|

|

|||||||

| Construction Equipment If it digs, pushes, hauls dirt "off road" post it here. |

|

|

|

Thread Tools | Display Modes |

|

#1

|

||||

|

||||

|

Since I don't have any trucks to fool around with I decided to convert an old 1953 Nylint Tournarocker sandbox toy to RC. The 1:1 machine was a diesel electric driven tractor steered by turning switches on and off on the dash and dumping is achieved by a winch with it's cable attached under the rear axle that pulls the rear forward dumping it's payload. I'll update some vintage photos when I scan them.

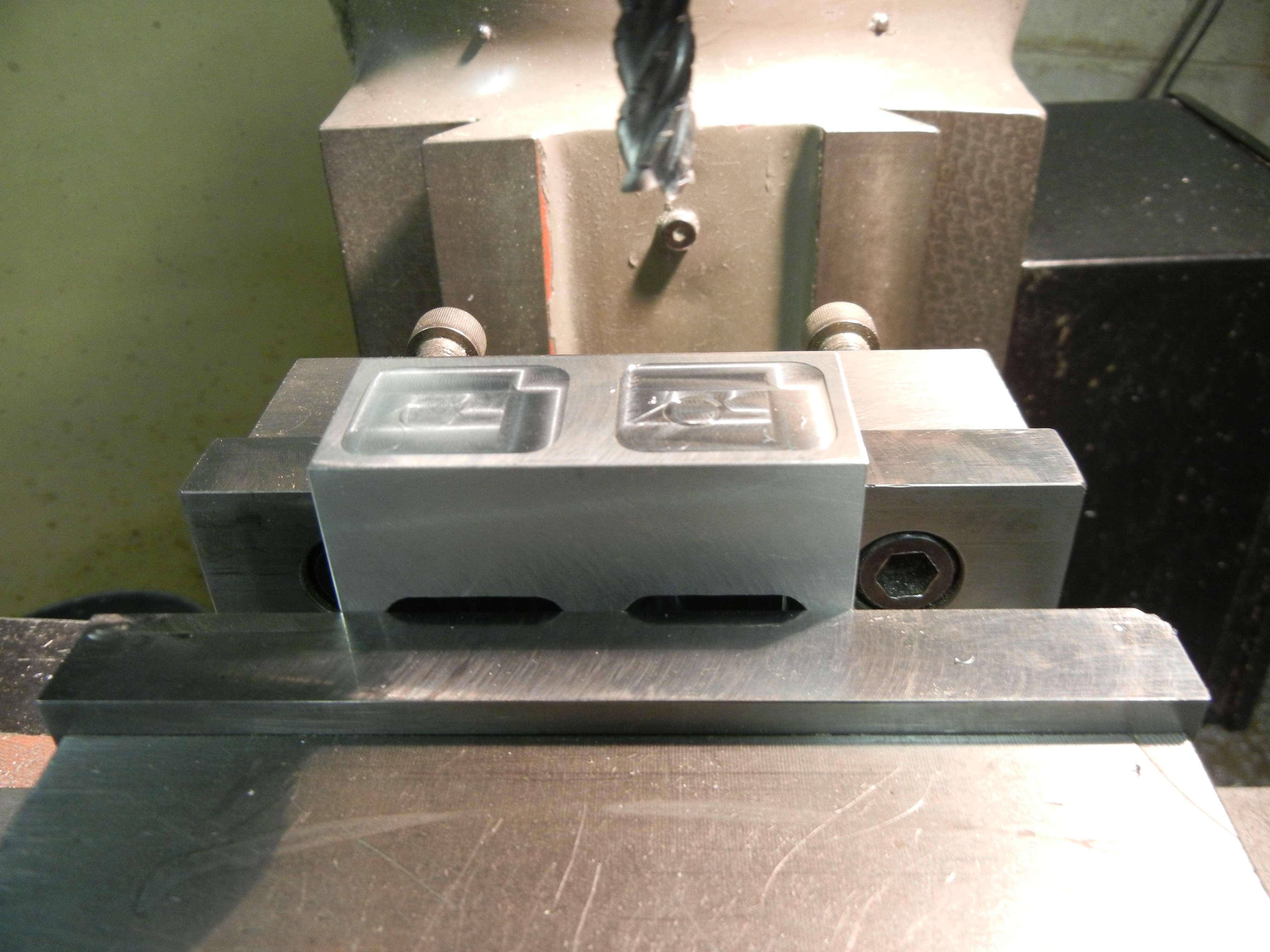

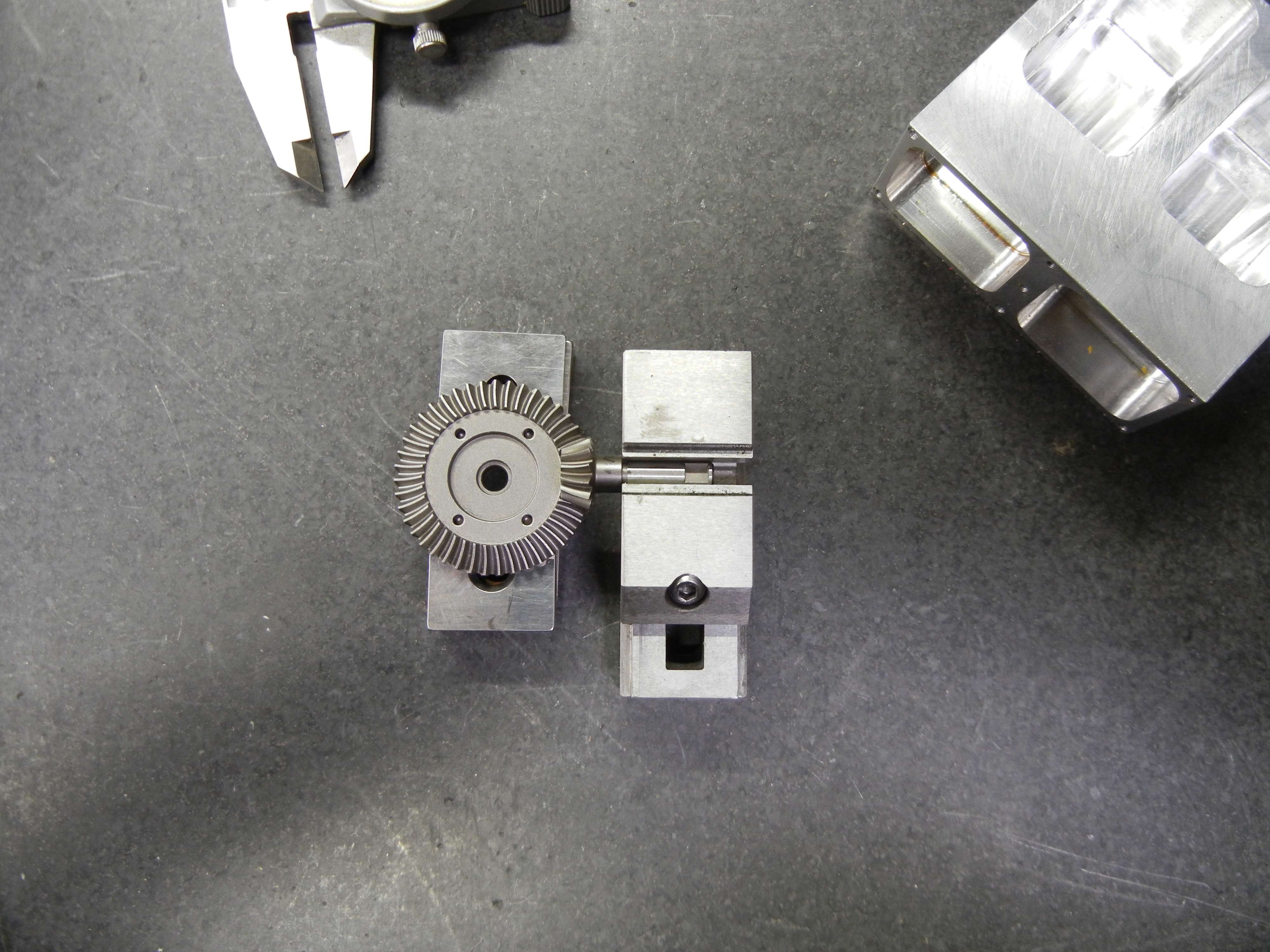

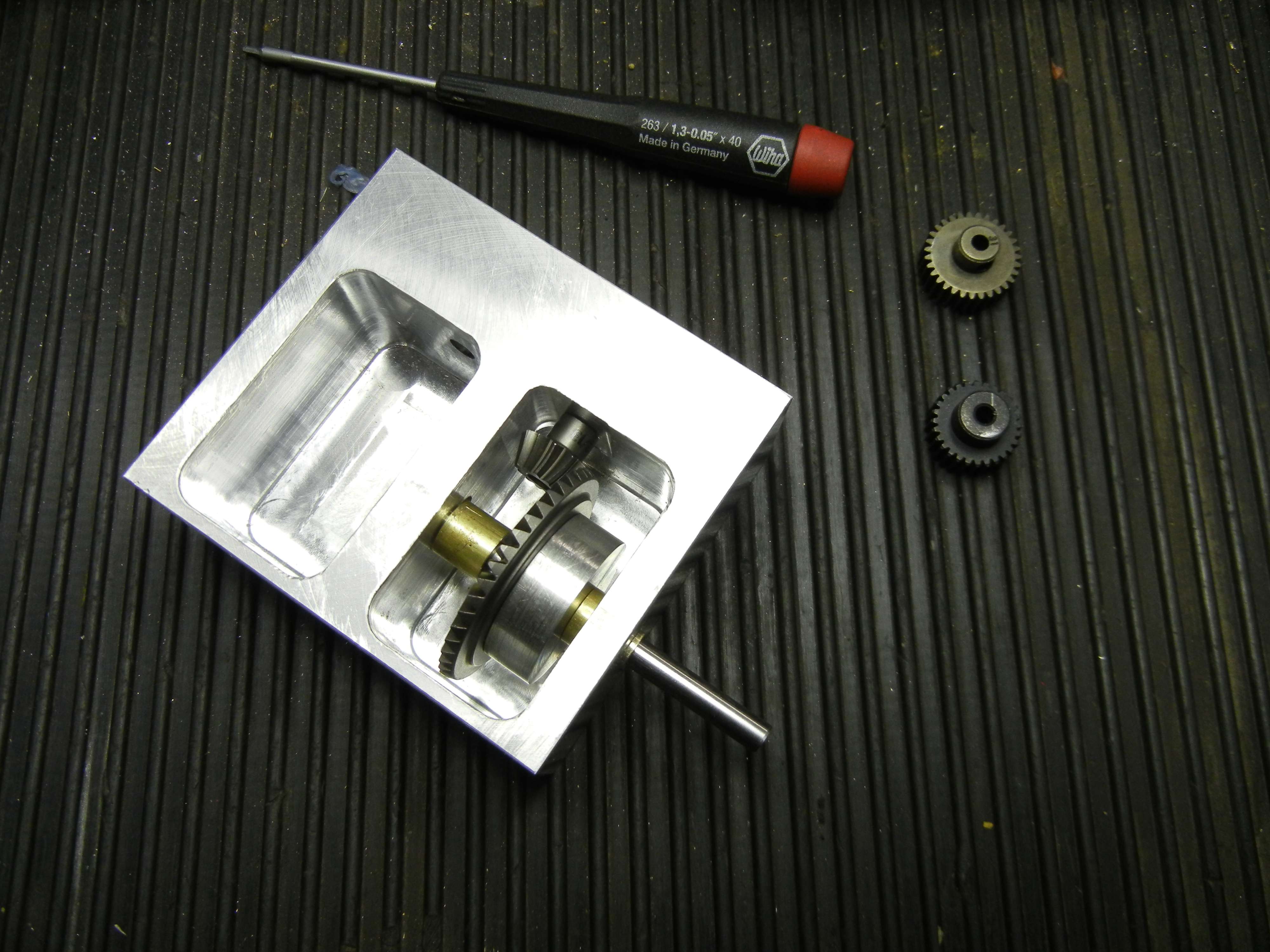

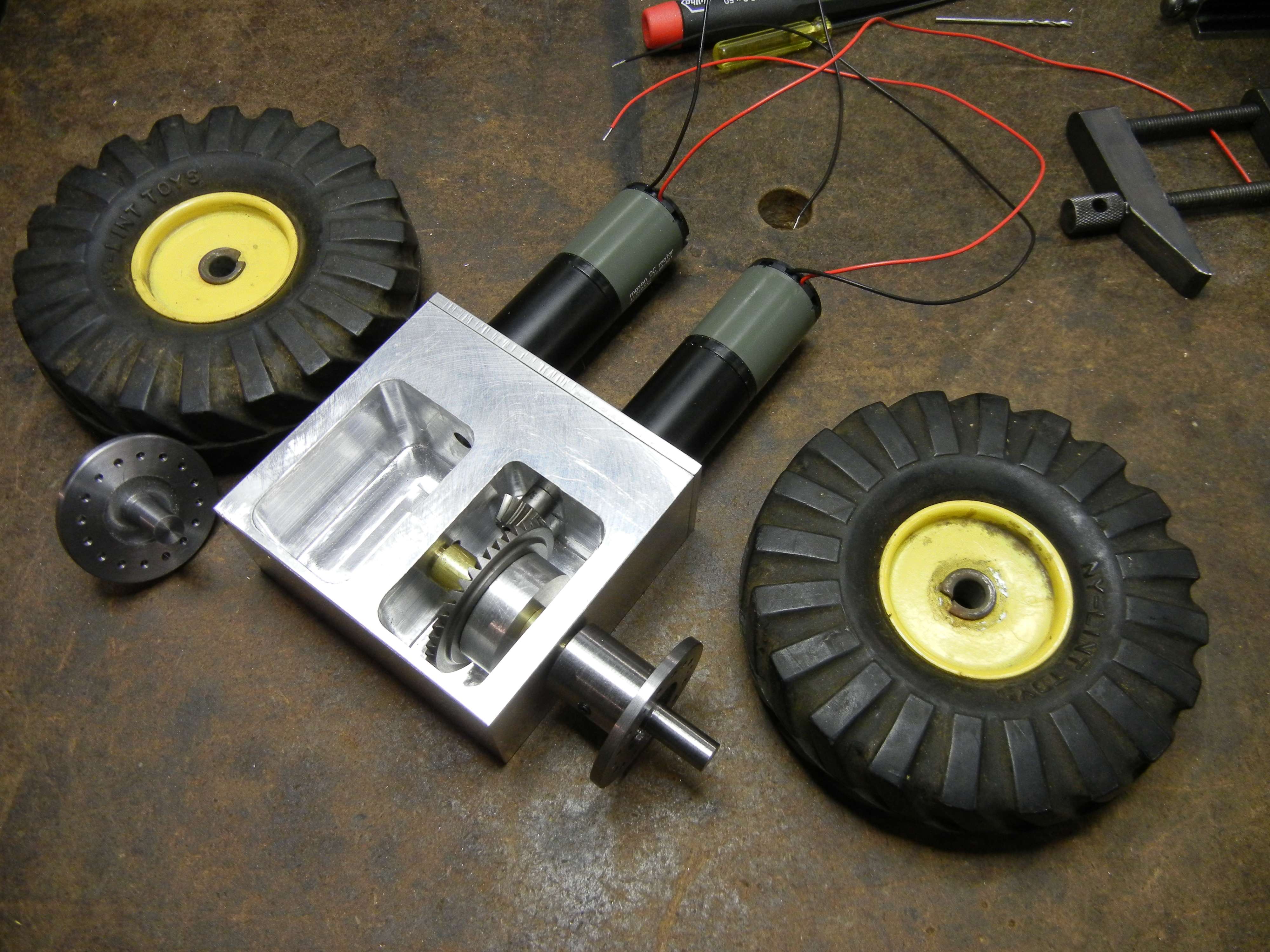

I want this to be a fairly simple conversion that uses a dual transmission controlled by a Dual Sabertooth motor control giving the machine "tank" steering similar to the 1:1 machine. Original toy only thing missing is the oscillating hitch :   Here is the start of the housing:    Tapping 1-72 threads is SO much easier than tapping the thousands of 0-80 threads on my dragline model.   Trying to find the sizes the ring and pinion are set up to.   