|

|

|||||||

| Euro Style Trucks and Trailers A place for the Euro style trucks single and twin axle trucks and trailers... |

|

|

|

Thread Tools | Display Modes |

|

#121

|

||||

|

||||

|

@ apubar - Thank you Andrew! It was thanks to your post on the German forum that made me realise I had to file out the hinges. I remembered reading about it. Sure helped big time! Sure glad the cabin is finished. Always worried of scratching the paint.

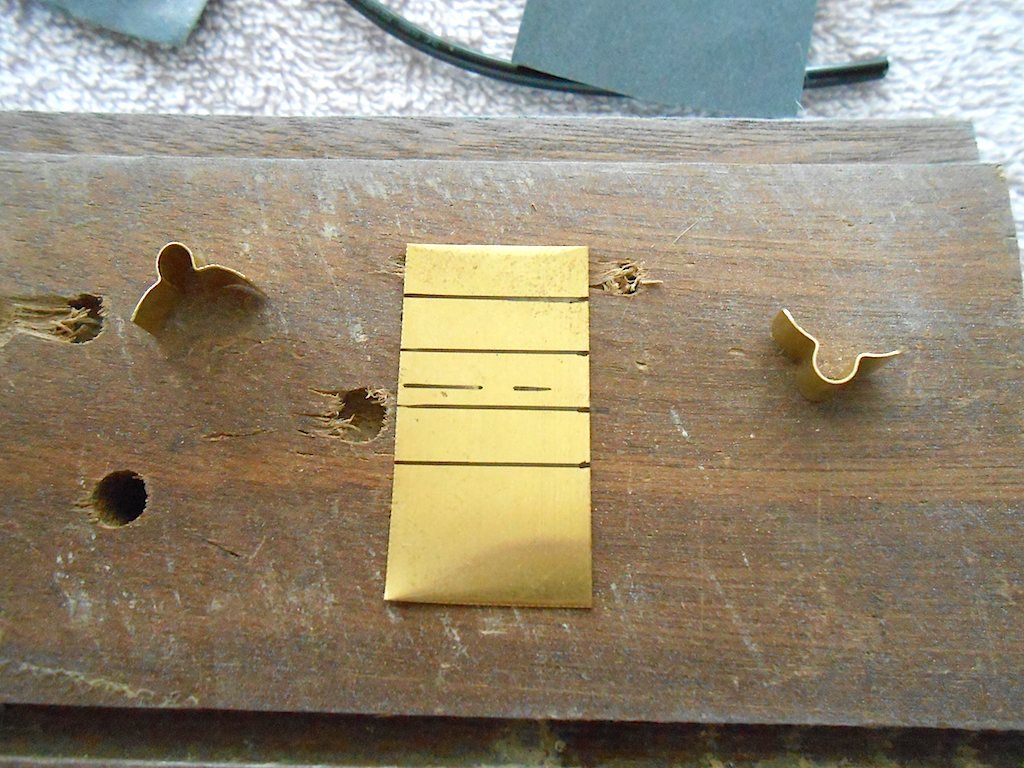

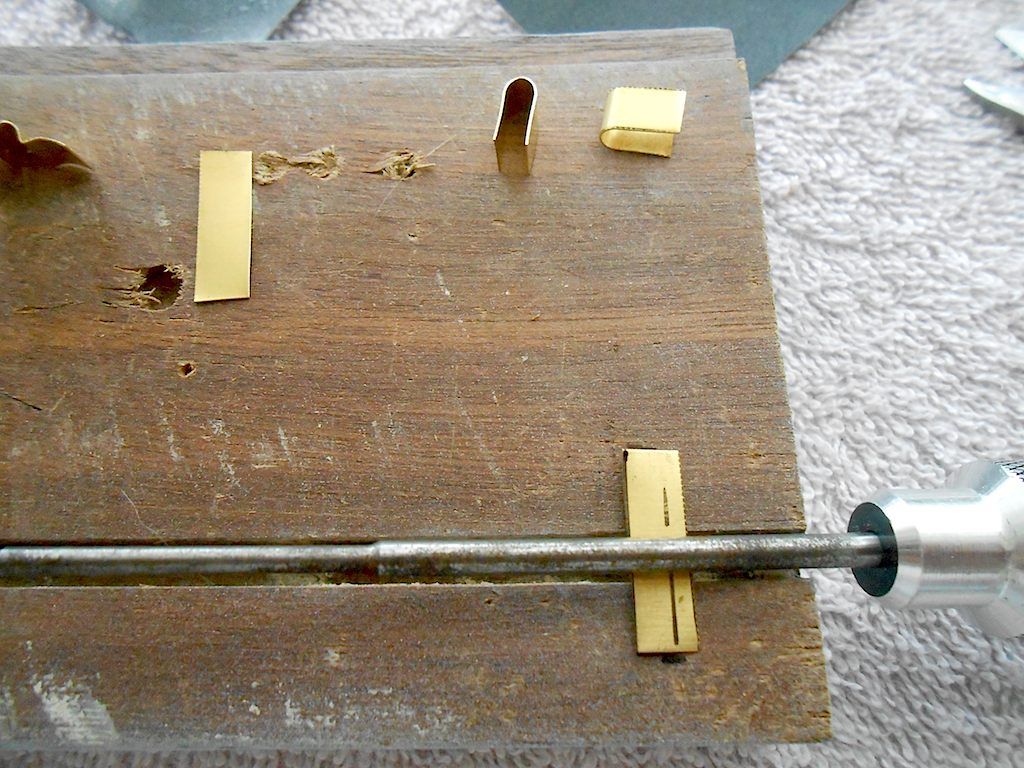

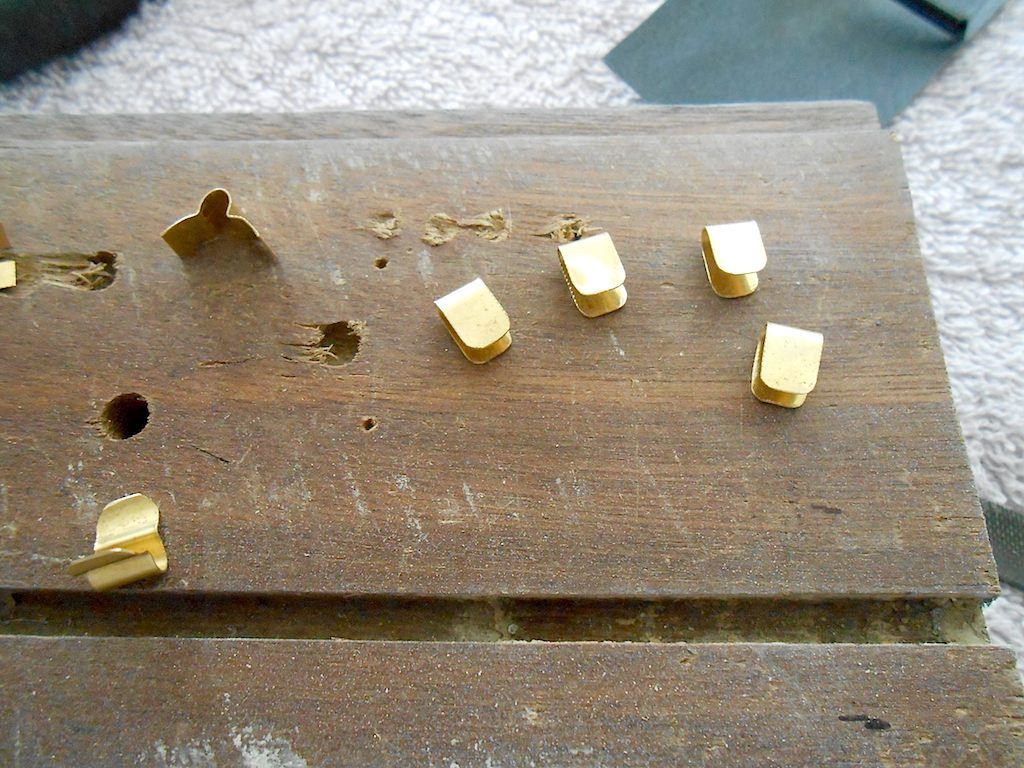

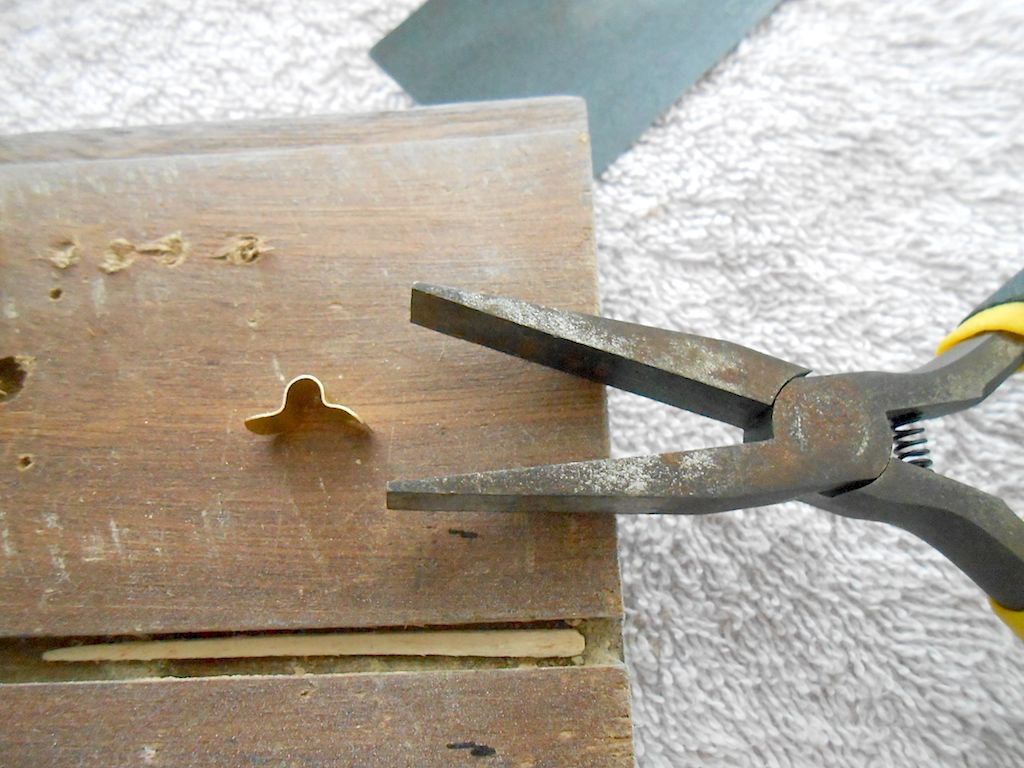

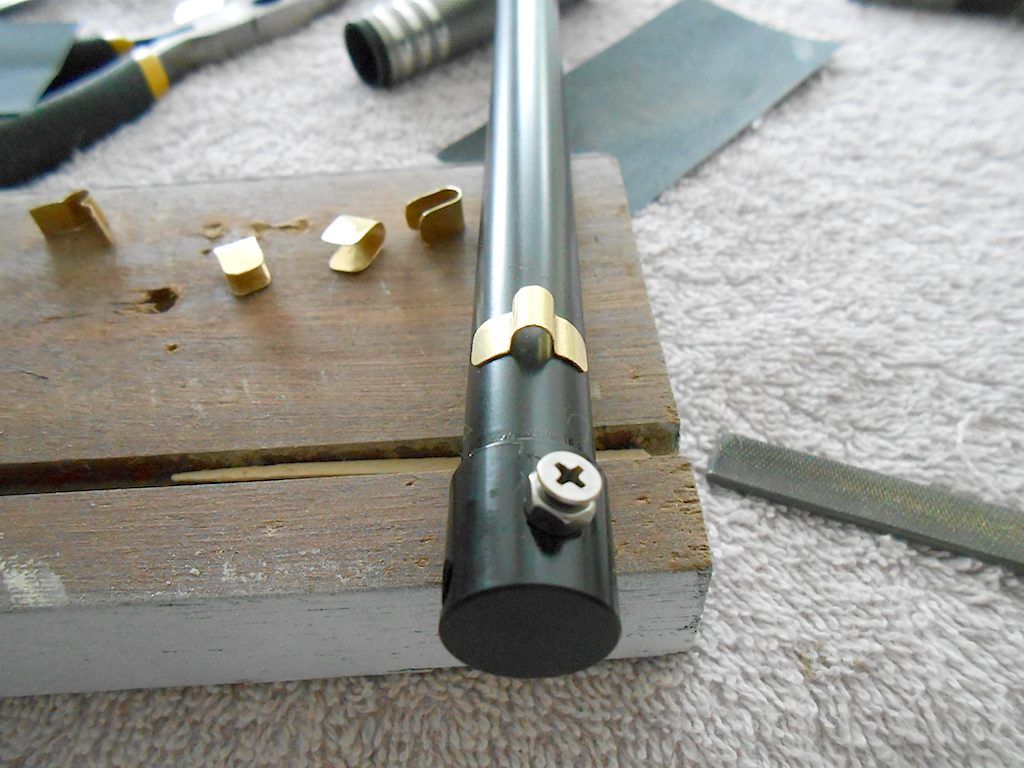

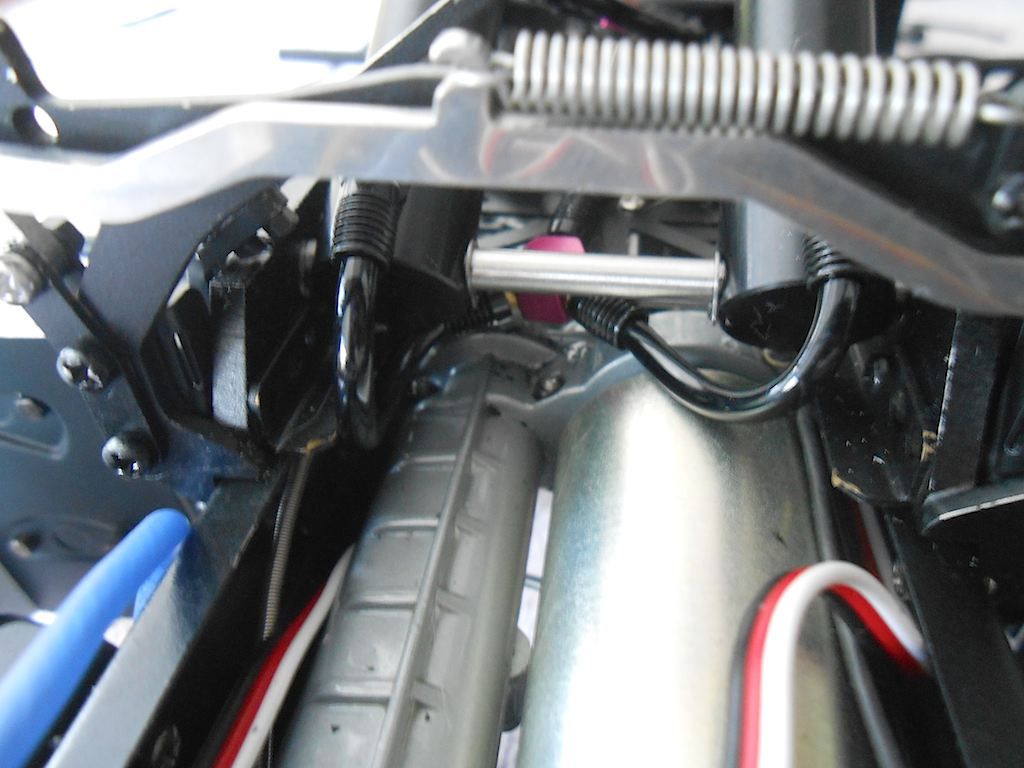

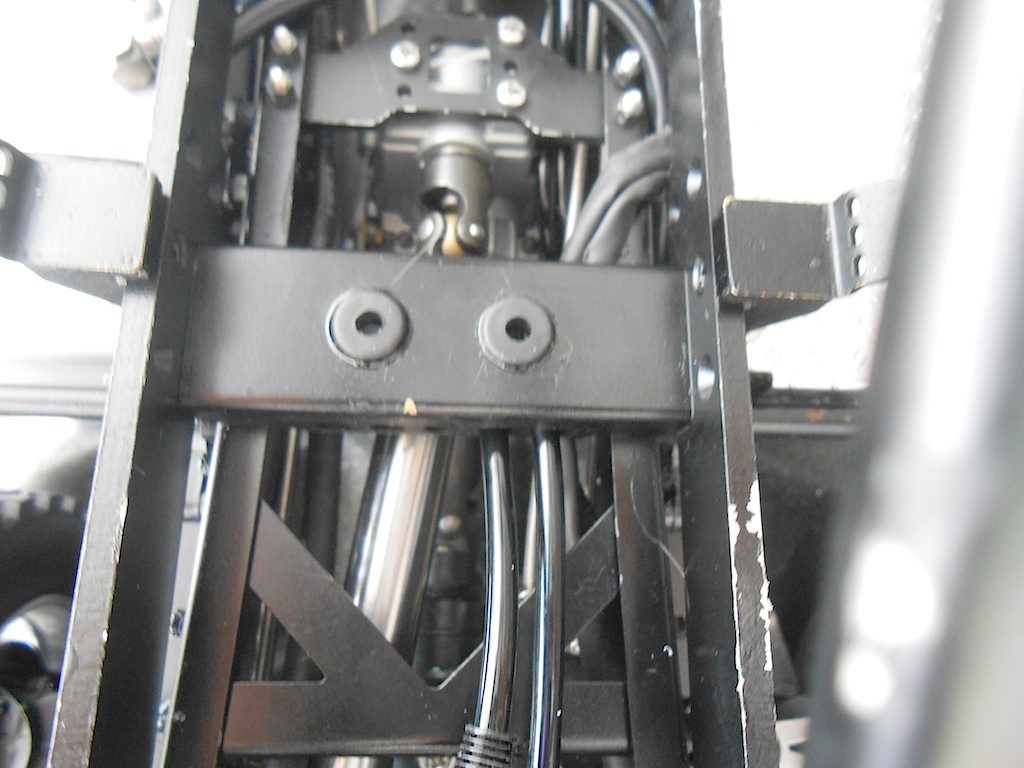

@egronvold - Must say am rather happy with the white and black myself. Looks better than I thought it would. @Brel - look great indeed but is rather front heavy at the moment. So could do with some weight at the back. Once the roll on/off stuff is on there should still look good without a container. @ crisis time - The amount of screws is what makes it fun! +++++++++++++++++++++++ Haven't done anything to the truck yet. From reading other threads on ScaleART and looking at pictures, I know there is no decent way to prevent the hydraulic lines from swaying when going from the 2 main cylinders to the oil pump. ScaleART fixes them to the cylinder with some shrink tubing or smal zip ties, not really a nice solution all things considered. So I figured to be "creative" and see if I could make some things to hold the line to the cylinder. After more than a couple of failed attempts I finally figured out how to make these simple looking things. Got the width down that I could work with the tools available to me  Messing cut into almost same width strips with scissors  Bend - the driver has the same diameter as the line.  Filed  Make roundish by bending with pliers in small increments (repeat until about right)  One done  4 done  and painted.  Not installing them yet. Will first so a test fitting of the hydraulic cylinders and see if I can use them yes or no. All I can say it that making these 4 simple things has made my respect for those who whip out whole models from scratch, go a lot of notches higher! Hat off.

