|

|

|||||||

| Construction Equipment If it digs, pushes, hauls dirt "off road" post it here. |

|

|

|

Thread Tools | Display Modes |

|

#1

|

||||

|

||||

|

Gentlemen,

I've been playing with rock crawlers over at scale 4x4 rc for a long time. Reccently while i was bored I ran across videos of Little Giants construction digging out his basement on youtube again. I thought that looked like fun, ventured back into the rc ag & industrial forums and started finding out that hydraulic models are in 'cubic dollars' so maybe not fun after all... Then i saw 'the stuff' and 'small haul' converting doepke Unit cranes and Tonka dump trucks and saw a more affordable entry into this world. Old toys and servos being massively cheaper than hydro, this could work. Cable machines are cool and have more visible stuff moving around and i don't have to worry about rivet counters telling me my build is wrong since it's a toy. So i started by finding my 1990s 1930s nylint dumptruck, and scaling up a papercraft crane i found on a japanese site, then began making it in brass.  While working on it i ran across a 1955-56 Nylint Clark T-24 Michigan Crane which saves a ton of time vs rolling my own. I noticed a couple guys on here have converted these already so i'm hoping i can steal some knowlege.  Right now i'm wanting to build 3 cable drums and slew, build a dragline bucket. i'd like to eventually add drive and steer and maybe lighting. Last edited by frizzen; 07-19-2017 at 03:51 AM. Reason: photobutt |

|

#2

|

||||

|

||||

|

Awesome! another crane!

here is what I used to get the main part to swing.   All my pics of conversion here - http://s15.photobucket.com/user/ANTh...?sort=4&page=1

__________________

Rc's are like pringles. You can't have just one!! my YouTube is - To view links or images in signatures your post count must be 10 or greater. You currently have 0 posts. Subscribe!! My Facebook - To view links or images in signatures your post count must be 10 or greater. You currently have 0 posts. |

|

#3

|

||||

|

||||

|

Here is a link to a video I just put together with some of the pictures of my NyLint conversion.

http://youtu.be/h_wDThHiDg4 I thought this was a pretty good conversion candidate. Lots of room in this cab for everything you will need to put in there. You can find my conversion thread that I made, but all of my photos were lost and the thread is pretty lacking without them  http://www.rctruckandconstruction.co...ead.php?t=9350 Jim Last edited by Rvjimd; 01-31-2016 at 08:20 PM. Reason: Added link |

|

#4

|

||||

|

||||

|

Thank you very much, i was hoping i'd be able to get more pics of your build! I apologise in advance for the amount of questions i'm going to ask of everyone.

Is there a good way to access the counterweight section, or are you just working through the windows? Were your pulleys for crowd and boom elevation home made or production? What diameters did you find work best for the winch drums? I saw a few sizes. So is the crane house just resting on the plastic swing gear, or is there a bearing setup other than just the pivot? |

|

#5

|

||||

|

||||

|

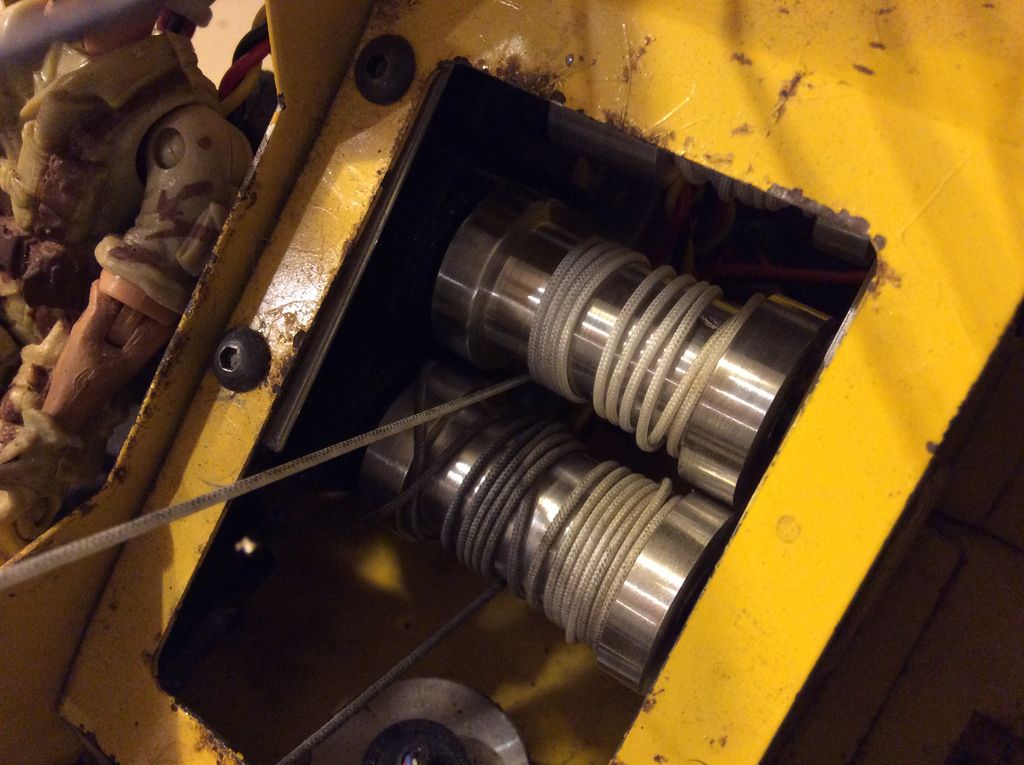

Getting into the counterweight part of the crane was my first issue.

