|

|

|||||||

| Construction Equipment If it digs, pushes, hauls dirt "off road" post it here. |

|

|

|

Thread Tools | Display Modes |

|

#81

|

||||

|

||||

|

Dang, to bad I wasn't as good as you were in the 12th grade! You're gonna go far, kid!

__________________

Nathan |

|

#82

|

|||

|

|||

|

Looks better with every update. When are you going to paint?

Chris has got a lot of talent, he's robots will be famous! I agree with Espeefan. It got me wondering, what is the average age of scratch builders here? |

|

#83

|

||||

|

||||

|

Quote:

Reg |

|

#84

|

||||

|

||||

|

Espeefan - Thank you very much!

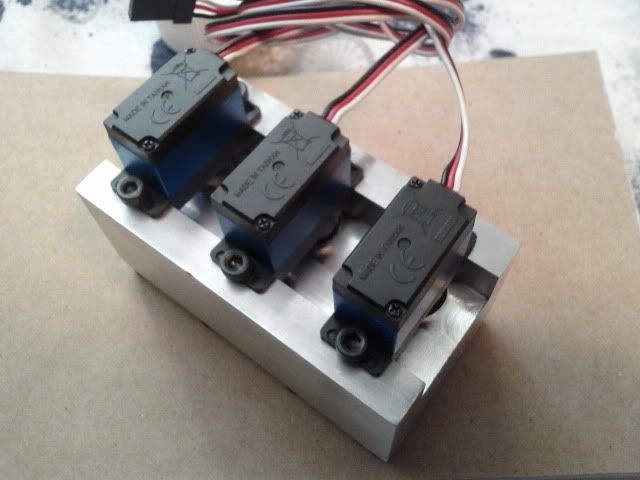

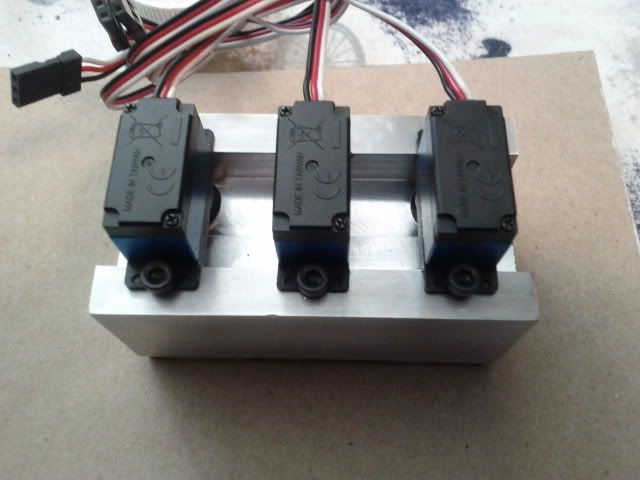

Madda - I plant to paint once I feel that i dont need to change anything because I don't want to paint it and start thinking im done when I still have lots to do. RCP57 - You got it! So today i got the housing for my belt reduction system for the pump, probably the longest part i have cut to date, 1 hour 40 mins and that doesn't even include re-setting the program after somebody thought it was a good idea to hit the shop power emergency switch in the middle of a cut.   Now i just need to get the pulleys installed and it should be good to go.      Thanks for reading! Chris |

|

#85

|

||||

|

||||

almost 2 hrs almost 2 hrs       JK , Chris JK , Chris  your doing a great job your doing a great job  your fortunate to have that type of stuff in the HS . I was lucky enough to be able to have industrial shop the last year they offered it your fortunate to have that type of stuff in the HS . I was lucky enough to be able to have industrial shop the last year they offered it  . 2 summers later they auctioned everything off . 2 summers later they auctioned everything off  No NC at that time not even a BP vertical mill . No NC at that time not even a BP vertical mill .some lathes a horizontal mill , sheet metal tools and a forge .

__________________

RIP FreddyGearDrive 2-12-59/12-19-11 To view links or images in signatures your post count must be 10 or greater. You currently have 0 posts. |

|

#86

|

||||

|

||||

|

ihbuilder - Thanks! Yea I really lucked out on the that one!

