|

|

|||||||

| Construction Equipment If it digs, pushes, hauls dirt "off road" post it here. |

|

|

|

Thread Tools | Display Modes |

|

#1

|

|||

|

|||

|

Hi,

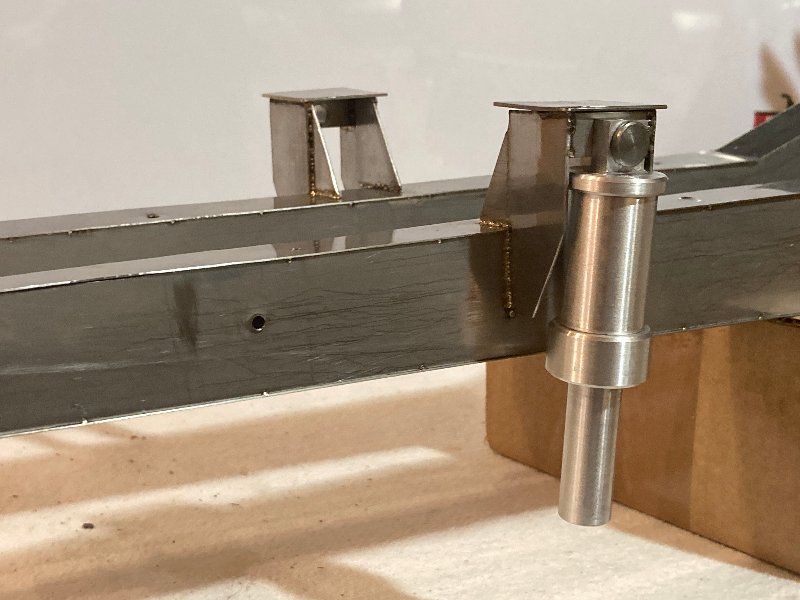

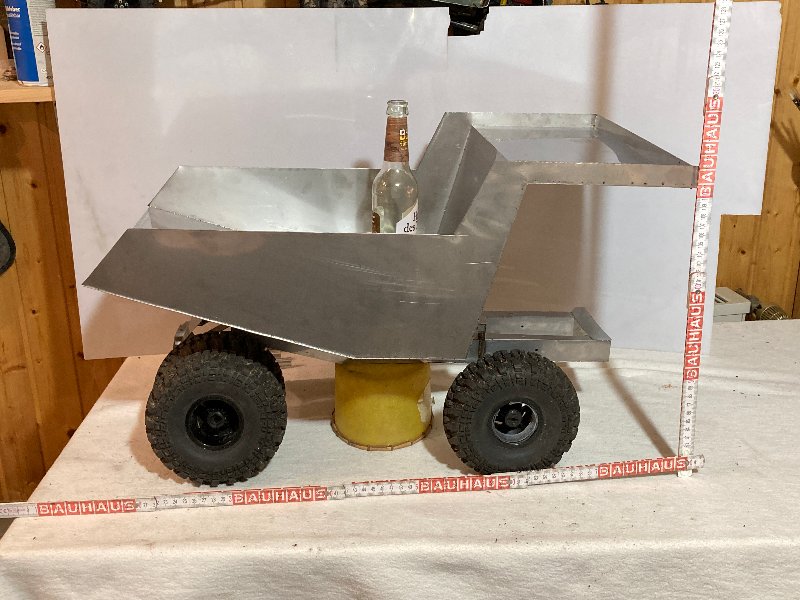

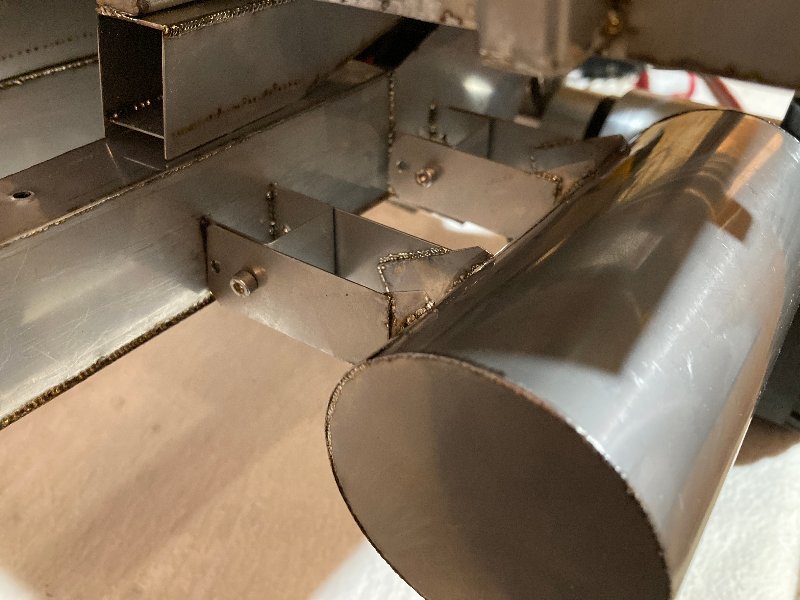

at first some few Words about what and why. I've build a Russian Mining Dump Truck called Belaz 7540. It is the smallest Model with 30 tons payload. In 1/10 that is 20KG weight and 30 kg payload. btw: wich measurement is usual in this forum, metric or imperial? Anyway. Why? Simple. I was tired of my small skills in handling plastics. So i've tried to handle metal. After many errors my skills has risen and little by little i've bought a lathe and a mill for widen my possibilities. So I've learned machining. And I've don't learned something called metal shaping. i.e. with a english wheel. By that, I have to look for simple shaped, edgy Bodies. And here it is  Looks simple but it will be complicated in details. Key features: Hydraulic Steering, Rear Drive, two telescopic lift cylinders. Latest Tool in my Shop is a Lampert M280 micro tig welder. And now the build starts. Fortunately i've found a very good parts catalogue with many sketches. Without any sizes but from the tire-size upwards i've take all needed sizes to start. Material will be stainless sheet metal .3 und .5 mm thick. First greater parts are the Backplate and the frame.   The frame are just four sheets without any additional internal structures.

