|

|

|

|

#1

|

||||

|

||||

Steve , how long did it take to mill the worm gear ? will you have the boom ready for january ? I'm on the push to get the pan running for cabin fever Steve , how long did it take to mill the worm gear ? will you have the boom ready for january ? I'm on the push to get the pan running for cabin fever IHSteve

__________________

RIP FreddyGearDrive 2-12-59/12-19-11 To view links or images in signatures your post count must be 10 or greater. You currently have 0 posts. |

|

#2

|

||||

|

||||

|

Tom, the graphics are a tool path simulation before actually turning on the spindle so I can check to see if there's any weird moves I've screwed up on while programming.

Steve, I bought the gear. I just wanted to dress it up to look like the 1:1 version. But that took 2hrs to do.Look at the picture in a previous post. I'm just trying to get moving on the boom. Soo much more design to do then get real good at silver soldering  I think I have all the metal needed now but I'll have to get about 200' of cable to reeve it up but before that's done I have to remove the "A" frame and machine the holes for the sheaves up there. It would be a miracle if the boom is finished. |

|

#3

|

||||

|

||||

|

Steve , in that 2 hrs , how much tool time and how much program time ? If the fund don't come in time then I'll be making everything for the hydros cept hose , fittings and seals . hydros put me back last year but not now with a mill in the shop even if it's a toy it still makes life easier . I looked at some of those booms on stripmine

I can see that taking some time and a few more grays on the chin I can see that taking some time and a few more grays on the chin  IHSteve

__________________

RIP FreddyGearDrive 2-12-59/12-19-11 To view links or images in signatures your post count must be 10 or greater. You currently have 0 posts. |

|

#4

|

||||

|

||||

|

The program only took about 5min but getting in the old mill didn't work. I was trying to rotate the pie shape on the mill but it didn't work. Long story. After a couple trips back and forth to the computer I figured it out. Now that I think of it maybe 3hrs in all

I took small cuts because I didn't have a good hold on the gear and if it got ######up I would be out some $$$ If it was held better I could hog that out in an hour. The 6 plates took about 50min. I took small cuts because I didn't have a good hold on the gear and if it got ######up I would be out some $$$ If it was held better I could hog that out in an hour. The 6 plates took about 50min.

|

|

#5

|

||||

|

||||

|

That is some beautiful work Steve, I can only dream of doing that kind of stuff.

__________________

Joe |

|

#6

|

|||

|

|||

|

Wow, that wheel looks so much better when milled, guess you have to run the machine without any superstructure on it. when milling in brass, how much do take in each pass?

Guess that with the time spent in machine, it would be max 1/16. Will it be milled all way? I have a RF35 milling machine, do you know of any good and cheap conversions for CNC. Guess that most CAD program can export right format to the CNC. When I draw for laser cutting most companies want DXF files. my hat of, Steve, looking forward for progress. Dan |

|

#7

|

||||

|

||||

|

Quote:

|

|

#8

|

|||

|

|||

|

Steve, what I ment was it´s a shame to cover all this beautiful machinery covered up with sheet metal. You have put so much work into it so it has to be seen. Maybee a removable roof?

Here´s a pic from HCEA2008 It must have taken lot of hour milling out those sides  is it same type of control on the drums as this old model but with r/c servos?

|

|

#9

|

||||

|

||||

|

Oh, I'm going to cover only half of the machine-The cab side. Yes I'll leave some of the roof open and the left side and I'll have lighting inside. I still need to make the big supports for the walking bearings that go into the roof and I have to make the curved roof trusses. The 3 motors are controlled with 100VDC regenerative drives similar to the 1:1 but solid state. The rc part was a real learning experience. When I have all that 100% I'll show more detail on that. I'm still on the trial and error method

I'll have to post some of my progress from this past weekend on the boom. I'll have to post some of my progress from this past weekend on the boom.I would love to have that stiff leg derrick toy that guy had at the show. I forgot to take some pictures of it like you did. |

