|

|

|||||||

| Highway Trucks and Trailers On road trucks and trailers single and twin axle trucks. |

|

|

|

Thread Tools | Display Modes |

|

|

|

#1

|

||||

|

||||

|

great job nate

"I think I'm on a machining high right now!" It doesn't take long does it "I think I'm on a machining high right now!" It doesn't take long does it

__________________

RIP FreddyGearDrive 2-12-59/12-19-11 To view links or images in signatures your post count must be 10 or greater. You currently have 0 posts. |

|

#2

|

||||

|

||||

|

Those steps look outstanding. Why not countersink the screws though?

__________________

"My son will have a chocolate milk" -J.P. Next East Coast Minitruckers Meet: Arioch |

|

#3

|

||||

|

||||

|

WOW! Very nice for sure.. Probie on the real ones some brands have alum rivets in the areas that he has the screws.. I like the look it is a nice touch..

__________________

Paul W. "Tamiya Cowboy" HI.. My name is Paul.. And.. I.. Have a Cabover Addiction. RIP FreddyGearDrive 2-12-59/12-19-11 "LET IT EAT" Like Us on Facebook "Corn Field Mafia" To view links or images in signatures your post count must be 10 or greater. You currently have 0 posts. |

|

#4

|

||||

|

||||

|

Turned out real nice Nathan, those screws look good!

|

|

#5

|

||||

|

||||

|

Thanks Scott. I appreciate that.

Quote:

Quote:

Quote:

Thanks Kent. Almost finished with these things. Then it's onto the the next set of parts. Some nicer fuel tank saddles, if I am capable!

__________________

Nathan |

|

#6

|

||||

|

||||

|

Youre wasting no time breaking in that mill!! Love the custom parts, looking forward to seeing more.

How will they mount?   that's too funny! Its actually Arioch, but I like Archie that's too funny! Its actually Arioch, but I like Archie

__________________

"If you build it, they will come" East Coast Mini Truckers To view links or images in signatures your post count must be 10 or greater. You currently have 0 posts. |

|

#7

|

||||

|

||||

|

Nathan those are the best steps i've seen great job the only thing missing are one slam locks

__________________

RIP FreddyGearDrive 2-12-59/12-19-11 Love my Kenworths To view links or images in signatures your post count must be 10 or greater. You currently have 0 posts. To view links or images in signatures your post count must be 10 or greater. You currently have 0 posts. |

|

#8

|

||||

|

||||

|

Thanks Tracy. I'm actually working on the doors with lock details. Have to see what I can up with. These aren't quite finished yet.

__________________

Nathan Last edited by Espeefan; 03-23-2012 at 08:52 PM. Reason: I can't run a keyboard. |

|

#9

|

||||

|

||||

|

Nathan, this build is the boom daddy. Those steps look great and are totally unique. I'm impatient to see the finished article.

Have you considered half counter sinking the screws? They wouldn't stick out so much and there would still be enough material for it all to be secure. You could even mill the protruding part of the screw off at a later date. Just a hare-brained idea.

__________________

Nick My Peterbilt build thread: To view links or images in signatures your post count must be 10 or greater. You currently have 0 posts. |

|

#10

|

||||

|

||||

|

WOW love the steps!!

|

|

#11

|

||||

|

||||

|

Quote:

Quote:

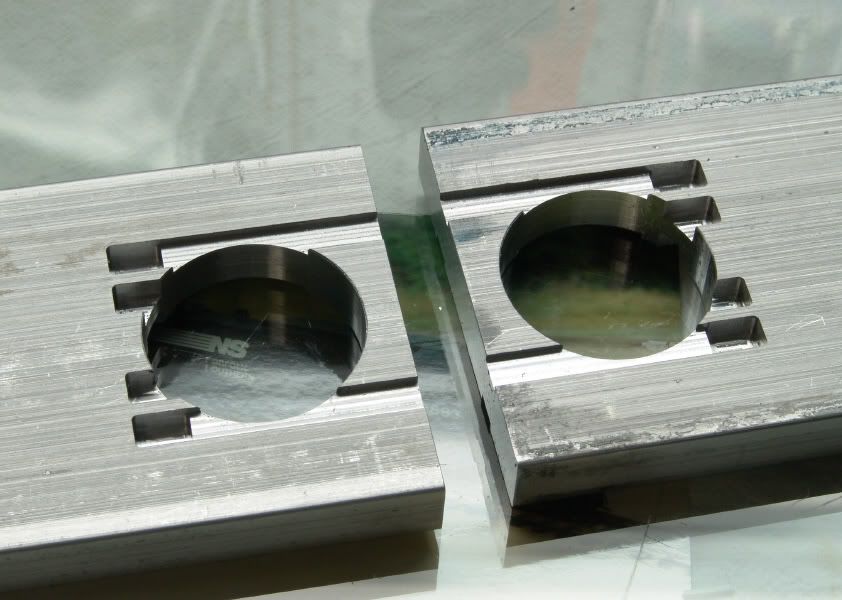

Anyway, the tool boxes will mount up pretty readily, from the rear. I think I'm just going to drill and tap some holes and bolt them to the frame rails. Easy and clean. The screws will be hidden! Argh! Arioch, I apologize! I'm not good with names! No harm intended! Thank you dabears. I think da steps are pretty cool too.  Okay fellas, I've got just a small update here. This will be all for the weekend edition. I'm needing to order up some more end mills and a little more material, but I did get a start on designing and machining up a couple extra mystery parts for the Wedico. I won't say what they are yet. They are in a pretty raw state. For a hint, there are two parts per plate.    The smart guys will probably figure it out! Any guesses?

