|

|

|||||||

| Construction Equipment If it digs, pushes, hauls dirt "off road" post it here. |

|

|

|

Thread Tools | Display Modes |

|

|

|

#1

|

|||

|

|||

|

Thanks rustybucket. I for some reason I've always been fascinated with the old cable machines. I run modern excavators but I find the old stuff more interesting.

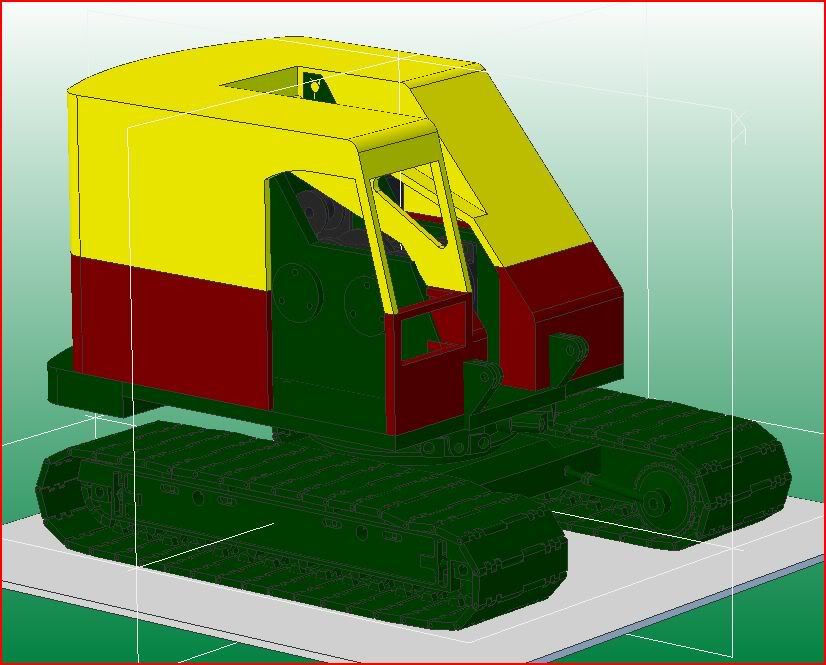

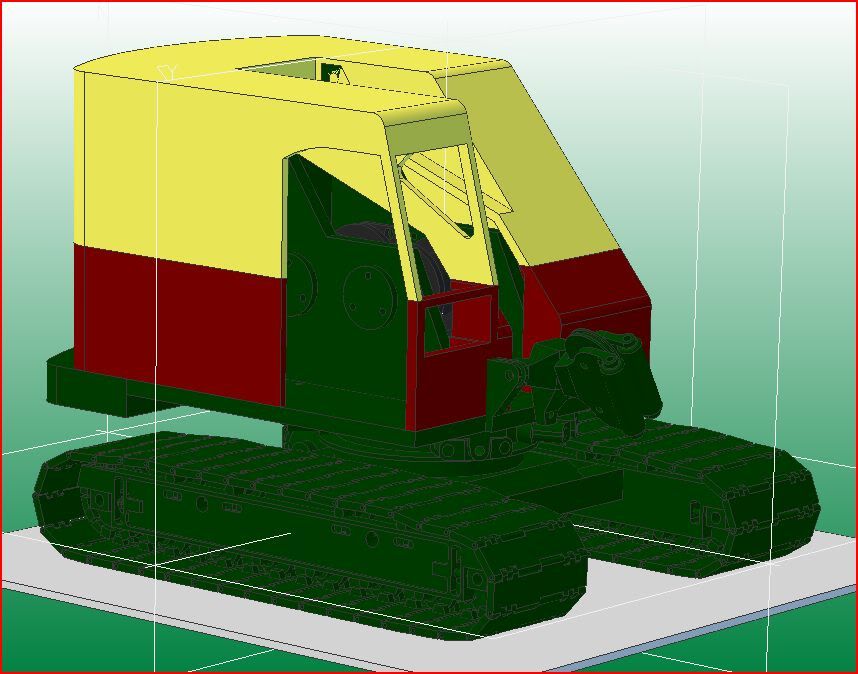

Thanks Papy. That's the story everywhere. I know of some guys that had a 15 or 22B. Notice my use of the word "had". A few years ago when scrap prices were really high, they fired it up, walked it on the lowboy and hauled it to the scrapyard. If I had known about it at the time, I might have offered them scrap value for it. I don't know what I would have done with it, but I hate to see good stuff like that thrown away. Breaking news: Instead of a 22B, this has evolved into a 25B. Part of the reason is that the 25 is basically a beefed-up 22 and has a 1-yard rating instead of 3/4 and all I have to do is make 8 hook rollers instead of 6. But the main reason for doing it is so I can put a bigger bucket on it. I spent a bunch of time with the drawings Steve and Dan sent along with some old sales brochures and spec sheets I ordered and did a bunch more tweaking and adjusting of my drawings and here is the latest iteration, but not necessarily the last. I'd change the thread title if I knew how (hint hint). Hoping tomorrow to get out in the garage and make chips.

|

|

#2

|

||||

|

||||

|

Changed the title for you.