__________________

Cheers, Stephan (Rakthi is the one in the avatar) |

|

#122

|

||||

|

||||

|

Hi Stephan,

that´s a great idea and a well done work. I think, I'll try to copy them.

__________________

Greetings Christian You can find some of my RC-models on To view links or images in signatures your post count must be 10 or greater. You currently have 0 posts. Normally I´m speaking german, please forgive my mistakes in English. |

|

#123

|

||||

|

||||

|

Hi Christian, Thanks and I'm glad I finally came up with something you might be able to use. Better wait and see if it works though. If I can use them I will just glue them holders to the cylinder with UHU Endfest.

__________________

Cheers, Stephan (Rakthi is the one in the avatar) |

|

#124

|

||||

|

||||

|

Hi Stephan,

ok, I'll stay tuned ... If you fix them with glue, I think there should be a little space between the cylinders, the lines and the holders, so you'll be able to change the lines if they once become leaky.

__________________

Greetings Christian You can find some of my RC-models on To view links or images in signatures your post count must be 10 or greater. You currently have 0 posts. Normally I´m speaking german, please forgive my mistakes in English. |

|

#125

|

||||

|

||||

|

Looks like a great solution to loose hydraulic hoses. Hope that they will work for you. You might want to try some rubber cement to attach them to the cylinder- not sure what cement you mentioned is.

__________________

LYNN |

|

#126

|

||||

|

||||

|

Good point Christian, thought about that too! Will only glue the holder to the cylinder first. There should be just enough room to push the hose through without too much effort once the glue has set. That is why I first want to try with a temporary fix (zip tie or tape)on the holders, to make sure the hose does not move too much or rubs. Last thing I want is a leaky hose spouting hydraulic oil!

Will see, maybe I have some time tomorrow. Will have to take a good look on how to run the hydraulic lines too.

__________________

Cheers, Stephan (Rakthi is the one in the avatar) |

|

#127

|

||||

|

||||

|

Quote:

You are right though, before I glue it like that, I will first try with something less strong. Thanks for the suggestion! Stephan

__________________

Cheers, Stephan (Rakthi is the one in the avatar) |

|

#128

|

||||

|

||||

|

Started on the hydraulics

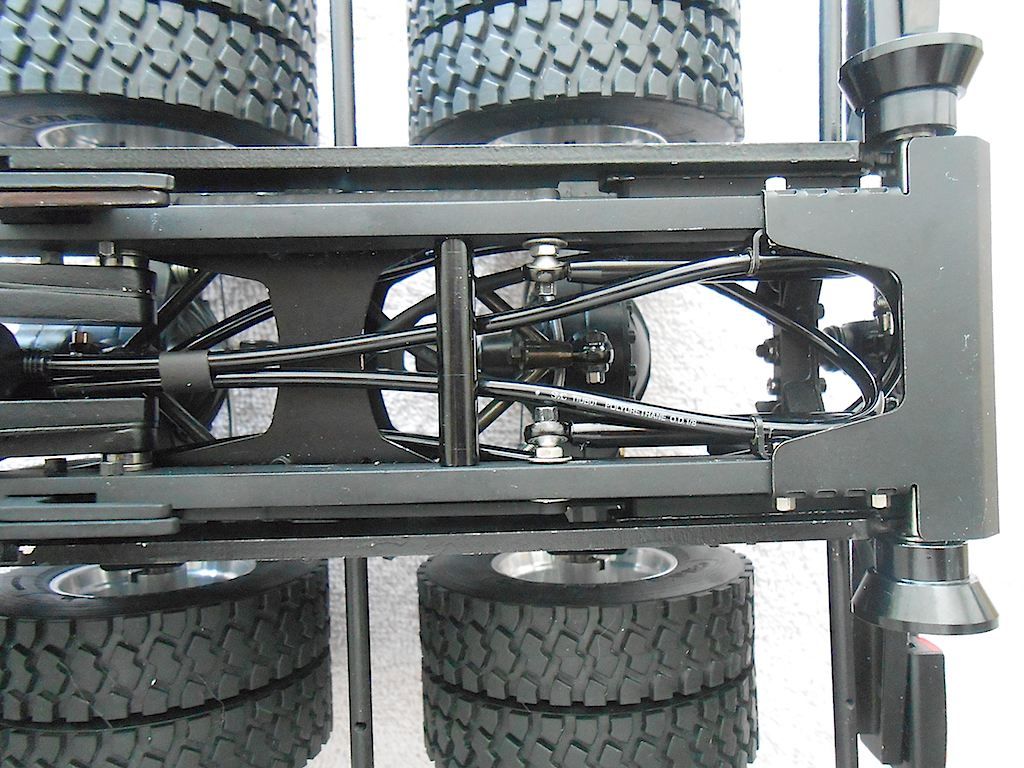

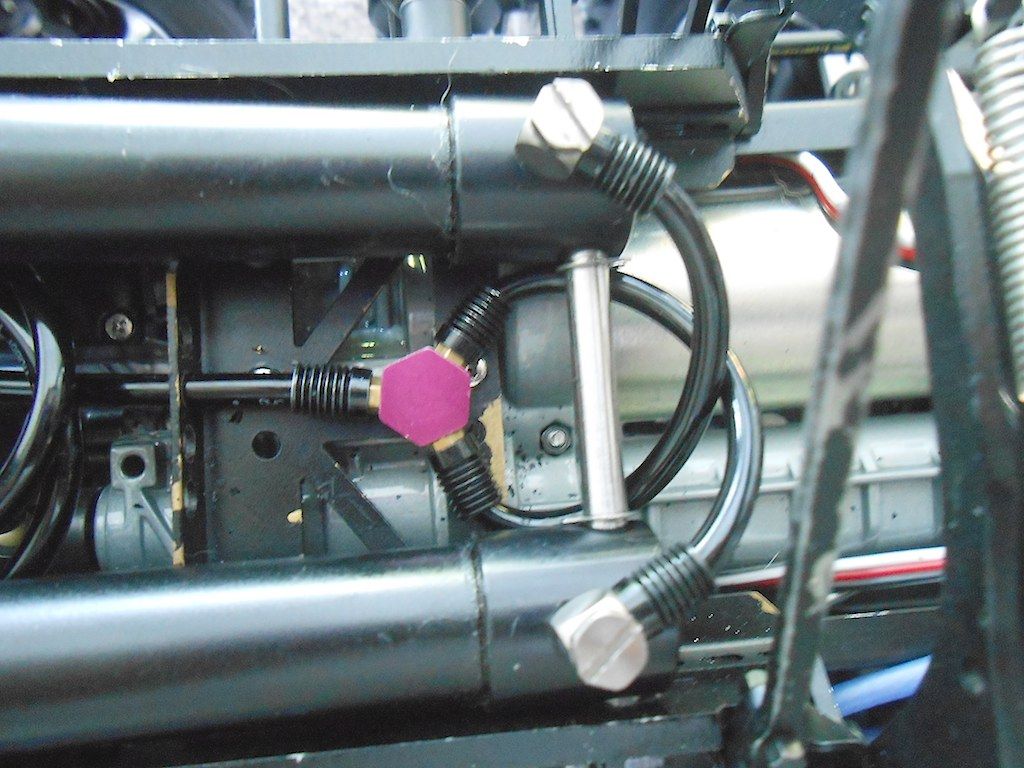

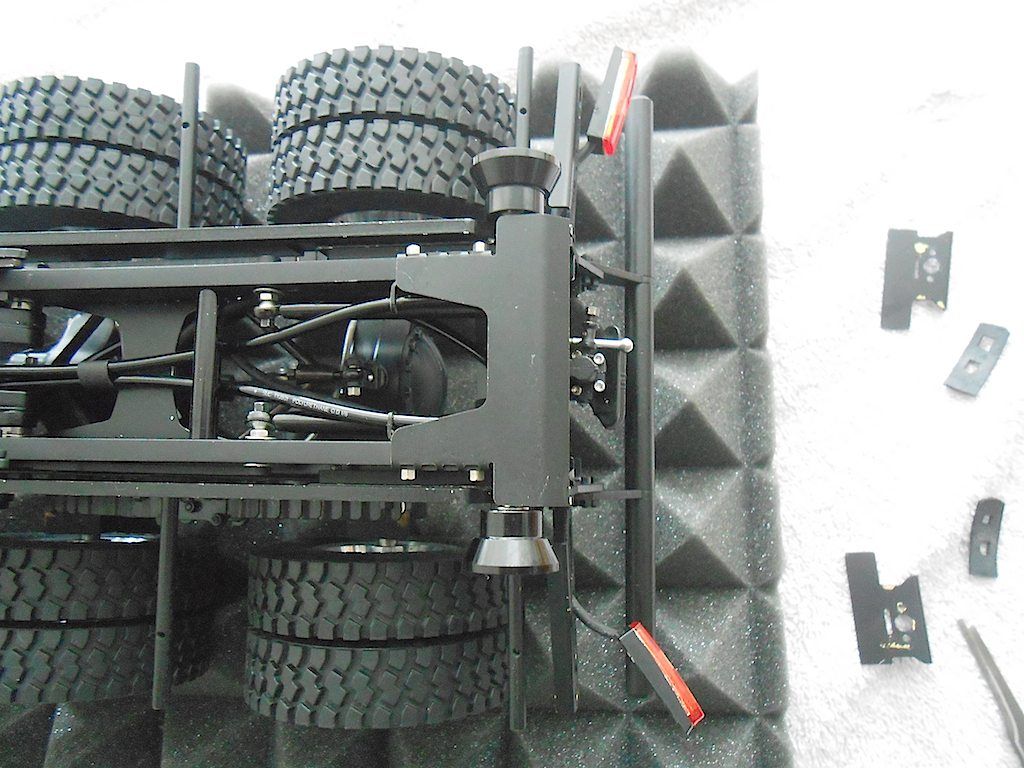

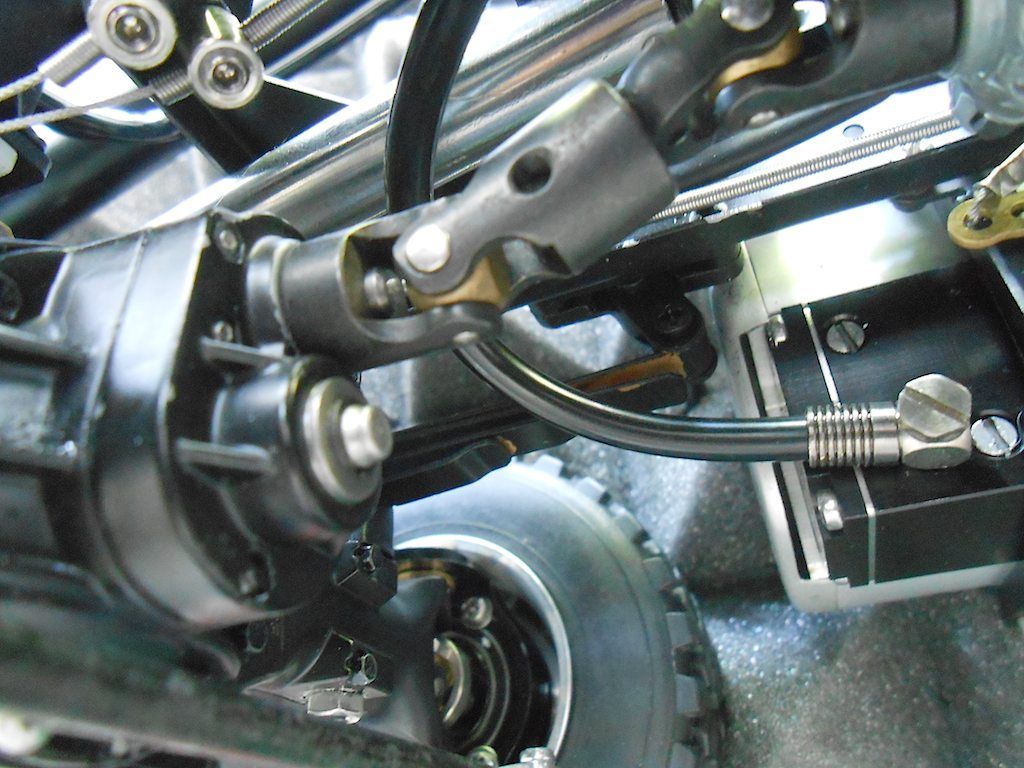

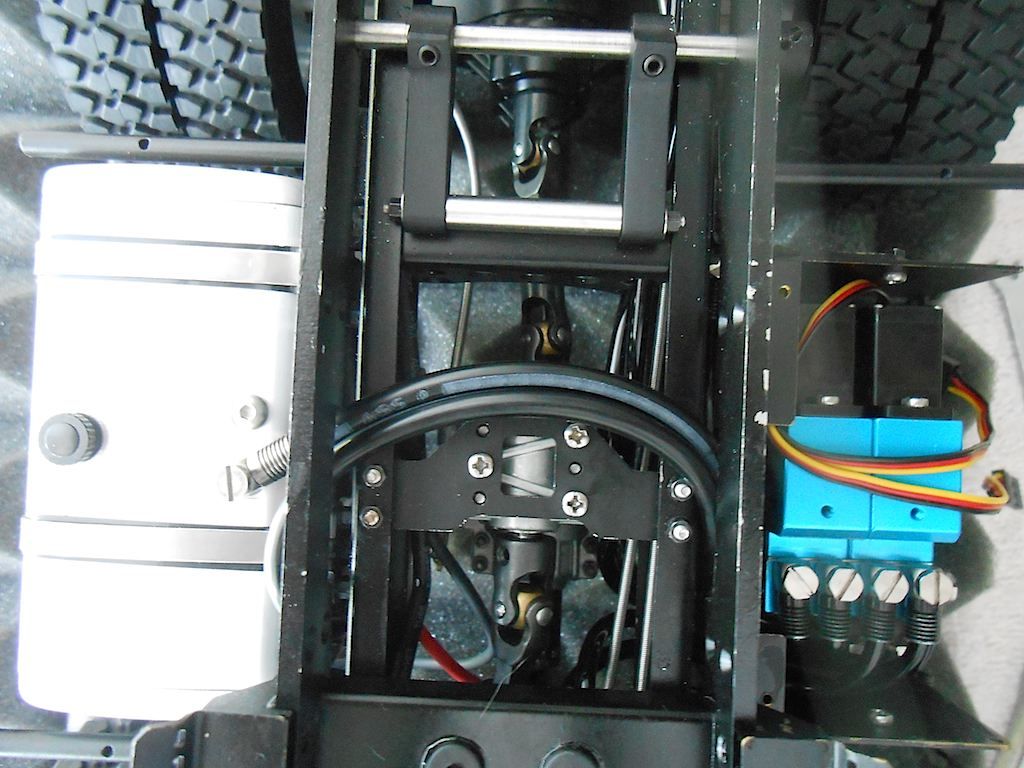

Prepped the 2 main cylinders. Basically cleaned them of the hydraulic oil that had seeped out.  Added the nipples  Added some hydraulic tubing so you can see what happens if not constrained in some way.   No problem when completely extended.  Anyway had to bolt the roll on / of part to the chassis. When I tried to take it off I ran into a problem ... one of the bolts holding it in the back sheared off  . A true WTF moment. Didn't figure I had tightened it that hard. When I took the bolts off on the other side, another one lost it's head . A true WTF moment. Didn't figure I had tightened it that hard. When I took the bolts off on the other side, another one lost it's head  . both of them were the ones at the back of the frame. . both of them were the ones at the back of the frame.  This is the part I'm talking about.  Here one of the pieces with the sheared of head. (the other bolt is temporary inserted. Is on the wrong side of the part)  Well, spend the rest of the day drilling out the rest of the screw. Stainless steel too. Took forever and broke 3 drill bits. Got both of them out, and luckily the parts are still useable.  No clue what happened. They were not cross threaded, but were jammed solid. Noticed when I removed the part that is was slightly bend where the bolts were. Should have tightened those 4 bolts evenly. Another lesson learned. Reinstalled the roll on/off assembly on the chassis and everything goes together smoothly. So basically no harm done apart from a couple of scratches made by the drill. But you can't see those anyway. Hopefully next session will be less stressful

__________________

Cheers, Stephan (Rakthi is the one in the avatar) |

|

#129

|

||||

|

||||

|

Had the reason for my little mishap explained by a person way more proficient in mechanical matters. When I screwed in the bolts, the last couple of turns were not smooth. Most probably this was caused by the black stuff or contamination on the threads. I had previously installed the Roll on / off stuff but never completely tightened the bolts. I should have stopped at once tightening the bolts and taken them back out. Then chase the threads with a tap or else put some copper grease on the bolts. Oh well water under the bridge.