__________________

Regards Ralf |

|

#2

|

|||

|

|||

|

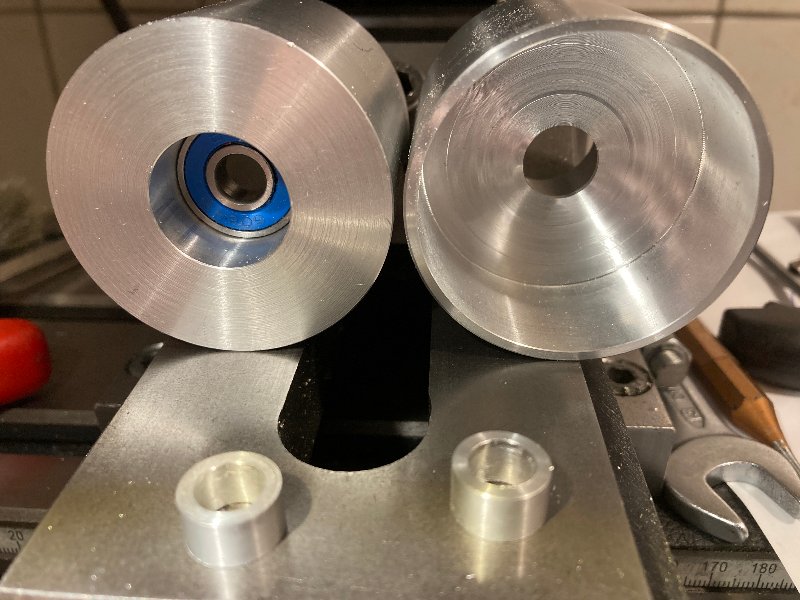

My simple "rules" for a all parts of a build

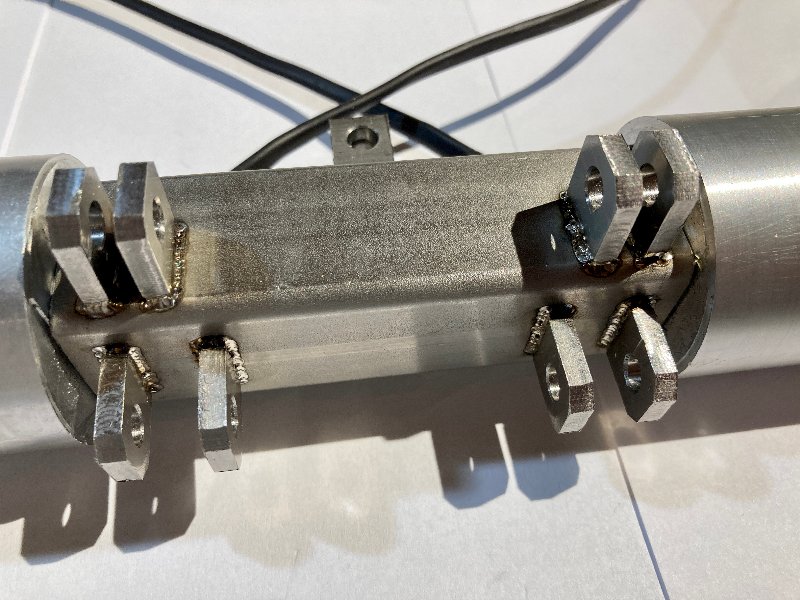

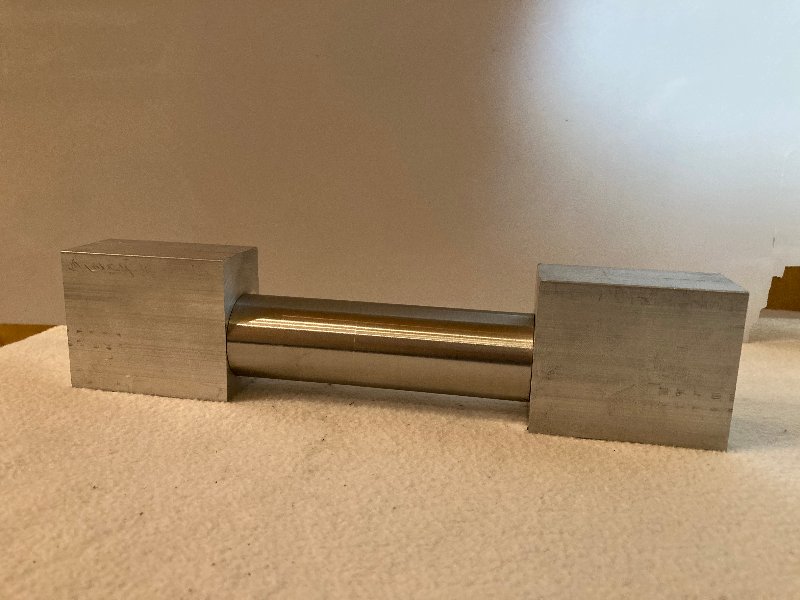

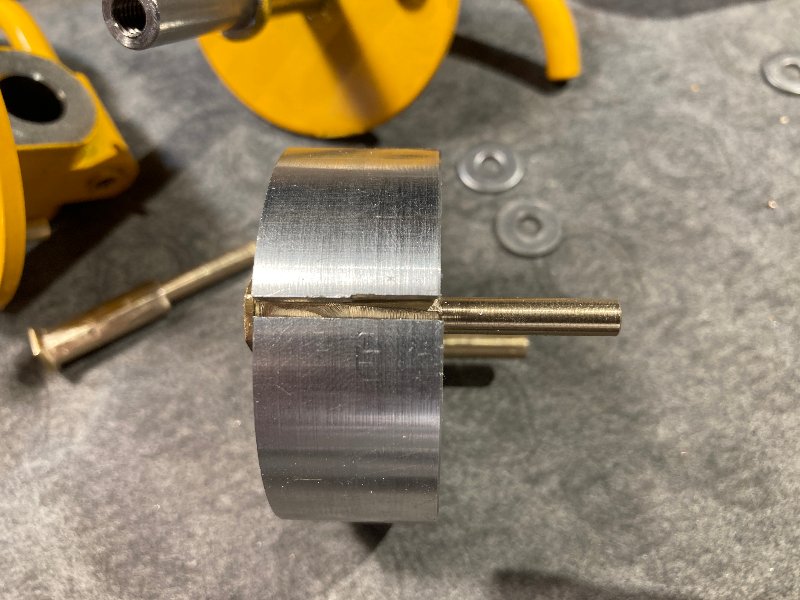

a) try to make on my own. if it is scale: wonderful. If not: so what.  b) if a) is negative or I'm too lazy for it: buy it. ------ So i've tried to made my own shock absorbers with internal springs. The result made from aluminium. With a minimum lubrication they works as I want up to 20 kg payload. Above this they are compressed, but that will be rare moments in the life of the dumper.  on their places

__________________

Regards Ralf |

|

#3

|

||||

|

||||

|

That's a neat looking truck.

Nice metalwork on the frame. Which welding method are you using? Those massive shocks look really amazing. A large portion of us use Imperial measurements, some Metric, some include both to be inclusive. Use what you're comfortable with 20kg payload dump truck is going to be a very impressive

__________________

What do ya mean "Cars are neither Trucks or Construction"? It's still scale, and i play fairly well with others, most of the time... |

|

#4

|

|||

|

|||

|

It's a pulsed tig.

