|

|

|||||||

| Big Boys of the road 4x4/6x6/8x8/10x10 Trucks This forum is for those multiple axle trucks and other vehicles on and off road. |

|

|

|

Thread Tools | Display Modes |

|

#1

|

|||

|

|||

|

First let me apologize for not posting a build thread on this site. I do everything on Tapatalk because i'm computer literate and it's easier.

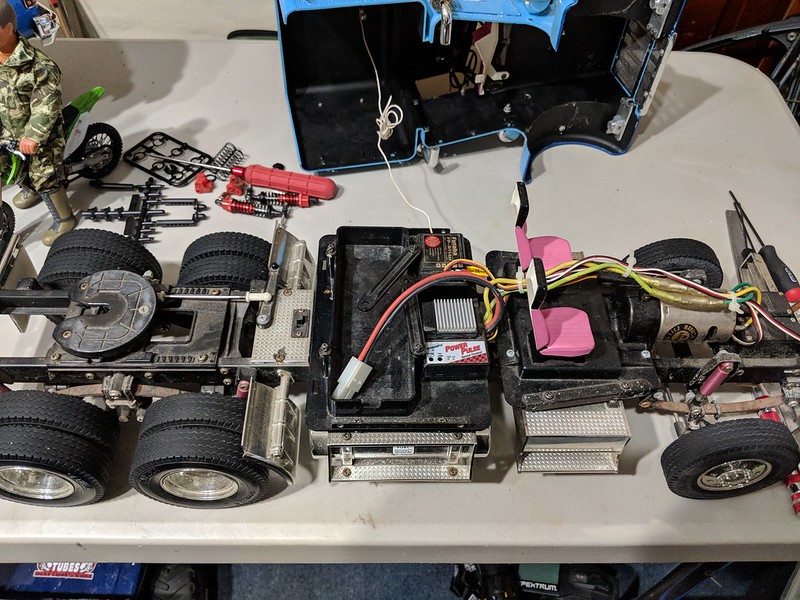

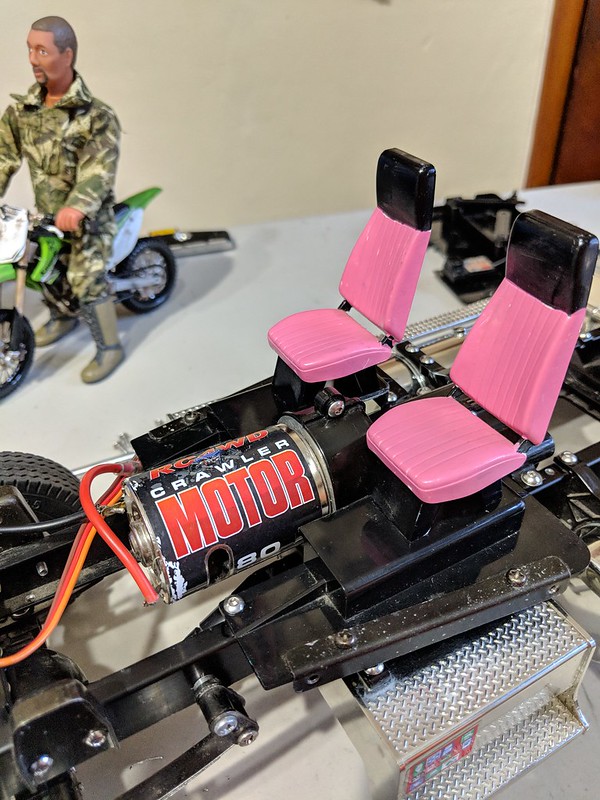

So bare with me on this. I'll be leaving out details and bring everyone up to speed quickly. Getting this truck has been a long time coming. Mike Kirby from KNK Hardware acquired it at the Toledo air show a couple years back and wouldn't part with it. I built an Axial based 6x6 build that Axial featured online and he wanted it in a bad way. Last year we came to a trade deal we were both happy with. so it began....        I believe this was an original from maybe the late 80's, early 90's? Looks like it was brush painted. All original condition. Even the pink interior. LOL Hopefully this all worked and i can share the rest of the build with you. |

|

#2

|

||||

|

||||

|

My oldest trk was bought April of 95, looks identical to yours

__________________

Sharing knowledge is one thing that defies basic arithmetic logic --- the more you share, the more you get! Joe |

|

#3

|

|||

|

|||

|

Thanks Lil Giants. I started in RC in the mid to late 80's so only going off what i remember from The Tamiya catalogs/flyers. And the electronics date it.

|

|

#4

|

||||

|

||||

|

Good to see you over here too! Nice looking vintage truck to start with. Does this turn into the grey/brown one?

Atleast the old electronics didn't have an MSC.

__________________

What do ya mean "Cars are neither Trucks or Construction"? It's still scale, and i play fairly well with others, most of the time... |

|

#5

|

|||

|

|||

|

Yes it does Frizzen......

