|

|

|||||||

| Construction Equipment If it digs, pushes, hauls dirt "off road" post it here. |

|

|

|

Thread Tools | Display Modes |

|

|

|

#1

|

||||

|

||||

|

Thanks Skeeter!! Yup the track pads/grousers are a bit aggressive for a shovel....LOL....these are the original tracks that were on the D11 dozer, only needed to add a few more links and pads to the original length......it was an easy way of repurposing old parts.

|

|

#2

|

||||

|

||||

|

|

|

#3

|

||||

|

||||

|

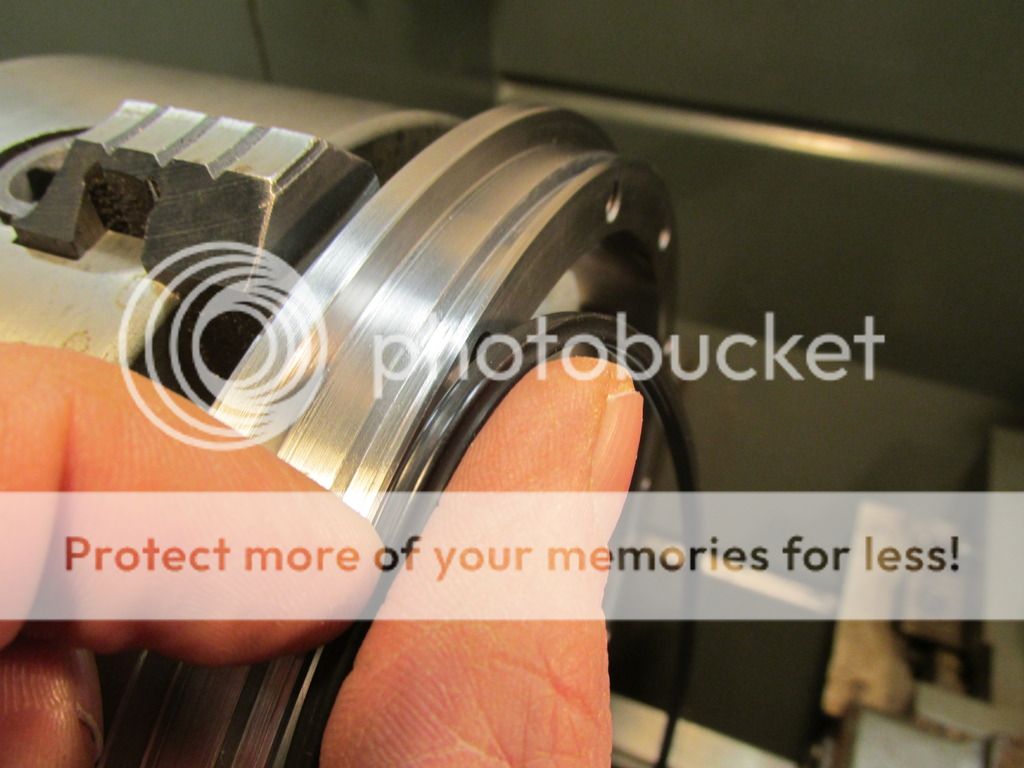

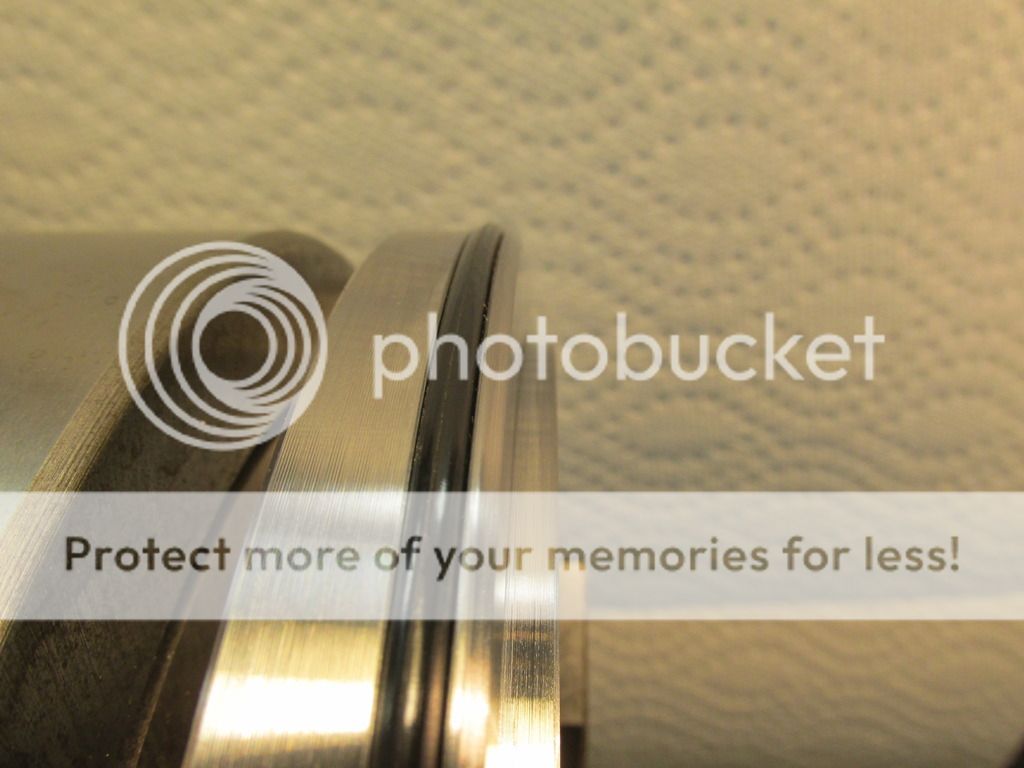

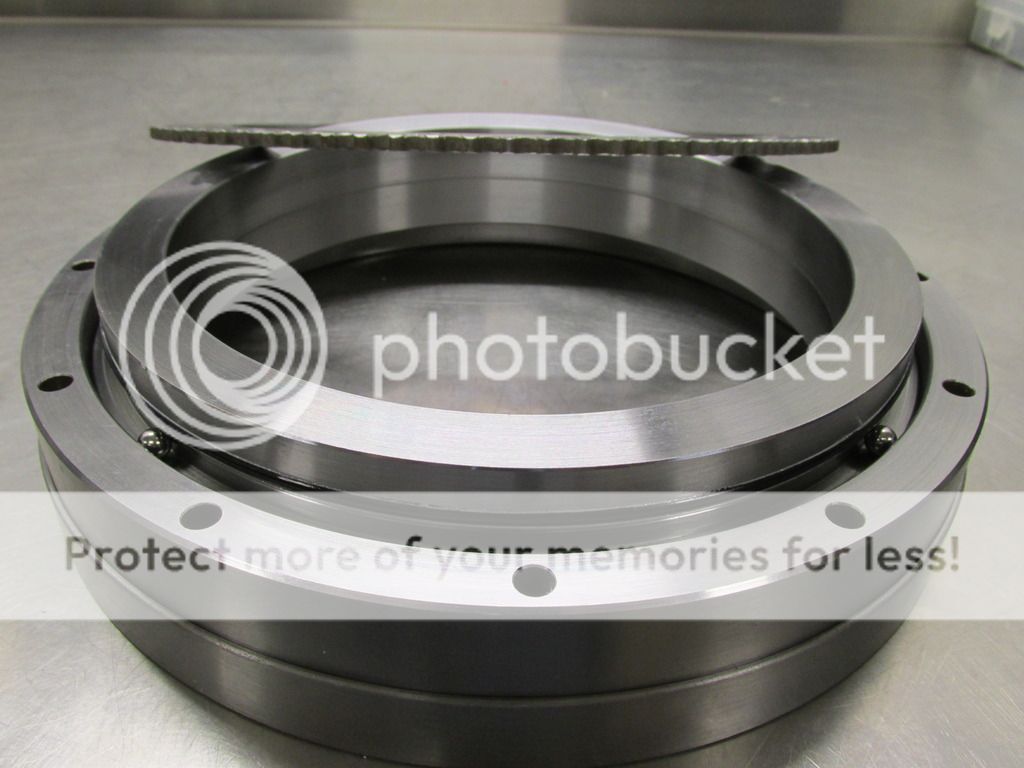

The new plan was to incorporate some small 1/8" quad rings to act as seals but decided to go with o-rings instead. (less contact area making it easier to turn)