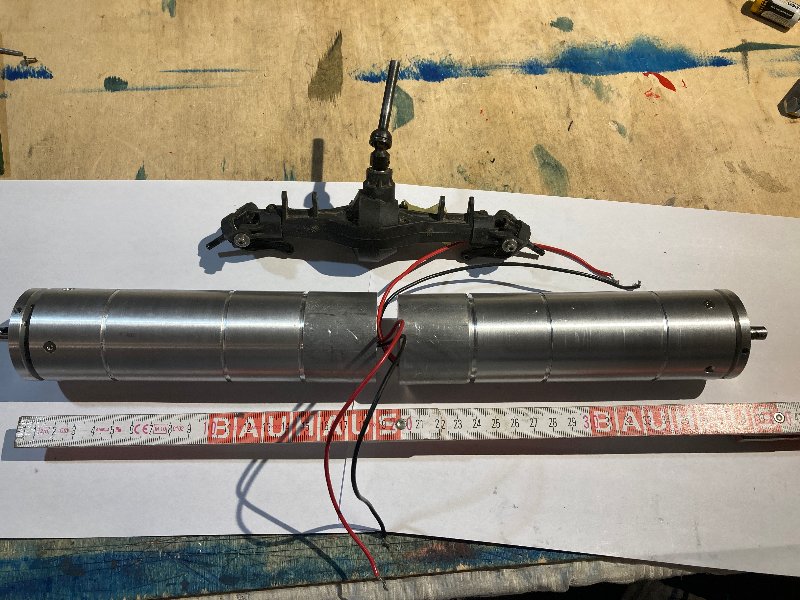

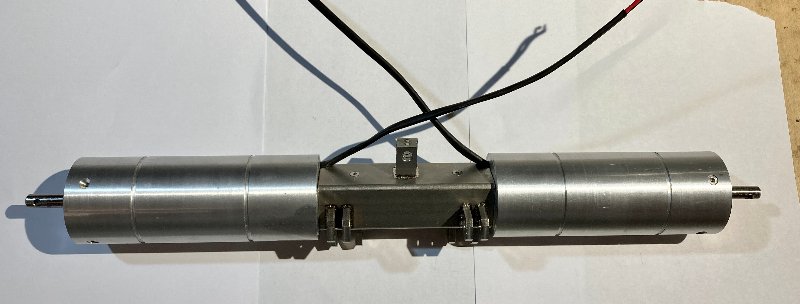

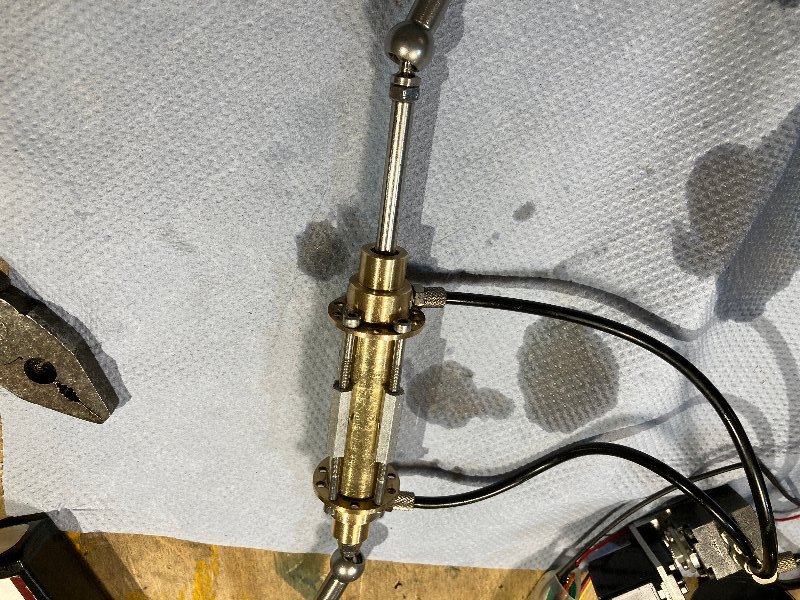

Originated at jewellers and dental technicians. ----------- During a former Project i've built a hydraulic cylinder. The car isn't run anymore so i've used the cylinders body again. A hydraulic steering needs piston rods in both directions. I convert it from  to  For scale it is way to big, but i need the diameter to get enough pressure for steering. Parallel the work on the trough begins the rough form is easy  but the typical beads are an enormous bulk of work   an intermediate result  ----- 50 kg / 110 lbs total weight? A usual 540 motor will be a bit overwhelmed. From a kind hobby colleague I've get two big 24v motors with very tough planetary gearboxes. side by side with a usual 540 with planetary gearbox

__________________

Regards Ralf |

|

#5

|

|||

|

|||

|

That's some nice looking work! Looking forward to watching your build progress.

|

|

#6

|

||||

|

||||

|

That's a great start to what I'm sure will be a rewarding project Ralf

__________________

Sharing knowledge is one thing that defies basic arithmetic logic --- the more you share, the more you get! Joe |

|

#7

|

|||

|

|||

|

Nice work Ralf

How do you like that Lampert M280? I have the older version M200 and I love it.

__________________

Ari To view links or images in signatures your post count must be 10 or greater. You currently have 0 posts. |

|

#8

|

||||

|

||||

|

What's the learning curve like on the pulse TIGs? Seams "easier" than tradition TIG welding, but looks can be deceiving when watching experts.

|

|

#9

|

|||

|

|||

|

Quote:

@blender: i don't have any other experiences with welding. for me the simpliest material to handle is 1.4301 stainless. and welding with additional wires are still not my thing  thereby my models are mainly from stainless