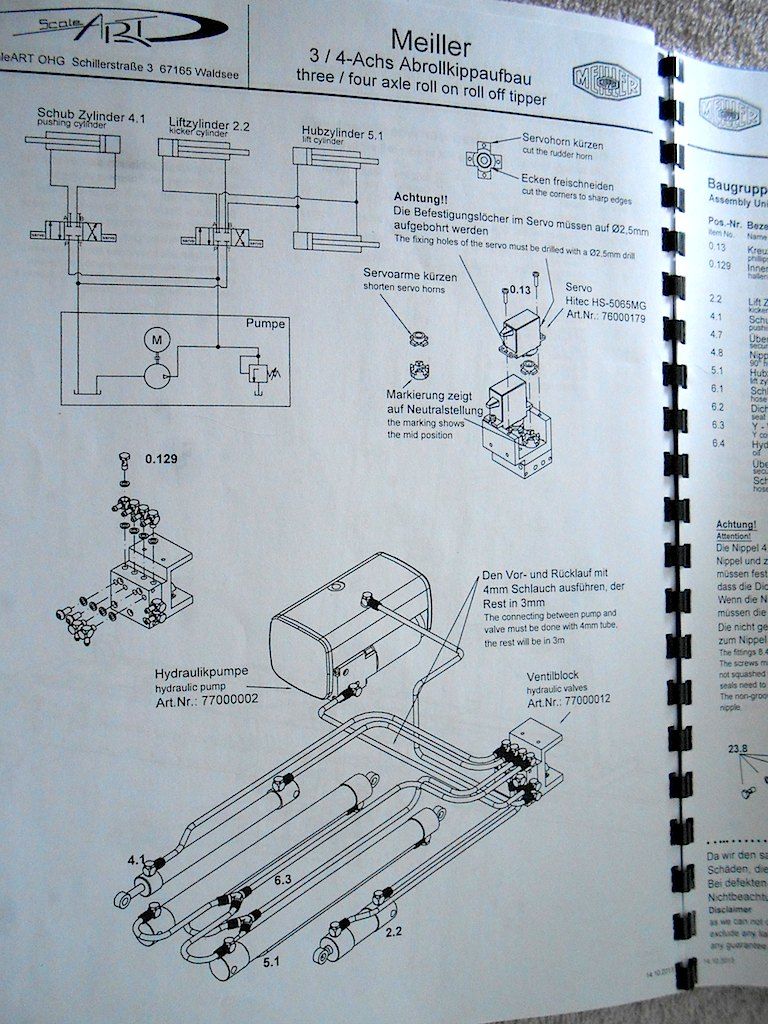

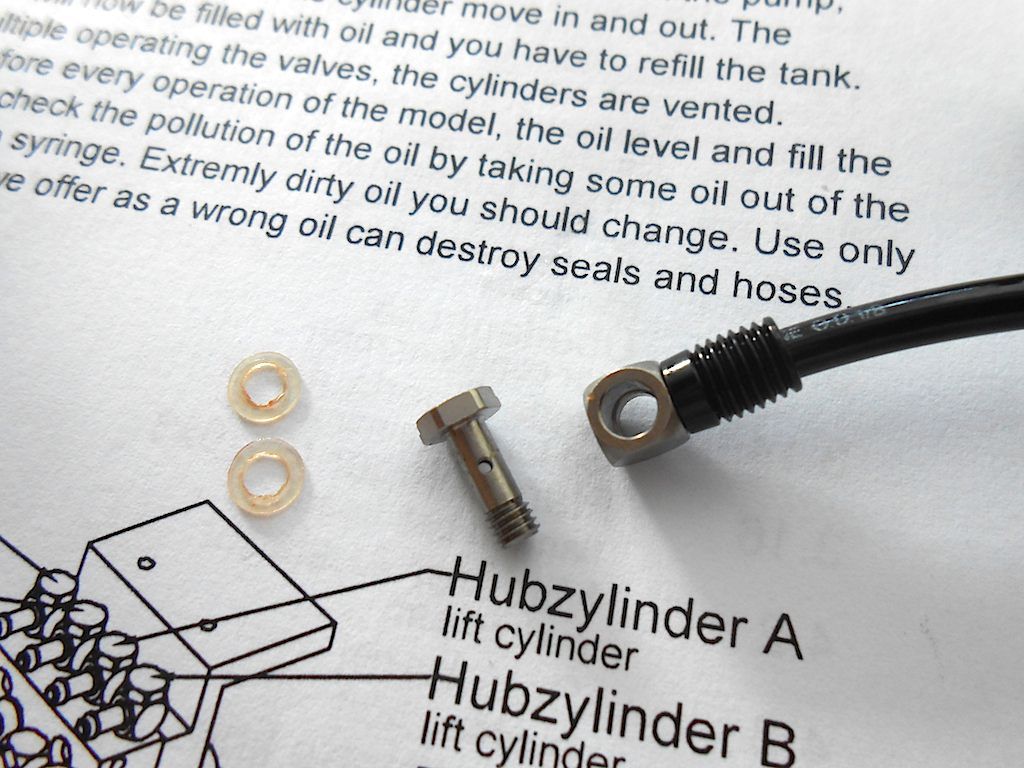

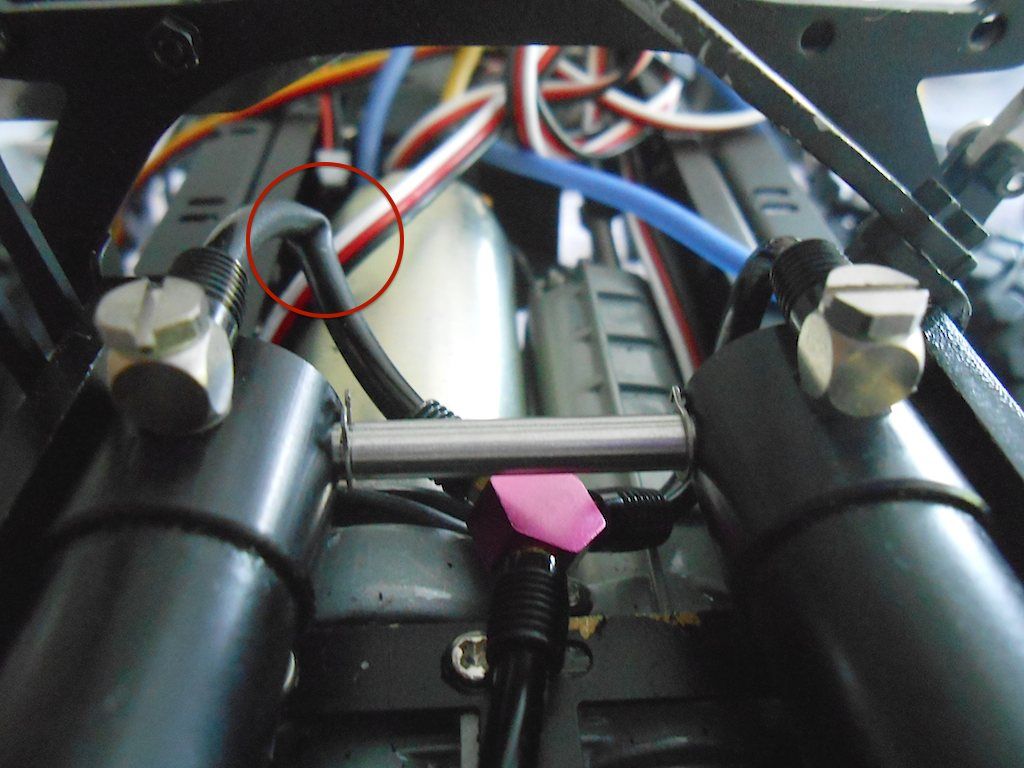

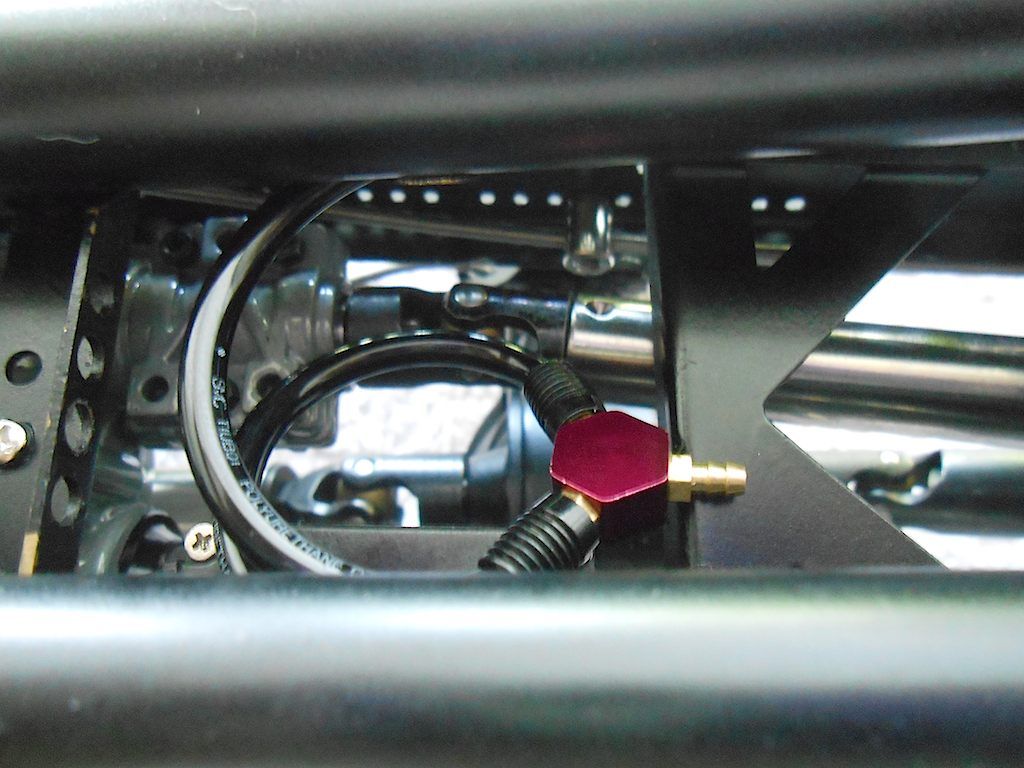

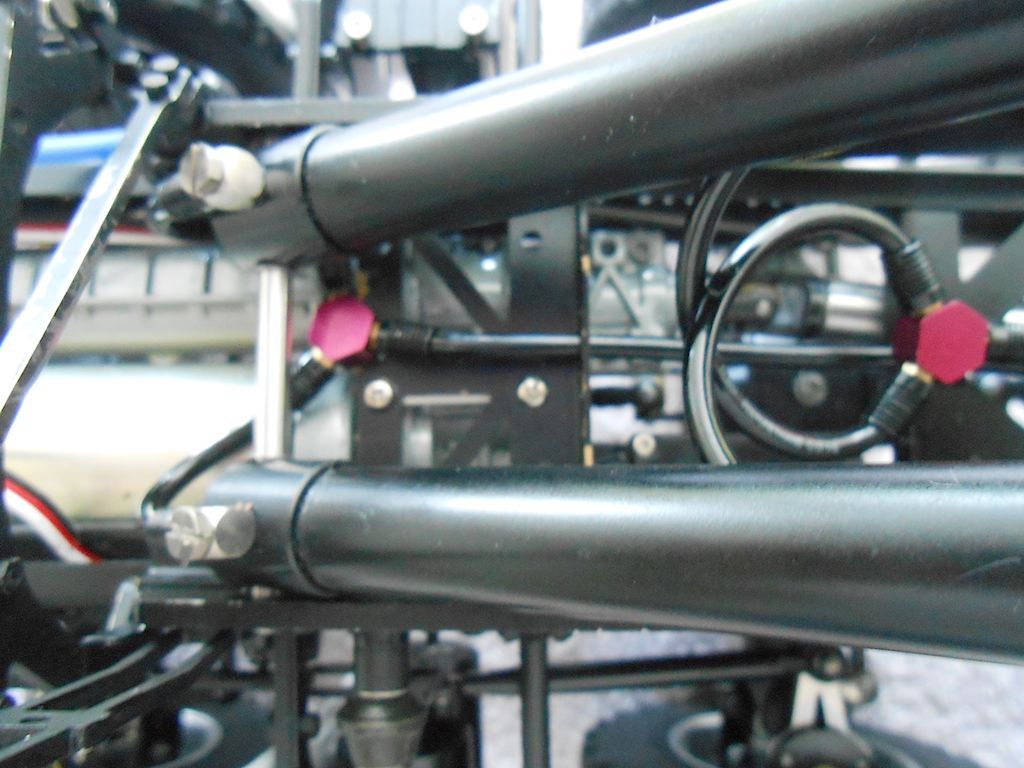

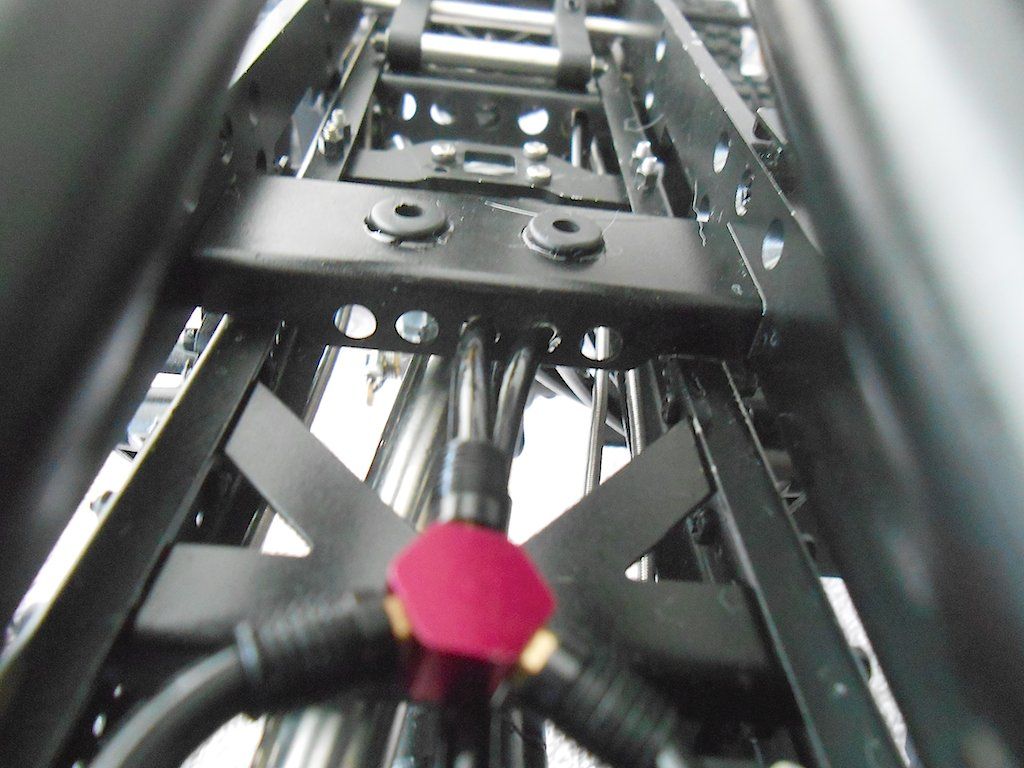

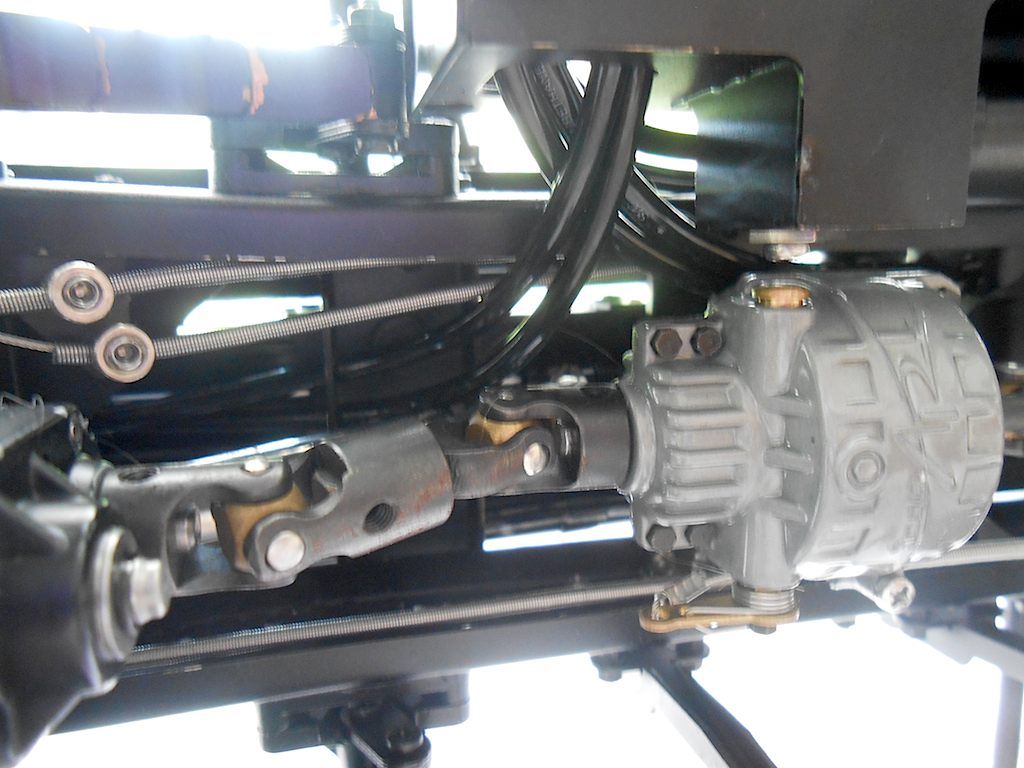

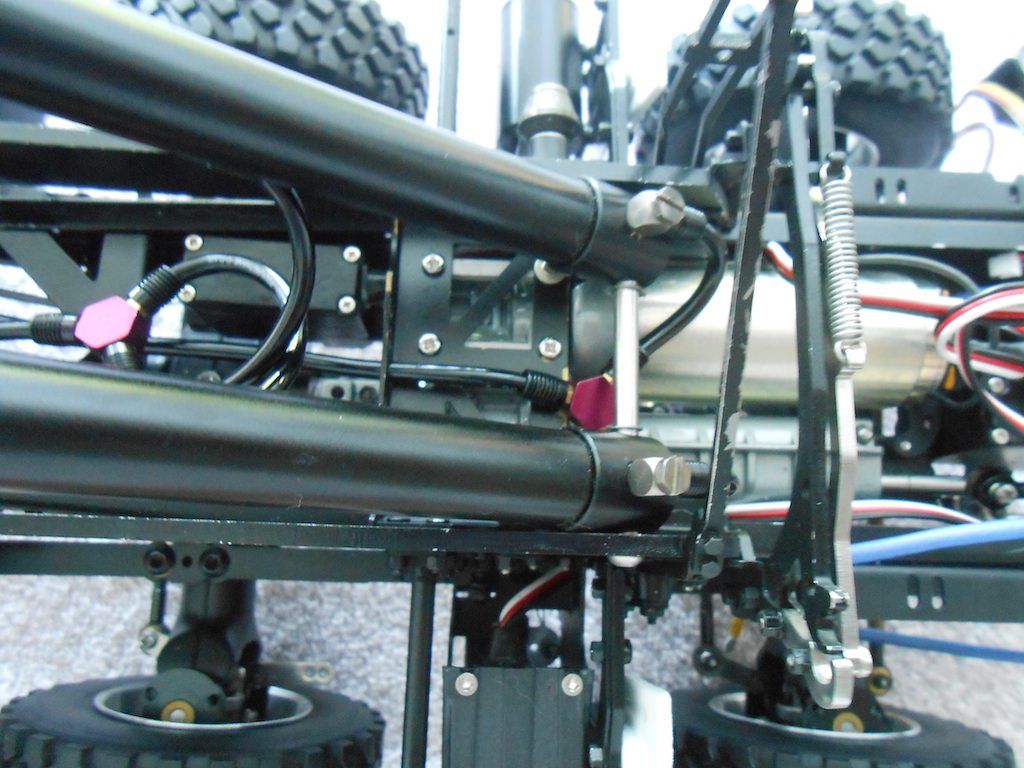

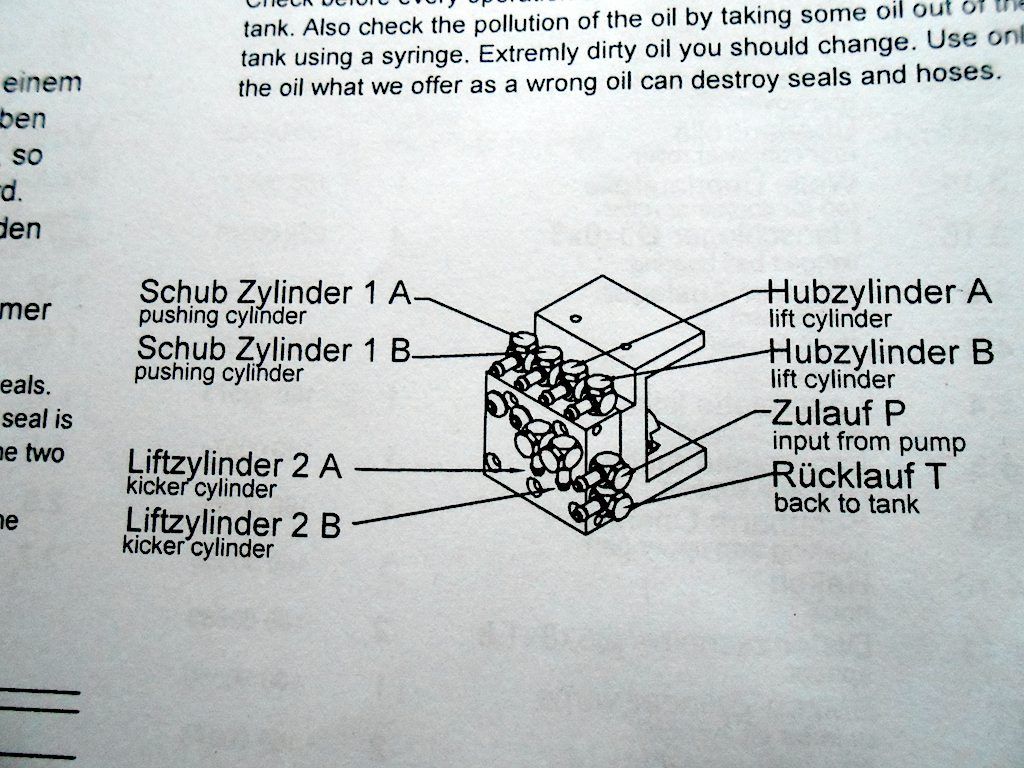

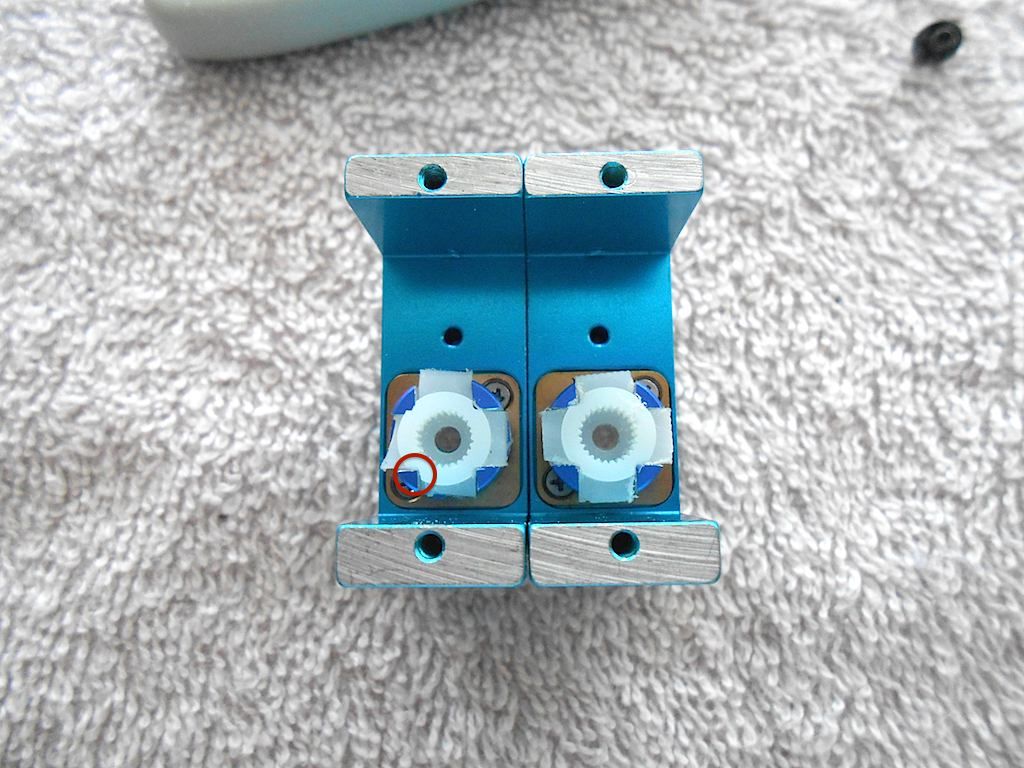

Before I continue here a picture of page in the manual. Makes it easier to follow this posting.  Spend yesterday evening messing with the placement of my holders and got it all kind of figured out. Glued them on last night and let them cure overnight. This is where I glued them. top one about 1 inch (2.5cm) from the top and the bottom one about 4.5 inch (11.5 cm) from the top.  The top one should have been further out. Had to unscrew the nipple to be able to attach the hydraulic hose. Which meant I had to replace the 2 seals also. (Plenty of spare ones supplied)  Both cylinders with hoses attached. I make a bit of an error ... the one on the op the hose should point inside. Had to redo that one later in the game. The hose comes rolled up and it does pay to work with the way it is curled. Following the manual, the small ones are 5 cm and the long ones about 17.5 cm.  Now time to fasten the cylinders to the frame and the rest of the mechanism. I had forgotten about those cir-clips.  Found a way to get them on without too much trouble. Got tweezers that fitted in the opening, and then just stuck in a flat screwdriver and slowly turned the blade opening the clip - did have a couple fly off though, but there are a spares.  Cylinders installed, and connected the short hoses. Immediately I got a knick  Bugger ... replaced it and same story. Ended up with a piece of only 4cm before it behaved itself. It is a pain getting the hoses and the holder on the nipple, but it is even harder getting the bleeding thing off again. Do hope I never have a hose failure. Bugger ... replaced it and same story. Ended up with a piece of only 4cm before it behaved itself. It is a pain getting the hoses and the holder on the nipple, but it is even harder getting the bleeding thing off again. Do hope I never have a hose failure. Here a view from the other side after finally (4 tries!) getting the bit of hose to stay in shape.  The longer hoses have to cross over to fit. Here is where the natural curve of the hose comes into play. By having one of the hoses bending the "wrong" way the whole thing got skewed.  