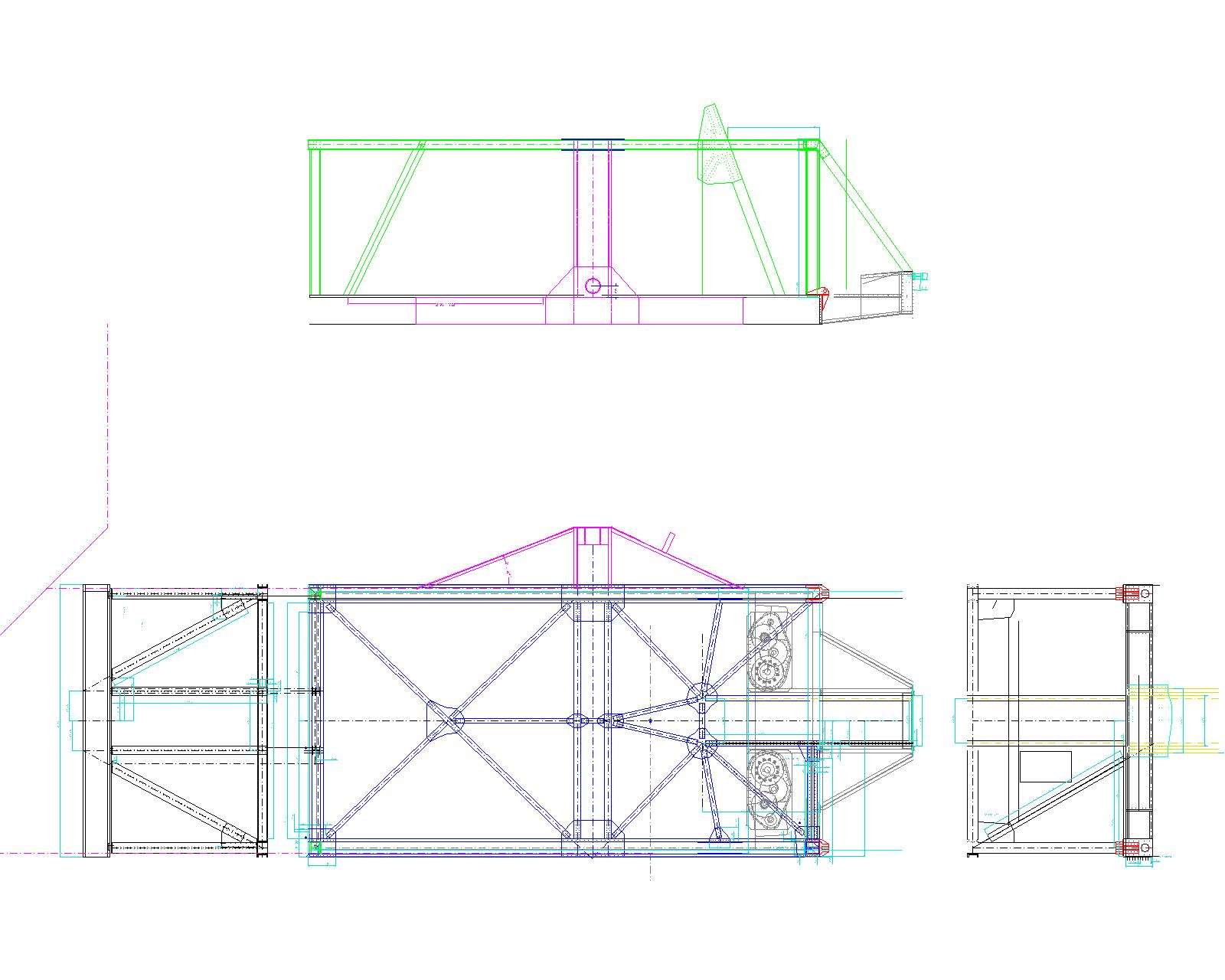

Since I have the day off I decided to update some of my older drawings pasting them on different layers .Here is some more details showing the steel I beams on the roof and the swing gearboxes in their place. Hope to get going on something soon.

|

|

#549

|

||||

|

||||

|

Can't wait to see the house finished and see it walking. Awesome job, she is massive! I found your next project too!!!

|

|

#550

|

||||

|

||||

|

Quote:

