|

|

#1281

|

||||

|

||||

|

Quote:

|

|

#1282

|

||||

|

||||

i seen an add for an attachment that goes with a gopro and tripod that will follow a person from a distance like the beach and a surferon a wave and the person just has to have an arm band on. And you could put it in a dump truck and make some cool vids. i seen an add for an attachment that goes with a gopro and tripod that will follow a person from a distance like the beach and a surferon a wave and the person just has to have an arm band on. And you could put it in a dump truck and make some cool vids. also from my last post you could use a humidifyer and dehumidifyer depem on moister in the air and result you want like less dust or mor dust lol

|

|

#1283

|

||||

|

||||

|

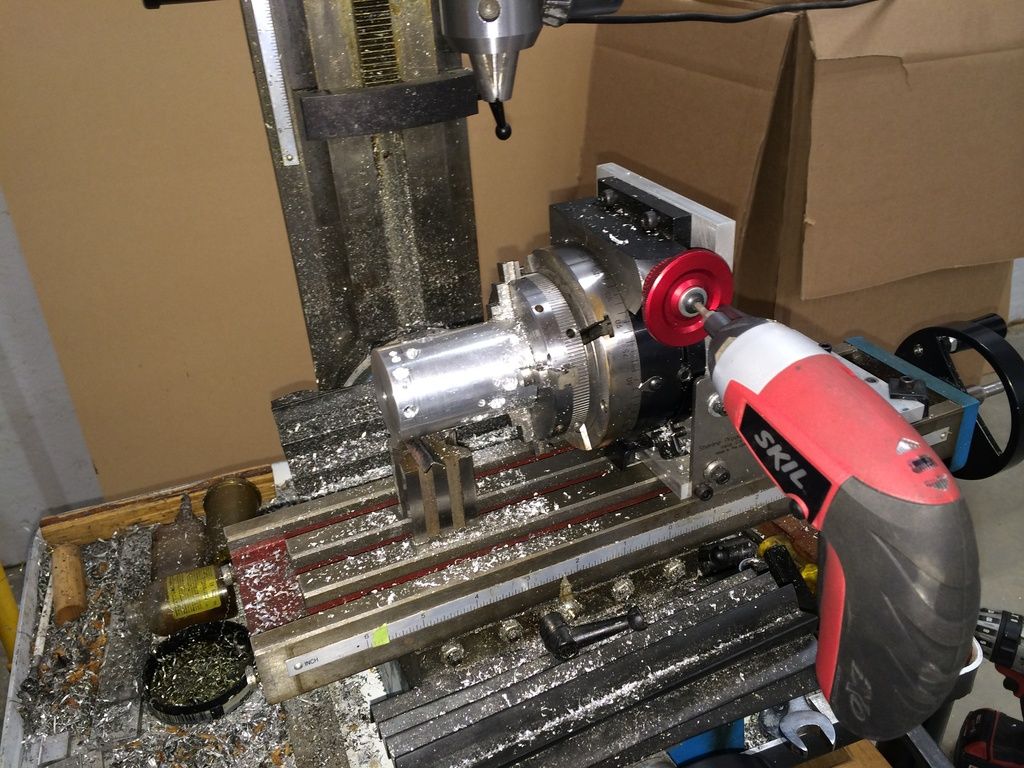

A little teaser of what I've been tinkering with the last couple weeks... it's almost done, maybe trials on the wkend.

__________________

Sharing knowledge is one thing that defies basic arithmetic logic --- the more you share, the more you get! Joe |

|

#1284

|

||||

|

||||

|

Are you going mount that on the excavator and turn it in to a tunnel boring machine?

|

|

#1285

|

|||

|

|||

|

Looks real good so far Joe. How is the tunnel coming along? Weather is changing need to be indoors now. I finally got my cnc mill working and now am working on the cnc working for the lathe almost don with that. Now I fan focus on making some parts for the trucks. Ed

|

|

#1286

|

||||

|

||||

|

You betcha Kent!

Vertical ripping just wasn't going that well, so I set my mind a few weeks ago to get this done! Vertical ripping just wasn't going that well, so I set my mind a few weeks ago to get this done! Are you gonna live long enough Ed to ever start producing parts with cnc?   The shortest movie I made to date!  https://youtu.be/2d5GuNDp7ZM

__________________

Sharing knowledge is one thing that defies basic arithmetic logic --- the more you share, the more you get! Joe |

|

#1287

|

||||

|

||||

|

Nice! Now lets see some dirt flying!

|

|

#1288

|

||||

|

||||

|

Awesome!! An underground miner!!! Next you'll have to set up a misting system, keep the dust down!!! I can see you having ripped apart a spray bottle nozzle hooked up to the garden hose!!! Cool idea joe!! Mine and grind!!!