__________________

Regards Ralf |

|

#10

|

|||

|

|||

|

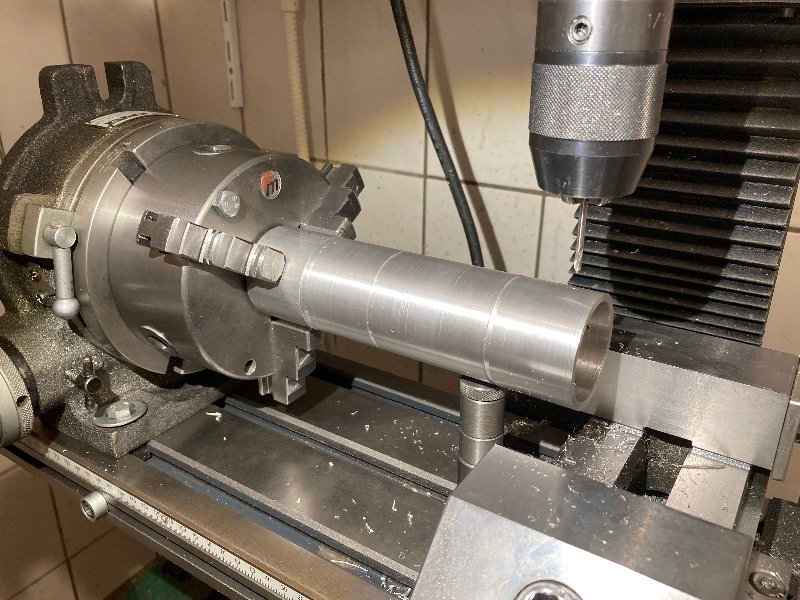

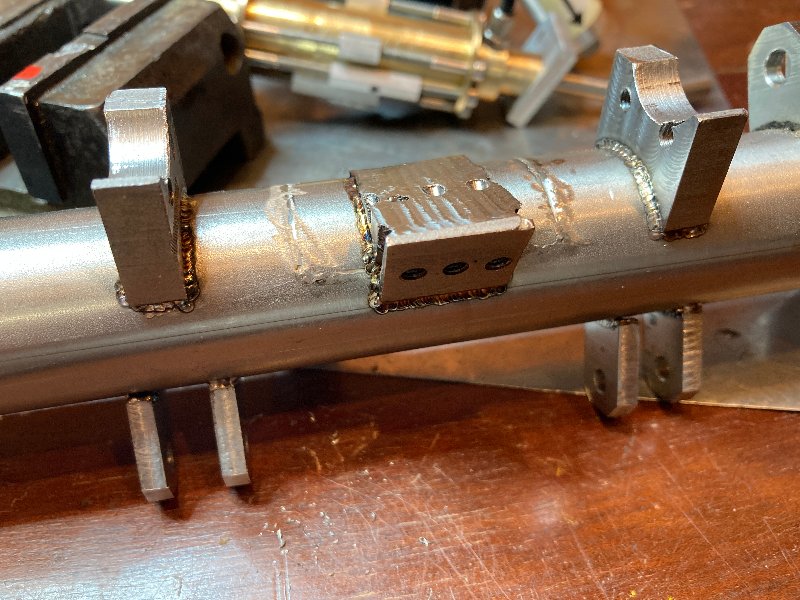

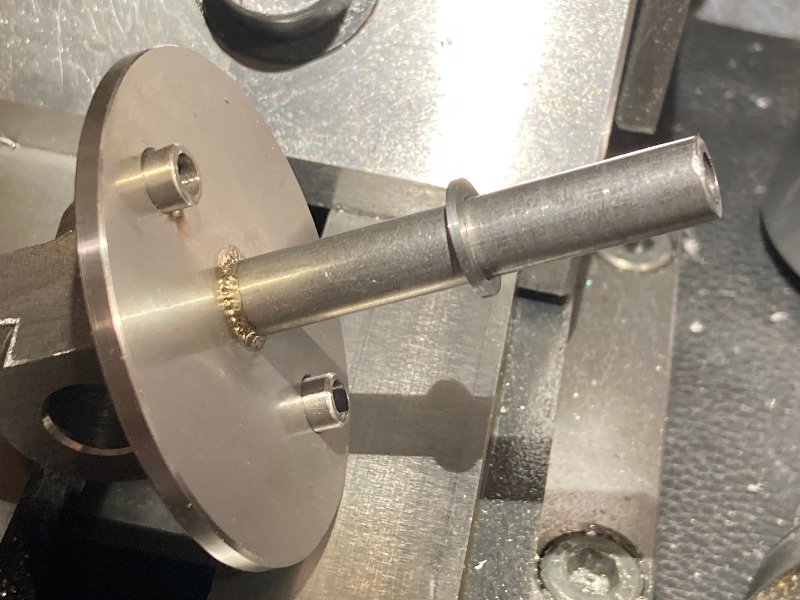

rear axle. the middle piece from stainless for the flanges for links and suspension.

50 kg total weight was too much for a usual 1/10 drivetrain but the fat wheels with their 60mm diameter enabled me to built a motor-in-axle drive the half axles are from aluminium 50 mm od.    to compare with a usual old scx10/1 axle.  the middle part. flanges from 4mm stainless

__________________

Regards Ralf |

|

#11

|

|||

|

|||

|

The build started in juni '21.

End August '21 i've reached a first milestone. the trough and his bead are provisional welded  the rear axle gets her links  so the axle is mounted on the frame and a first loading test starts pre weighed 10 kg stones  nothing cracked . the shock absorbers moves just a few mm.  20 kg stones  nothing cracked . the shock absorbers moves just a few more mm.  30 kg stones. maximum payload is reached  nothing cracked . the shock absorbers down.  some manual flexing works well too. Now I've knew, that all the main components will work on full payload. At this point i'm very pleased with the build so far.

__________________

Regards Ralf |

|

#12

|

|||

|

|||

|

Very interesting build, will be quite fun to watch your progress. Sounds like you got into this hobby for the same reason I did, learn new methods and techniques. Keep up the great work and post often.

|

|

#13

|

|||

|

|||

|

Quote:

-------- After this Milestone, I've got the motivation back to weld all the beads on the trough (endless small sparks in .8 second rythm) and improve the strength of the frame.   Frame and struts are real scale. Always fascinating what a few pieces of sheet metal doing with the stability. Meanwhile the tires arrived. Bespoked fabricated. Full, hard Rubber.  The enormous wheigth...  .... result in exact 8 kg for the completed rear axle. I think it looks quiet nice  rims made  and a little stack of wheel caps too   As a little intermezzo the non-functional fuel-tank was done

__________________

Regards Ralf |

|

#14

|

|||

|

|||

|

Very nice fabrication! That is one solid looking truck!

|

|

#15

|

|||

|

|||

|

Thank you.