|

|

#6

|

|||

|

|||

|

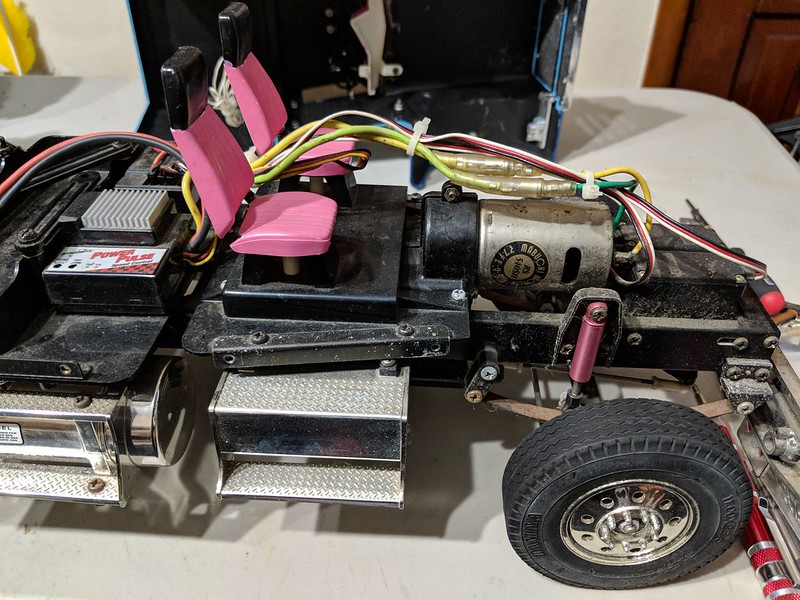

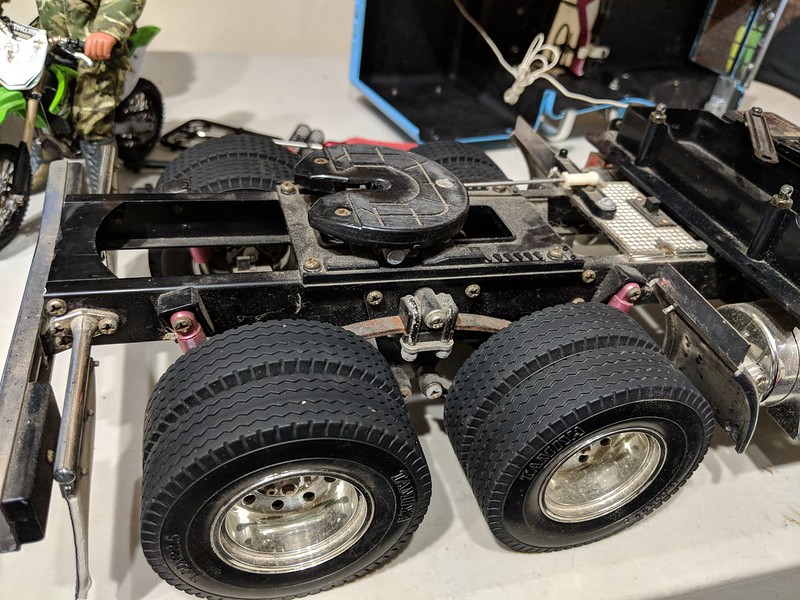

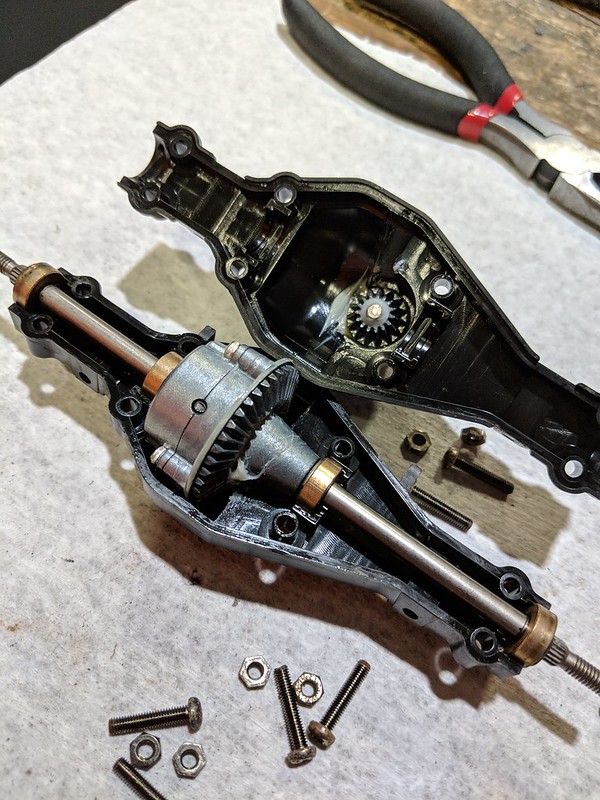

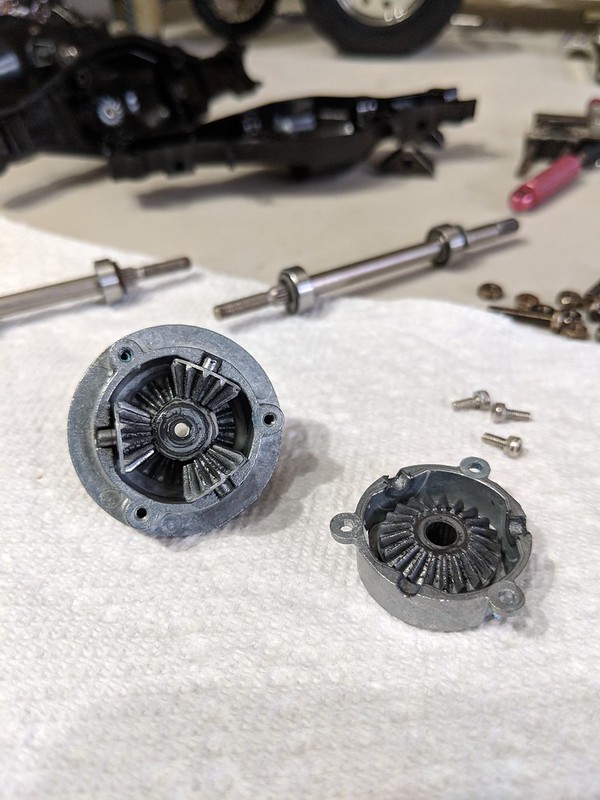

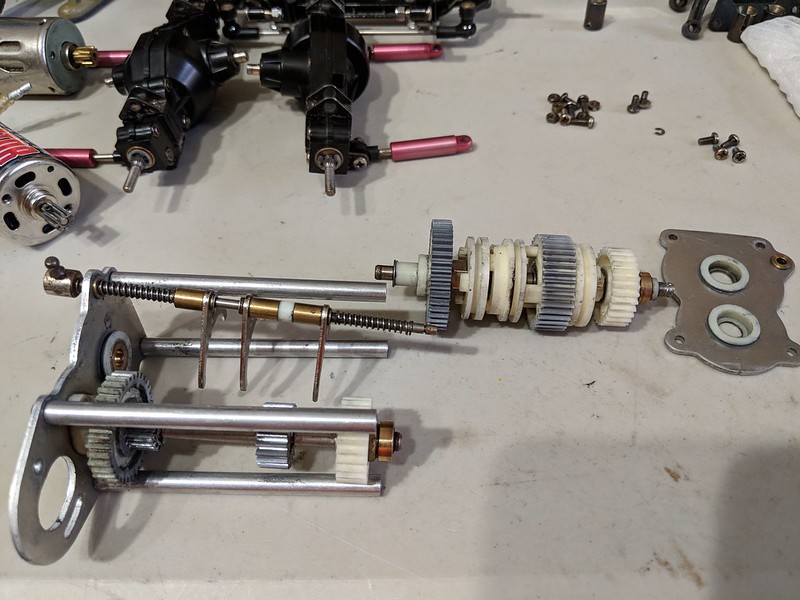

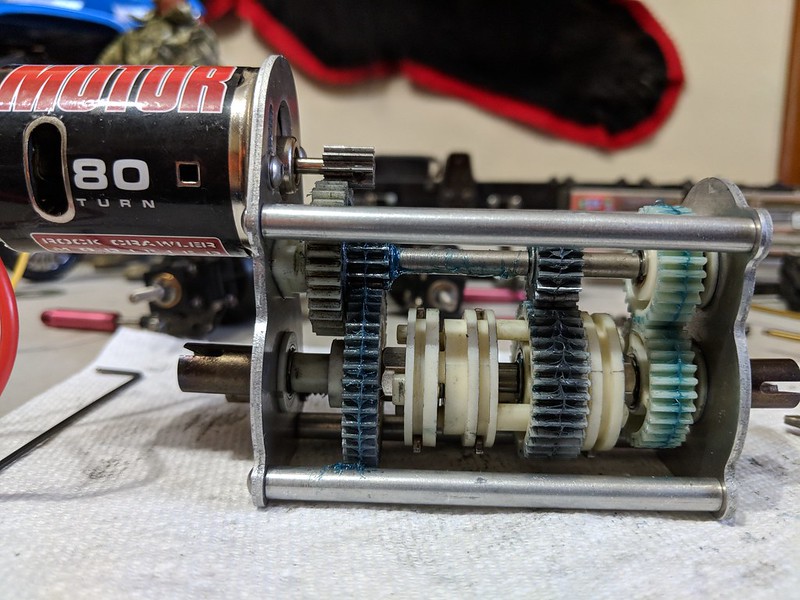

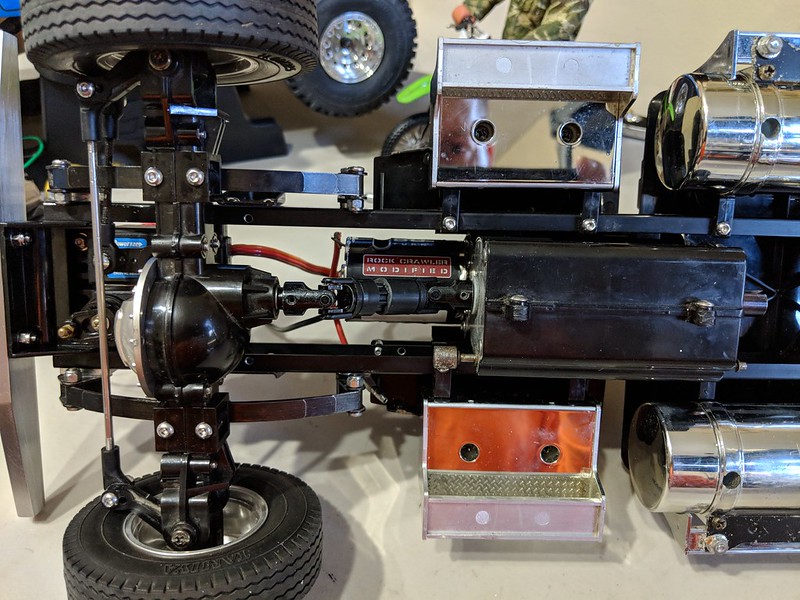

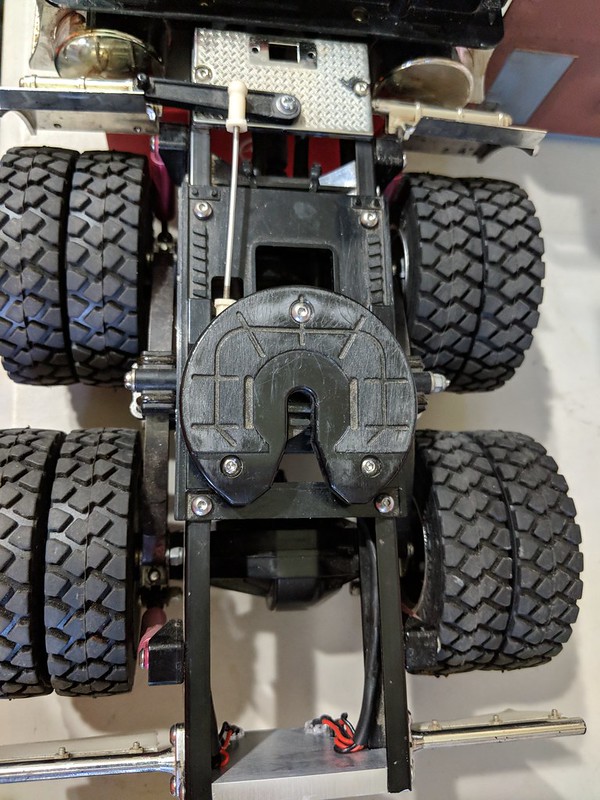

I disassembled everything to clean it up a bit. Scrubbed all the steel parts to remove rust and oxidation and lightly oiled suspension parts.

It appeared to still have the original Tamiya grease in it. This truck didn't have much run time on it.  Being a scale crawler guy i had to lock the diffs seeing how this truck will be used on dirt more than on pavement. I thought i took a pic, basically just add a fourth spider gear inside the diff to lock everything up.   Once locked up i applied some Marine grease and Fast Eddy bearings to make everything run smoother.  Now we have two fresh rear drive axles, next up is a driven front axle.... |