The "inner race ring" will be installed upside down and an o-ring added to seal against the inside face of the shoulder that supports the 100 - 1/4" balls on the stationary outer race. (Sorry the photo shows the quad ring)  A new taller top spacer ring was made with an o-ring installed that will seal up against the ID of the sprocket.  The new top spacer ring also needed to be a bit bigger in diameter to match up with the original ID of the sprocket.....Yikes....just enough clearance for the balls once the angle was cut on the spacer.......fun fun......more obstacles!!

|

|

#4

|

||||

|

||||

|

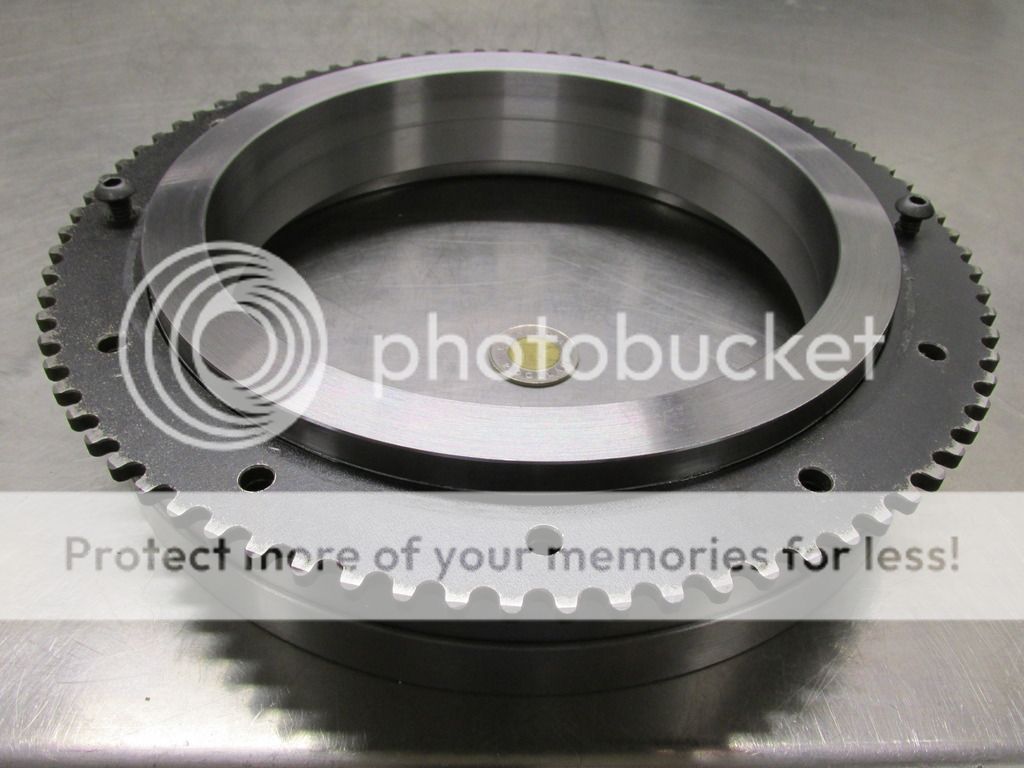

This is the order of how all this mess fits together....LOL...still need to drill the holes in the new top spacer!!

Hopefully this will help someone else get ideas on building a swing bearing from scratch!! One thing to remember is that the rolling elements (balls) are only running on a flat surface and not on a radius. Because this bearing only has point contact on the balls it will most likely wear a bit faster. Thanks for looking!! KP |

|

| Currently Active Users Viewing This Thread: 1 (0 members and 1 guests) | |

|

|