Connector towards the valves of the short hoses and the longer one after replacement now giving a better curve and not trying to twist away when the cylinders go up.  and the long ones joined to the line for the valves.  The rear ones just cross over and run through the holes in the cross members of the frame towards the valves  Gets a bit busy at the transfer box. The hoses are far enough from the shaft. Only look close in the picture. Might run the 2 hoses coming from the main cylinder over the ones coming from the back though. (noticed I already have surface rust ... sub tropical climate and sea air takes it's toll!)  All end up here labelled and waiting to be hooked up to the valve body. Sill have to do the lines coming from the tank.   ScaleART delivers the truck with 2.5 meter of hydraulic hose. I had ordered an extra meter just for safety sake. That meter turned out to be 1.25 meter. After finishing this part I measured the left over hose and have about 1.30 meter left. I made some extra pieces so there is enough hose with the kit. Now nursing my sore fingertips. Getting those metal locks on the hoses sure takes its toll.  Next would be the oil tank and it's lines. According to the drawing they seem to indicate to run the pressure line underneath? Seems a tad weird because that way prone to getting stuck to things when in "rough" terrain. Stephan

__________________

Cheers, Stephan (Rakthi is the one in the avatar) Last edited by Rakthi; 07-11-2015 at 03:24 AM. |

|

#130

|

||||

|

||||

|

Short update. Am not really happy with the way the 2 short hydraulic hoses run. Just doesn't look right at all.

So had another look at it. Took that bit out. For some reason I have about 5 extra nipples so nothing was stopping me to do some little experimenting. I only tightened the nipples about 2 turns, so they could move freely and came to this result:  This looked much better and still sticks to the 5 cm ScaleART recommends as length for these pieces. I did try longer pieces of hose thinking to run them through the holes in the holder, but then the coupling connecting them pushes up the other hoses that then interfere with the hook sliding back and forth.  Final installation. Looks much better. Will have to clean up all those bit of loose paint I scraped while messing around and do some retouching. A small bit of double sided tape to hold the coupling in place might prevent further paint damage.  While I was at it took a picture of the back to show how the hoses run there.  That's it for today. My head is not really with it so I better leave it for now before I make another stupid mistake. Stephan