|

#7

|

|||

|

|||

|

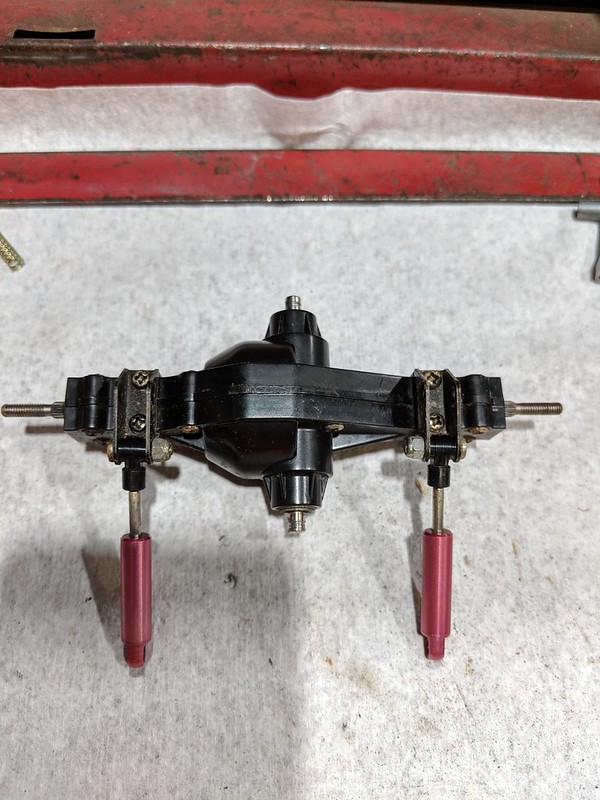

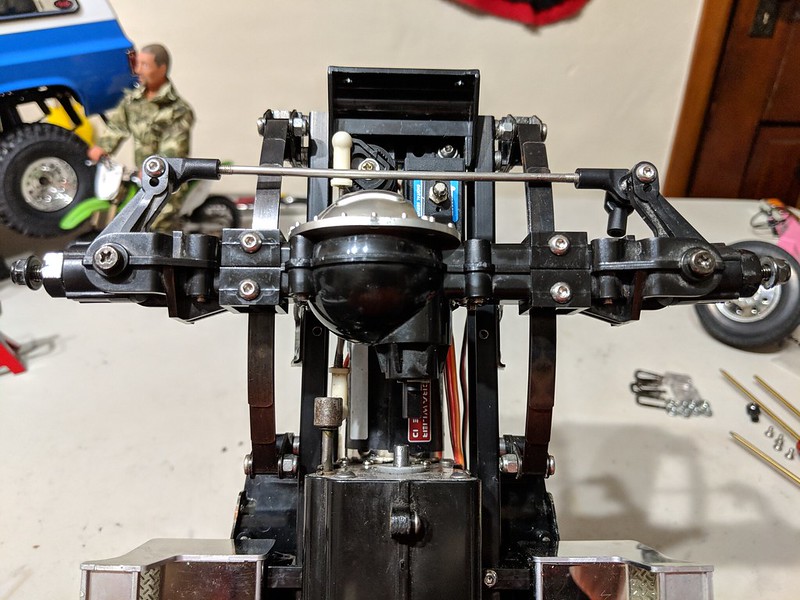

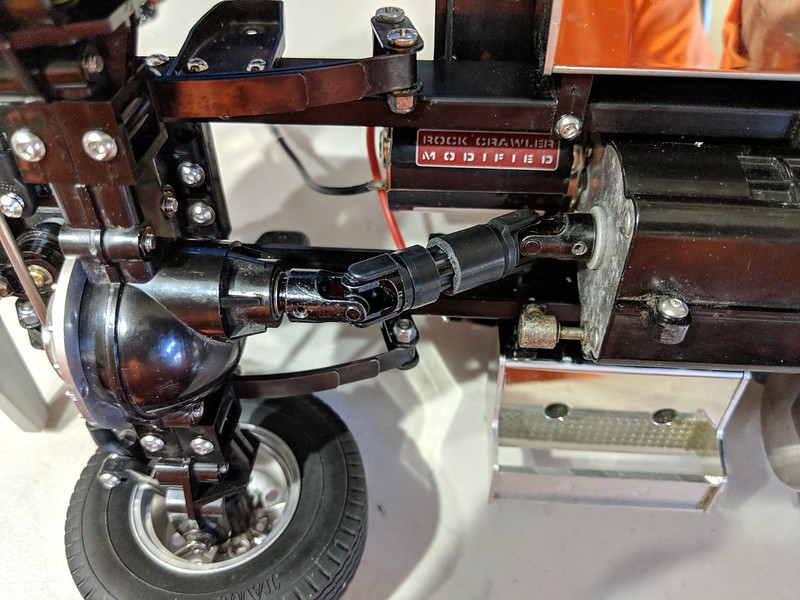

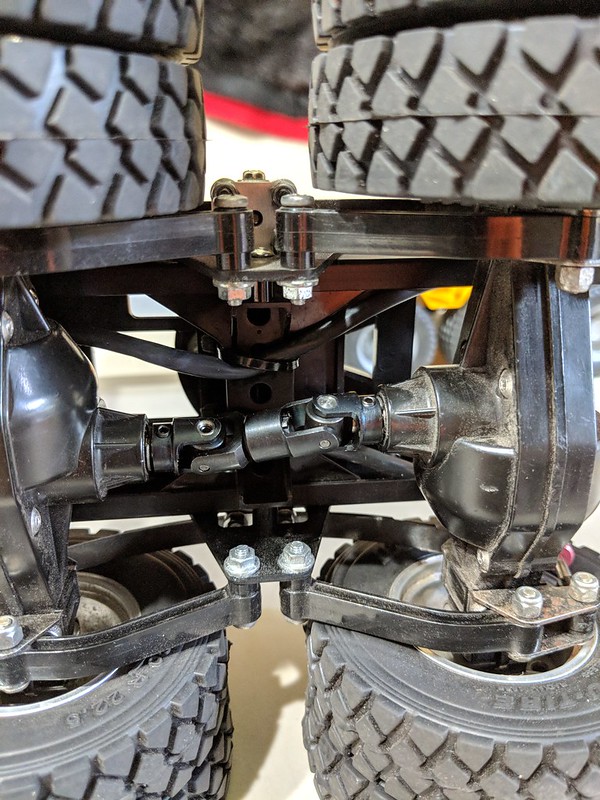

Let me add i used Team KNK SS hardware everywhere i could.

There are several options for front drive axles. In staying with my cheap hauler theme i chose the cheapest option. I scored a set of Tamiya Hi Lift/F350 axles complete for a really good price at a swap meet. The ratio is the same as the big rigs. These axles are the widest option from pin to pin but i wanted a slightly wider, tough looking stance anyways.   I kept the stock King leaf spring pack so i had to drill two mounting holes in them. Use a coolant and go slow and it's fairly easy to do. I also drilled a little indent in the top of the axle housing for the rivet to sit down into.   A complete front drive axle with steering components.  Next up will be mounting to the chassis..... |

|

#8

|

|||

|

|||

|

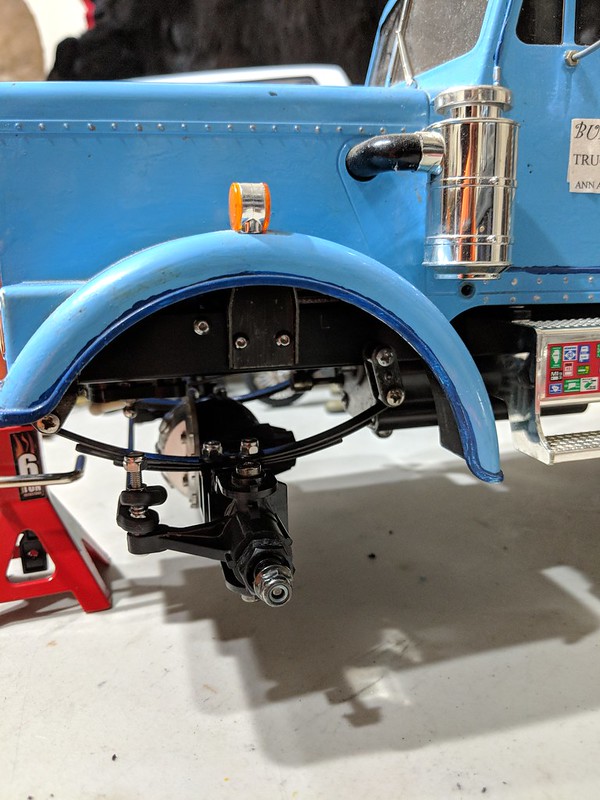

I didn't care for the high front stance with the springs mounted in the original chassis holes. I drilled new holes 5mm higher to mount the springs. This got the stance where i like it.