HA HA too big for me. I want a large shovel next if possible. |

|

#551

|

|||

|

|||

|

|

|

#552

|

||||

|

||||

|

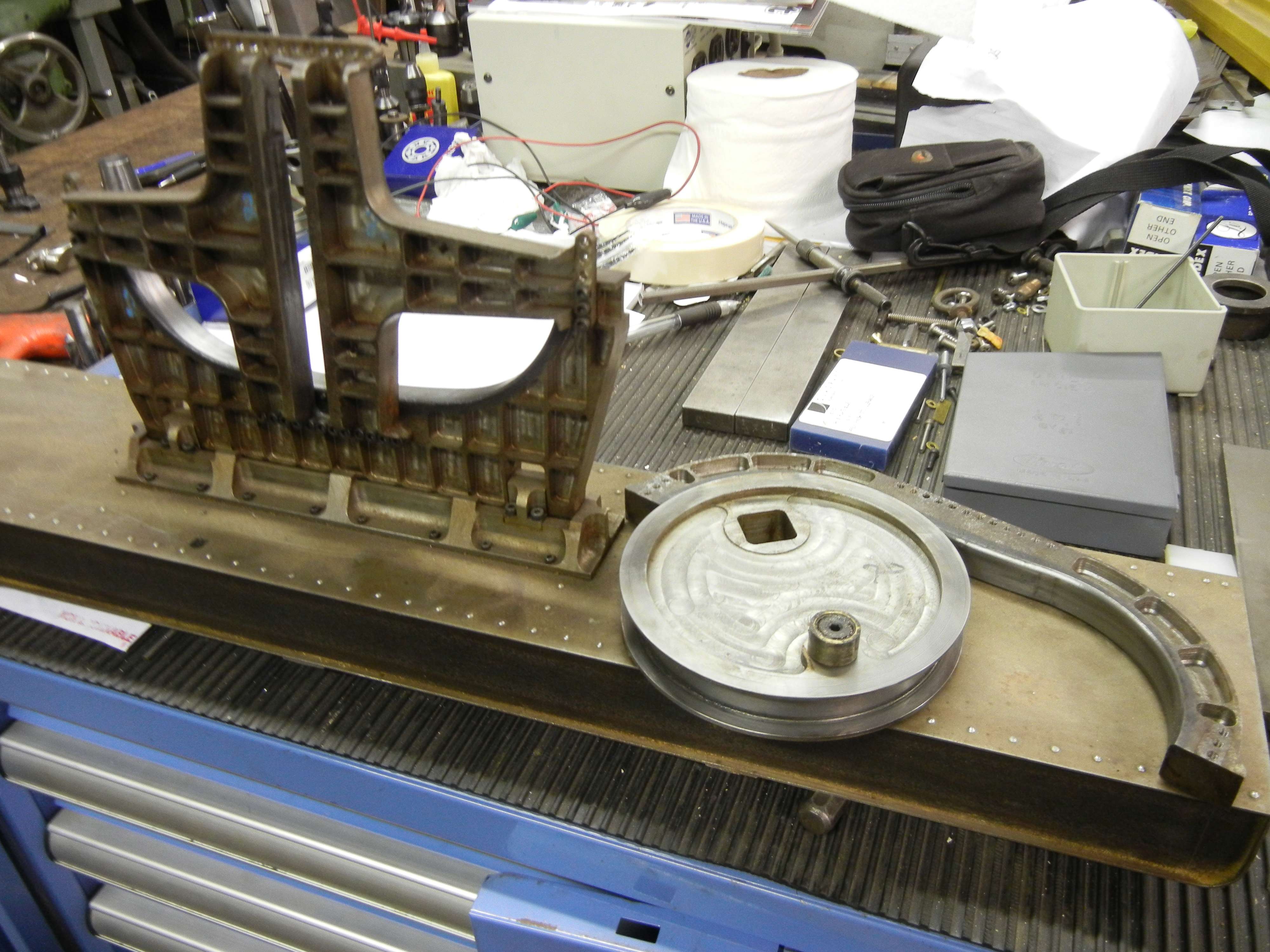

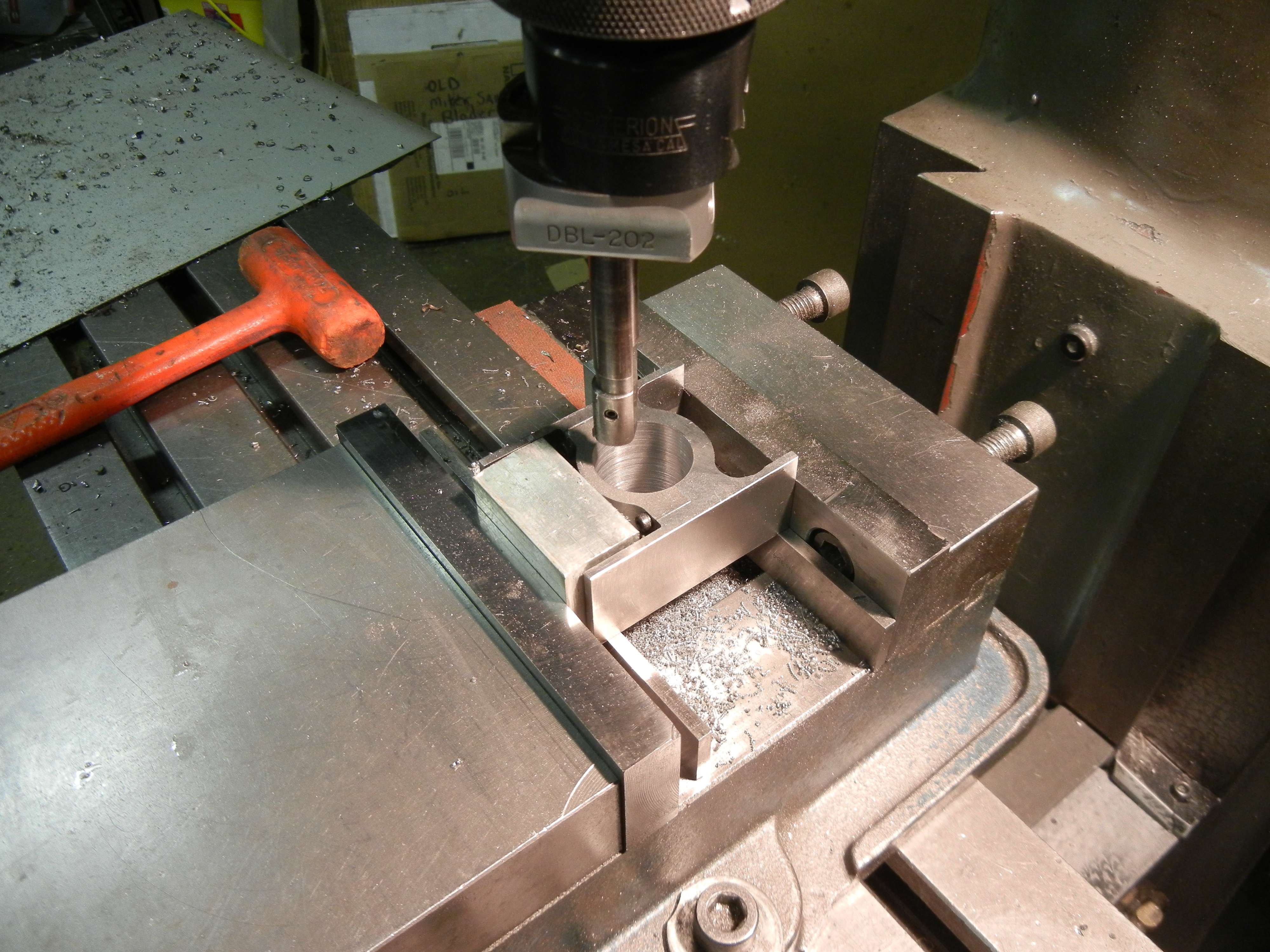

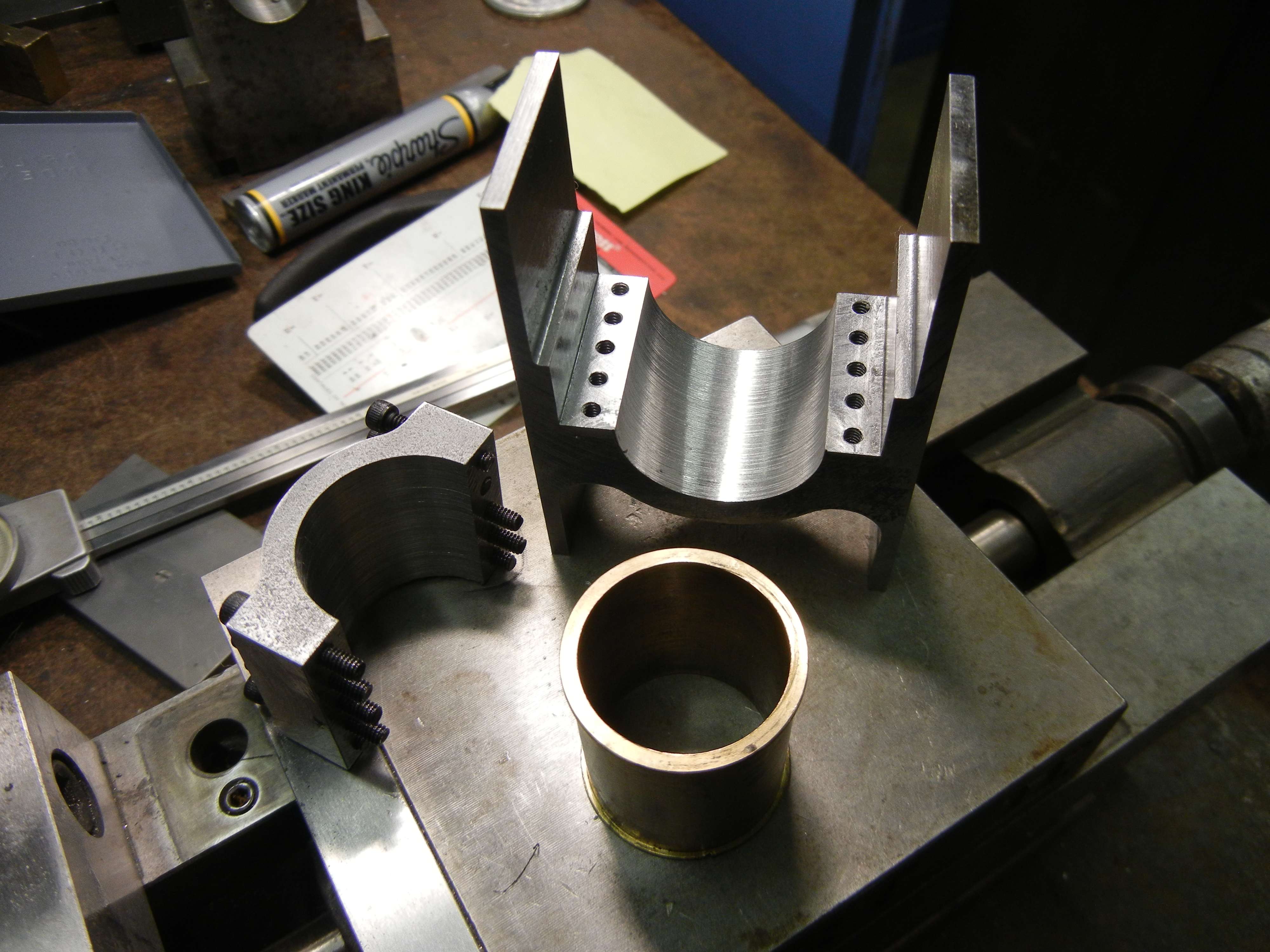

Well it's time to dust this machine off again and get working on it. My project now is to redo the outer bearing blocks. Originally I made these upside down not thinking that one day I would get accurate sizes of the 1:1 machine.

Removed shoe assembly  Old blocks ready for the scrap bin.  Here is a start on the new blocks.

|

|

#553

|

|||

|

|||

|

Steve,

What is it (the bearing) supposed to look like, do you have any photos? are the bearings impregnated, alum/bronze etc.? as far as the next project, a shovel would be a good choice. How big? |

|

#554

|

|||

|

|||

|

Nice to see you have started building again, Steve. This is and will be a outstanding model, working just like the real one!