__________________

Cheers, Stephan (Rakthi is the one in the avatar) |

|

#131

|

||||

|

||||

|

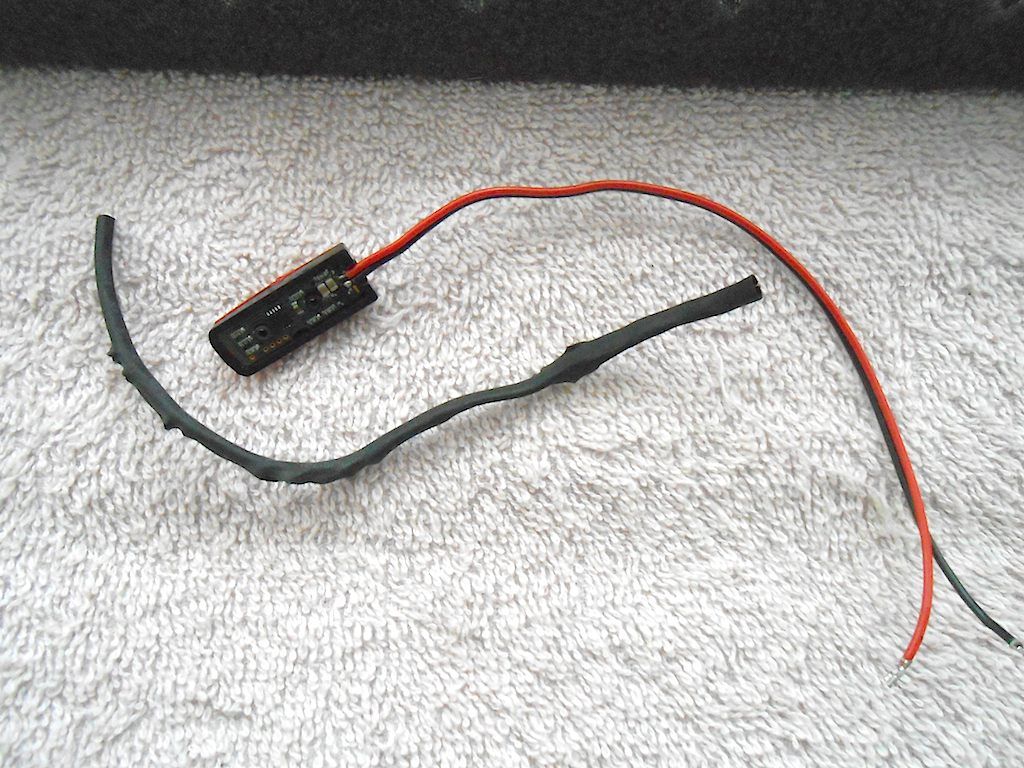

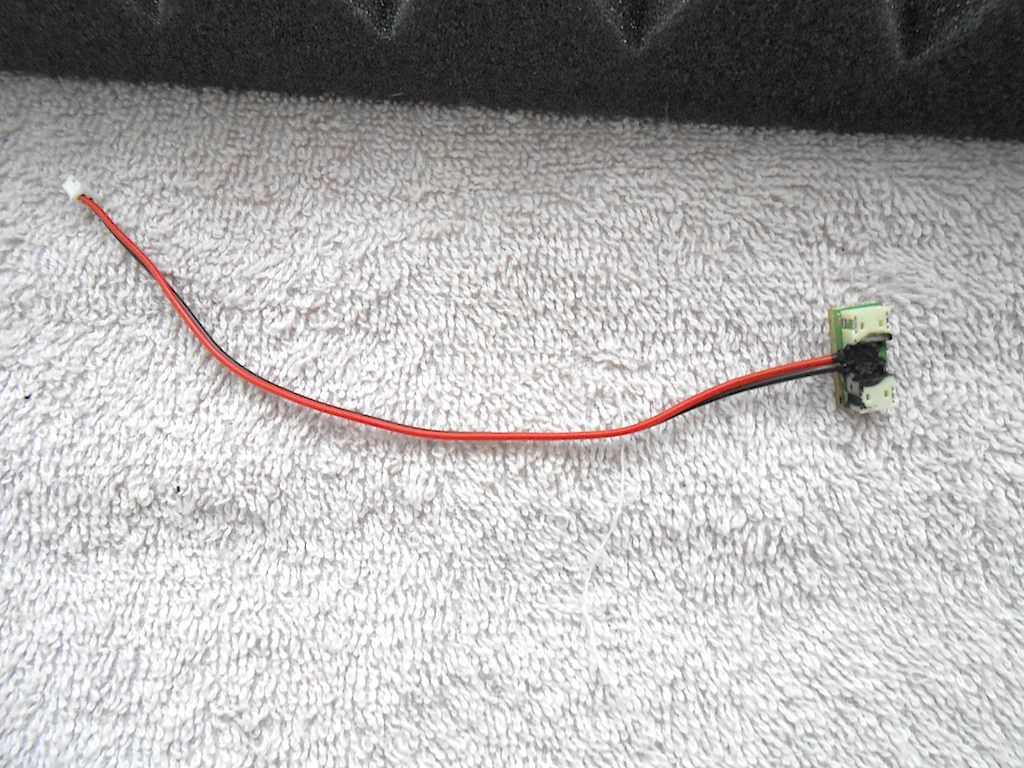

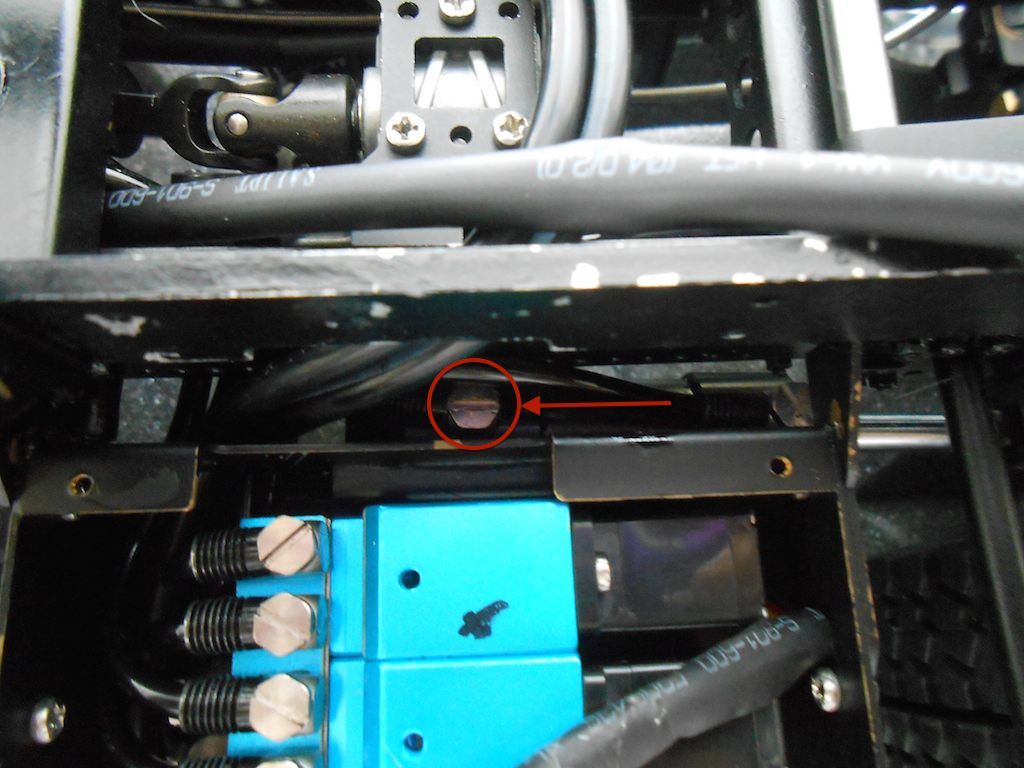

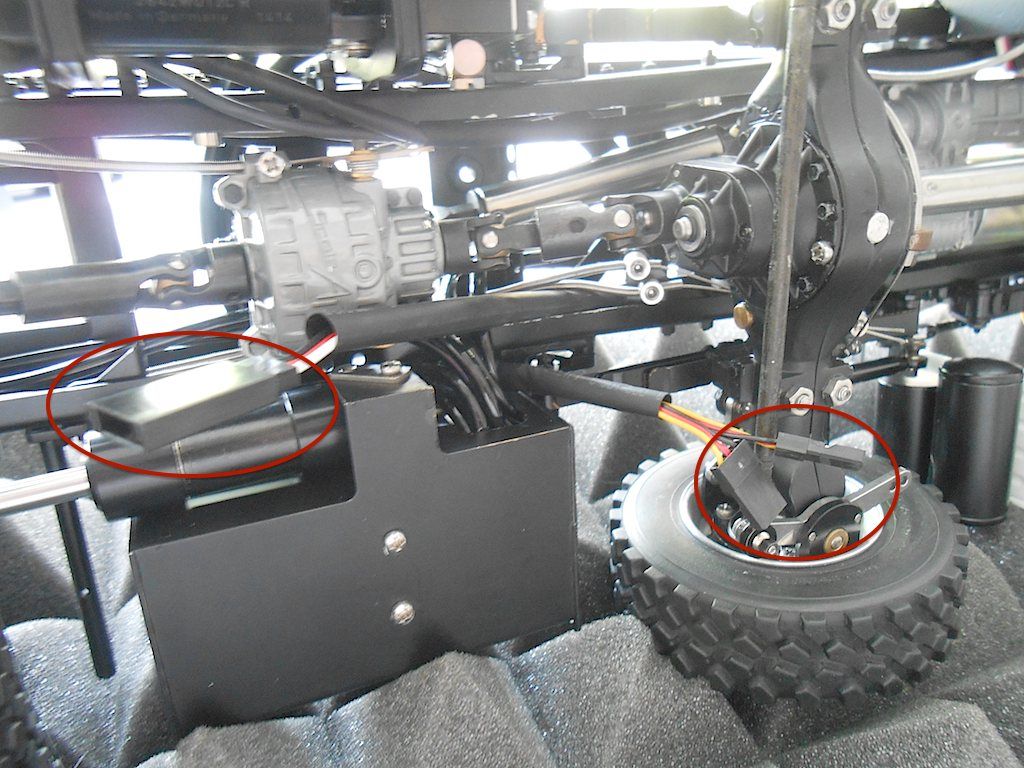

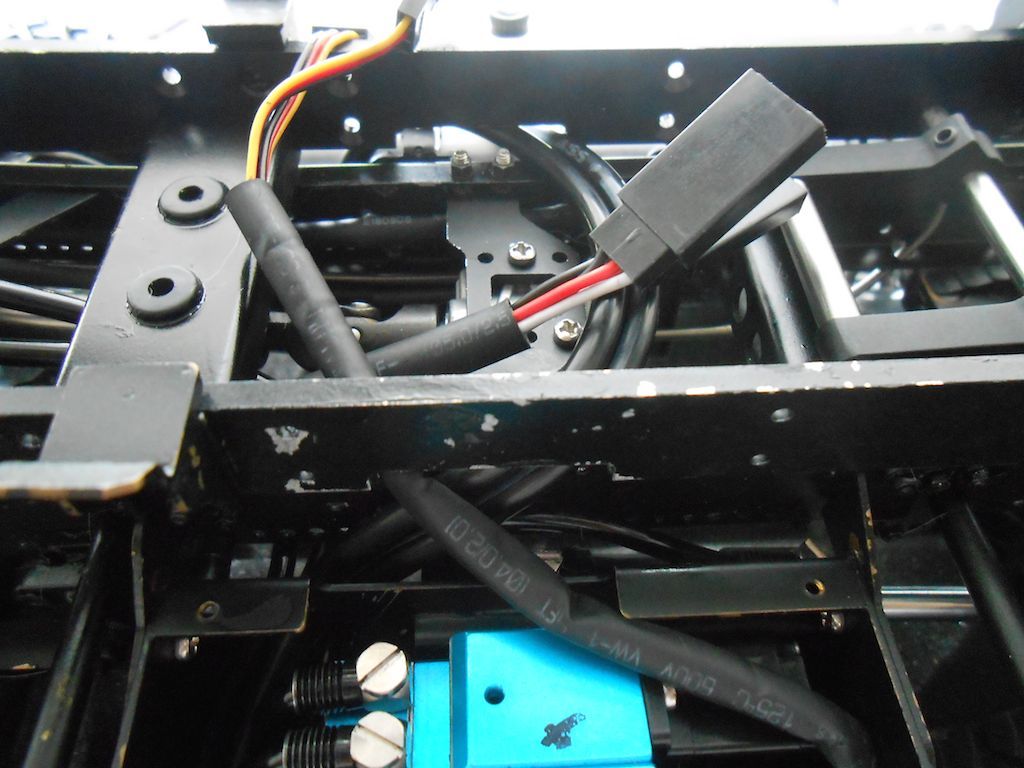

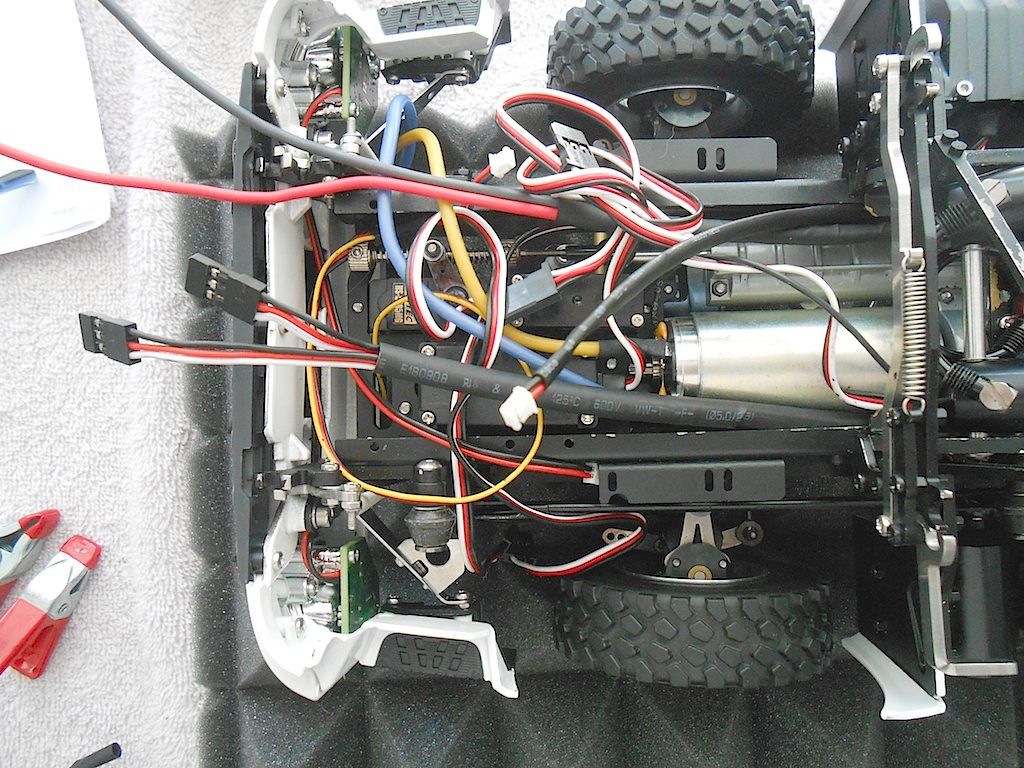

Good thing I took some time out. Realized that with the hook mechanism in place and hooked up to the valves, I will no longer be able to move it up or down until pump and electrics sorted out.

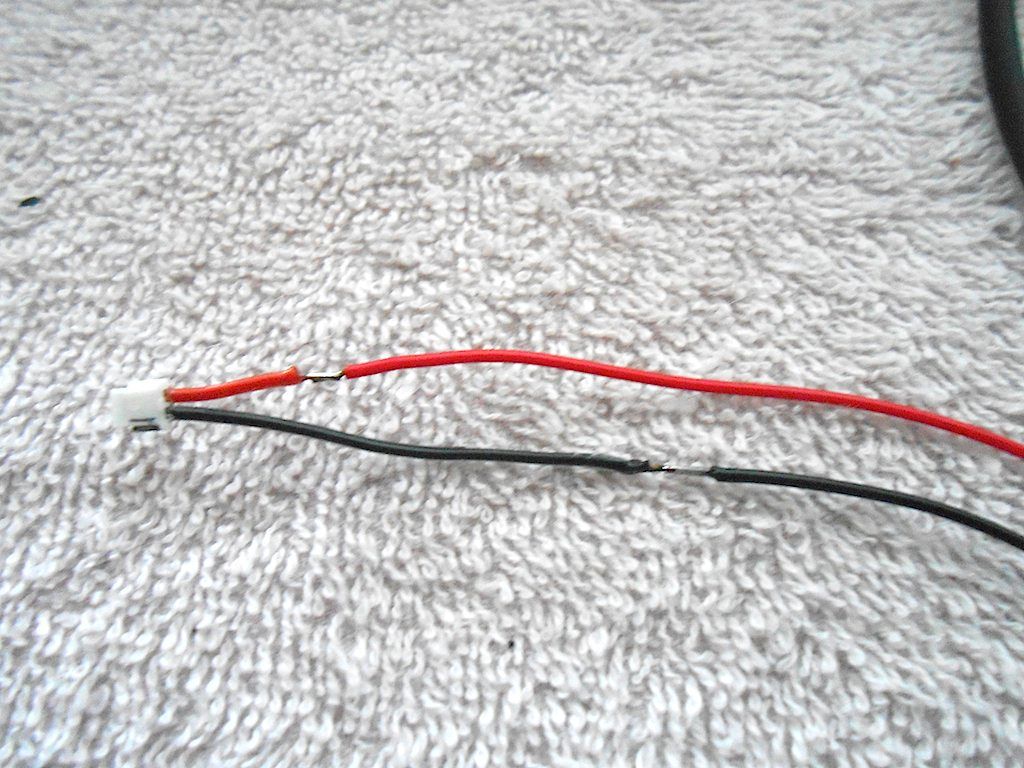

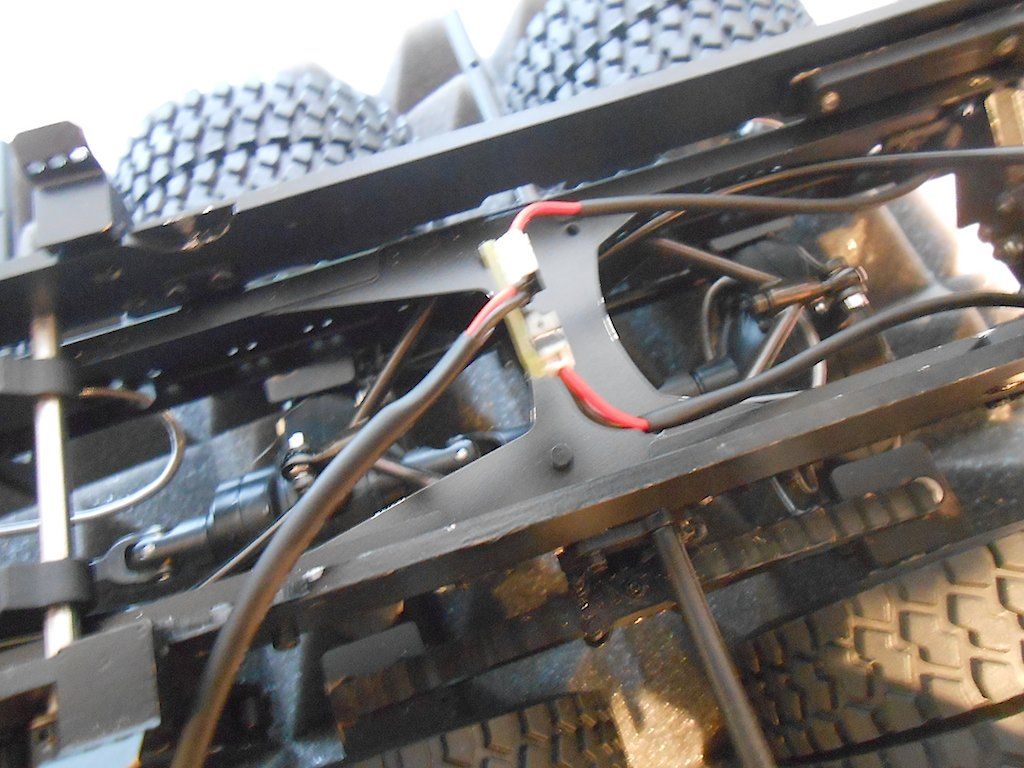

Then I would no longer be able to sort out the rear lights! So that is what I did today. Got the rear lights of  Removed the shrink tube  Covered the back with Liquid Tape and screwed it back on to the support with M2x5 self tapping screws I sourced on the bay. Followed my own advice and first put on the lights and then pulled the wire through the frame. The new shrink tubing is 3mm one. Could barely get the wires through so used some silicone grease on them. The tubing has not been shrunk so it's way more supple too.  Bus connector for the 2 rear lights.  Cable is too short to go al the way to the front. So extended it. Made sure the connections were spaced to avoid a thick area where the 2 unions are. Put some of the Liquid Tape on them before I pulled it through the shrink tube.  Lights plugged in. (only shrank the tube at beginning and end)  Bus connector installed inside the cross beam for now. Have to sort out a cover for it later. (Looks like all my wires and hoses are crossing one another)  Looked at installing the servo for the trailer coupling, but that will be a real pain in the neck without taking the hook stuff off. I'm just going to forget about that for now. Stephan