And added some spacers due to the spring width being slightly wider than the stock straight axle.  The washers were temporary, i made an aluminum spacer once i knew how much was needed.  And the front axle and springs bolted in place.    And in keeping with my cheap theme the easiest, cheapest way to put front drive wheels on is use the stock plastic inner rear dual wheel because it has the hex drive.   Now onto the cheapest way to drive that front axle..... |

|

#9

|

|||

|

|||

|

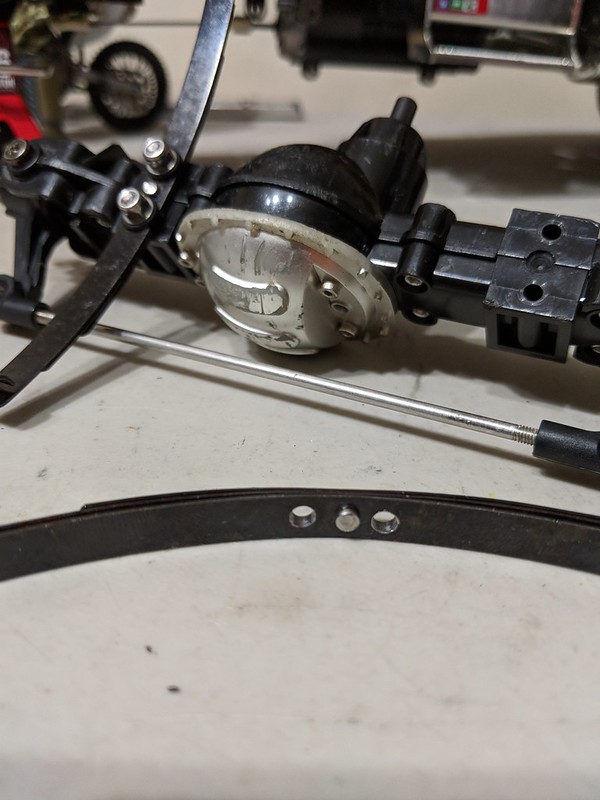

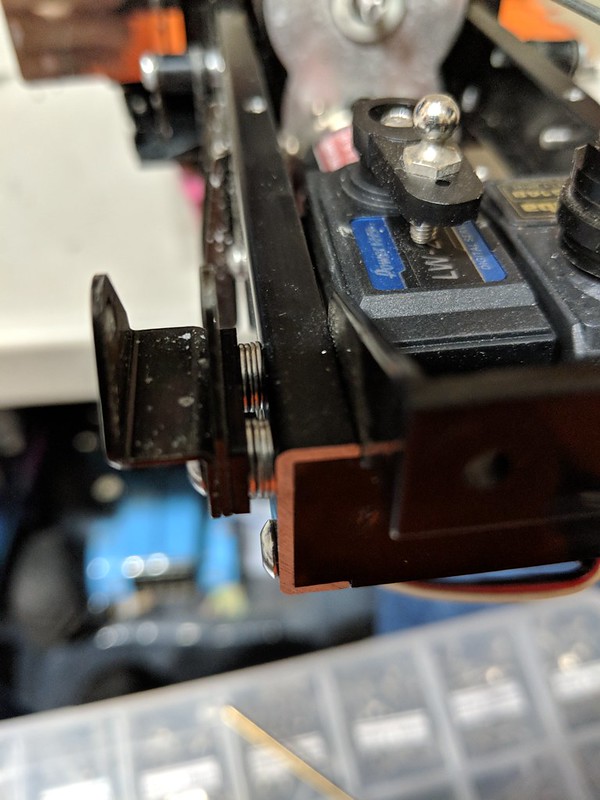

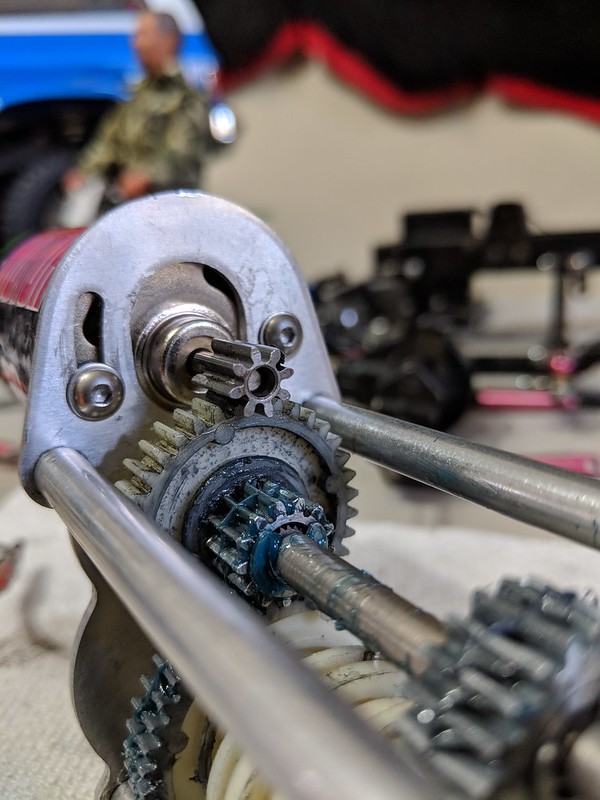

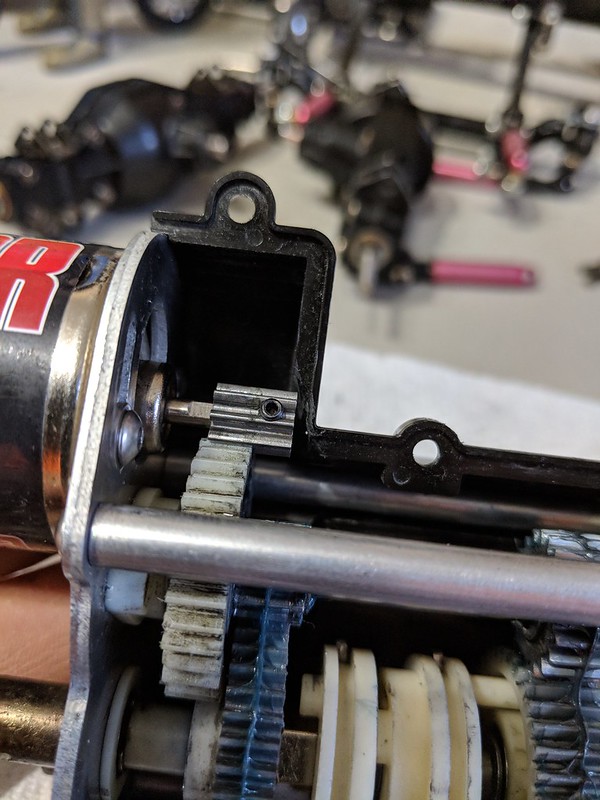

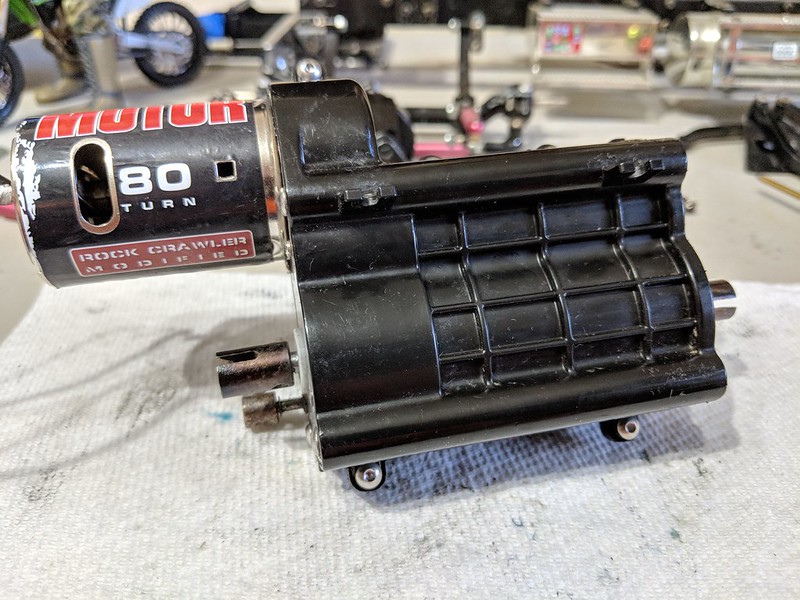

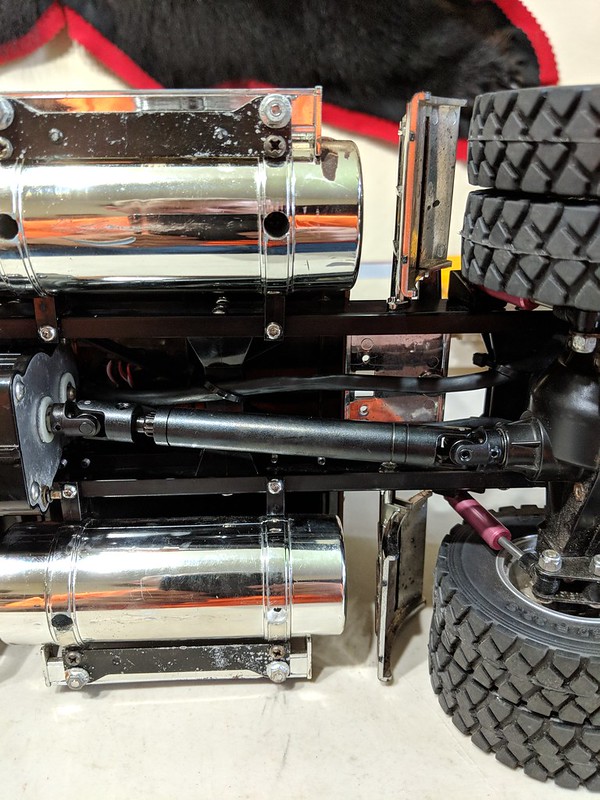

Lets disassemble the stock three speed to clean, re grease and add bearings to it.

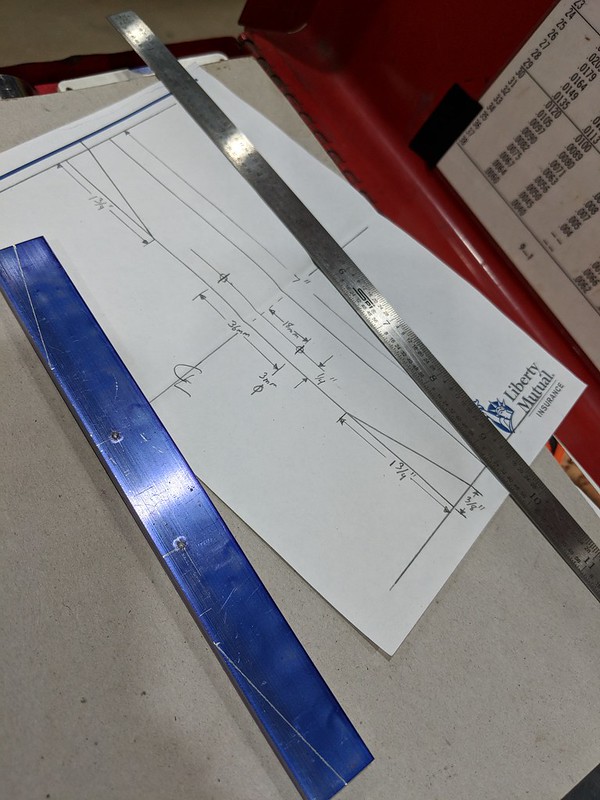

Coming from a welding background and being a Millwright the cheapest way to get a front driveshaft spinning was to weld up the main output shaft and file a flat spot for a set screw to snug up against. stock shaft.  Newly extended shaft.   Even running an 80 turn crawler motor i wanted a bit more low end grunt. I ground the motor mounting holes some to get an 8T pinion installed.    Being as i had this long pinion gear in my box and keeping it cheap i had to grind the transmission cases just a little for clearance.  All buttoned up and running smooth.  To get a driveshaft in the front and a decent pinion angle i opted to move the transmission rearward as far as it could go and still retain the stock body mounting brackets. To do this i cut the seat platform into two pieces so the motor could slide between them and still retain stock body mounting position.   For measurement purposes i cut up an RC4WD Marlin Crawler driveshaft to make sure everything was going to work. Steel driveshafts will be ordered once final dimensions are set.    And for steering purposes a waterproof 20kg servo.  Next up we'll try to remove that old brushed on paint..... |