There are spot welds around the top of the "lid". I drilled out the welds and the lid can be removed for really good access. This makes a great conversion in my opinion because of all the space. Be careful removing the lid and you will be able to use it as a removable lid to change batteries. I run two separate lipo batteries as well as lead counterweight and there is plenty of room for all of it.   I made all the rope drums for mine on the little unimat lathe. it works good on hoist and drag/crowd drums to make the diameter as large as possible and still let you "stack" the servos together. I made the boom drum pretty small diameter thinking I didn't want it to move fast. You could use that approach on the hoist if you were planning to do lots of heavy lifting but I don't think it matters much. I think this part of the conversion is more about making the servo mounts work well and easy to install, then make the drums.  Here is a pic of the pulleys I made for the boom required for dragline configuration. I really want to make a fairleed but haven't done it yet. You could probably just run the drag rope out thru a small hole in the front of the cab without the two pulleys. They way I have these keeps the drag rope from riding on the cab. The house is simply sitting on top of the plastic gear. I don't even have a retaining nut to hold it down. Here is a picture of the truck chassis and the slightly different version on my custom crawler base. When you detach the house from the truck, carefully grind off the top of the stud to leave the stud attached to the truck, and as long as possible. On the truck, I did drill and tap the stud and add a cap washer and screw to hold it together. This way if someone picks up the house it won't separate from the truck. Here is the crawler version, I enlarged the hole and made a large post/stud to mount to the crawler base. This has a small center hole to hold the slip ring needed for power transfer to the tracks. My plan was to mod the truck to match so I could move the crane back to the truck if I wanted.   Feels like I have hijacked your build thread, sorry  Jim |

|

#6

|

||||

|

||||

|

I don't think it's a hijack at all, i asked you for advice. If you'd prefer i can ask all kinds of questions over in your build thread.

Awesome i hadn't figured out if it was spotwelds or tabs yet. Those pics are really helpful. It's not really a build thread yet, all i've done on the crane is string it, start straightening a few things, and fix the outriggers. I'm planning, and gathering advice and ideas, and um making motor noises while playing with it. You guys have done the hard work i'm just going to steal whatever ideas i can. |

|

#7

|

||||

|

||||

|

Glad to help, we can continue here, fine with me. And, let's make this a build thread, get to work, I can't wait to see another dragline moving dirt!

Jim |

|

#8

|

||||

|

||||

|

Well that's embarassing, the back fell off.

Spot welds on mine weren't as clean as yours ___ if you follow my lead, you NEED to add a screw hole in the cab before removing this. walkway side of the cable drum window. there is no tack weld there and the lid is structural. Last edited by frizzen; 07-19-2017 at 03:45 AM. Reason: photobutt |

|

#9

|

||||

|

||||

|

Cool, glad to see you working on it!

I was able to drill and tap the stud on the truck (5th wheel). Then I made a simple thrust washer to slip over the stud to hold the house on the truck. Keep at it, I thought it was fairly easy to convert and the hi tec servos that I used are really easy and stable conversions to continuously rotating servos. Jim |

|

#10

|

||||

|

||||

|

So far im just thinking i'll start off with a 1/4'' id bushing over the stock pin, and open up the crane house a little. Maybe tap a hole into the pin for a washer or bearing to keep the house connected. Need to pick up a slew gear to figure out height.

What kind of servos do you guys reccomend? I know one of you guys used tower MG996R, those are out of stock everywhere i've seen. I've seen some using hs-645mg like i run in my crawlers, but thats a $30 servo to need 4-5 of, it was a $40 chassis... For the truck i'm figuring it's gonna drive a little, dig a lot. So i can probably wimp out some on that part. 2 channel cheap servo and esc. I may try to find/make some springs later on, bushings and bearings would be good to add, but it's already had 60+ years without them. Since i've got a 1955/56 with the best steering setup of any of them, i'm probably just gonna roll with most of that as is and just mount up a servo to it. I'm thinking i may try to cobble up a way for drive off an old screwgun in my scrap pile. It's a nice planetary reduction. Probably going to try for both rear axles powered. Maybe eventually throw some better axles under it. I really like the 'but it's a toy' vibe it has so far, and i'm not having much luck finding anything out about the Clark T-24 Michigan Crane to make more detailed. |

|

#11

|

||||

|

||||

|

I like the 645MG, they convert to 360 rotation really well. Some Futaba servos have the pot on the circuit board and are not to friendly for the conversion.