__________________

Cheers, Stephan (Rakthi is the one in the avatar) |

|

#132

|

||||

|

||||

|

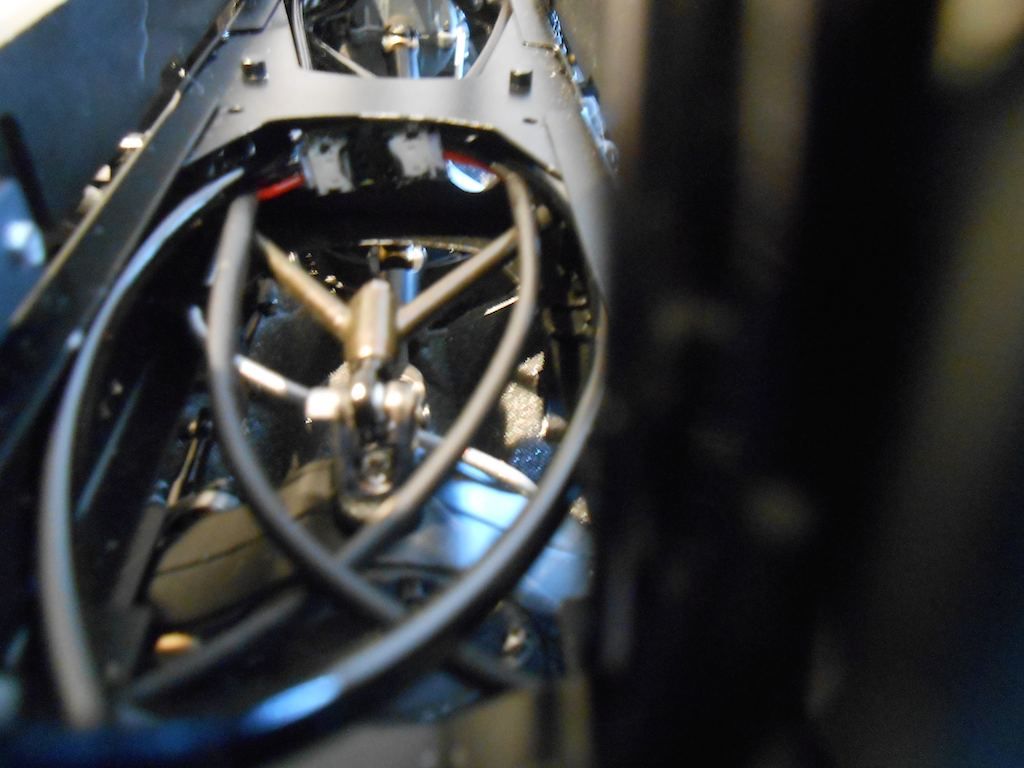

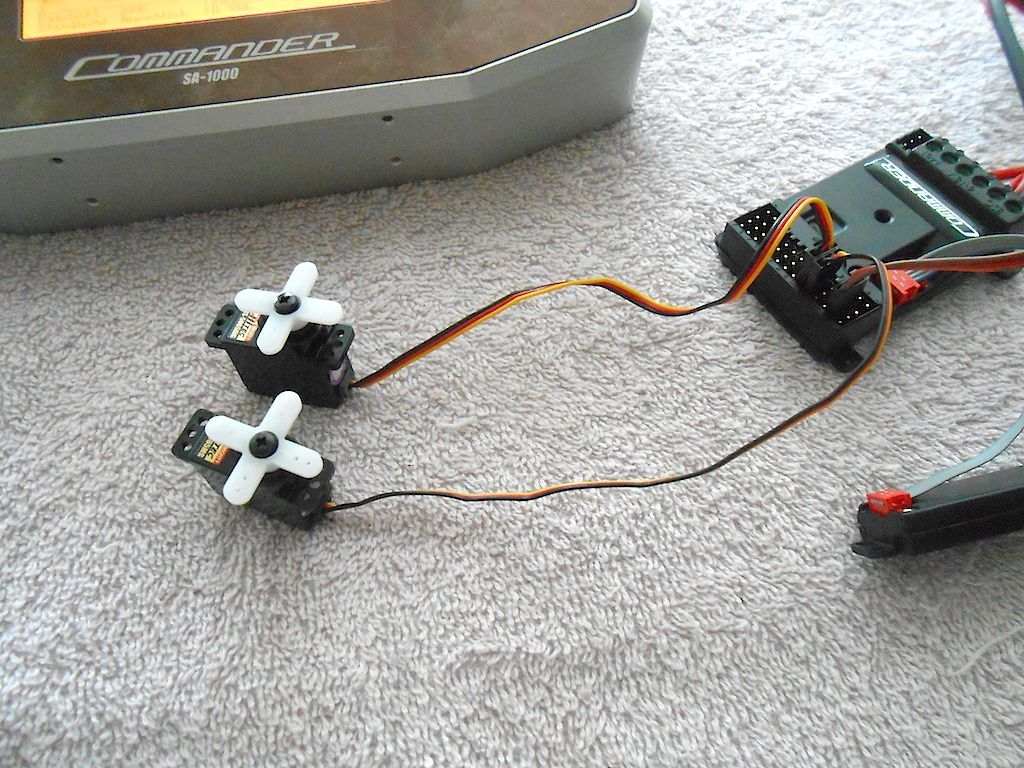

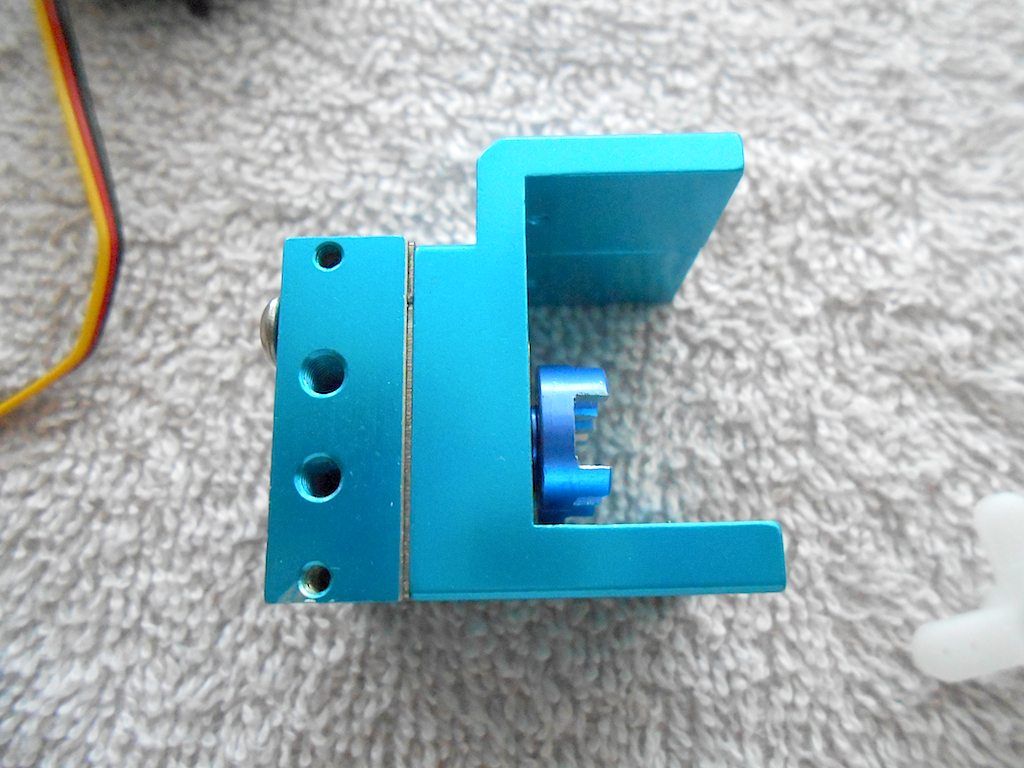

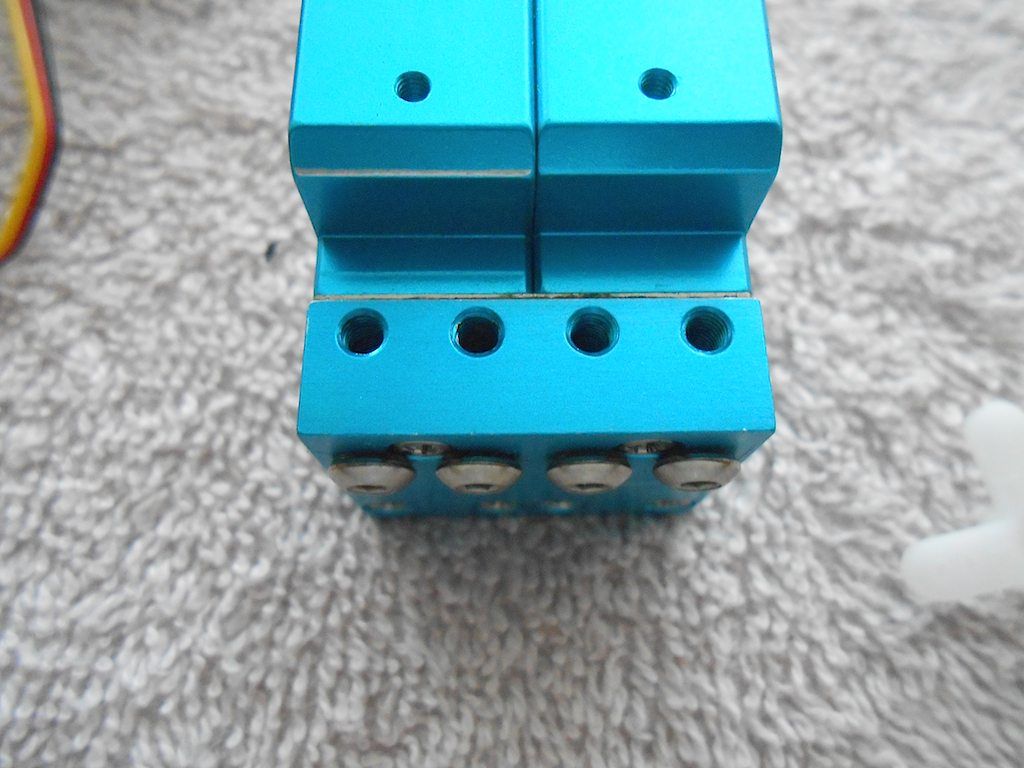

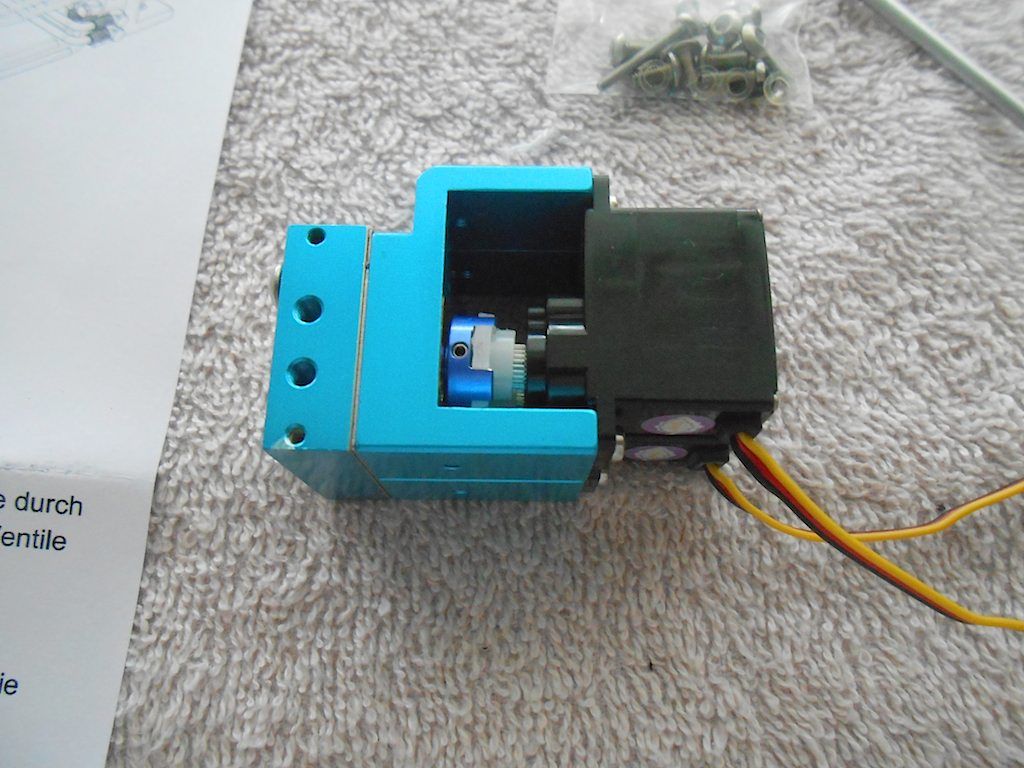

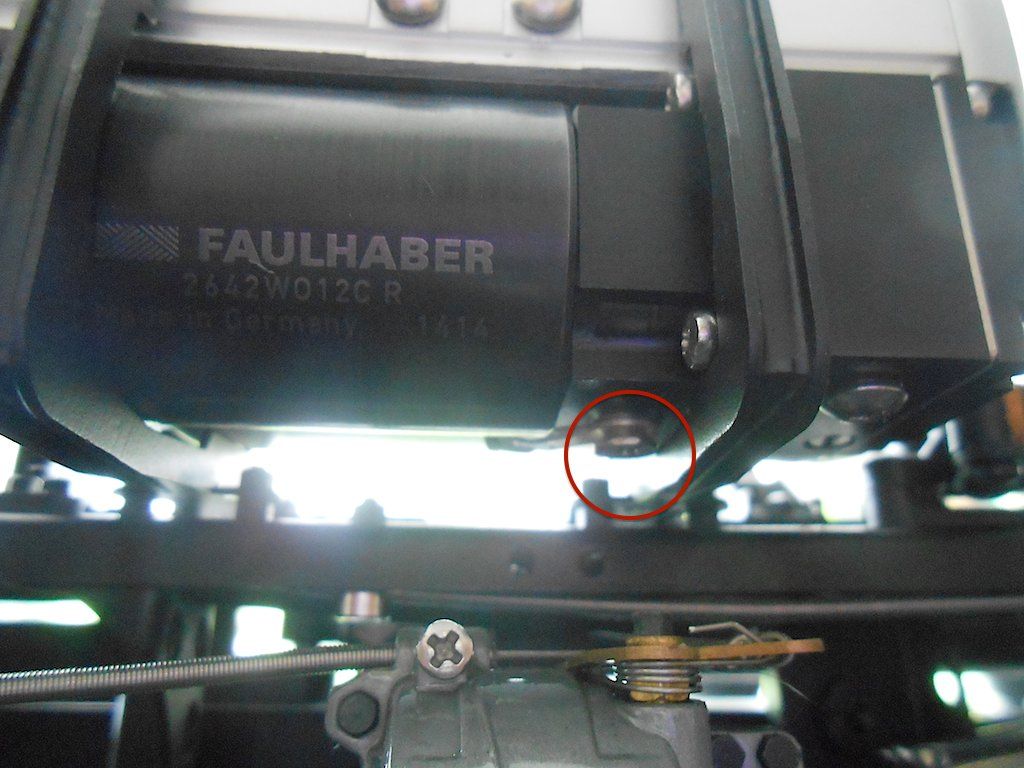

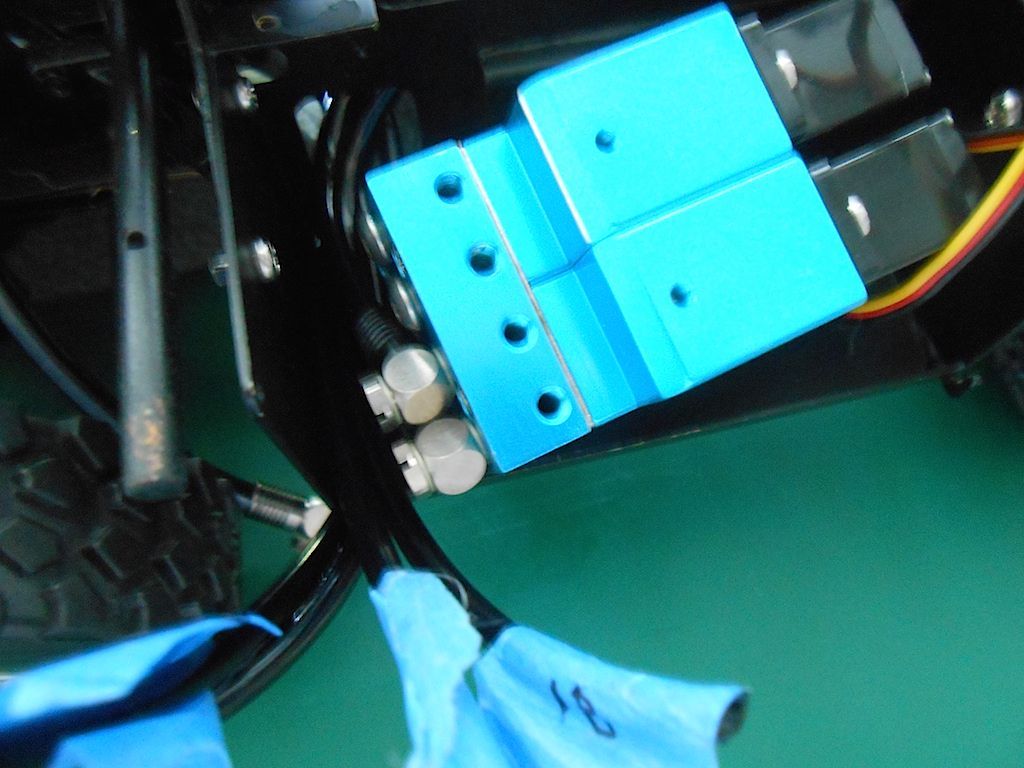

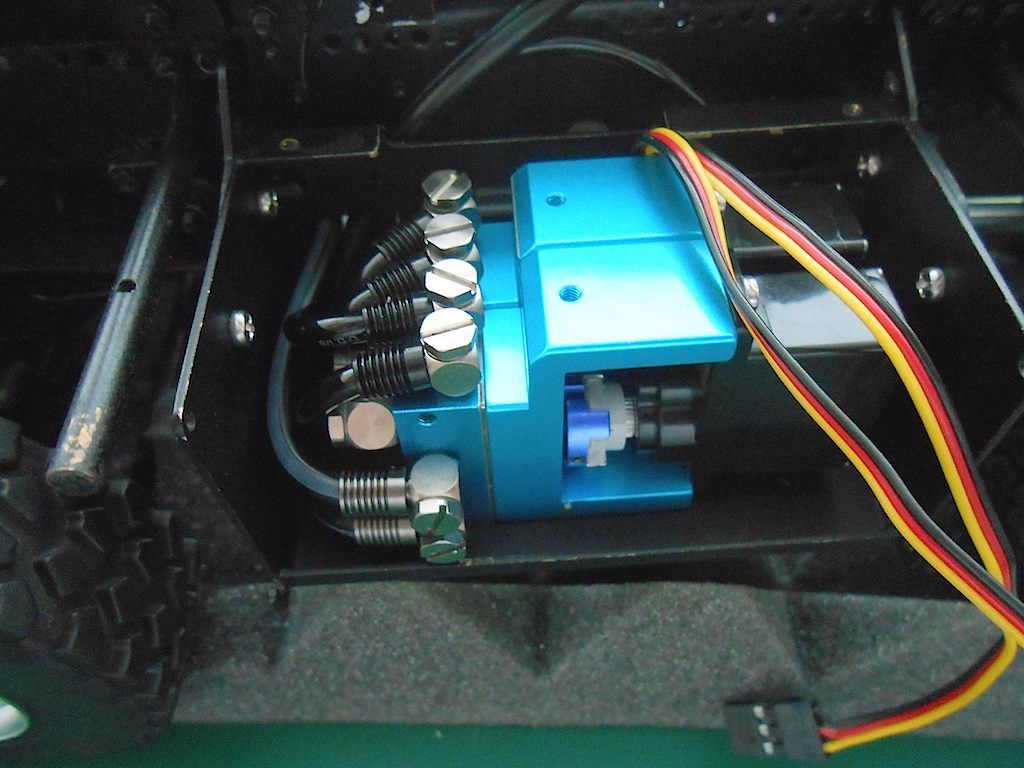

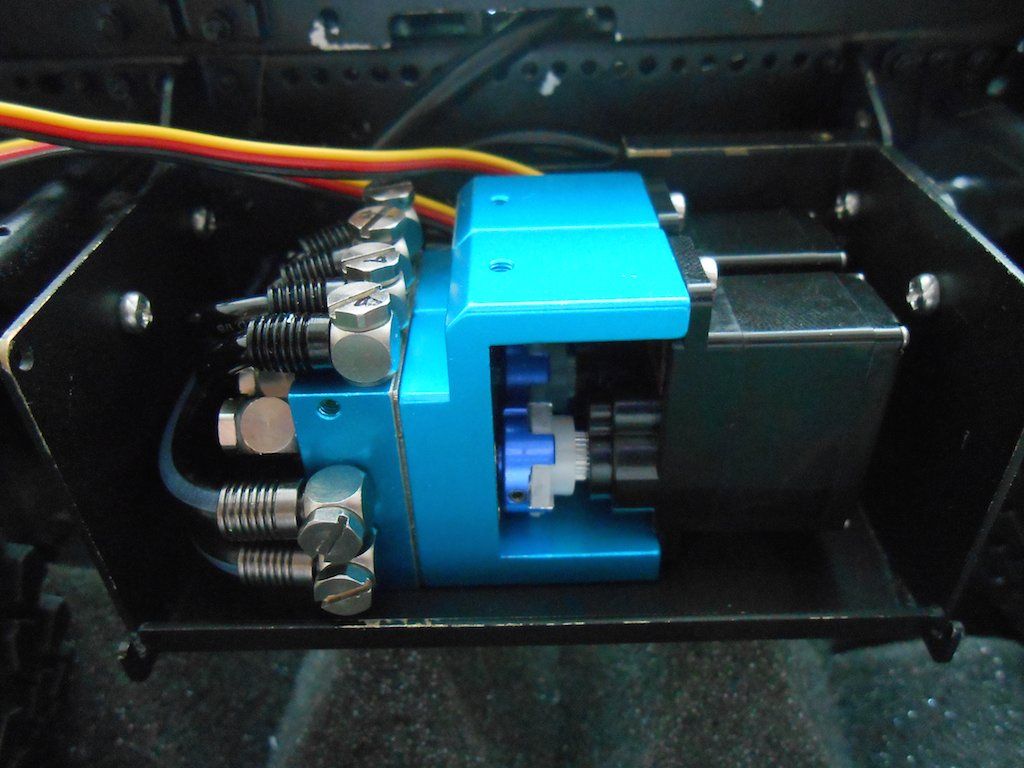

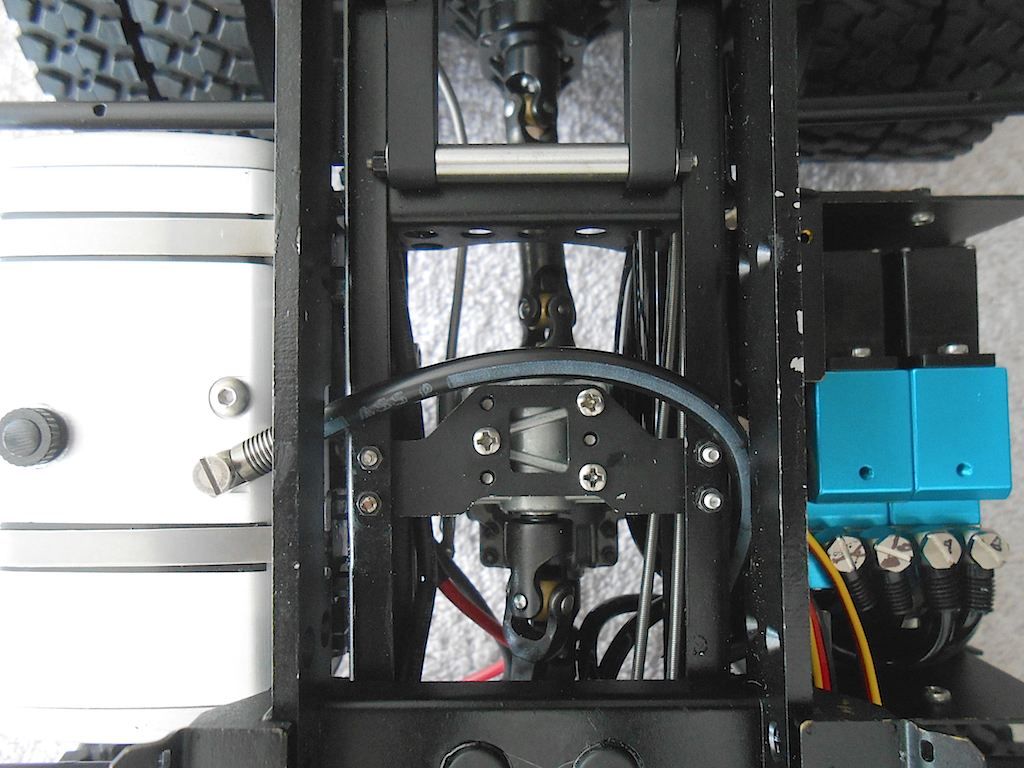

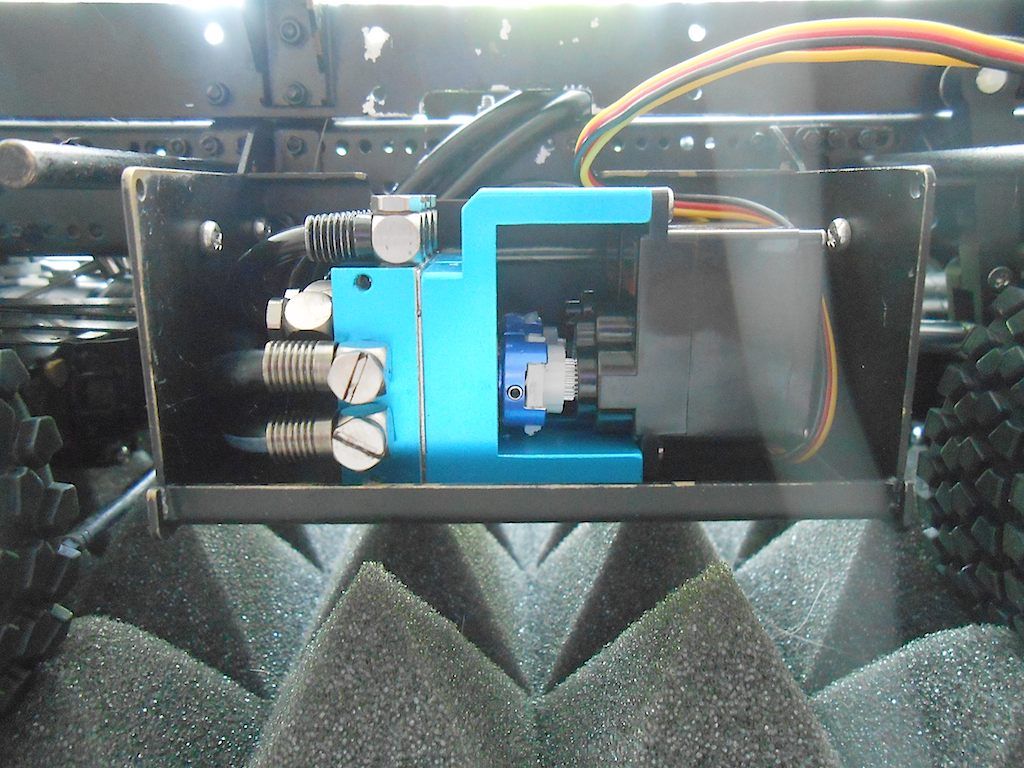

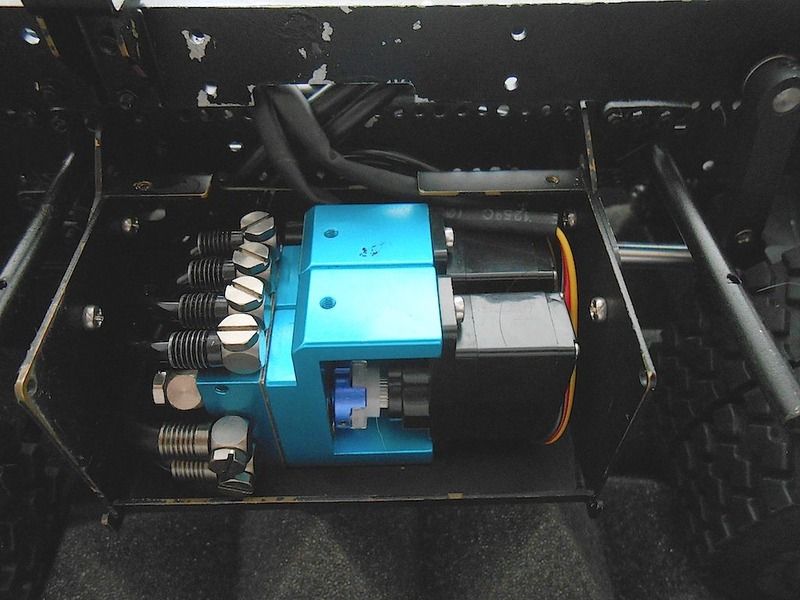

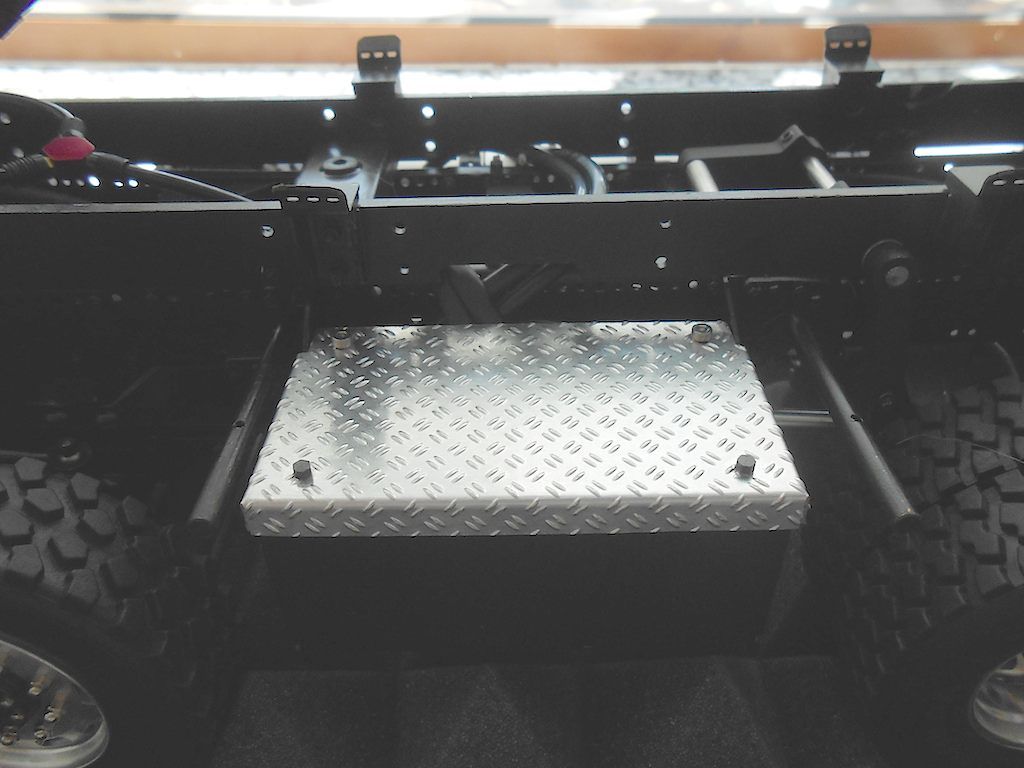

Started off with the servos for the valves.

They get controlled with these two knobs. The further left of right you turn, the wider the valve opens. I am sure they also control the pump through one of the mixer functions.  The valve body. The indent indicates the valve is in the middle potion (closed)  Side view  top view  Front view  What hose hooks up where  Servo horns cut and corners in plastic cut as per instructions. Pressed in place.  Servos attached.  Got some unwanted assistance from one of our cats  Test fitting tank so I can finish the hydraulics ...  And bummer ... I had to move that support didn't I ... the screw holding the earth wire of the motor interferes with the tank support forcing it too much towards the back so I will never be able to get the fender in place  Tried different solutions, didn't want to mess with the tank support so