|

#10

|

|||

|

|||

|

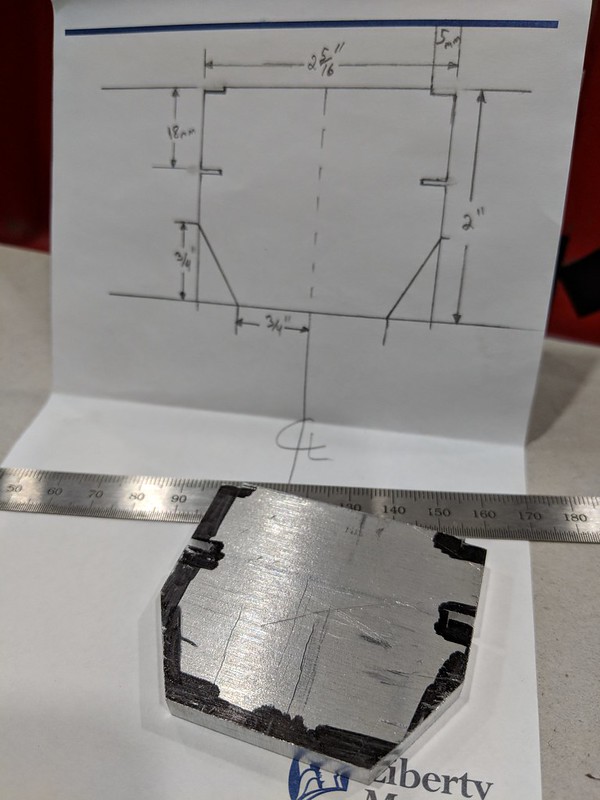

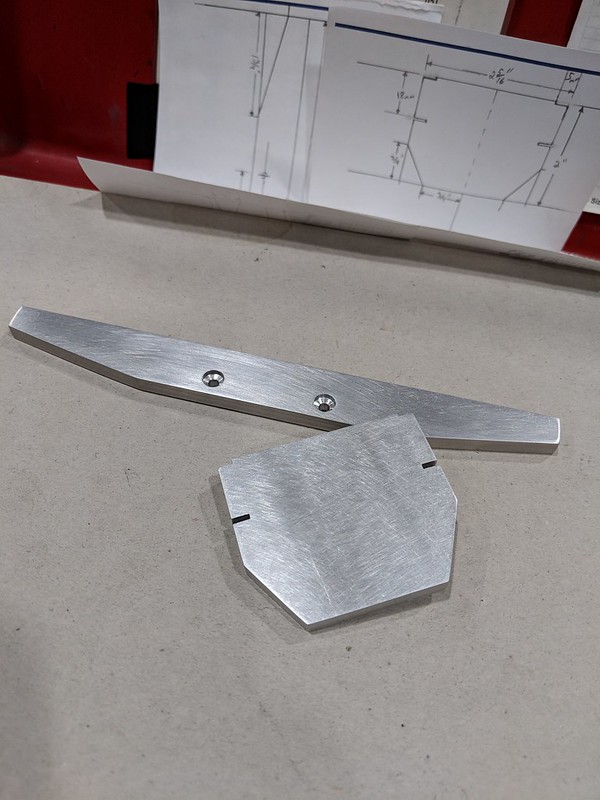

Building was kind of out of order. Did things in a not so very organized fashion.

Here are some quick aluminum bumpers i cut during my lunch breaks.     Mounted before i put the True Scale light buckets and LED's in.   Now onto trying to remove that old paint. I tried the oven cleaner in a bag trick. It didn't touch the stuff. So i got some 99% alcohol to soak it in. It worked to some small degree. This paint was just not coming off.    Now i got it a little better than that last pic shows but there was no way of getting a super nice paint job out of it. That's when i decided this will be an old barn find and someone is in the middle of restoring it little by little. So a two tone primer paint job and then some light weathering was in order. I didn't document the painting procedure. Basically sprayed the whole truck with rust primer then masked off areas and sprayed with grey primer. Then once dry i weathered it with Citadel gaming paints. so the next build pics really aren't about the paint but will give sneak peaks of it while explaining something else to the build. |

|

#11

|

|||

|

|||

|

I got the G.T. Power cargo truck sound unit/light kit module. Again, it fit the cheap budget theme.

Once i understood the sketchy directions and watched a few YouTube videos in foreign languages i was able to get it properly hooked up. I'm running it with a Turnigy i9x in mode 2, throttle on left stick. I ordered another steering gimble so i could use the spring return parts for the throttle stick and now both sticks self center. With the GT power unit once the transmitter is powered up you move the left (throttle) stick to the right position and this starts up the engine. If you do not start the engine the truck will not have power to the ESC. Which i'm running an Axial AE5 crawler esc because the drag brake function is pretty nice. All other functions will operate; steering, lights, horn but the truck will not move unless the engine is started first. This position also shuts the engine off and an air release noise is emitted. The only complaint i have is for the size of the speaker it isn't loud enough. I have it taped up in the sleeper pointing down and back. At a recent indoor show where there was background noise and people talking my truck was hard to hear running. I'm going to look into a smaller, louder speaker if i can find one. The LED's are labeled and self explanatory. I did have to add five additional yellow 3mm LED's for the cab lights. The GT kit didn't have enough.

|

|

#12

|

|||

|

|||

|

Very nice explanation of your rebuilding process, thanks.

|

|

#13

|

||||

|

||||

|

That's really cool. When i saw it at the show, i hadn't noticed how much was custom.

For next time you overhaul a truck, a DOT-3 brake fluid soak is pretty good about stripping paint off bodies. Oven cleaner works well to strip chrome.

__________________

What do ya mean "Cars are neither Trucks or Construction"? It's still scale, and i play fairly well with others, most of the time... |

|

#14

|

|||

|

|||

|

Thanks Zabco.

|

|

#15

|

|||

|

|||

|

Quote:

I'll try the brake fluid next time and going to do the chrome thing this weekend on another project. Thanks. |

|

#16

|

|||

|

|||

|

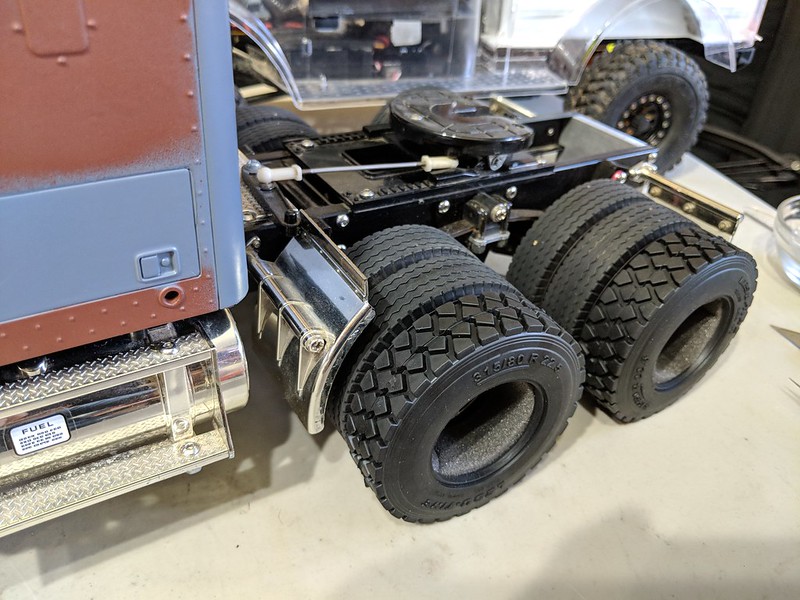

We needed a good set of tires since this truck is to be used off pavement more than on. So many choices out there but you can't beat the Lesu's for the money. Had to wait about three weeks for the boat ride to the States but they were well worth it.