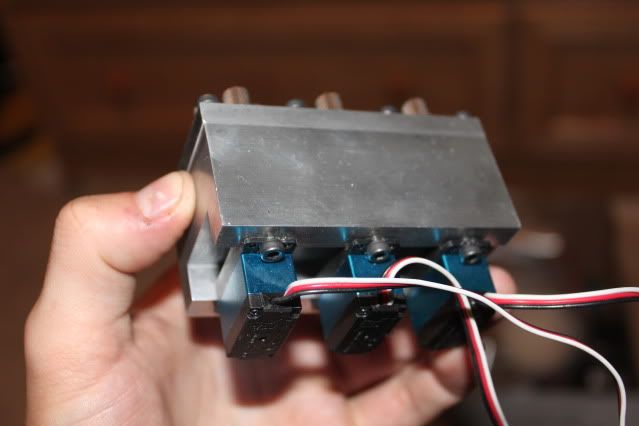

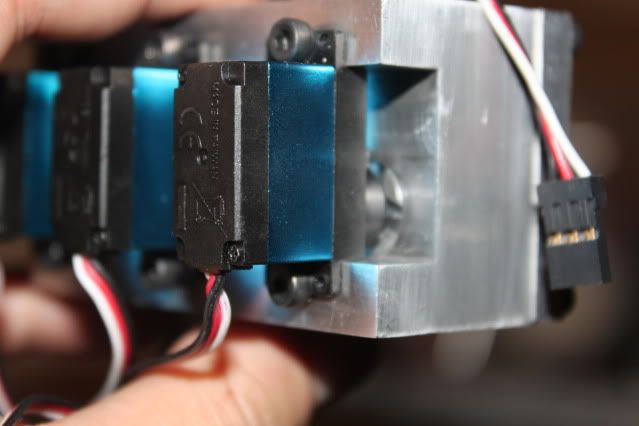

So Got the belt drive all finished and ready to be installed. And it came out great. It has a 2.85:1 reduction from motor to pump. I also got some other smaller parts cut out here and there. Just wanting for some metal to come in to get working on some other parts.    Chris |

|

#87

|

|||

|

|||

|

nice!!!!

|

|

#88

|

||||

|

||||

|

aussietrckerguy - thanks!

So today I cut out the reservoir tank out of a 2.25" x 2" x 1" block, it has a 43mL capacity, M5 Inlet and output ports and a solid top cap. Hopefully it doesn't leak but only time will tell.   Hopefully tomorrow I can get back to work on the valves again. Thanks! -Chris |

|

#89

|

||||

|

||||

|

Do you have a vent in it Chris?

Reg |

|

#90

|

|||

|

|||

|

Wohoo, fast progress few last days, keep it going!

I'm waiting the results, high school boy building his own hydraulics

|

|

#91

|

||||

|

||||

|

RCP57 - No not yet as i don't quite know the orientation of the tank so i don't want to drill a hole for the vent line and then end up having it in a spot I cant get to.

Madda - Yea I have to move quick!! Time is really sneaking up in me, my first exam is in less than a month      On that note I might have to wait for lights and such until summer after I graduate, but luckily i talked to my teachers and they are fine with me doing that. Anyways today I finished machining the body of the valve system and now i just need to redo the face plate, make the rotars and she's good to go. Then Ill finish the cylinders and we should be good to go on the hydraulics as long as we have no catastrophes  As always here are some pictures: Inside the tank:   Valve assembly:      Start of the lift cylinders:  Thanks for lookin! Chris |

|

#92

|

||||

|

||||

|

So what did you do there with the valve? You going to have a pressured line & a return line coming from each valve?

What size fittings & tubings to the cylinders?

__________________

Sharing knowledge is one thing that defies basic arithmetic logic --- the more you share, the more you get! Joe |

|

#93

|

||||

|

||||

|

Lil Giants - Yea on each valve i hill have a supply and return like you said with an external manifold. But looking at it now i should have milled in the supply and return lines into the valve block. Oh well, thats part of learning.

the fittings are M5 thread with 4mm OD tubing i believe, i'll try to get a pick up to showing the scale of the valves and the new front plate because that one in the pictures the fittings were to close. Chris |