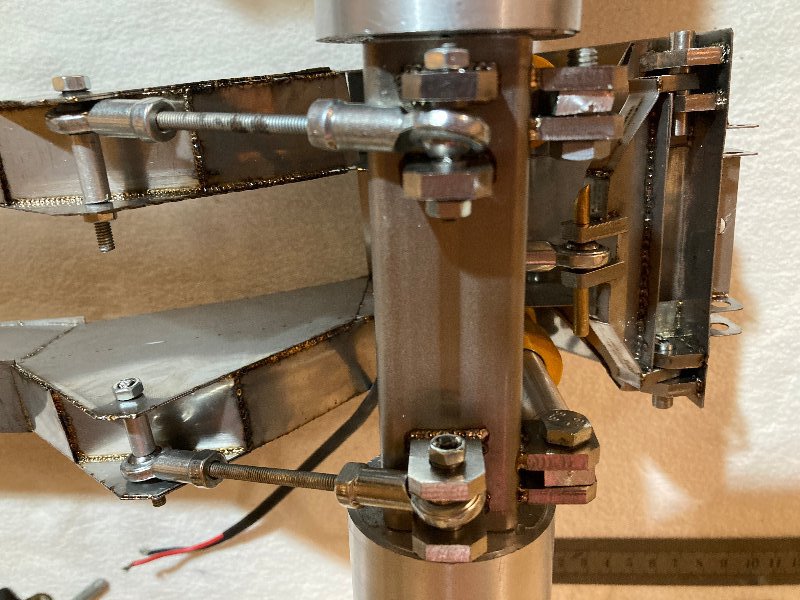

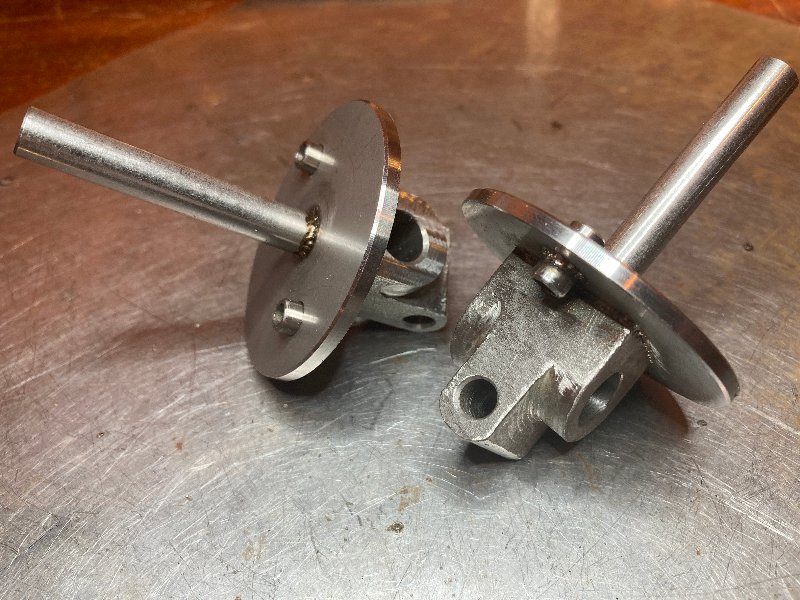

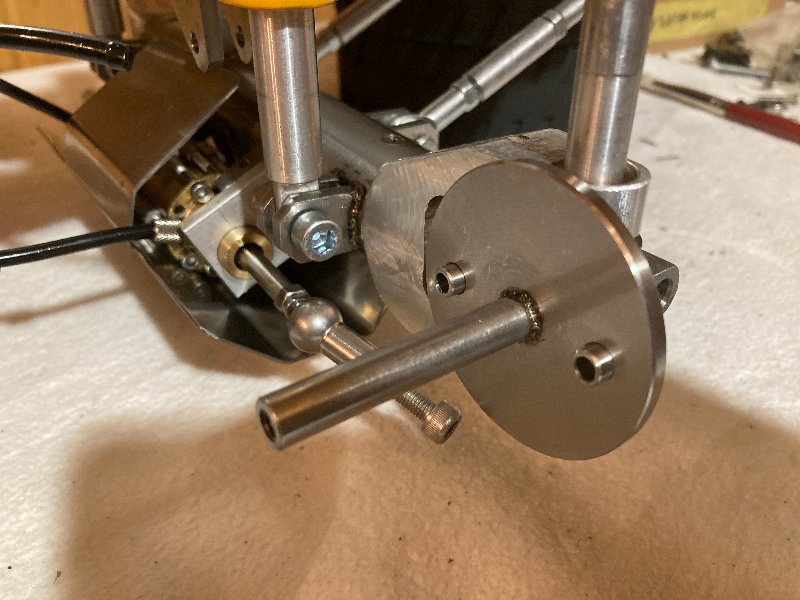

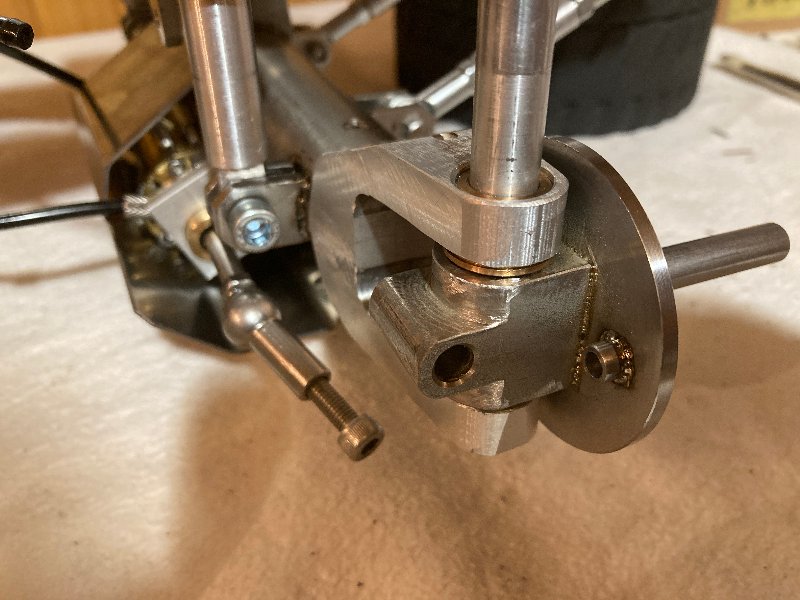

Making the front axle was much more complicated as the rear axle. Due to the great weight i need a real brake. the esc hillbreak wasn't enough to hold the little monster. The motors in the rear axle prohibit any break in them. Ergo the front axles must have breaks. The original has drum brakes. Consequently I plan my first drum brake in my life. That was a real exciting phase of the build. The axles body is from stainless 30mmx3 to hold the steering cylinder, three links and the panhard. The space looks wide but, as usual, at least I've to fight for every mm. The c hubs are made from aluminium. All sizes and shapes, except the hydraulic cylinder, are scale.  the c-hubs gets 3° tilt to prevent understeering        Flanges are from 4mm stainless....  ....or some more mm   Links done     overview and end of the simple part of the axle