This set up is a Axial 13/43 ratio. This is a nice gear set -Helical and heat treated.  Half partially done. I want to install ball bearings through out when Im sure I have the ring and pinion set correctly.

|

|

#2

|

|||

|

|||

|

I've seen video of the 1:1 and its a pretty interesting machine. This will be a cool build.

|

|

#3

|

||||

|

||||

|

Cant wait to see this working.

|

|

#4

|

|||

|

|||

|

Love it! Those are good looking gears! Those are some of the more conventional Letourneau machines. My dad ran one a little. He said if you spin out you can inch your way out by setting the front brakes, raising the box, setting the rear brakes and lowering it. Repeat as often as needed.

|

|

#5

|

||||

|

||||

|

Looks cool Steve. I had a toy similar to that when I was younger. I think it was green though?

Brian |

|

#6

|

||||

|

||||

|

Wow!! Amazing already! Cool that it is so different too.

|

|

#7

|

||||

|

||||

|

Nice start Steve.

__________________

Scott "No load is too Small" |

|

#8

|

||||

|

||||

|

I like your machine work! You are already off to a great start. Any project that begins with custom machined parts is a good one. This will be an interesting project. I have never seen anything this Tournarocker before.

__________________

Nathan |

|

#9

|

|||

|

|||

|

Very nice work as always steve-although I am not real clear on what you are doing I'm sure it will make sense later.

|

|

#10

|

|||

|

|||

|

Fascinating project!

Looking good already

|

|

#11

|

||||

|

||||

|

Great idea and it looks like you are off to a good start. Now if I understand what you are doing with the drive it will be front wheel drive and use separate motors for each side and the front will do the driving and steering as well. If that is the plan you will probably have a traction problem especially when it is loaded. You are going to need a lot of weight in the front with some tires with a lot of traction. Good luck and I cant wait to see how it turns out.

Travis

__________________

AKA "00" Biddle RIP FreddyGearDrive 2-12-59/12-19-11 |

|

#12

|

||||

|

||||

|

Thanks for all the encouraging words you guys. SmallHaul Scott captured a nice video of one of these machines at our steam show this past August.

http://www.youtube.com/user/SmallHau.../1/RRxBpOnc3pw Travis, The way it can wiggle side to side should give decent traction. I'm real skeptical about the original hard rubber tires but they're going to be tried before I change them. I may have to set them up in the mill and cut some relief in the lugs like pulling tractor tires. As far as weight, I'll play that by ear. The thing is pretty heavy already. I don't know what battery setup I'll need yet. I'm looking for about 12v. |

|

#13

|

||||

|

||||

|

I've never seen anything like this before, toy or real life. What a concept for simplicity!

Great video Scott. |

|

#14

|

|||

|

|||

|

Any progress on the drive system?

|

|

#15

|

||||

|

||||

|

No progress yet Tom. I have some side work that's occupying my time in the evenings.

|

|

#16

|

||||

|

||||

|

What a different type of truck

Can't wait to see yours running! Can't wait to see yours running!

__________________

LYNN |

|

#17

|

||||

|

||||

|

Decided to work on this some more this weekend. I still have to get another ring and pinion to put both sides together. I tested the one side and it works very smoothly and not much gear noise at all. I did manage to make the wheel hubs but I need some longer #2-56 lug bolts. Maybe by the end of the week I'll be able to test run it.