Much more treadier. lol

|

|

#17

|

|||

|

|||

|

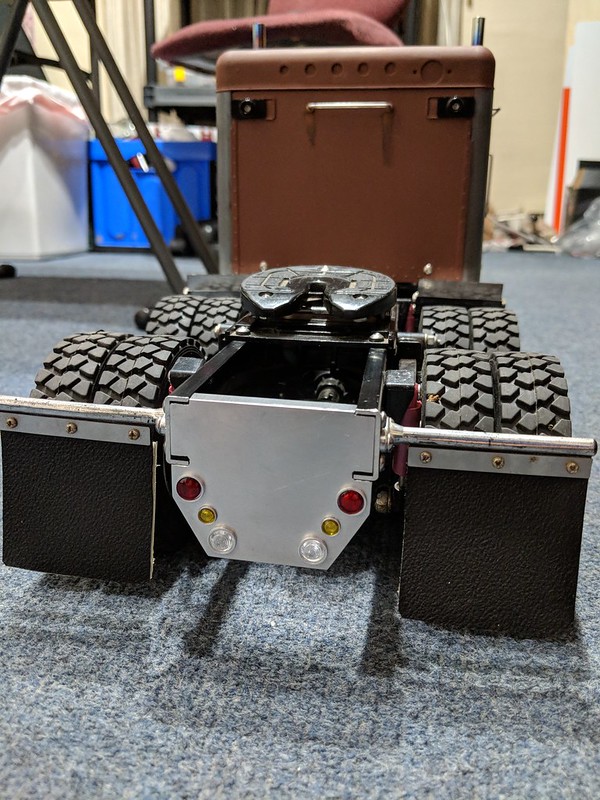

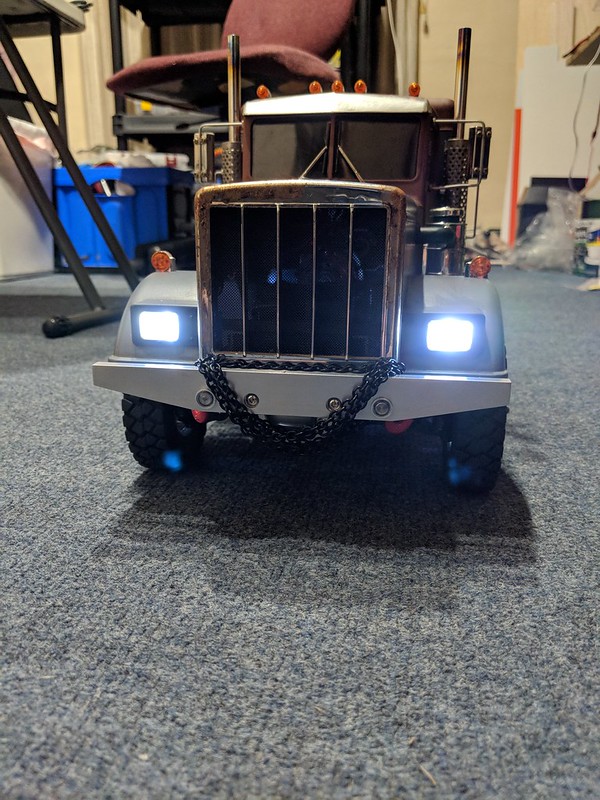

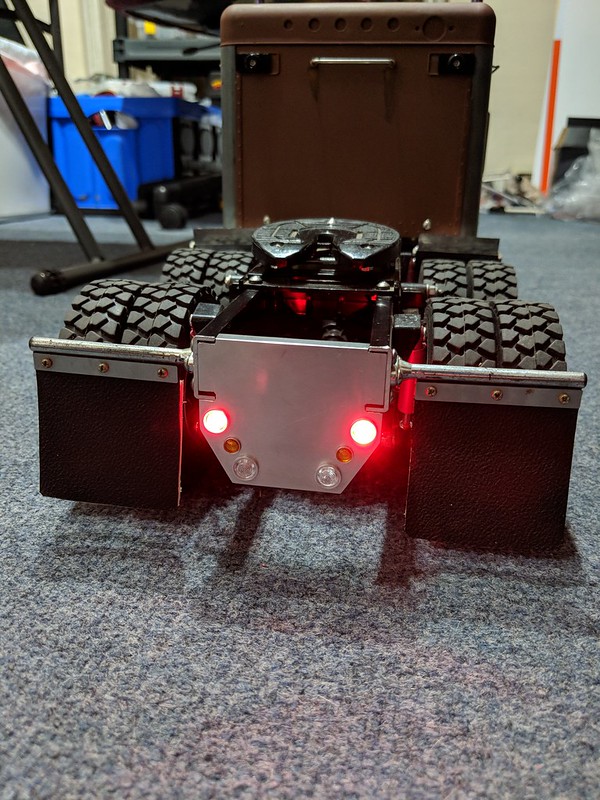

Closer to road legal, we need some lighting. I used True Scale light bezels in 3mm and 5mm. The GT Power unit came pre wired and had plenty of length for this build. I did have to add the five extra yellow LED's for the cab lights later on. I just used a Y harness to plug them into the headlight connector. The blinkers work with the controller motions and if you put it in reverse the backup lights come on. This does require two motions of the reverse stick to make that happen though.

I didn't have the cab lights in it when i took these pics. And i must not have taken one with reverse lights on.     And the wires run through heat shrink tubing to tidy them up a bit.

|

|

#18

|

|||

|

|||

|

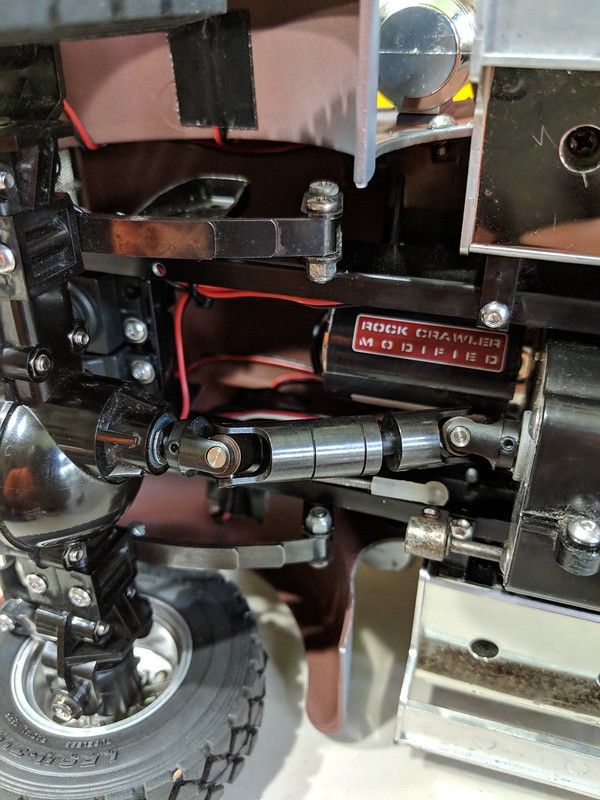

In searching for steel driveshafts i came across some china made units that fit this cheap budget build. Again, a long boat ride over but they are worth it i think. Pretty well built units so we will see how they hold up.

That was a pretty quick get you up to speed build. I'll post up some more things that went along with the build and events I've taken it too..... |

|

#19

|

|||

|

|||

|

I LOVE it! I've been thinking of tinkering with a front wheel drive dump truck. I just on't have the confidence to hack a Tamiya 3 speed xmish to make the front driveshaft. I fear I would booger it up & ruin the Xmish

|

|

#20

|

|||

|

|||

|

I'm going to do another one in the future. I might go a different route though and use a gear reduction/transfer case setup. Simpler, less bulk. I leave my three speed locked in low gear anyways, it's perfect in my opinion.

|

|

| Currently Active Users Viewing This Thread: 1 (0 members and 1 guests) | |

|

|