__________________

Regards Ralf |

|

#16

|

|||

|

|||

|

Nice work , you should be proud of yourself.

|

|

#17

|

|||

|

|||

|

Thanks. I am

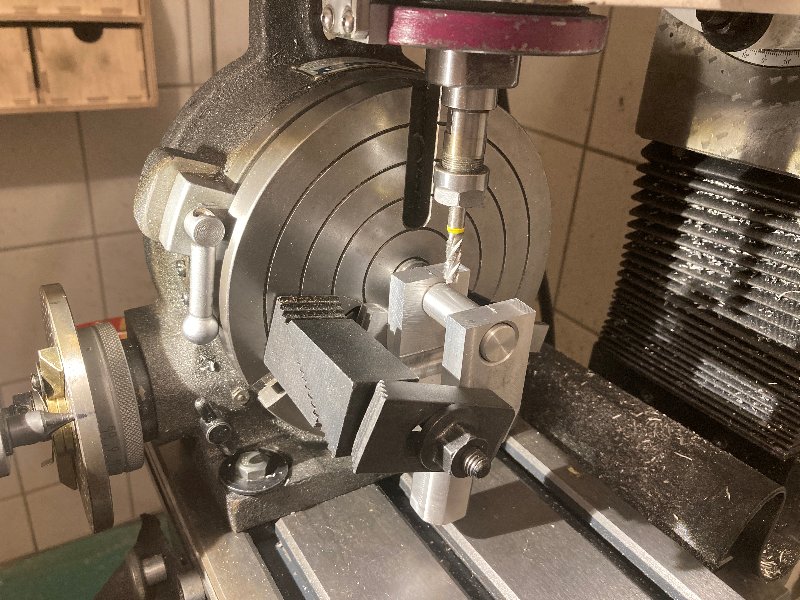

------------- The complicated parts of the front axles needed intensely research and planning time. Enough time for painting. Not my favourite task. But sometimes it has to be   Bored from painting, i've made the baseplate for the Front (1mm stainless)    Planning has closed and the work begins. Milling the Joints from stainless  After some tests about steering radius etc i've to shorten the steering cylinder. So i've take the opportunitiy and build it a bit more scale. later you will see nothing from it, but i know, it's almost scale.  changed cylinder needs a changed flange. from  to  at least mounted and covered from a heavy duty skid plate

__________________

Regards Ralf |

|

#18

|

||||

|

||||

|

I always enjoy seeing machine work photos, especially like seeing the work holding solutions. Jim

