|

|

|||||||

| Construction Equipment If it digs, pushes, hauls dirt "off road" post it here. |

|

|

|

Thread Tools | Display Modes |

|

|

|

#1

|

||||

|

||||

|

http://www.ebay.com/itm/Inline-Fuel-...pVuezG&vxp=mtr

I wanted to use this (fuel) filter in my stuff but it is too big, probably good for this size model. Oil filter/fuel filter, they both are trapping particles of a certain size, 5~500 microns,,, the ones I use are very small disposable I get from McMaster. I have to drill out ends and thread for m5 fittings. I'm sure they are way too small for this. My opinion on hydro volumes is about same as above, double the system volume and you'll be good. On an hydro guys side, as big of a tank as weight/size/practicality allows. More oil is just better all way around. Temp, contaminants, lifespan of oil, ect. But on 1:1 machines, lifespan, cost of replacing, and available size is what restrictions are. One thing to try is to have tank suction on bottom and tank return line on top (baffle or just opposite side) allows air in oil to migrate to top and not back into pump. That's the frothing of agitated oil, a lot of oil has additives to lessen foaming. I've never had temp come into issue in any of my models. Excavator cylinders get warm after a hour use in summertime, but never hot. (At least that I am aware of  ) ) And that school you talk about, one of the best I've ever attended!!!

__________________

Always wasting money, as the wife says. To view links or images in signatures your post count must be 10 or greater. You currently have 0 posts. |

|

#2

|

|||

|

|||

|

Love the 777. This build is going to be great. It's going to influence me when I build my excavator. Using regular parts. I like it. Keep up the great work.

|

|

#3

|

||||

|

||||

|

Thanks for all the feed back on the hydraulic questions, now I will have to put it to good use....

