|

|

#61

|

||||

|

||||

|

|

|

#62

|

||||

|

||||

|

Not sure why that photo is upside down....strange...it looks right on photo bucket, I'll try rotate it and see if it changes. First time that has happened???

|

|

#63

|

||||

|

||||

|

It's right side up!

|

|

#64

|

|||

|

|||

|

For the sliders you could try dyeing them black.

|

|

#65

|

||||

|

||||

|

I was going to suggest that also, can't find the info I ran across sometime ago about painting/dye plastic , acetal. Someone painted something non important and then they used dye on another part. The dye penetrated a little bit verses the paint scratched off. It might even have been a thread on anodizing?!?!?? Couldn't find the info so I didn't say anything as it may have been a figment of my imagination too!!! Lol!!

__________________

Always wasting money, as the wife says. To view links or images in signatures your post count must be 10 or greater. You currently have 0 posts. |

|

#66

|

||||

|

||||

|

You can buy black UHMW . No need to paint or dye anything.

|

|

#67

|

|||

|

|||

|

Yes, that be it! I have a handfull of those inserts, though i did not k ow thats what they were for! I made a tool holder for one to use on my lathe, works good for aluminum. Chatters with steel! I believe i will be purchasing a facing cutter for sure now. Less stress on my little mill is what i thought would be a plus also!

|

|

#68

|

||||

|

||||

|

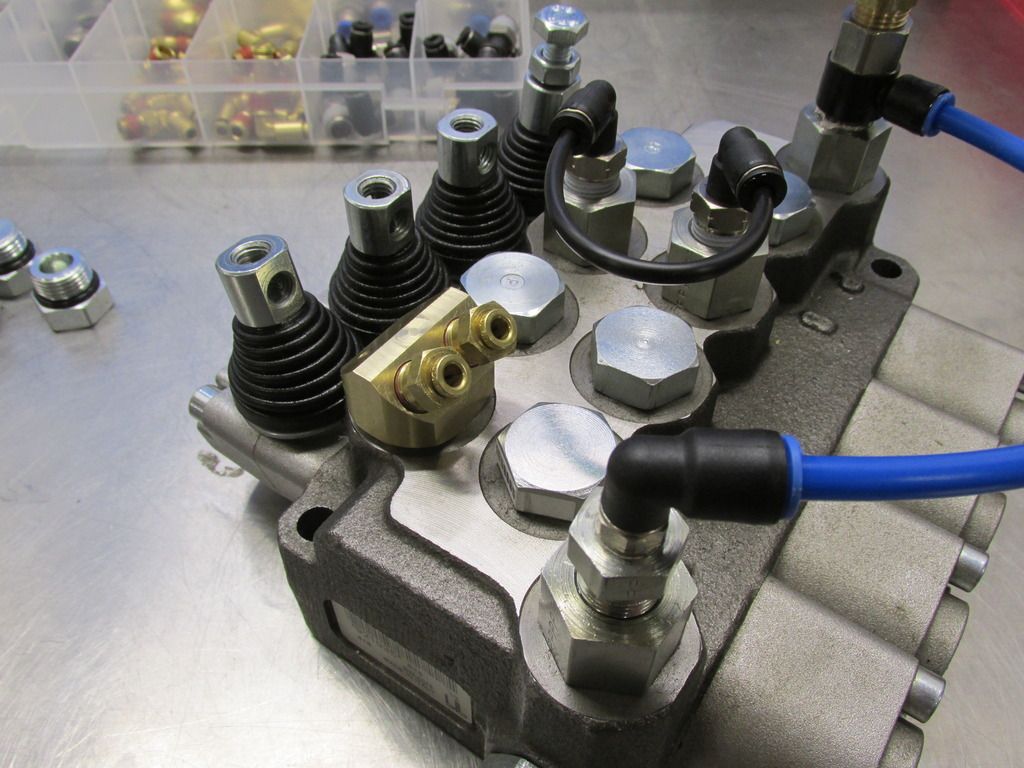

Couldn't stop thinking about the hydraulics so today I built a prototype of the fitting needed in the valve body. Need two hoses for each port, 16 hoses total. Here are some pics of the 45 deg. fitting, #8 ORB to a double 1/8" NPT.