|

|

#19

|

|||

|

|||

|

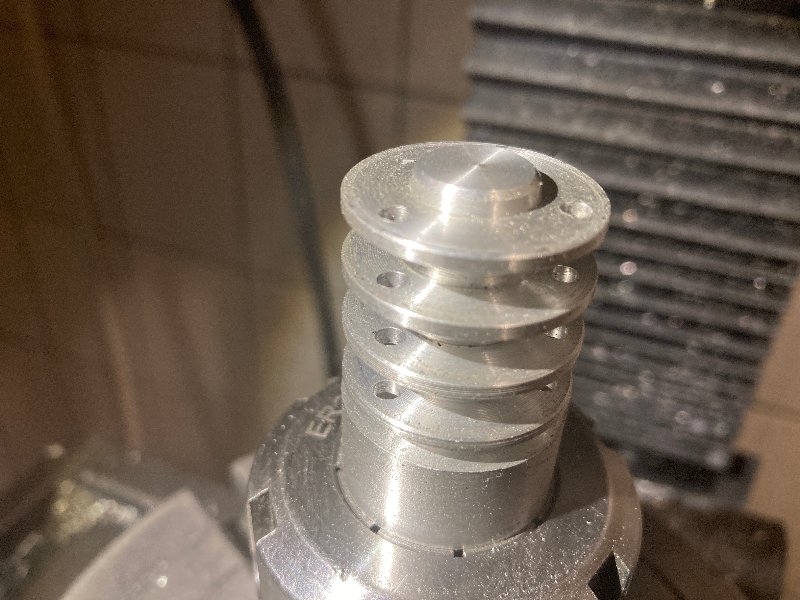

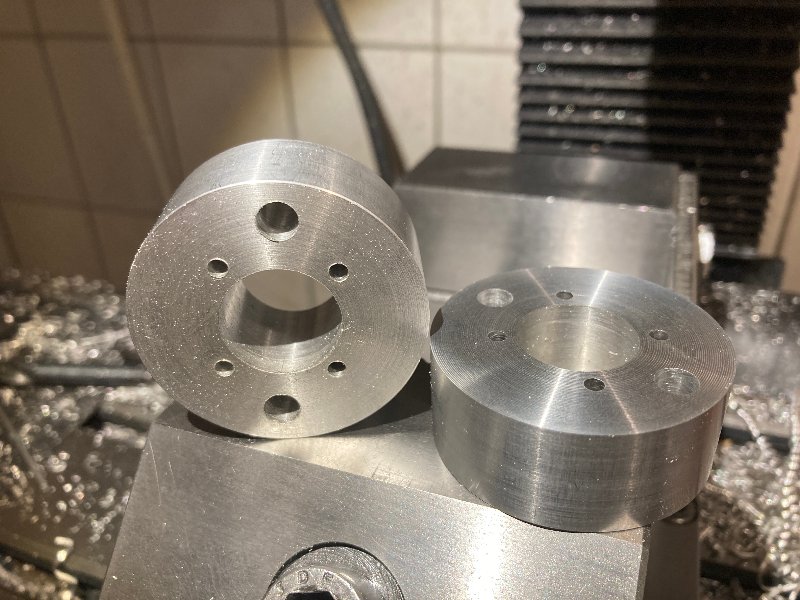

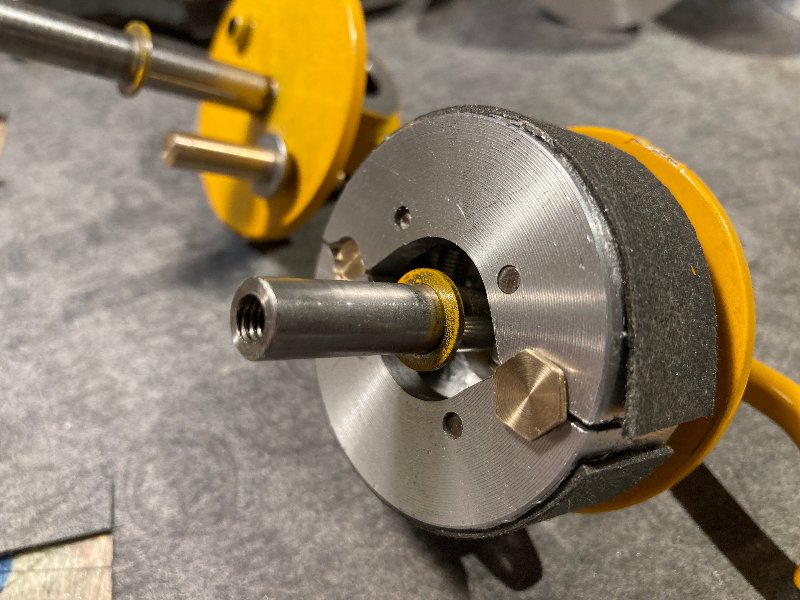

Drum Brakes.

some stainless sheet , 3mm thick, aluminium for the drums and some 6x1 stainless pipes  the square sheets are turning into round and welded together with the pipes  welded onto the joints  first tests. all things going well.   i need stops on the axles to prevent the drum from contact with the baseplate a lack of suitable stainless washers forces me to made my own small pieces of a 1mm sheet  turned together to the od  et voila  welded on position  in the their front , the drums has holes to hold two bearing and a spacer. in the back the big hole for the brake pad holders  put on the axle, the drum fits well and has no contact. the double bearings are strong enough to avoid tilting.  