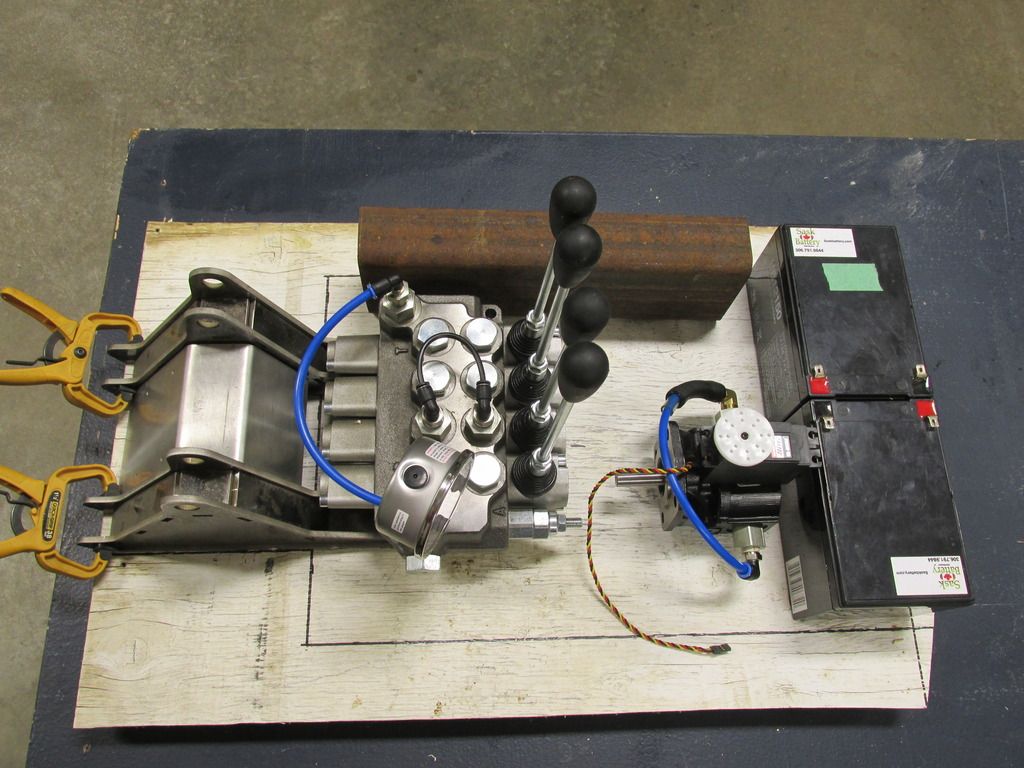

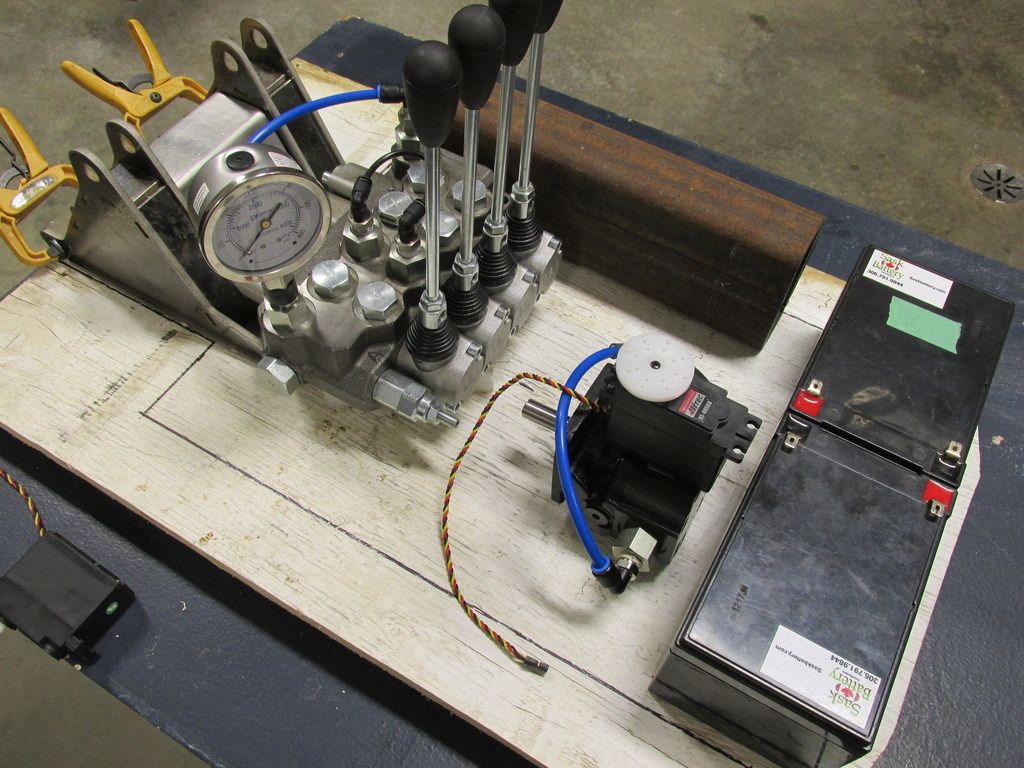

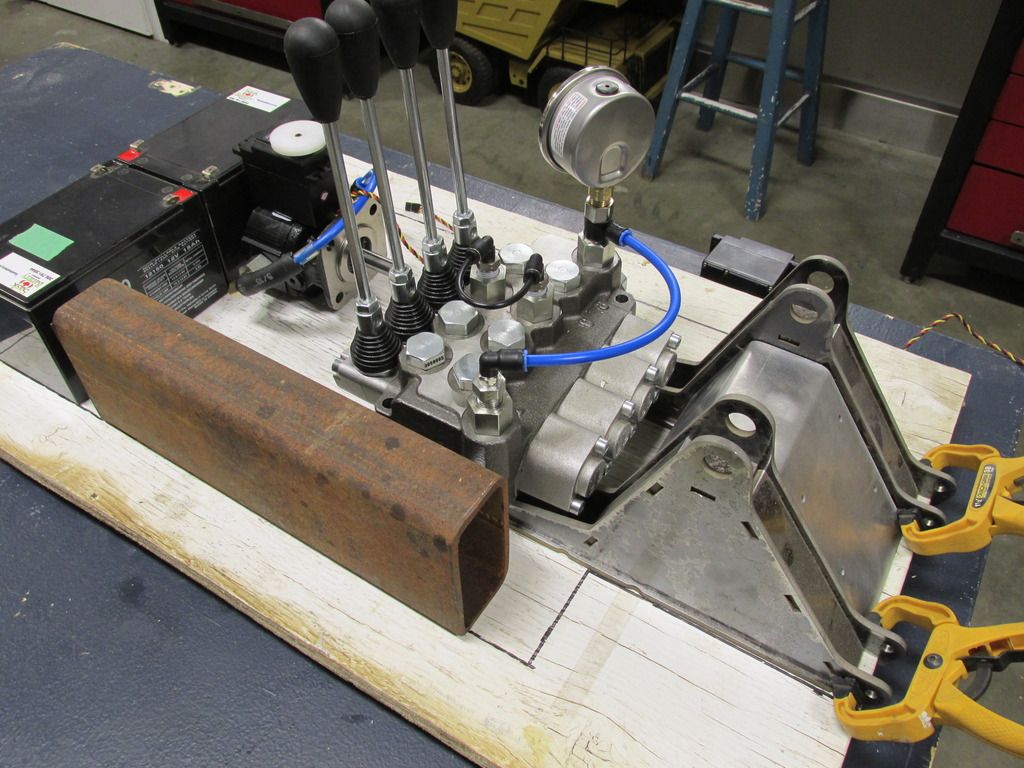

Next trick will be getting everything to fit, even though this is a good size model there isn't a lot of extra space left over after all the "big goodies" are in place. Played around with different placements of everything on a plywood template, this seems to be about the best use of the space....the rusty 2"x4" HSS may end up being used as the tank, after getting a good cleaning and cut to proper length it will hold about 1000cc. I dont have the drive motor yet for the pump, it will be belt drive with about 3:1 reduction using a small 2L vbelt. The servos will be mounted on a plate above the motor/pump, the handle shafts on the valve will be cut shorter and then connected to the servos with ball linkage rods. Nothing to exciting but here are some pics.... [IMG]  [IMG]  [/IMG] [/IMG][IMG]  [/IMG] [/IMG]Thanks for looking!! KP |

|

#4

|

|||

|

|||

|

Only a suggestion but why don't you go with an aluminum tank it would seem to have better heat transfer to help keep the oil cooler. Ed

|

|

| Currently Active Users Viewing This Thread: 1 (0 members and 1 guests) | |

|

|