[IMG]  [IMG]  [IMG]  [IMG]  Built it as small and short as possible...I think it should work nicely...so just need to refine the design and build all eight fittings, time to go back to the garage  KP |

|

#69

|

||||

|

||||

|

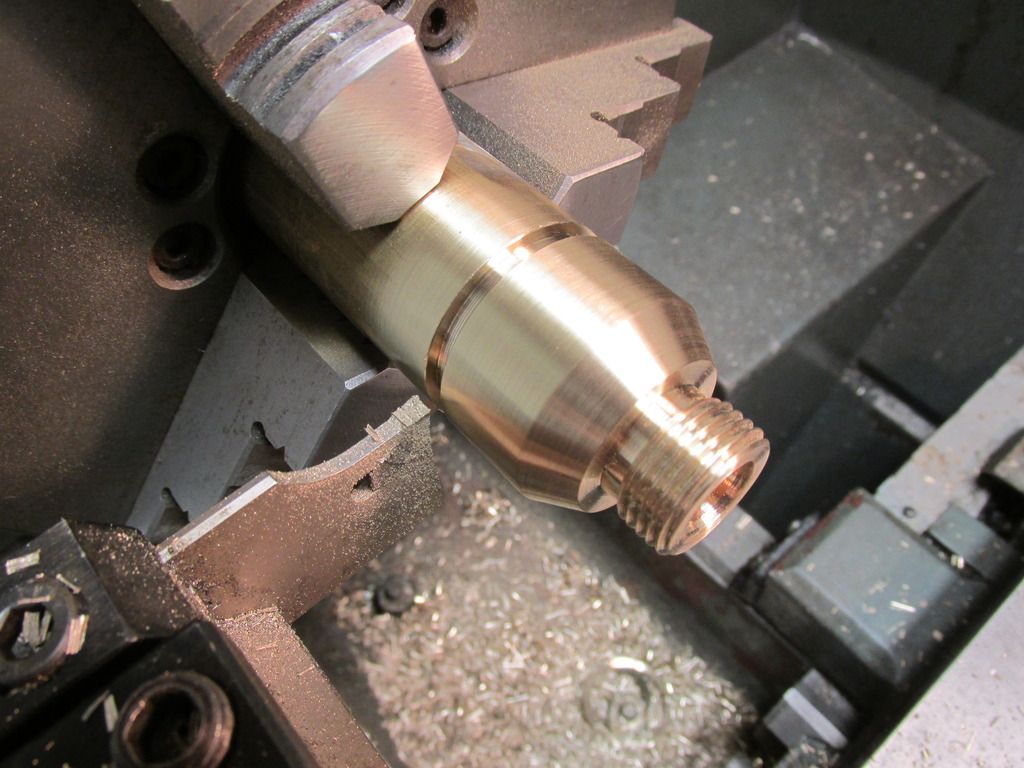

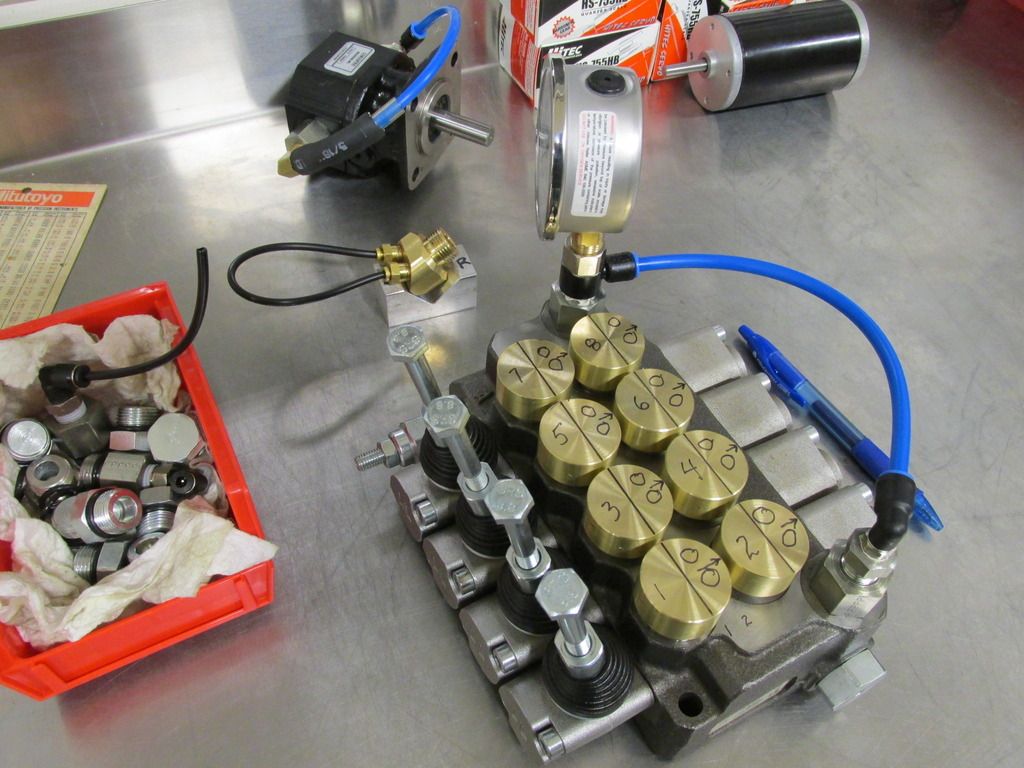

Made a little more progress on the brass hydraulic fittings, got them turned/threaded. Then they were threaded in until they firmly bottomed out on the face of the valve body, this will insure that the angles are milled in the proper direction and that all of the small fittings for the 5/32 tubing are all pointing forward. Next job will be to mill all the flats and then drill/tap the hole for the small fittings....

[IMG]  [IMG]  [IMG]  The ports and fittings will need be numbered because the valve ports will most likely all have different thread start timing. |

|

#70

|

||||

|

||||

|

Quote:

__________________

Sharing knowledge is one thing that defies basic arithmetic logic --- the more you share, the more you get! Joe |

|

#71

|

||||

|

||||

|

He means each fitting will be machined to fit a given port because the threads will be cut different in every one. If he just makes the fittings and threads them in to any old hole they will point in different directions when tightened down.

Looking good KP! |

|

#72

|

||||

|

||||

|

Quote:

__________________

Sharing knowledge is one thing that defies basic arithmetic logic --- the more you share, the more you get! Joe |

|

#73

|

|||

|

|||

|

I got lucky on mine but thats what had happend to me to. It took a half hour of threading and re-threading before i found which way they went cause i did mark the sides but never labeled them!

|

|

#74

|

||||

|

||||

|

What??? haha sorry Joe...I see Reg already nailed the answer for me...I even understand it better now...lol...Thanks Reg, well said!!

One other thing that would affect the orientation of the fittings would be the location of the bottom face in relation to the length and start point of the threads on each fitting, any changes to that would allow the fittings to rotate more or less before it bottoms out on the valve port face. And I know none of the fittings I made are exactly the same.   ( For any technical support please contact RCP57, or just wait until he gets time to figure out my "BS" and then translate it into english!!  ) )

|

|

#75

|

||||

|

||||

|

"The ports and fittings will need be numbered because the valve ports will most likely all have different thread start timing."