__________________

Nathan |

|

#12

|

||||

|

||||

|

A flux capacitor?

__________________

Never judge a man until you have walked a mile in his shoes. Then, when you judge him, you are a mile away and you have his shoes! To view links or images in signatures your post count must be 10 or greater. You currently have 0 posts. |

|

#13

|

||||

|

||||

|

I bet I'm close!

|

|

#14

|

|||

|

|||

|

The steps look amazing! It's amazing how much work can go into one part. I have broken off small taps and drills and it is not fun. I understand about being fearful of breaking off a tap. Although somewhat larger than a small tap, I recently broke a 1/8 carbide end mill off and was able to "drill" it out with an expensive OmegaDrill tap drill. It worked great. Unlike the last time I drilled to drill out a broken tap where I ended up trying various other drills and endmills that only resulted in making them dull.

|

|

#15

|

||||

|

||||

|

Quote:

http://omegadrill.com/ http://omegadrill.com/Cheer's, Neil. |

|

#16

|

||||

|

||||

|

I'm a big fan of Back To The Future, so I appreciate the humor, but I don't think this truck will hit 88mph.

If you are thinking what I am thinking, quite! Quote:

Quote:

__________________

Nathan |

|

#17

|

||||

|

||||

|

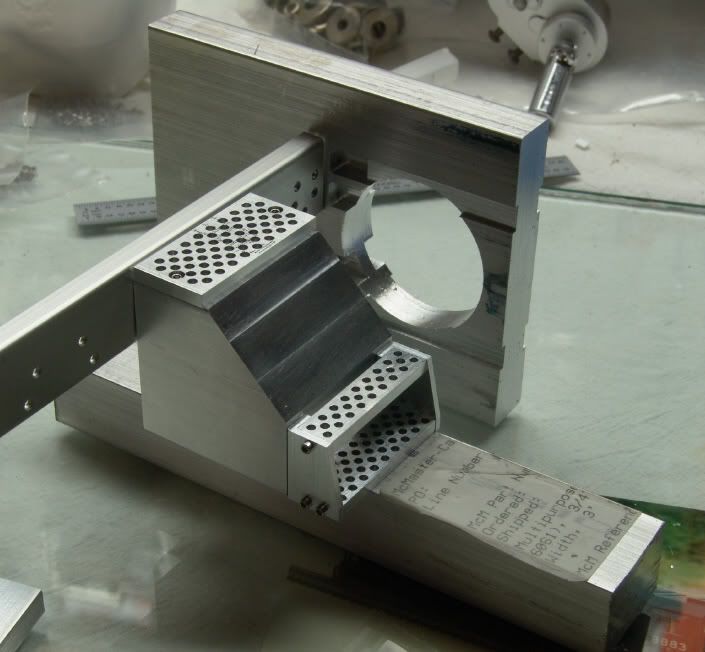

Okay, here's a hint on the mystery parts.

Just sizing it up.

__________________

Nathan |

|

#18

|

||||

|

||||

|

TANK SUPPORTS!?

|

|

#19

|

|||

|

|||

|

I guessed tank fuel supports .. in my head.

Re the Omega Drill, I was amazed at how well the Omega Drill worked. I first flattened the top of the broken endmill with an expensive endmill purpose made for it and then used the Omega Drill. It didn't drill through the endmill like butter but it went through without too much difficulty. I bought it from MSC for about $20 and it is well worth it. I thought about buying the set but in the end did not. I believe the smallest size is 5/64. This may not be small enough for some broken off taps (because the ones that break tend to be smaller than that) but at least you could drill them out, fill with JB Weld and re-dril/tap which is better than leaving a broken tap in your part. Gotta love a DRO for nice even spacing. You have a DRO PROS or am I remembering wrong? I had one on my Grizzly G0704 but sold it with the mill. Actually it was a new replacement because I had a problem with the readout. I have an Anilam Wizard 1000 now and love it (bought it for something like 55% off at Enco last year). |

|

#20

|

||||

|

||||

|

Yup, that's what they are....supposed to be! These things are going to be a little harder to machine for a newbie, like myself!

Quote:

__________________

Nathan |

|

| Currently Active Users Viewing This Thread: 1 (0 members and 1 guests) | |

|

|