A good start into this chapter.

__________________

Regards Ralf |

|

#20

|

|||

|

|||

|

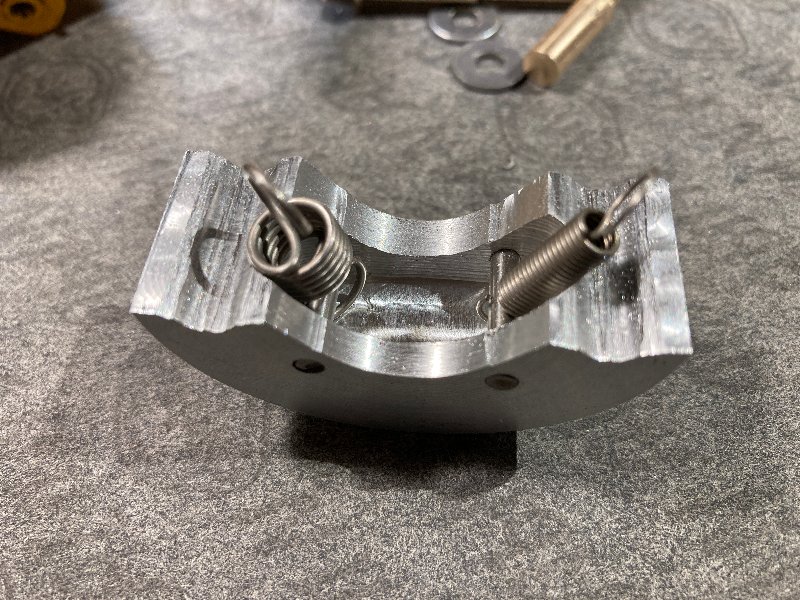

Drum bakes: Brake pad holders.

aluminium round  simple method to hold the round parallel to the middle  sawed and milled  brass bolts  fitted with springs  set up   a little problem are the brake pads themself. after a lot of research i've found the tip that gasket paper (abil eg) was a pretty simple material  and really: it works perfect. mocked up  next and last part: bowden cable and the mechanics to activate the breaks.

__________________

Regards Ralf |

|

| Currently Active Users Viewing This Thread: 1 (0 members and 1 guests) | |

|

|