I understood what you meant when you said this from a machining stand point but the sad thing is I've never played with hydraulics like this to understand what difference or importance it has.

|

|

#76

|

||||

|

||||

|

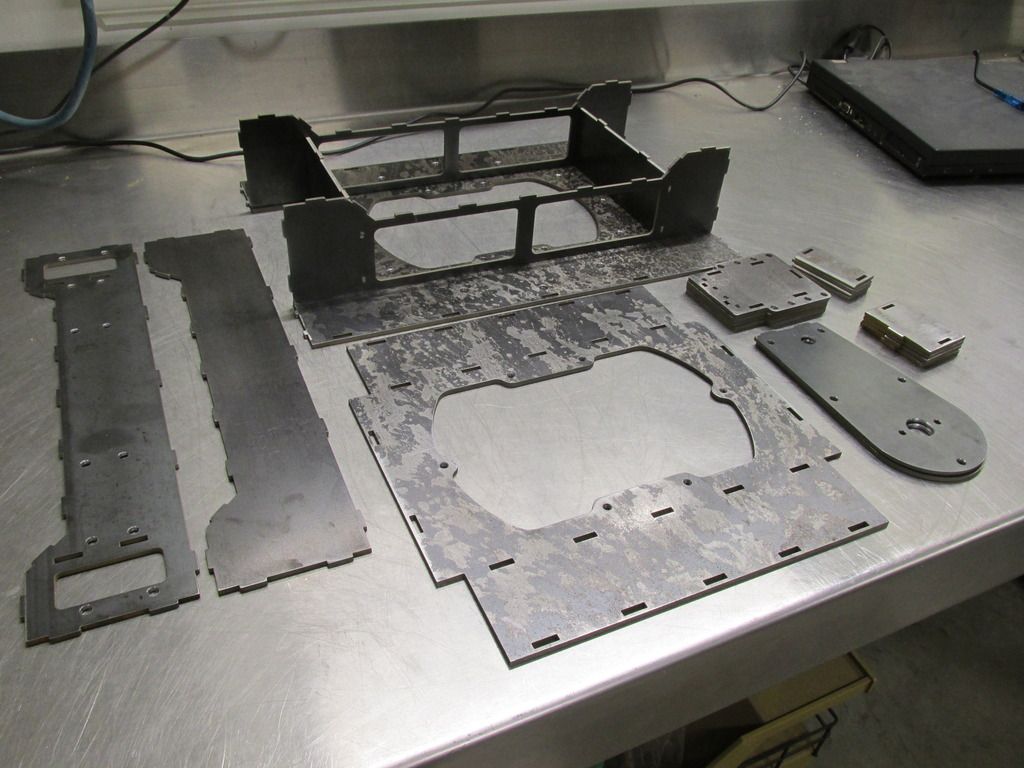

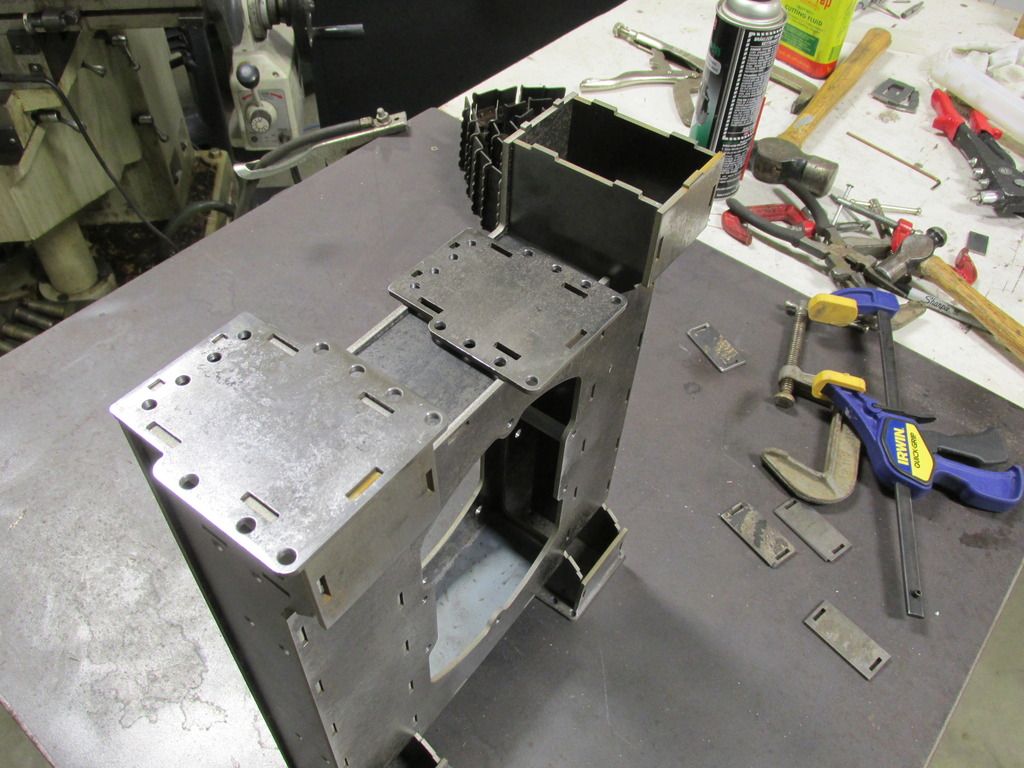

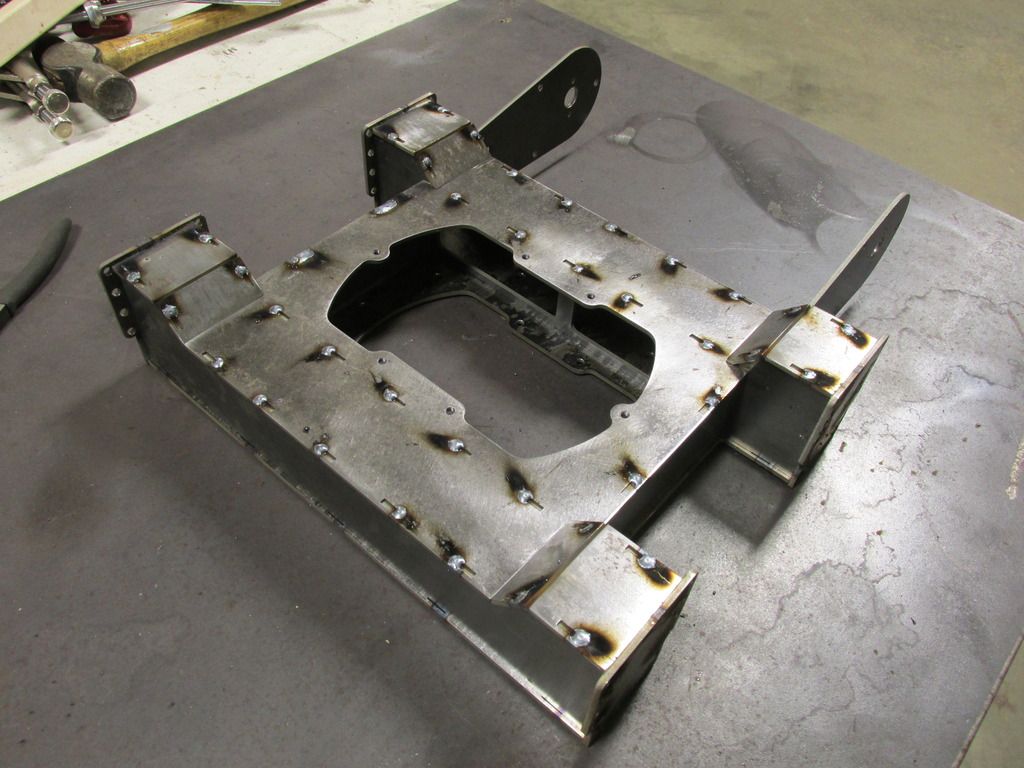

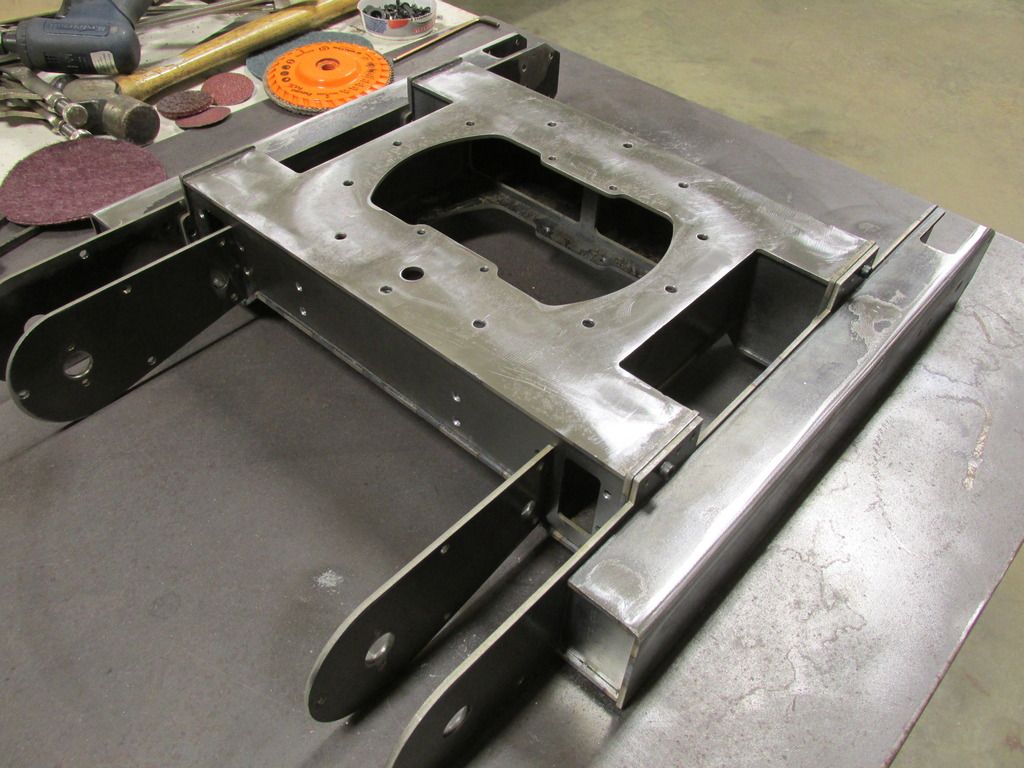

Enough about the boring hydraulic fittings, everyone is most likely sick of looking at them already...I know I will be by the time I finish machining them...lol...

Here are some pics of something a bit more interesting, building the center frame section [IMG]  [IMG]  [IMG]  [IMG]  [IMG]  [IMG]  [IMG]  [IMG]  The two track drive motors ( banebots 256:1 gearbox 540 motor) will be mounted inside the center frame and #25 chain will be used to drive each track. |

|

#77

|

||||

|

||||

|

Here is my translation of KP's last post...

SWEET!!!!!!!!!!! SWEET!!!!!!!!!!!

|

|

#78

|

||||

|

||||

|

the wow factor just went up by 10xxx

|

|

#79

|

||||

|

||||

|

And here is my judgement : Sweet Sweet Sweet........and so on....

|

|

#80

|

||||

|

||||

|

You certainly have one of the better assets that's gives you an edge over everyone else in this hobby, a water jet at your fingertips!

__________________

Sharing knowledge is one thing that defies basic arithmetic logic --- the more you share, the more you get! Joe |

|

| Currently Active Users Viewing This Thread: 1 (0 members and 1 guests) | |

|

|