At one moment I was afraid that you shouldn't finish the model since you have it operational, this could happen to me, that's why I try to get everything done before starting up my machine. |

|

#555

|

||||

|

||||

|

Quote:

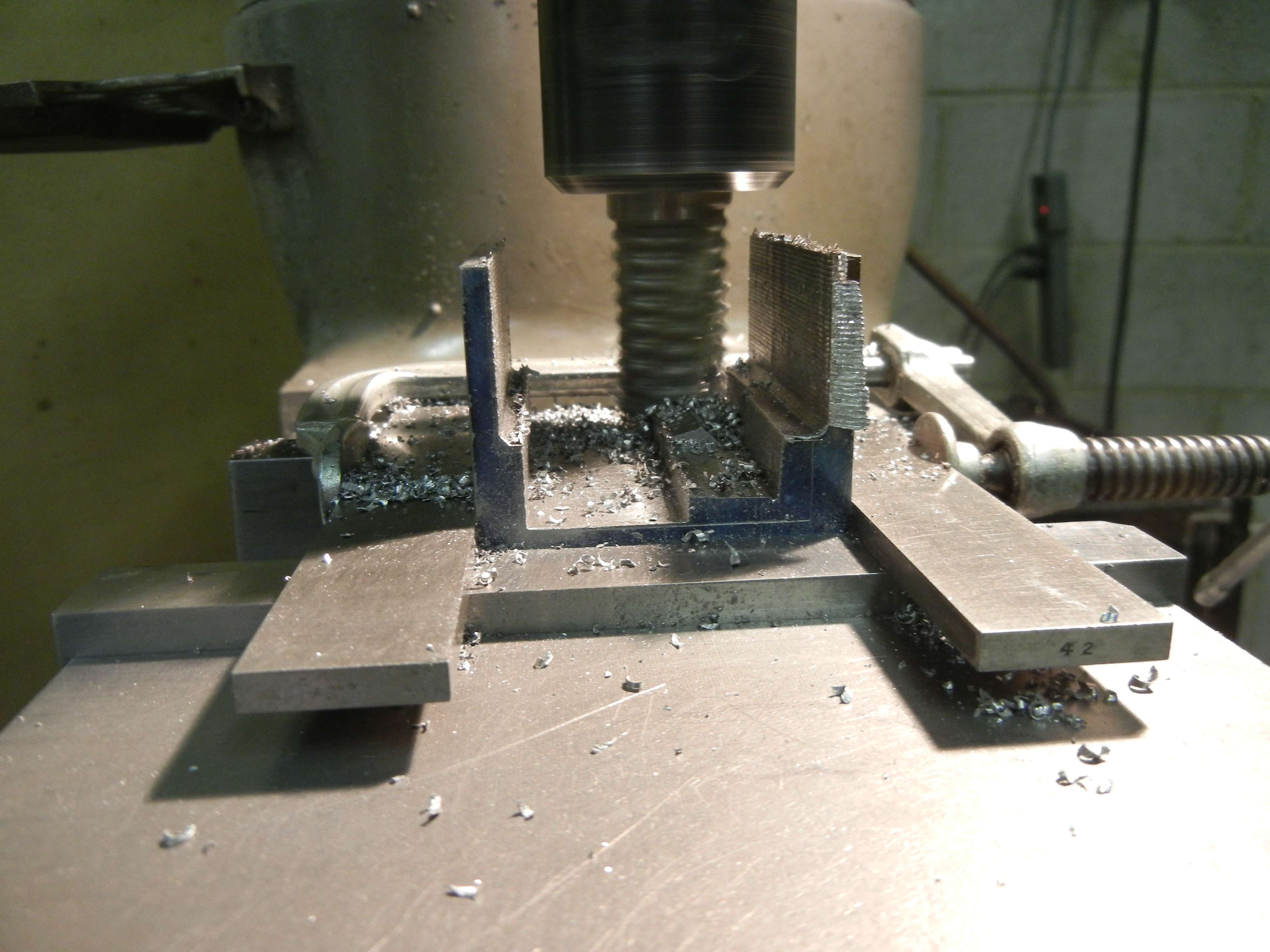

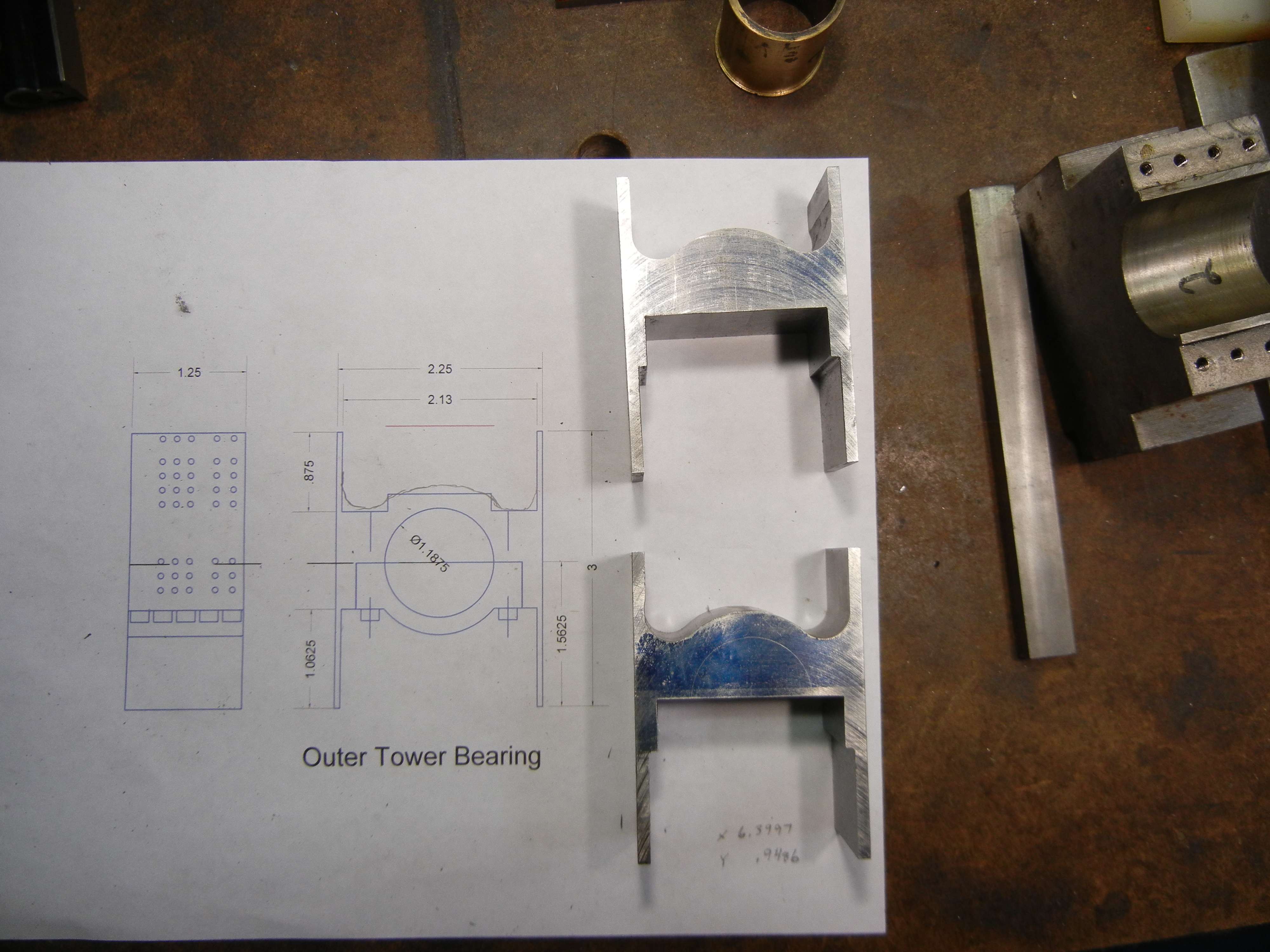

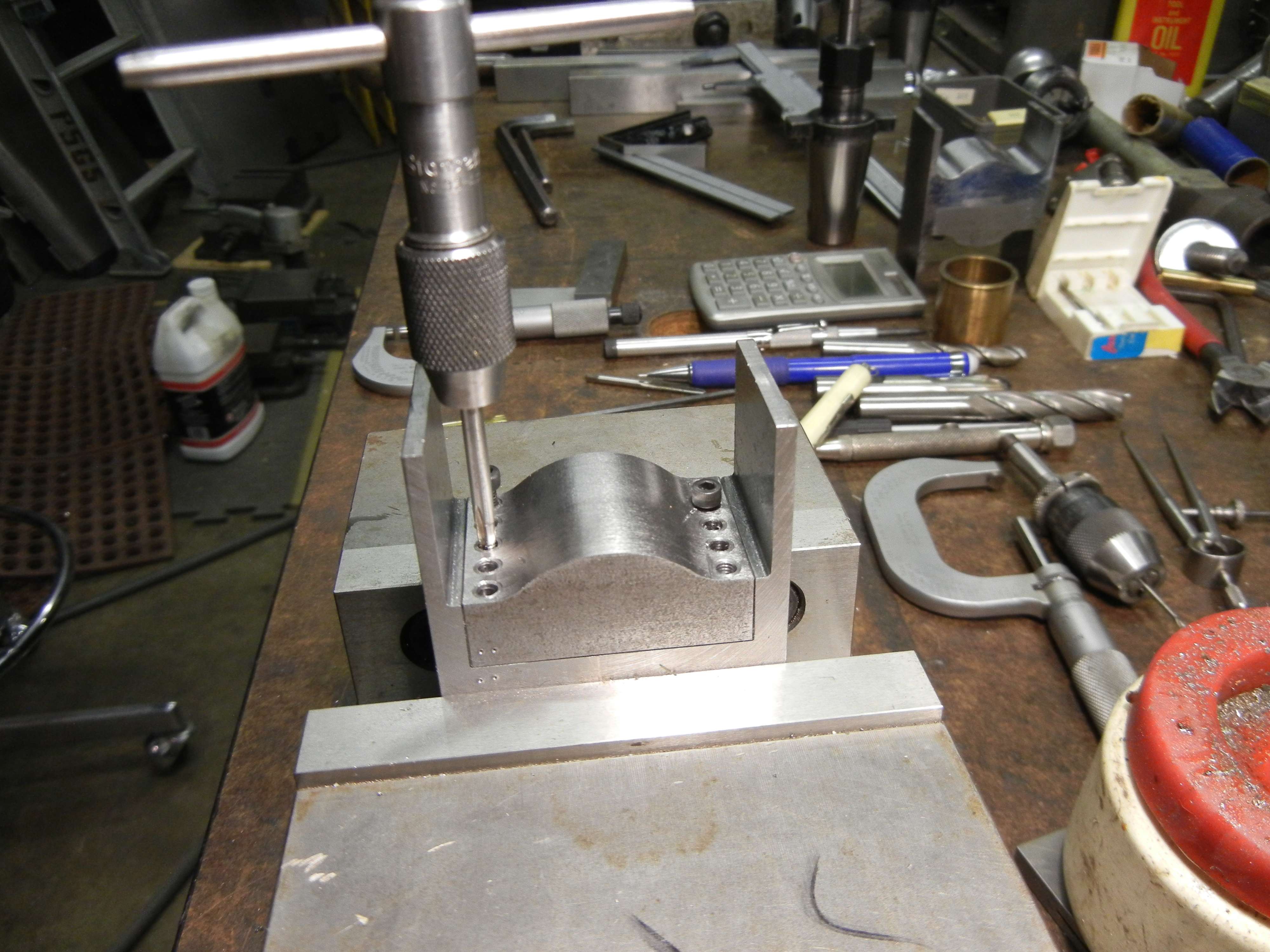

out in the center because I don't want to tap a 1-72 thread into a blind hole.  Here is the progress yesterday. I hope to finish the caps tonight.

|

|

#556

|

||||

|

||||

|

Great to see you back on the dragline Steve...I find im a little less anxious to finish when the machine is funtional..lol Go out and play ..ha ha ..I always learn more stuff