ended up filing the head of an M3 bolt down to almost nothing - lucky it is only to hold the earth wire - until it the tank fit in place. If I had left the support in place or moved it over one opening more towards the front this would not have been a issue.  Hopefully next update I will get around to fixing the tank in place and finishing the hydraulic connections - time permitting. Stephan

__________________

Cheers, Stephan (Rakthi is the one in the avatar) |

|

#133

|

||||

|

||||

|

Great update Stephen. I love this project and I am following it every day.

Great work !! Alan

__________________

To view links or images in signatures your post count must be 10 or greater. You currently have 0 posts. |

|

#134

|

||||

|

||||

|

Hi Alan, thank you for letting me know! Makes me happy to know you enjoy the updates! Too bad I haven't got the time for one today.

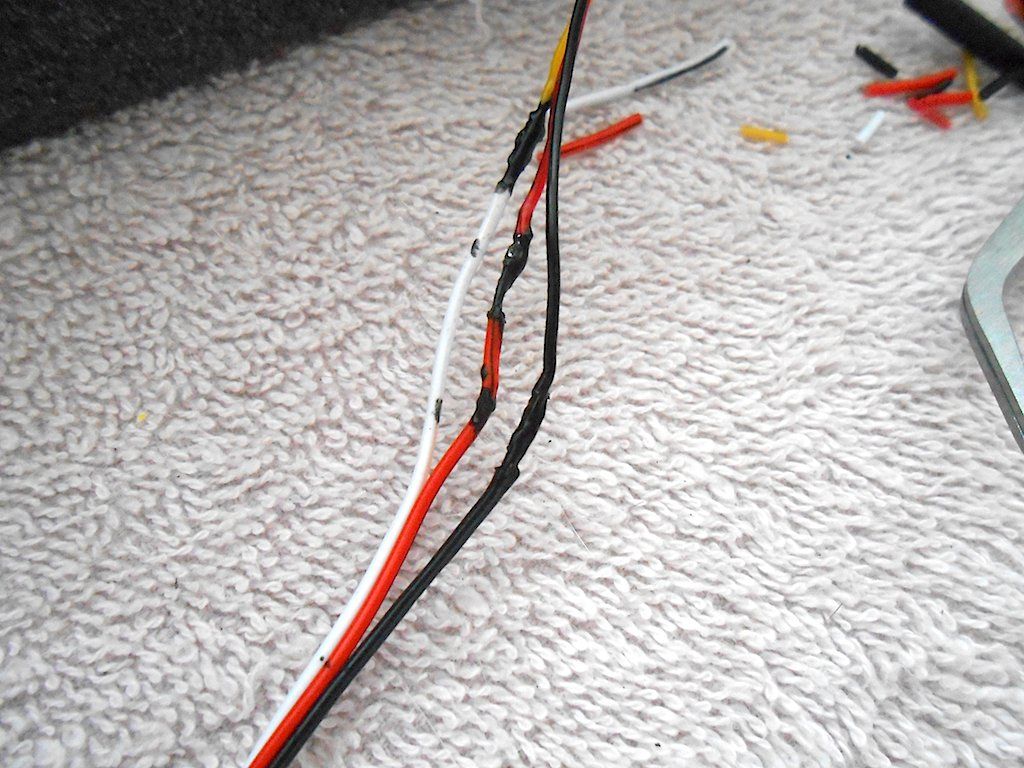

Have to fix the gate camera. Someone cut through the low voltage wiring.  A real bugger of a job repairing that thin cable. A real bugger of a job repairing that thin cable.Cheers! Stephan

__________________

Cheers, Stephan (Rakthi is the one in the avatar) |

|

#135

|

||||

|

||||

|

Holy cow what a LOT of small parts! This is going to be really cool when you get it running!

Jim |

|

#136

|

||||

|

||||

|

Hi Jim, indeed lots of parts that need assembling. Wish I had the room to place it and the time to learn how to use the equipment to make my own parts like you did.

