|

|

#221

|

|||

|

|||

|

had to stop for a lunch break , I have some update pictures.

got main drive in and now need to source or make a drive belt. conveyor motors , I know how im going to fit them but need material to finish them. so Ive made a start on some walk ways ect, need to try and weld some fencing wire to see if I can make some hand rails. will see how many times I burn my fingers later. got the fines shut in and sorted  where the fines will fall through  main drive motor  and a outside in the sun picture  cheers andy

|

|

#222

|

|||

|

|||

|

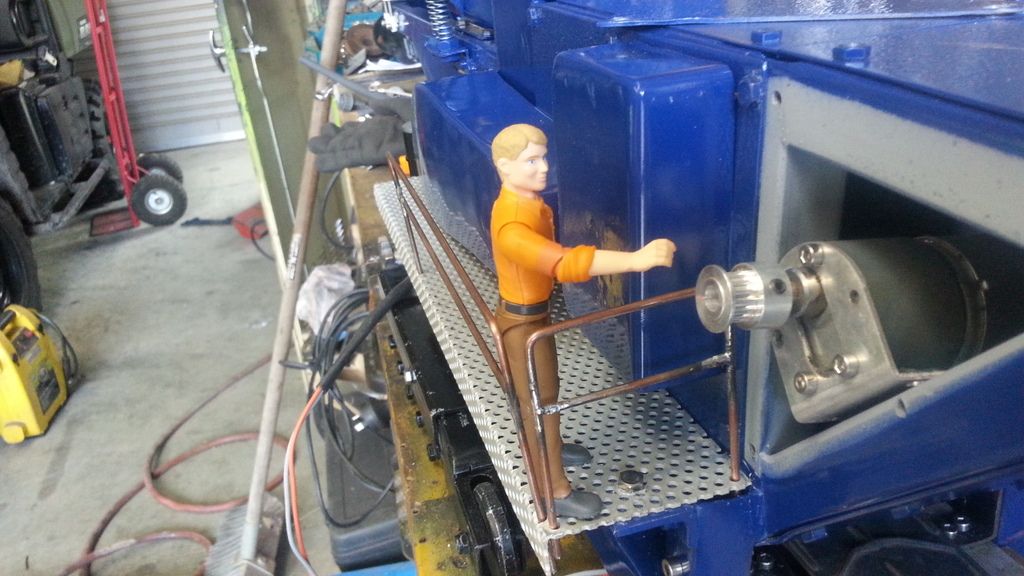

if learnt something today, if you use a mig welder to weld galvanised fence wire you are lighting a fuse.

Ive welded galv steel before and its not that great, clean the galv off and its not too bad. but the wire just started burning and fizzled out about 10mm shorter than what I started with. plan B was needed , I had a length of tig welder filler. cut and bend to suite and weld with mig , works nicely. Unfortunately I only had 1 length so got to get some more to finish the safety rails. Bob seem impressed with the crusher. this is where the main conveyor drive will be  rocks come down this way  safety rails, check .  I have no idea what he's up to in this photo, I think he wants to be fired even before it has run.   time to light the fire , its way too cold to be in the shed. cheers andy |

|

#223

|

|||

|

|||

|

That looks awesome mate how long and high is this machine wat size is the jaw crusher box.

Cheers justin |

|

#224

|

|||

|

|||

|

|

|

#225

|

|||

|

|||

|

been trying out windows movie maker, just a mess around of rc stuff in slow motion.

https://youtu.be/lKefR_tvNww |

|

#226

|

|||

|

|||

|

hey Justin heres a real quick video of the crusher crushing dirt lumps.

just fitted battery drill to shaft and had it set on low 0- 400 rpm, it appears to work better at the higher speed but needs conveyors running to take away the crushed dirt as it blocks up with out them running. the crusher motor is a 1200 rpm unit so I can slow it down on the pot on my power supply box. http://youtu.be/TE4-31RpFto cheers andy |

|

#227

|

|||

|

|||

|

heres test #2 , big rock ( hard dirt) may have to change crusher plate to make gap smaller at bottom but first I need my conveyors running so it has a chance to break the lumps.

I think the problem is that the dirt is pilling up on conveyor and dirt isn't going far enough into jaws to be broken down. I think once the conveyors are running and there is weight ( more dirt) on top of the rocks in the jaws they will be forced down the shute to be crushed. heres a quick video , let me know if my theory is right? cheers andy http://youtu.be/Oce8bhDK7gE |

|

#228

|

||||

|

||||

|

Your right Andy. The more in the chute the better. Crushers are hungry and need a steady flow of material otherwise single chunks will skip and dance around. That's cool if you can easily adjust jaw distance and crush different grades or size of material.

|

|

#229

|

|||

|

|||

|

|

|

#230

|

||||

|

||||

|

Your screening holes prior to the crusher, I've discovered the fines help move the chunks around in the box, constantly changing the bite of the jaws. Sometimes chunks lodge & stay in one position, then the jaw pivots on that one chunk, not breaking it any further.