|

#10

|

||||

|

||||

|

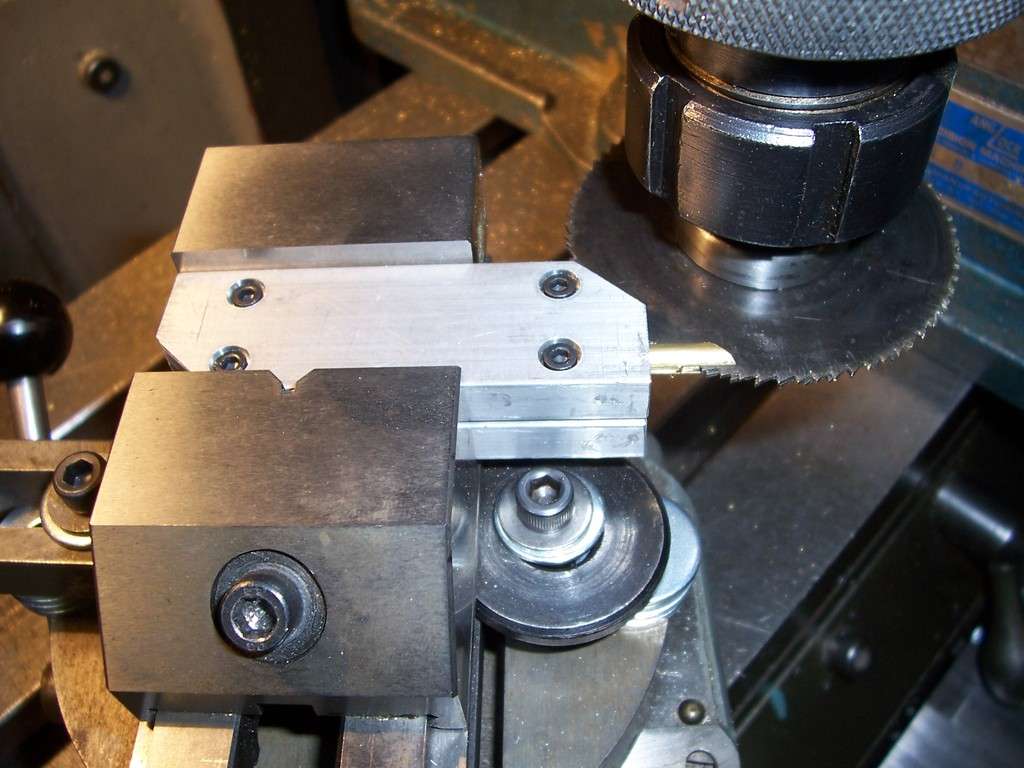

Here's some progress on the boom.

Fixture for side of first section.   This is the first piece of tube cut and notched of hundreds    Checking for fit.

|

|

#11

|

||||

|

||||

|

Looking good Steve!

Great idea on the fixture to make it.

__________________

Scott "No load is too Small" |

|

#12

|

|||

|

|||

|

Steve-I cannot even imagine how long that is going to take but you will be rewarded. It should look "outta this world"!!

|

|

#13

|

|||

|

|||

|

Steve-you may already have a plan for your silver soldering but I thought I would mention this. I had a lot of problems soldering joints close to each other. The heat would melt the joints loose. If you are soldering both inside & outside of the boom this may be a problem. I found this stuff after I had finished my project but it looks like it will do this job. It is called "cool blue" heat paste and it seems pretty amazing. They have some videos of it being used and you might want to check it out. It is pricey but you can re-use it many times. Here is a link-

http://www.muggyweld.com/hpclip1.html |

|

#14

|

||||

|

||||

|

great work! very inspiring!

thanks for sharing, Kerst |

|

#15

|

||||

|

||||

|

Thanks Kerst..

Tom, I've heard of heat blocking putty. I think we tried that 25yrs ago but we never needed it for our work but like you said; It may come in handy for the intricate work on the boom. I have a tiny jewelers torch if my resistance soldering setup doesn't work. I hope with the resistance machine it will locate the heat right where I need it. Something I noticed with the closeup picture that's hard to see without glasses is the tube bends up on the ends. My slitting saw needs to be a couple thousandths wider. My milling was on the big side of my intended size because trying to mill those long pieces,it's hard to hold straight and no deflection. I would love to have a vice setup with 32'' long jaws but I never built one. Last edited by 9W Monighan; 10-05-2010 at 12:31 PM. |

|

#16

|

||||

|

||||

|

Steve , I would use the torch . if you have it all clamped in the jig ready to solder , you can heat a muti joint area and solder at once .

IHSteve

__________________

RIP FreddyGearDrive 2-12-59/12-19-11 To view links or images in signatures your post count must be 10 or greater. You currently have 0 posts. |

|

#17

|

|||

|

|||

|

Yeah steve-I noticed the gaps but couldn't tell how big they are. The silver will fill in some gaps. I have heard of the resistance soldering but never seen it used. That may be the way to go. Using the torch ,the thick angles will take a lot of heat and it may be too much for the thin-wall tubing. I'm sure you will figure it out.

Last edited by modelman; 10-05-2010 at 01:46 PM. Reason: adding something |

|

#18

|

||||

|

||||

|

WOW!! Your work is always top notch. Silver soldering is an art in itself. Not sure a resistance iron will work with the brass frame being so much thicker than the cross bracing. Torch is going to be just as challenging due to the size difference. Some sort of heat sinks or the heat blocking putty may be your best bet.

Took me awhile to get the hang of soldering on my Studebaker. The grill alone took over a hour to solder together and I made a jig first. Glad I only have to do about 8 or 9 more solder joints and it will be back to machining again. Would really like to see your work in person. Course I would probably just stare and drool over it.  I do a lot of that at the NAMES show each year. I do a lot of that at the NAMES show each year.

|

|

#19

|

||||

|

||||

|

Quote:

Why don't you come to York in January with some of us other guys and bring the Studebaker. Work in progress are always welcome. I want to look that truck over. I have resistance power supply's up to 2500W I picked them up when they were cheap enough. I hope to find a use for them just need the proper jaws maybe. |

|

#20

|

||||

|

||||

|

I spent 3hrs last night trying to mill these tighter angled pieces. I got one almost right. Today I had to make a small vee block fixture to hold the tube further out of the vice so the slitting saw won't hit the vice. I also found the problem with the narrow groove Tom. The saw I was using measured .060'' and my tee is .063'' so I stacked up two saws that measure .064'' wide.

|

|

| Currently Active Users Viewing This Thread: 1 (0 members and 1 guests) | |

|

|