|

|

|||||||

| Highway Trucks and Trailers On road trucks and trailers single and twin axle trucks. |

|

|

Thread Tools | Display Modes |

|

#1

|

|||

|

|||

|

Okay guys...been wanting to do this one for awhile. I imagine this has been done before but I haven't seen any myself. This is pretty much my first model project so...hope it turns out.

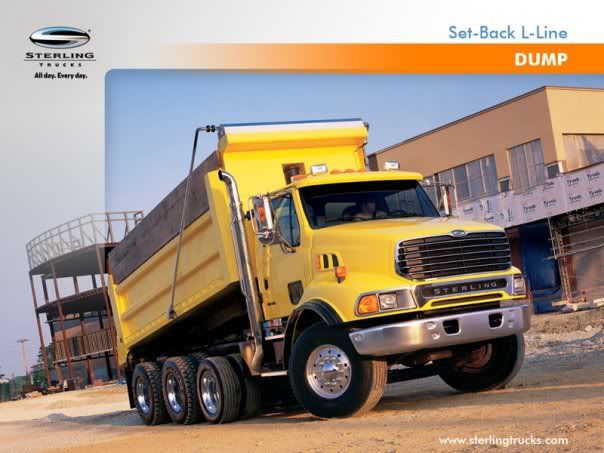

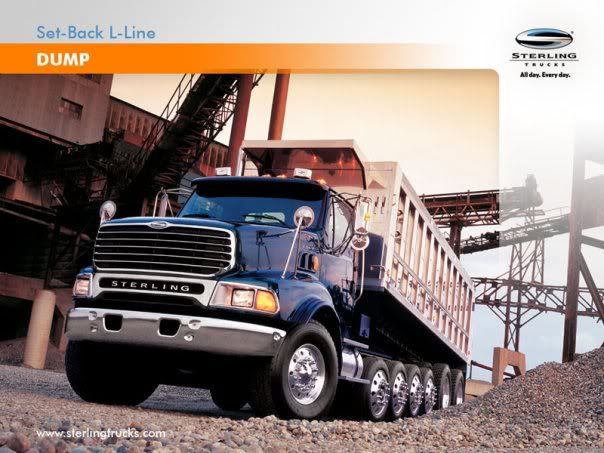

Was going to wait until I got my backhoe build thread going but there is soooo much waiting for parts and drafting plans that I was looking for something to tinker with in between. (BTW, the backhoe project is alive and well...tires on way from Germany, booms and cylinders all sized and mocked up in balsa wood and most remaining pre-manufactured parts on way from PMD or Germany). Was going to wait until I got my backhoe build thread going but there is soooo much waiting for parts and drafting plans that I was looking for something to tinker with in between. (BTW, the backhoe project is alive and well...tires on way from Germany, booms and cylinders all sized and mocked up in balsa wood and most remaining pre-manufactured parts on way from PMD or Germany).I don't know all the details but the first Sterlings were pretty much the Aeromax with a new front grill. Even the most recent class 8 models, (prior to the Sterling line being discontinued), continued to look a lot like the Aeromax - just sleeker...in fact, the last model before they shut 'em down was a **** good looking truck (IMO). Anyway...some back story here...my pop retired from a management job with an oil company in 1999 and set out to "enjoy" his retirement driving a truck. He was a truck driver earlier in life and that's what he really enjoyed most. So he landed a job with a local concrete company hauling stone and they set him up in a Sterling dump with a single drop axle very similar to the white truck pictured below but in blue (Mom is looking for pics for me but no luck so far). Well, in January 2001 he had a massive seizure driving the Sterling through town in a 25mph zone. Lucky for all he was giving a guy a ride to pick up a repaired truck and they got the truck pulled over without anyone getting hurt. Turns out he had brain cancer....and that's the last time he ever drove a big truck. Happy to report Dad is alive today and doing pretty well considering....so this one's for you Pop. On to the build...so here's the general inspiration...you can see what I mean about the newer models looking pretty cool (yellow and blue)...  :  :  Picked up this Aeromax from Vince a couple weeks back. I'm sure some of you saw the truck on Buy & Sell. Vince seems like a pretty good guy. Thanks Vince.  An hour later...  Cab disassembled and sleeper cut off...  Mocked up with cardboard dump body to get the feel...definitely on the right track here...frame length pretty close as is but I got some frame rails from Freddy and will be starting from scratch to fine tune the length after I finish the design on the dump body.  Now to make the all important Sterling front grill. First to remove the Ford grill and carve away the vertical sections and Ford emblem. (Before I did this I transferred the shape of the grill by wrapping a piece of paper around the front real tight and shading w/ side of pencil point to pick up the lines).  The little Taig CNC in action...  ...and the prototypes after some scroll saw and pan brake trickery.  Temporarily set in place...not bad.  I'm in process of reworking the grill (hopefully for the last time). Will have the Sterling S milled in and ends of grill slots will better match the original. Have some miniature stub end mills on order that should be able to do the job on the S logo. Hopefully the Taig is up to the challenge...I've never done anything that small in aluminum. Might post some more tomorrow with mock up of the lower grill piece. Need the new end mills before I can attempt the STERLING relief carving. Doubt I will have anything on the new front bumper but maybe...still mulling over fabrication methods on that one. As for rest of truck? - New frame rails from Freddy - Truck came w/ PMD 4:1 gear reduction so that will stay - Wedico telescopic hydraulic pump/cylinder on the way - Fabricating the dump body Rest I will work out along the way. Thanks for looking. Comments and suggestions welcome! Joe Last edited by Heavy Metal; 02-20-2011 at 09:38 PM. Reason: update |

| Currently Active Users Viewing This Thread: 1 (0 members and 1 guests) | |

|

|