Stephan

__________________

Cheers, Stephan (Rakthi is the one in the avatar) |

|

#137

|

||||

|

||||

|

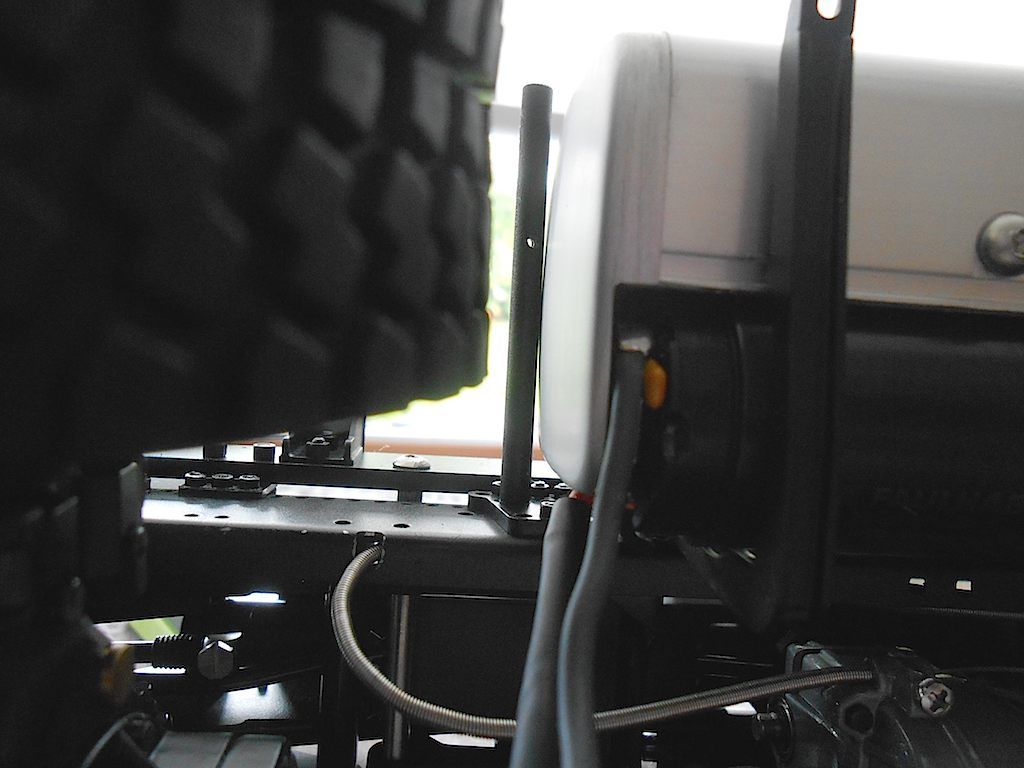

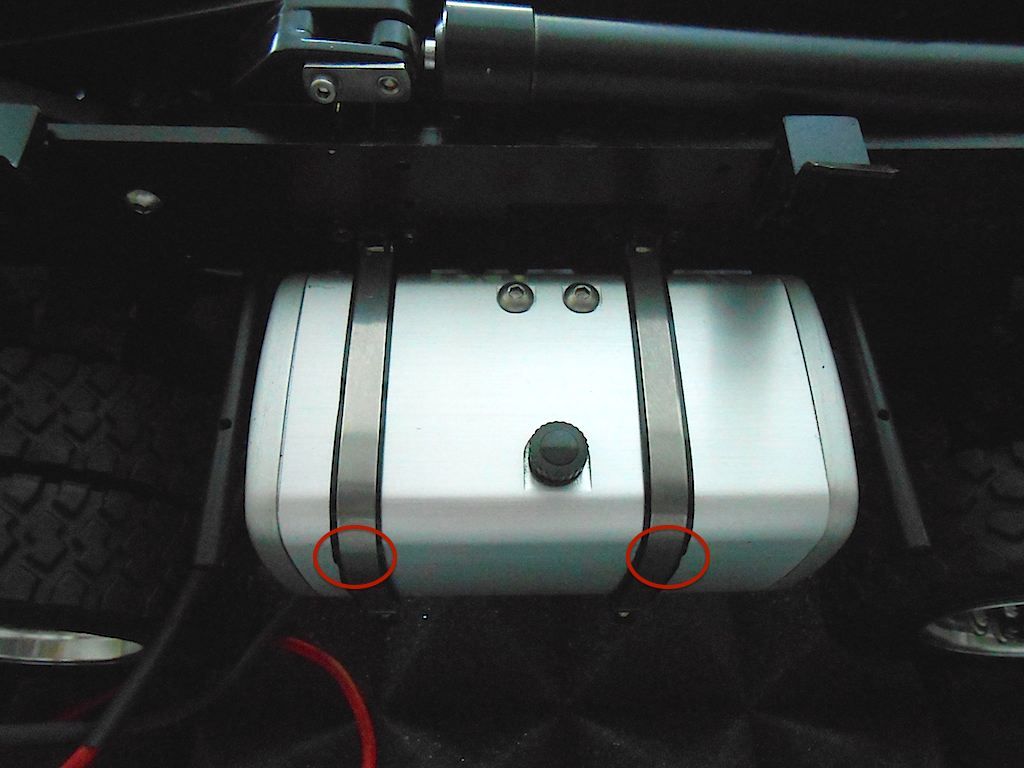

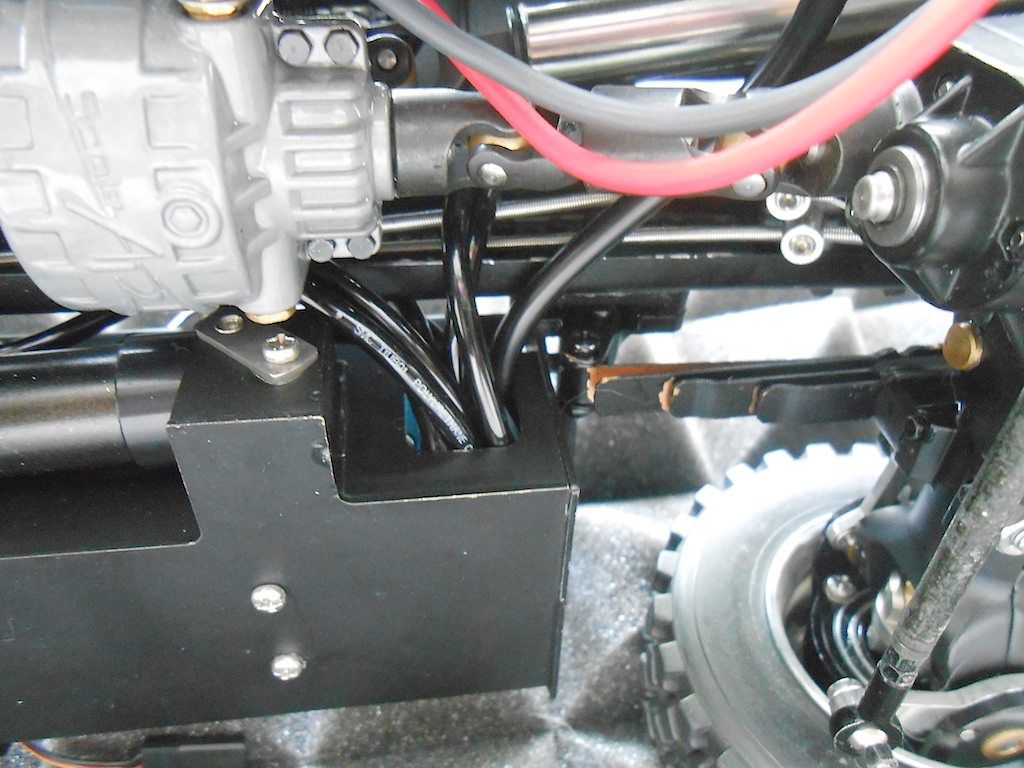

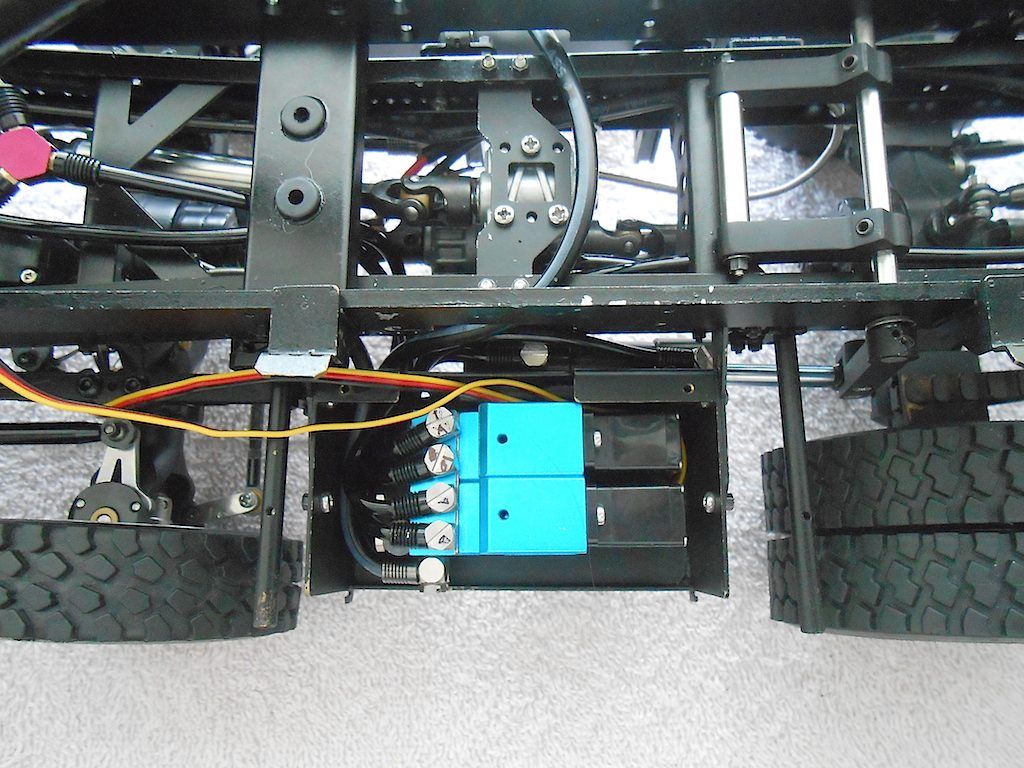

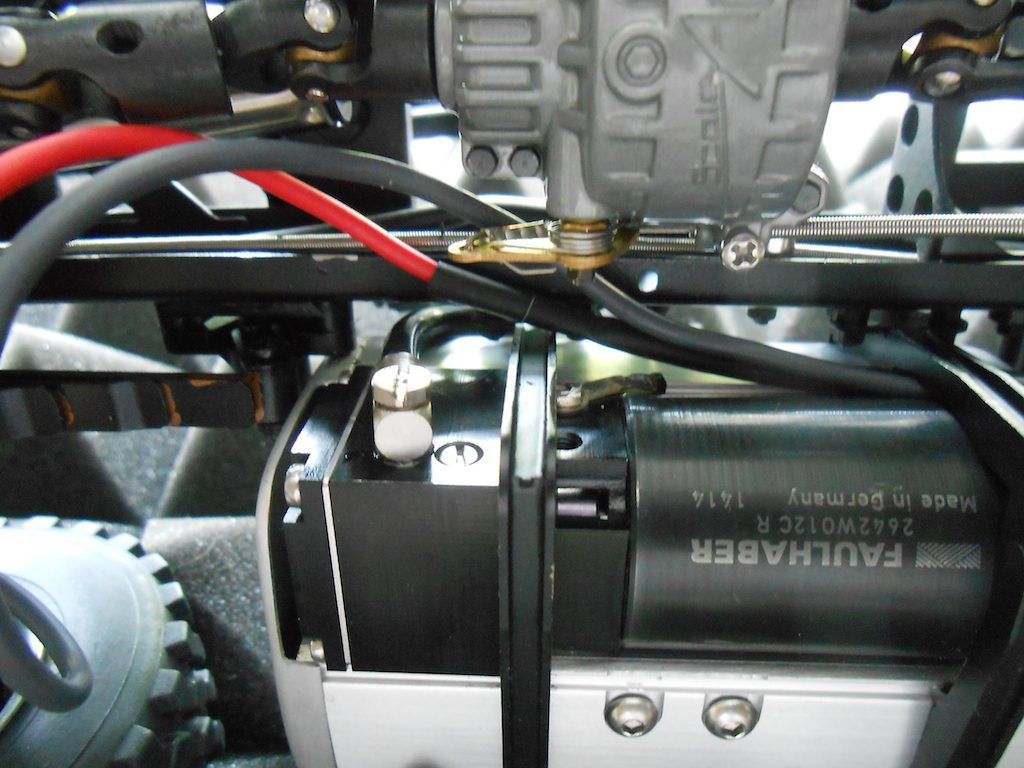

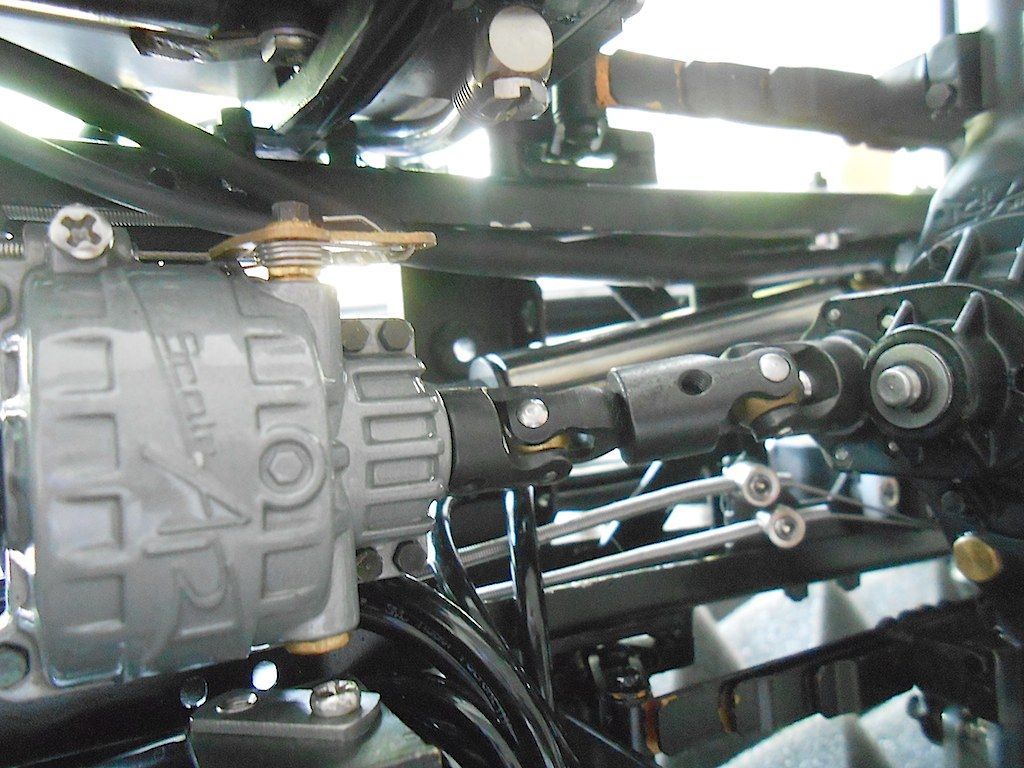

Before I can finish the hydraulics. I need to sort out the oil tank/pump part.

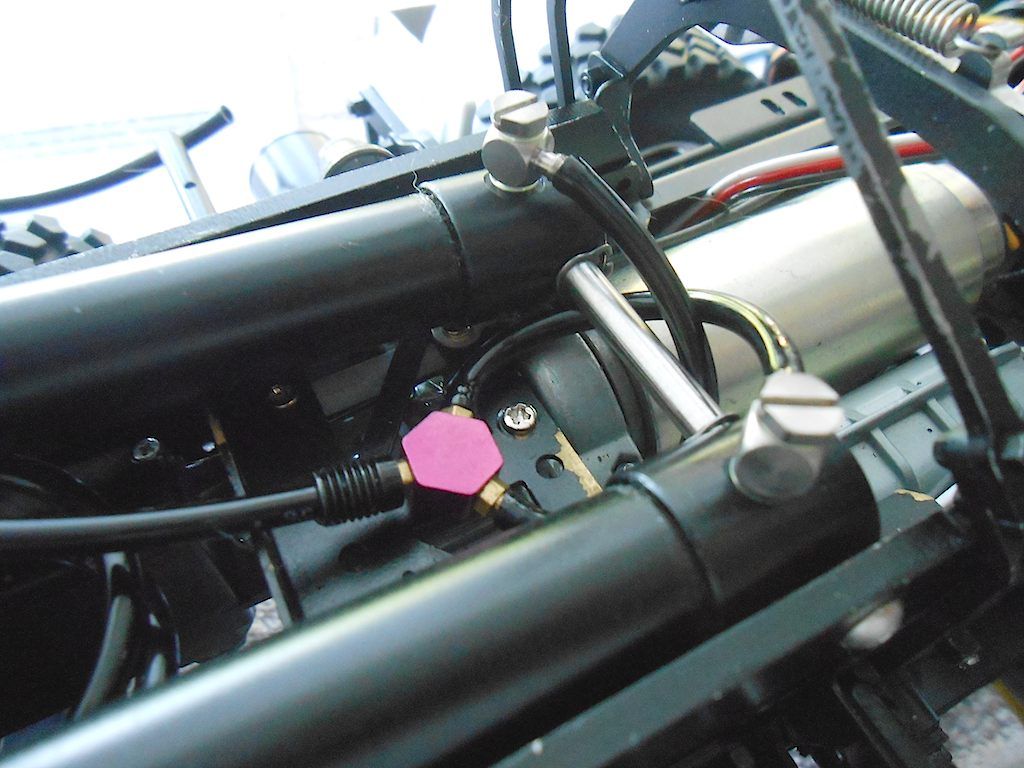

First the straps that hold it to the frame. After removing the bit of shrink tubing that protects the threads, you can see that some of the solder has contaminated them  Lucky I had an M2 thread cutter. So a couple of minutes later  As seen on other people's threads, the tank straps are having black rubber underneath. I could use some rubber from an old bike tire, but scaled up from 1/14.5 to 1.1 that bit of rubber would be way to thick. Ended up glueing two pieces of PVC film to one another and cutting some strips and gluing them to the straps with super glue.  Installed the tank. The PVC - stainless and Super Glue didn't work. PVC film buckled. Something to deal with later.  After trying different paths for the hose to go from pump to valve body ended up with this. Looks close to both props hafts, but plenty of room really. Very hard to get a picture of it. And those 4mm clamps that go on the nipple are absolutely impossible to get on. Used a 4.5 mm wrench as aid. (As seen in one of Newcomer_2's threads)  After sorting how to run both 4mm hoses. Have to connect the 2 hoses from the small kicker cylinder.  Then attach the 2 4mm hoses, and the rest of the connections. A bit of a job all this. Not really much room the work in. Found it was easier to get the nipples on the hoses and then attach to the valve block. The 4 nipples on top are not tightened yet to allow me to move the hook mechanism up and down. In the picture you can see one 3mm hose underneath the 4mm one at the chassis. I'll get back to that one ...   After this tightened up de straps of the oil pump after cutting 2 new strips from the PVC film. This time I just shoved it under the straps before tightening them. Works fine.  The electrical wires from the motor fitted just in between the curvature of the motor and the tank holder  View of the back side of the Valve box  That brings us back to the hose I mentioned before ... Good thing I checked, as it turned out that I had swapped the 2 hoses. So had to take the whole thing out again and move those 2 from place. Of course they had to be the ones I installed first. Anyway about 15 minutes later... much better.  And since I was at it, here the pictures of the return line I forgot to take   Now I have to figure out how to run the electrical wires to the front and sort it out on that end. This might take me some time. Stephan

__________________

Cheers, Stephan (Rakthi is the one in the avatar) |

|

#138

|

||||

|

||||

|

I'm loving this build. Thanks for the update..

__________________

To view links or images in signatures your post count must be 10 or greater. You currently have 0 posts. |

|

#139

|

||||

|

||||

|

Hi Al, you're in luck .. didn't think I would have the time today to work on the truck.

Well, spend yesterday evening a couple of house googling images of roll on/roll off kipper, abrollkipper, haak kipper and whatever language variation I came across. All this to see how other people run their hydraulic line from the pump. Not much to be found though. Found 2 who ran underneath and 2 who went up and over. So guess what ... decided to do the whole connection to the valve block again. I had left some of the lines too long being worried of getting them too short. New direction pressure line  Top view  Side view  In the course of redoing the connections, I had seen that the hose from the small cylinder tucked away behind the valve box had a kink in it. I feared I would have to take the whole lot off, but succeeded in removing the nipple, and replace the hose without unbolting anything else. Just enough room to go in from the top. Getting the nipple back on after replacing the hose was a true "zen" experience.  Shoved the + and - wire of the pump in a shrink hose and ran it to the front.  Since the servo wires are way to short, decided to see if I could fit an extension wire so it would be easier to make a repair at a later date. Inserted a 6mm shrink tube in-between frame and motor and behind the rear diff servo. This would allow me to pull 2 extensions through after removing the plugs. Couldn't get it to work in a decent way. The bowden cables from the rear diff locks and their servo are hampering anything on the chassis beam there.  So tried to go the other way ... also didn't work. The connector is just too big.  So soldered it together staggered to prevent the big clump when they are all soldered in the same place. This way don't have to worry too much about them shorting on each other either.  Still add some of the liquid rubber since I have it anyway.  Wires from servos fixed and valve box ready to be closed.   Sorted (also retouched the paint a bit)  All electrics are now in front, so next is my least favourite part of this build: the electronics and wiring, although I can still do the fenders first  Almost forgot, I have put the side under run protections in such a safe place I can't remember where I put them.  Cheers, Stephan

__________________

Cheers, Stephan (Rakthi is the one in the avatar) |

|

#140

|

||||

|

||||

|

Here a pic of what needs sorting ... actually is not THAT bad (I hope) but those cables from the cabin have to somehow join here. (Already happy I paid the extra for the Bus system, saves a lot of wiring!)

Stephan

__________________

Cheers, Stephan (Rakthi is the one in the avatar) |

|

| Tags |

| 8x8, arocs, scaleart |

| Currently Active Users Viewing This Thread: 1 (0 members and 1 guests) | |

|

|