O rings for belts... to drive your crusher? Won't last very long, they stretch too easily. Cog belt or V belt with steel in it.

__________________

Sharing knowledge is one thing that defies basic arithmetic logic --- the more you share, the more you get! Joe |

|

#231

|

|||

|

|||

|

I have been told the same about the fines shute.

we have a guy at work who used to repair them in South Africa and he suggested a sliding mech under the hopper slots that I can adjust to suit the material im crushing and that the shute must be full to work properly. And apparently it needs to lift the rocks on the jaws when crushing other wise they will jam in place. I do intend to use a toothed or a vee belt but I had the seals ( o rings ) lying around so for initial testing and a zero budget they will have to do for a couple of weeks. this has been a bit of a learning curve but still fun. by the way Ive also learnt that you dont put a large plastic handle of a screw driver into it to see what happens. I now have a large square shanked handle less screw driver and lots of yellow plastic bits. cheers andy

|

|

#232

|

||||

|

||||

|

So what is your offset of the crankshaft?

__________________

Sharing knowledge is one thing that defies basic arithmetic logic --- the more you share, the more you get! Joe |

|

#233

|

|||

|

|||

|

Never realy measured it , but im guessing around 6mm.

the top moves more than the bottom of the crusher plate.. I also need to change the shape of the jaws to a rounded shape so the majority of the crushing happens in the middle of the plates. there is a lot more to just smashing up rocks. my design is a little different to a real jaw crusher but it actually works. maybe I should pattern my design LOL. cheers andy |

|

#234

|

|||

|

|||

|

just a small up date , got all motors mounted and tested.

track drives all good . a few hand rails to go and a total repaint, also still having trouble finding drive belts that im happy with. Also picked up a king hauler day cab with a wedico 3 stage hydraulic ram on a home made tipper trailer , needs some loving but that's what winter is for. any way heres some crusher progress    cheers andy |

|

#235

|

||||

|

||||

|

As fast as it seemed to initially go together, I was hoping to see a video by now of it breaking rocks?

__________________

Sharing knowledge is one thing that defies basic arithmetic logic --- the more you share, the more you get! Joe |

|

#236

|

|||

|

|||

|

you and me both, but the mrs dosent quite share the same enthusiasm , hence the jobs that need doing around the farm.

now that the fencing is all finished and creek cleared, did I mention trees cut down and made into next years firewood...... I now have a few days play time, I need to find some closed loop timing belts for the crusher drive as the home made ones don't last and my initial orings were never going to be permanent . I will measure up what I need and order them and also make a start on the control wiring. I want be able to drive tracks via rc but want to use my power supply to run vibrator, conveyors and crusher motor. cheers andy |

|

#237

|

|||

|

|||

|

still waiting for some belts to show up for the crusher , so I made a start on the latest project.

I picked up a second hand king hauler with a home made tipper trailer , which has a 4 stage wedico hydraulic system. the plan was to clean it up and a quick paint job.... the previous owner wasn't too kind to the truck and a little rough in the building side of things. so the plan changed a little, I was going to make a trailer and fit the hydraulics but looking at the truck , as a day cab it looked too long. plan B , make the truck into a dump truck and make a smaller pup since Ive already ordered some axels I might as well use them. heres a few progress pictures, The cab will be lowered as all the plastic parts holding the cab were broken of butchered.        cheers andy |

|

#238

|

|||

|

|||

|

|

|

#239

|

|||

|

|||

|

got a little more done on the dump truck.

not overly happy with the tipper body, due to a little warping when welding. No gas for the tig so had to use the mig, blown a few holes here and there but nothing a little filler wont hide. I will also replace the plastic tanks and make two stainless ones so that one of them will be full of hydraulic oil and the other possibly to hold the pump. its been an interesting week, the mrs has been laid off , new parts are turning up daily for the dump truck and pup build and the dogs ate the spa pool cover and chewed through the spa pool power cord when it was turned on!!!!!  what do ya do...  Ive also got another wedico ram and pump coming from a fellow RC chap in ausie , so pup will match the truck.  got some more sanding to do then it is the big decision on colour choice. enough talk heres a few pictures   cheers andy |

|

#240

|

||||

|

||||

|

So what size wire do you run in your mig? I have .023" in a small hobby mig & welding light gauge works very well.

So... did the dog(s) get electrocuted?

__________________

Sharing knowledge is one thing that defies basic arithmetic logic --- the more you share, the more you get! Joe |

|

| Currently Active Users Viewing This Thread: 3 (0 members and 3 guests) | |

|

|