Take some good pics of the chassis conversion, I still have not done mine. Jim |

|

#12

|

||||

|

||||

|

I figured out my trucks steering throw being off had to do with a couple bent linkages, and straightening up the steering shaft got a whole lot more throw now. Also straightened up the bumper, took the lid off the cab.

Do you guys think it'd look better keeping the stock steering wheel that turns with wheels, or delete that in favor of easier setup and more scale look? Yeah you're probably right on the servos, i just didn't know if any of the other cable machine operators had suggestions. If they convert easy and have a wide deadband, it beats cheap and creepy. |

|

#13

|

||||

|

||||

|

Random stuff.

http://ccmodels.com/shop/michigan-t-24-conversion-kit/ was available 2009 for $325. Looks like it had crawler tracks, dragline bucket, main boom extension, secondary boom, grapple claw, a bent boom, extra top rigging, third crank drum... in brass, based off michigan factory info. And to be helpful it's! not available, and the pictures are ms-paint. Truckmaker was kind enough to tell me his trucks aftermarket boom extension was 15" OAL, pin holes 14_3/4 centers. He also shared some detail pics. It looks like they designated t-24 for truck mounted, c-24 for crawler. And i'm not having much luck learning about the cranes, or the michigan company, or clark who bought them, but there's some goofy looking bird that shows up in every search. |

|

#14

|

||||

|

||||

|

Making cable drums is really slow with a redneck lathe setup, so i broke it more instead.

The cab roof is 4 spotwelds, 2 inboard side, 2 outboard. The steering support has 3 spotwelds and a joggle through a slot in floor. Steering wheel is brazed onto a splined shaft, if you want to keep steering shaft intact the cab would have to come off frame. |

|

#15

|

||||

|

||||

|

I looked at a bunch of pictures, and made some guesses, and started to cobble up a dragline bucket out of stuff i had on hand so I could play around with the mechanics of it. Brass sheet thats too thin, hollow tube, and some electronics solder...

BUT I think it's acting about like it should and once the rigging is done in chain i might be onto something. (I started before i saw the patent drawings to copy, but it should work on soft loose stuff.)  Prototypes aren't pretty.  Also started setting up for hoist and crowd drum servo mounts, and working toward getting steering servo in. Last edited by frizzen; 07-19-2017 at 03:57 AM. Reason: photobutt |

|

#16

|

||||

|

||||

|

next up, i took some 0.063" aluminum 2024 t3, and graph paper. I think this is a good start on side panels for a boom extension. That's the longest i could fit on 8.5x11 paper, i can post up template if anyone wants. Planning to make an even longer mid-boom just because i've got some longer aluminum. This one will put my boom reach at 32" once complete.

Then some brass stock turned into a windshield wiper and side mirror. I really should try to get back to making drums soon so i can get back to servo mounts... Last edited by frizzen; 07-19-2017 at 03:59 AM. Reason: photobutt |

|

#17

|

||||

|

||||

|

I've been looking at servo accessories, trying to to come up with the easy way to do this instead of needing a lathe.

On servocity I've stumbled across 'servo shaft hubs' which are a splined 0.5" shaft and one end of the winch drum. Or they have 'servo shafts' that are just a shaft in 0.5 or 0.375 with the spline drive. I can probably fab up the other side plate, tap/die, and with a little locktite. Hs645 uses their 'C1' 24t splines and i can find 32pitch and 48pitch gears to fit it made of Acetyl and brass. But i haven't figured out what the slew gear donor should be to make it all work.. i also learned the vex gears are 24 pitch. Last edited by frizzen; 08-27-2016 at 04:27 AM. |

|

#18

|

|||

|

|||

|

What about a small gear motor with a drum on it, like this one?

- http://www.ebay.com/itm/262553977068 And control it with an ESC. Best regards, Stein :-) |

|

#19

|

|||

|

|||

|

As an alternative, for the slew and pinon gears, maybe you could use something like this:

- Pinion: http://www.ebay.com/itm/151889646562 - Slew: http://www.ebay.com/itm/161891095040 You can see they have almost all types of bores, mods and number of teeth: - http://www.ebay.com/sch/m.html?_odkw...+gear&_sacat=0 If you select a 4mm bore, then you can use a gear motor like this one: - http://www.ebay.com/itm/381486411254 60 RPM / (66 teeth / 12 teeth) = 60rpm / 5.5 = 11 RPM 11 RPM for the swing would be quite ok, I think. Best regards, Stein :-) |

|

#20

|

||||

|

||||

|

Frizz,

I'll turn the drums for you if you know what you want/need. Mine are pretty simple. You want them as large in diameter as you can fit nested next to each other. And for width I just wanted the drum to be centered in the "window". Now, for the tricky part. I don't like the way I attached mine to the servo, but I have had no problems with them so far. I drilled and taped the servo spline screw hole to something larger, probably 2-56 or 4-40 I don't recall which. Then a matching stud installed in the drive end of each drum and a pin in the off end of the drum which is held by the support channel at the other end. Ideally you would want the drive end to be a spline to match the servo but that is way past my machine skills and tooling. Jim |

|

| Currently Active Users Viewing This Thread: 3 (0 members and 3 guests) | |

|

|