__________________

Always wasting money, as the wife says. To view links or images in signatures your post count must be 10 or greater. You currently have 0 posts. |

|

#1289

|

||||

|

||||

|

Super cool ! So does this mean your building the worlds first scale continuous miner?

definitely the best man for the task! Can't wait to see this in action. definitely the best man for the task! Can't wait to see this in action. http://youtu.be/nRCanZ1VVJc |

|

#1290

|

||||

|

||||

|

I'm glad to see you decided to take this on yourself Joe! It looks like it will work awesome in the soil you have there. Better put an extra layer of safety glass on the 850's windshield though

. .

|

|

#1291

|

||||

|

||||

|

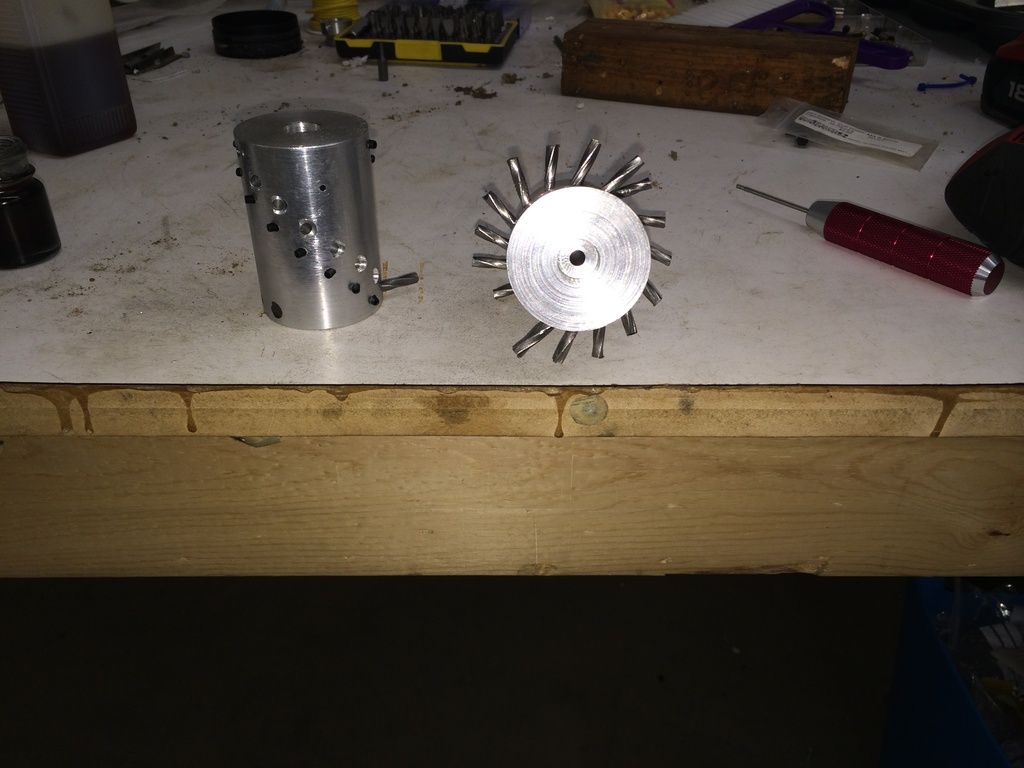

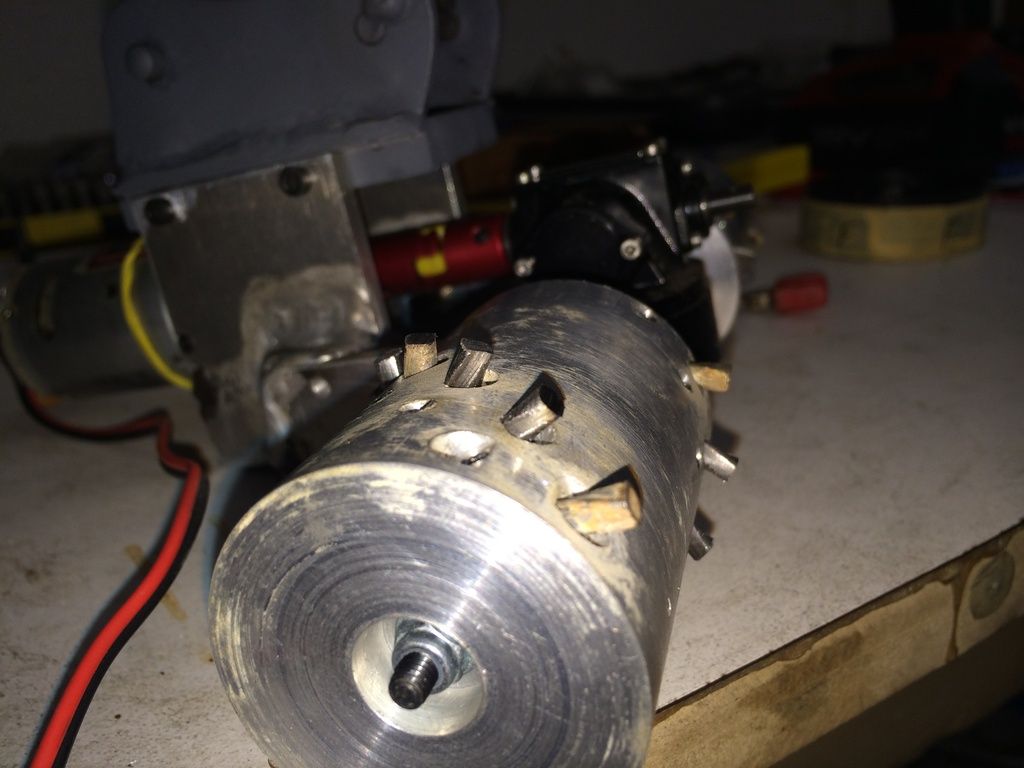

Hardest part of any job Reg is getting started

Sure looked good running on the bench... didn't it?!   ... then into the pit for trials  This clay is sooooo sticky!!! it's ripping in chunks! and wants to walk up the wall. I took out half the teeth (4 per row) & tried it, but it still wanted to grab too much & walk. Then I cut the remaining teeth in half (from 12mm to 6mm) that helped, but the clay just doesn't want to crumble or peel away... it's just too sticky. I knew it from the start that that wide of cutting drum on each side would likely be too much cutting surface... I didn't want to hack up the original Blackwell axle incase it was a total bust of an idea... I'll check with RC4WD to see if I can get just the solid steel shafts that come out of the differential, so I can experiment with different widths of cutting drums... definitely needs to be half the width or less. Motor got really hot too! need more reduction. I'll have to ponder awhile, come up with a new plan... in the mean time just keep ripping & digging.

__________________

Sharing knowledge is one thing that defies basic arithmetic logic --- the more you share, the more you get! Joe |

|

#1292

|

||||

|

||||

|

Pictures? Video? Something?

|

|

#1293

|

||||

|

||||

|

Is this going to be an attachment for the 850 Joe?

Calum |

|

#1294

|

||||

|

||||

|

Leading edge of the teeth is 4mm tall.