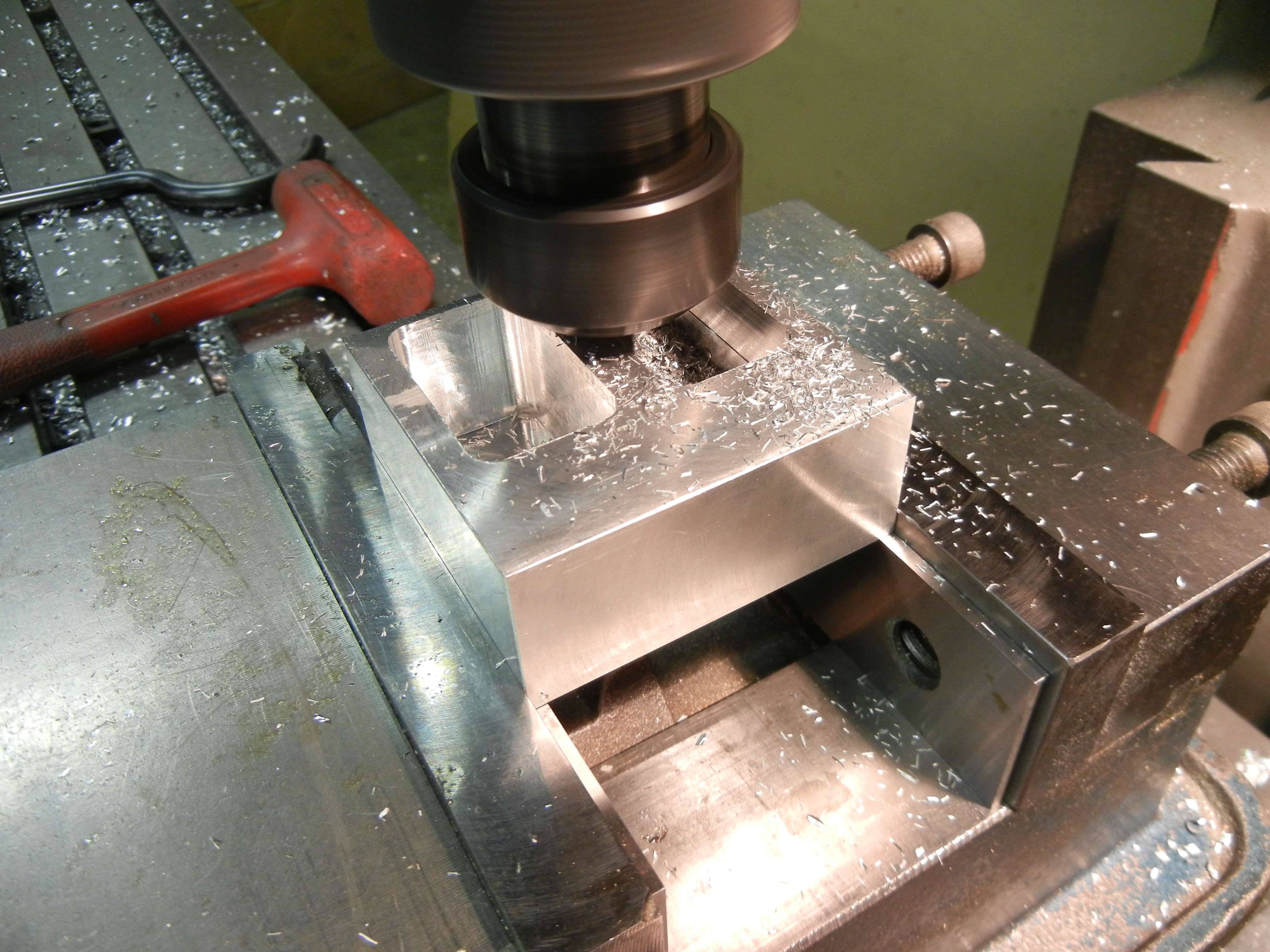

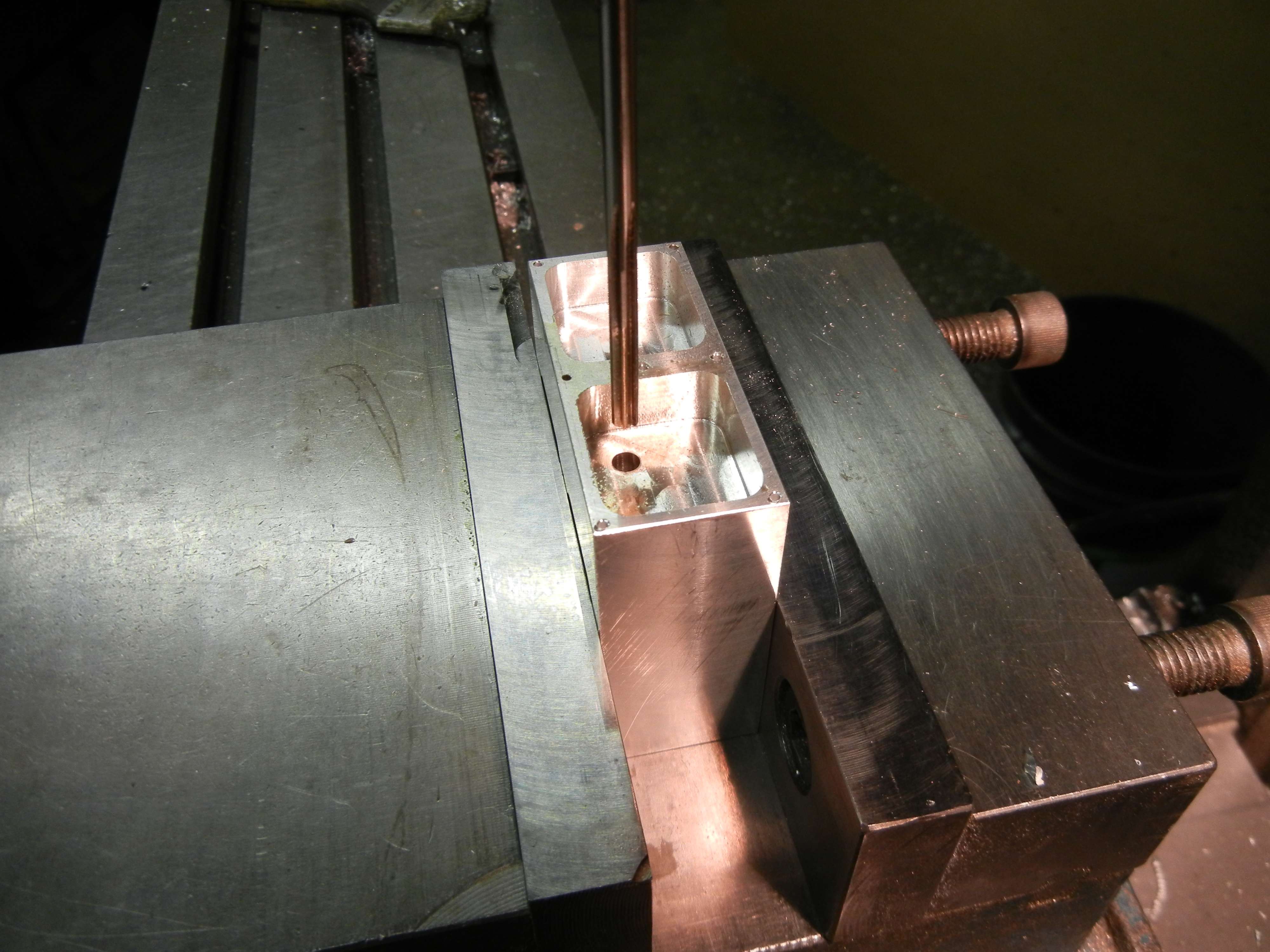

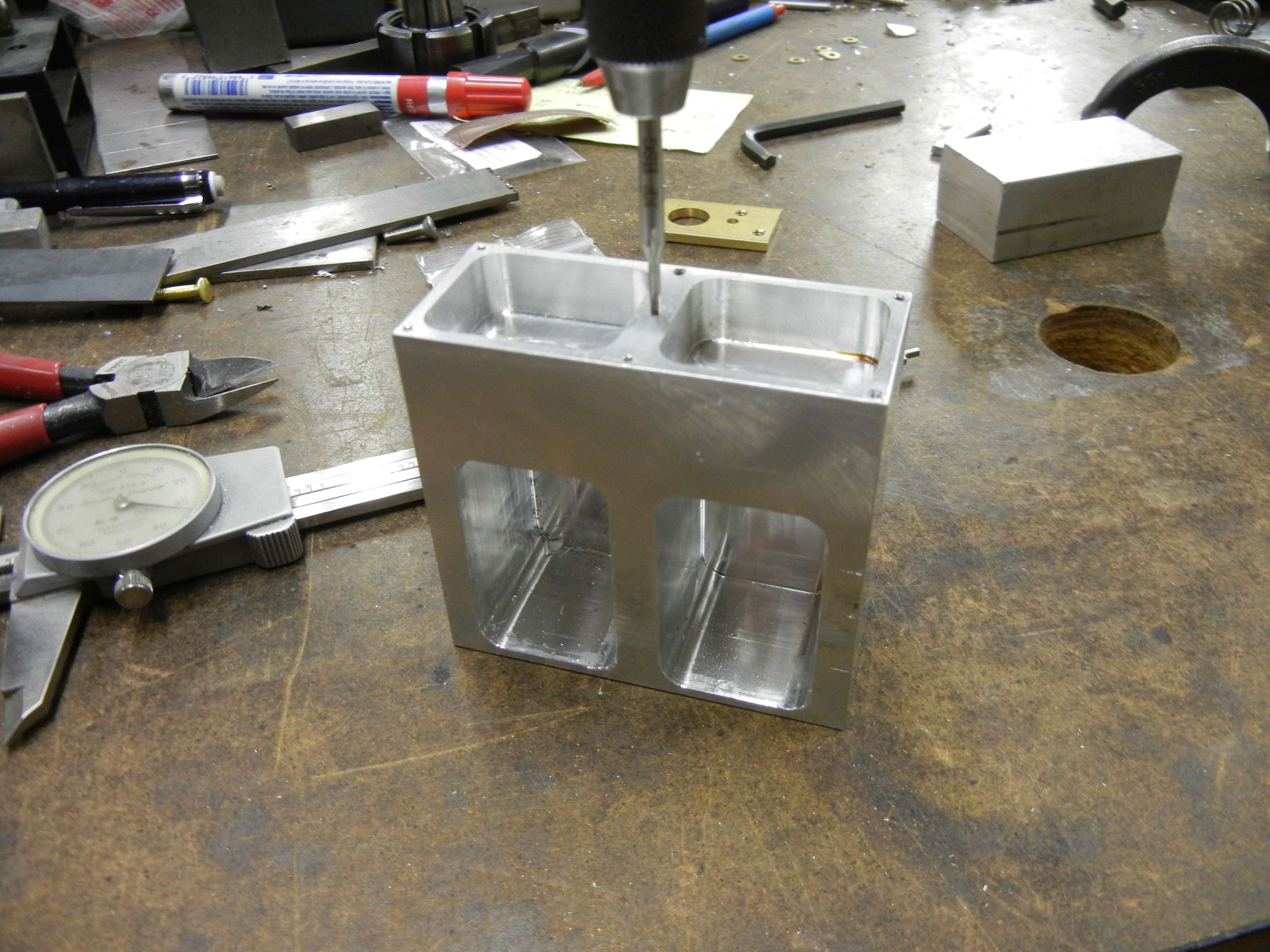

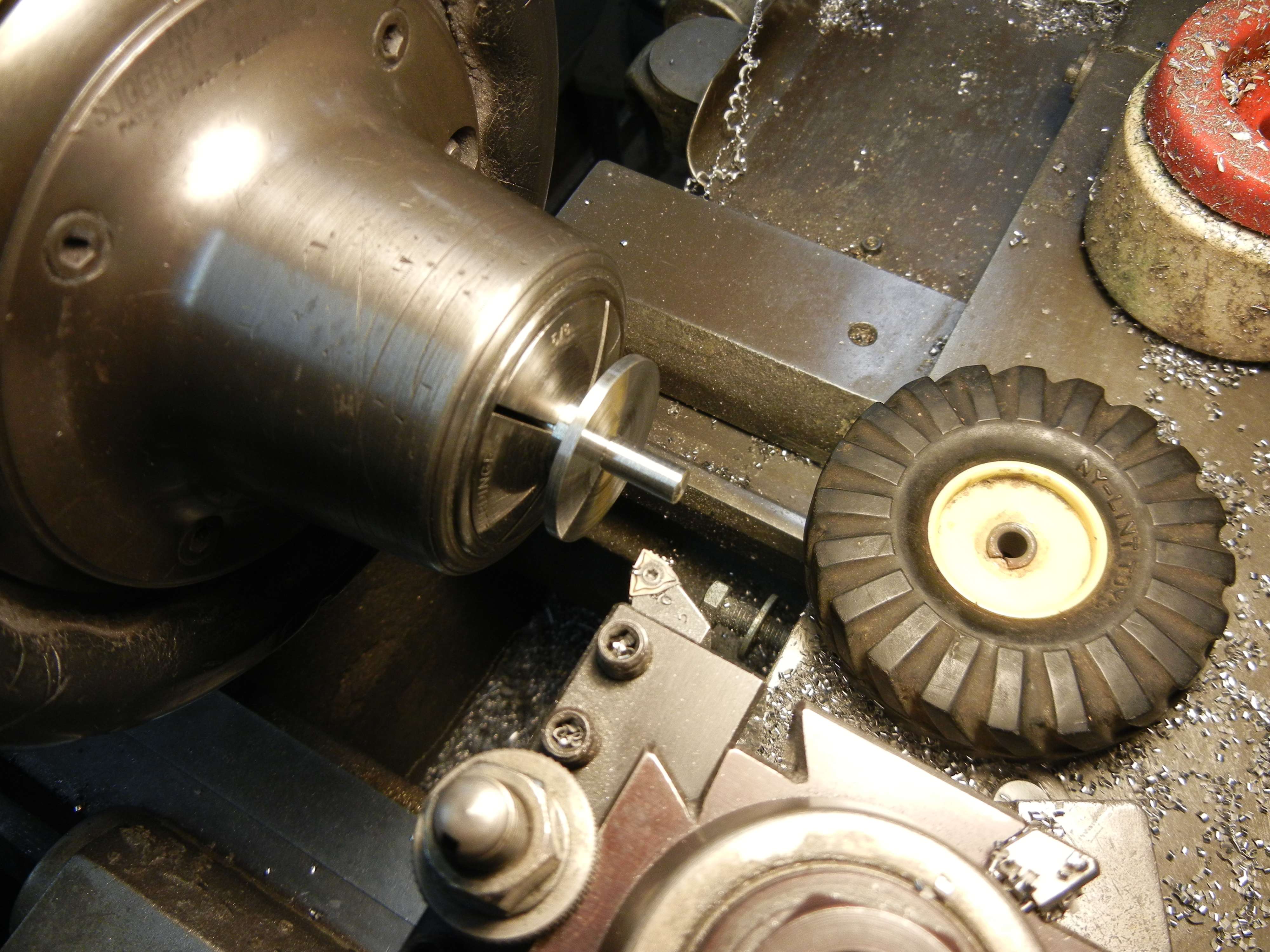

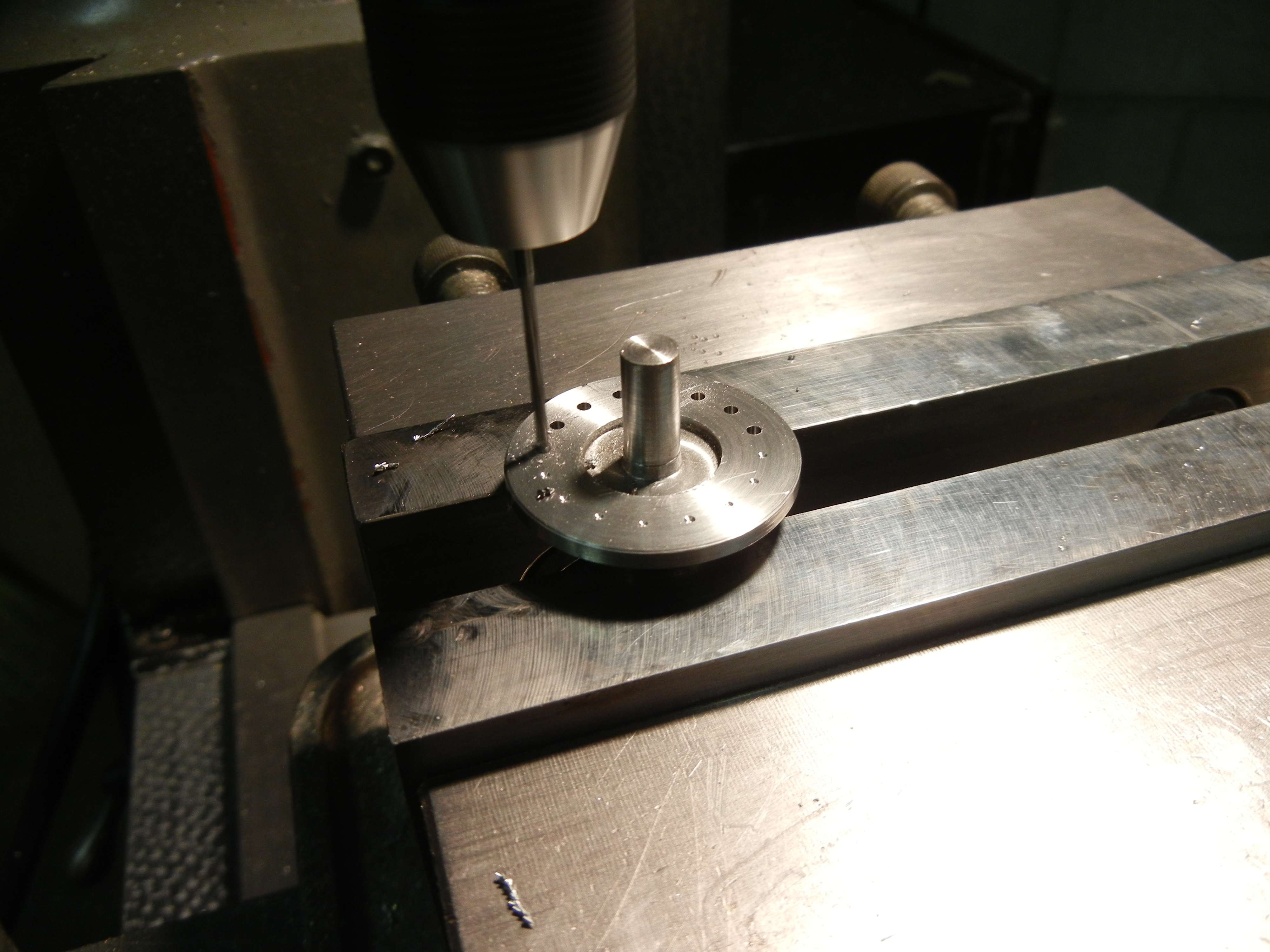

Cutting the gearbox cover:   Turning one of the hubs. I used steel so I get as much weight as possible for better traction.  Centering part to get the lug bolt holes and undercut where the original toy's bearing would hit:  Undercutting for the original hub bushing:  Drill:  Tap for #2-56 bolts:  3/4 done:

Last edited by 9W Monighan; 10-23-2011 at 09:15 PM. |

|

#18

|

||||

|

||||

|

Great progress! I take it your mill is CNC? I don't see a rotary indexing table in the photo, taken during the undercutting picture or hole drilling process.

How hard was it to set up your gear mesh? I'm kind of curious how you went about it. Looks like you took some measurements off the granite table and adjusted the shims under the gear till the mesh was perfect. Then bored the holes in the gearbox to get it right on. I like how you share photos of the machining process. Helps newbies, like me, learn some new things.

__________________

Nathan |

|

#19

|

||||

|

||||

|

Quote:

|

|

#20

|

||||

|

||||

|

Very nice! Thanks for the insight! So judging from your photos, it looks like you use a reamer to make the bushing and bearing holes more precise? Would an end mill leave the fit sloppy?

__________________

Nathan |

|

| Currently Active Users Viewing This Thread: 2 (0 members and 2 guests) | |

|

|