|

#94

|

||||

|

||||

|

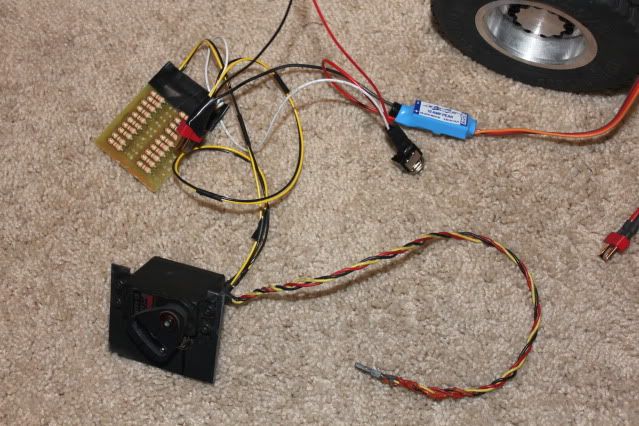

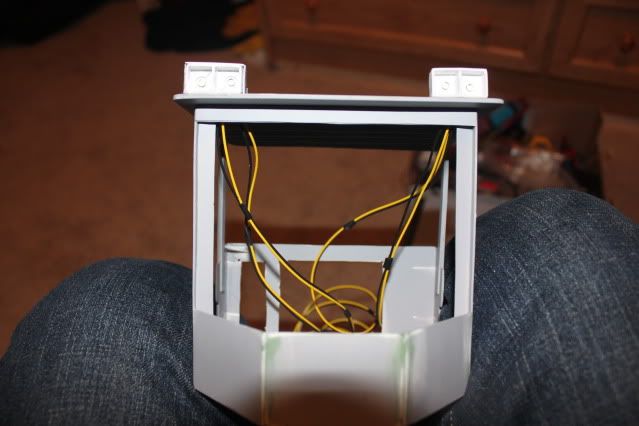

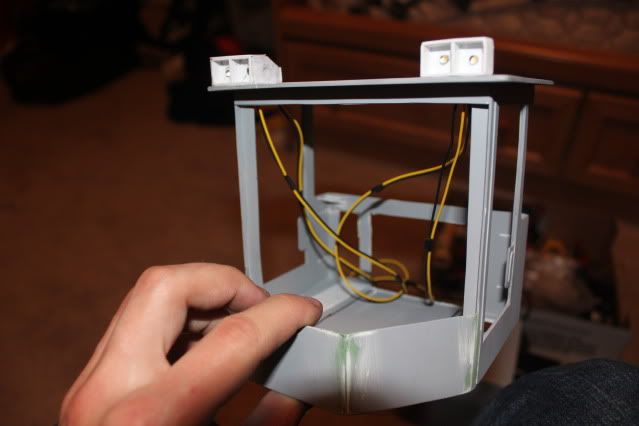

Well we sure are getting close!! I got all the electronics sorted out for now all i need is a servo slower or a servo tester to control the pump rpm/pressure. Until I accidently dropped a motor controlled and it shorted out on a metal shaving near my drill press

i was even working on wood to prevent problems like this i was even working on wood to prevent problems like this  The valves are now done but I need to finish the cylinders to be able to test and see if it works. I got all the bucket linkage worked out and now need to weld and braze the bucket but i have to pick up some argon for the MIG my dad has got because our industrial sized welder at school burns through 14 GA. Heres some pics of the progress: The valves are now done but I need to finish the cylinders to be able to test and see if it works. I got all the bucket linkage worked out and now need to weld and braze the bucket but i have to pick up some argon for the MIG my dad has got because our industrial sized welder at school burns through 14 GA. Heres some pics of the progress:showing everything that needs to fit, ill cut some wires and clean it up once i know the final lengths.    Low current draw branch of the wiring harness.  Manifold from pump to valves and from valves to tank.  Finished valves:    Cab Lights   Bucket linkage  Lift and turning cylinders  Thats all for now and i've got one week to get this thing working!! Time to get er done! Chris |

|

#95

|

|||

|

|||

|

Very good job Chris!

I wish you good luck to get everything working, you must be pretty nervous to see what's going to happen when all hooked together? Put video here asap you get some action! |

|

#96

|

||||

|

||||

|

Thanks Madda!

yea its a pretty nerve racking especially because i don't have any more time or money to fix thing if they dont go as planned. Plus so many people who have helped build it wanna see how it works so i gotta make sure it actually runs!! Will do, might be after i get it all done but ill get some up asap! Chris |

|

#97

|

||||

|

||||

|

Hi Chris

Looking great I'am sure it will all come toghter and work. Very high standard of work wishing you well. Regards Mark |

|

#98

|

||||

|

||||

|

OK Chris, you are well outta school so where is the finished product?

|

|

#99

|

||||

|

||||

|

Hey sorry for the lack of updates but I needed a break, i was working 6+ hrs a day trying to finish it and needed a break before i got to tired and said screw it. Unfortunately i ran into some problems with the loader and some other things and didn't get it done in time but i got an all access pass to the shop so on my days off ill be in the shop finishing it up! Dont worry ill get it done come **** or high water!

Chris |

|

#100

|

|||

|

|||

|

Hi Chris, any update on the loader?

Question on your valve design, what do you use as seals between rotator and base? Dan |

|

| Currently Active Users Viewing This Thread: 1 (0 members and 1 guests) | |

|

|