Here's a quick vid showing the dismal result of my grinder idea   https://www.youtube.com/watch?v=mVqz9mOMUM0 Camera doesn't show depth very well... tunnel is about 3ft inward.

__________________

Sharing knowledge is one thing that defies basic arithmetic logic --- the more you share, the more you get! Joe |

|

#1295

|

||||

|

||||

|

I wonder if it would be better to operate them like a screw? Maybe two sphere shapes spinning opposing each other like a twin screw on a boat. One motor per sphere or a gearbox between the two? At least it would try to crawl up the wall.

|

|

#1296

|

||||

|

||||

|

Joe- before you give up on that idea have you experimented with RPM. I'm wondering whether doubling your cutting speed would change the out come. I know changing wheel speed in the trucks changes how they handle in some off road scenarios, just due to the electric motor output.

|

|

#1297

|

||||

|

||||

|

Can you try double the rpm and change rotation direction ?

Start grinding low and go up. it might work. just an idea. Love your project . |

|

#1298

|

||||

|

||||

|

If you give up on the continuous miner idea, make a drill unit for the hoe then drill and blast the material.

I have been thinking about how to do this when using my dragline but safety around spectators would be a problem if a shot went wild.  In your basement there's nobody around to get hurt. In your basement there's nobody around to get hurt.

|

|

#1299

|

||||

|

||||

|

Forgot to mention about the video, Looks like You need more weight and power to be able to grind through that material. Are the spider gears still in the truck rear you're using. Get a worm gear drive so power is to both sides equal and like the other have said; up the RPM

|

|

#1300

|

||||

|

||||

|

The way I think after watching your vid of this in action I wonder if much larger drums with a few more rows of teeth might work better. when you look at the continuous miner machines they always have several rows of teeth contacting the surface at the same time.

Just my thoughts. Shawn |

|

| Currently Active Users Viewing This Thread: 36 (0 members and 36 guests) | |

|

|