about machining from you guys .Work holding ..Processes and how they are made in the different stages ..Learning from the masters ..thanks for posting all the great pictures

|

|

#557

|

|||

|

|||

|

Looks great, is the steel hot rolled?

|

|

#558

|

||||

|

||||

|

The caps are 1018 Cold Finished bar. The main body are cut offs from a thick plate of Hot Rolled 1018.

Finished the blocks other than the mounting holes.  #5-40 tap  Setup and staring the bore  Finished bore 1.1875''  Reusing the bronze bushing from the first blocks.  Ready for the brass sheets that will make up the support towers.

|

|

#559

|

||||

|

||||

|

I'm at a bit of a loss to understand why you changed that from the original assembly you had, it appears you've now lost quite a bit of rigidity from a vital area that carries the entire weight of the model at distant end points during travel.

__________________

Sharing knowledge is one thing that defies basic arithmetic logic --- the more you share, the more you get! Joe |

|

#560

|

||||

|

||||

|

Quote:

The bearing will be stronger once I build the rest of the tower. Like I said in a previous post; I made the bearing upside down and now I'm fixing it like it's supposed to be . Or close to. Joe, Take a look at what still needs built to complete the entire bearing tower support.

|

|

| Currently Active Users Viewing This Thread: 1 (0 members and 1 guests) | |

|

|