__________________

LYNN |

|

#3

|

||||

|

||||

|

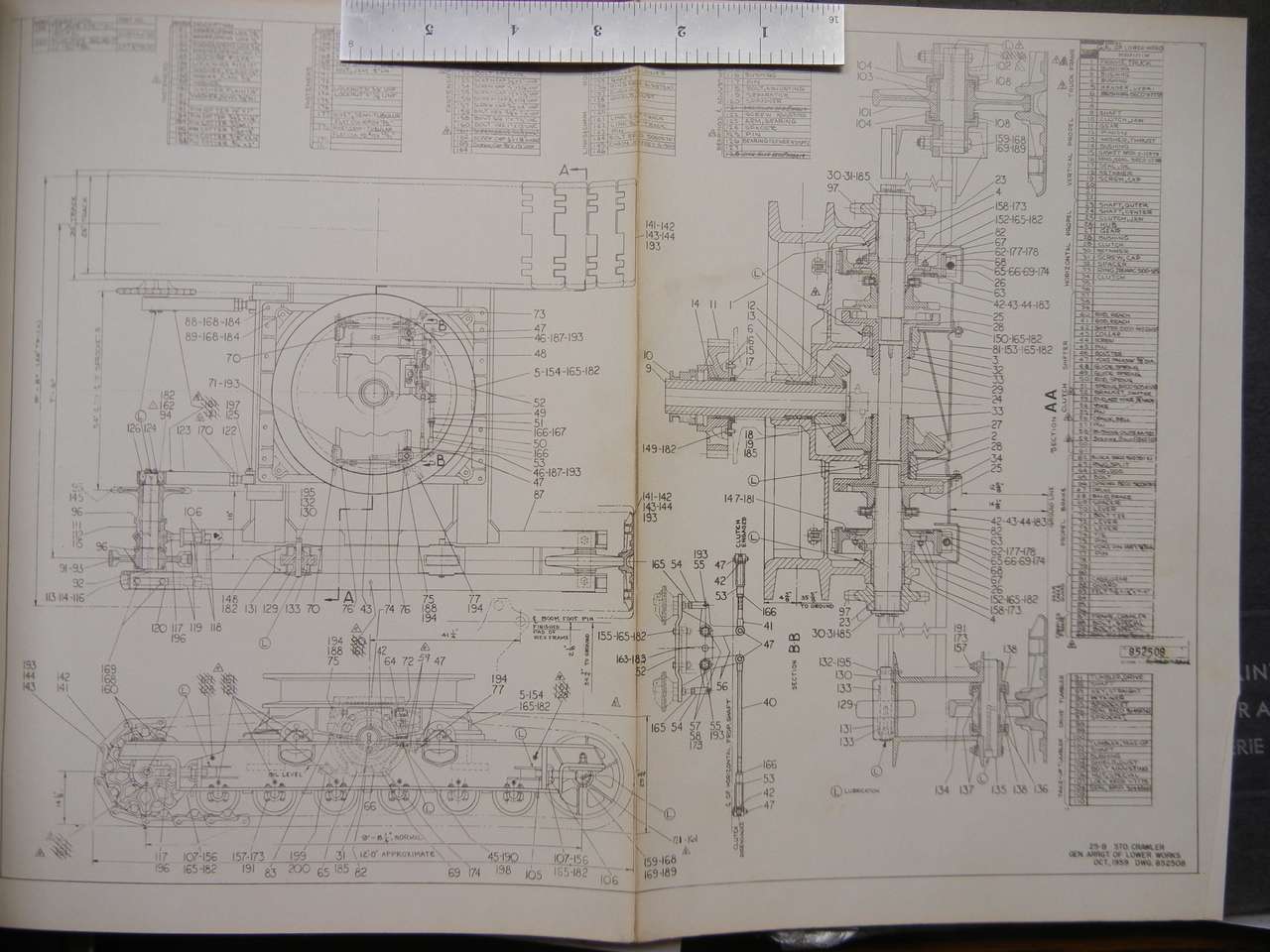

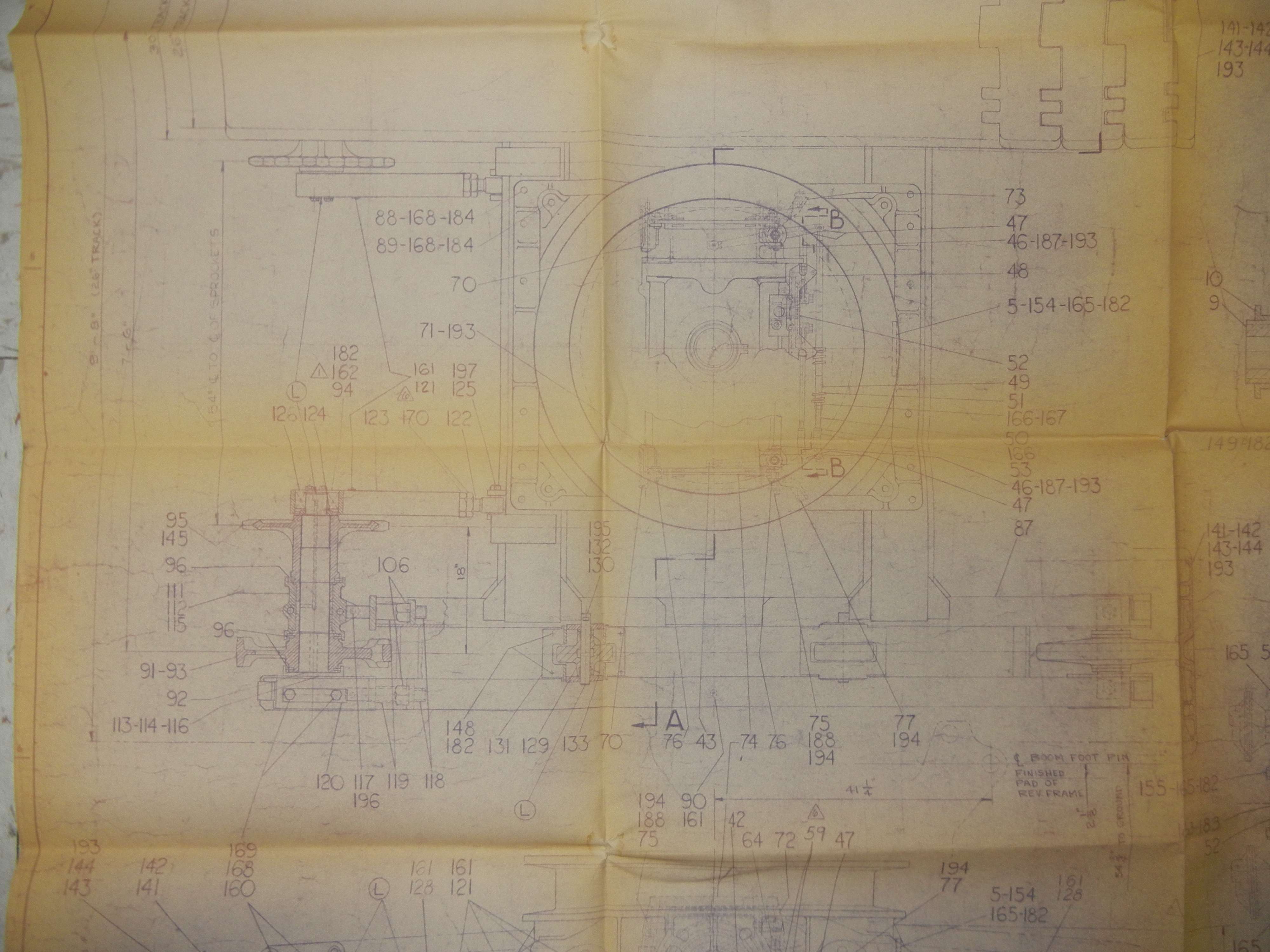

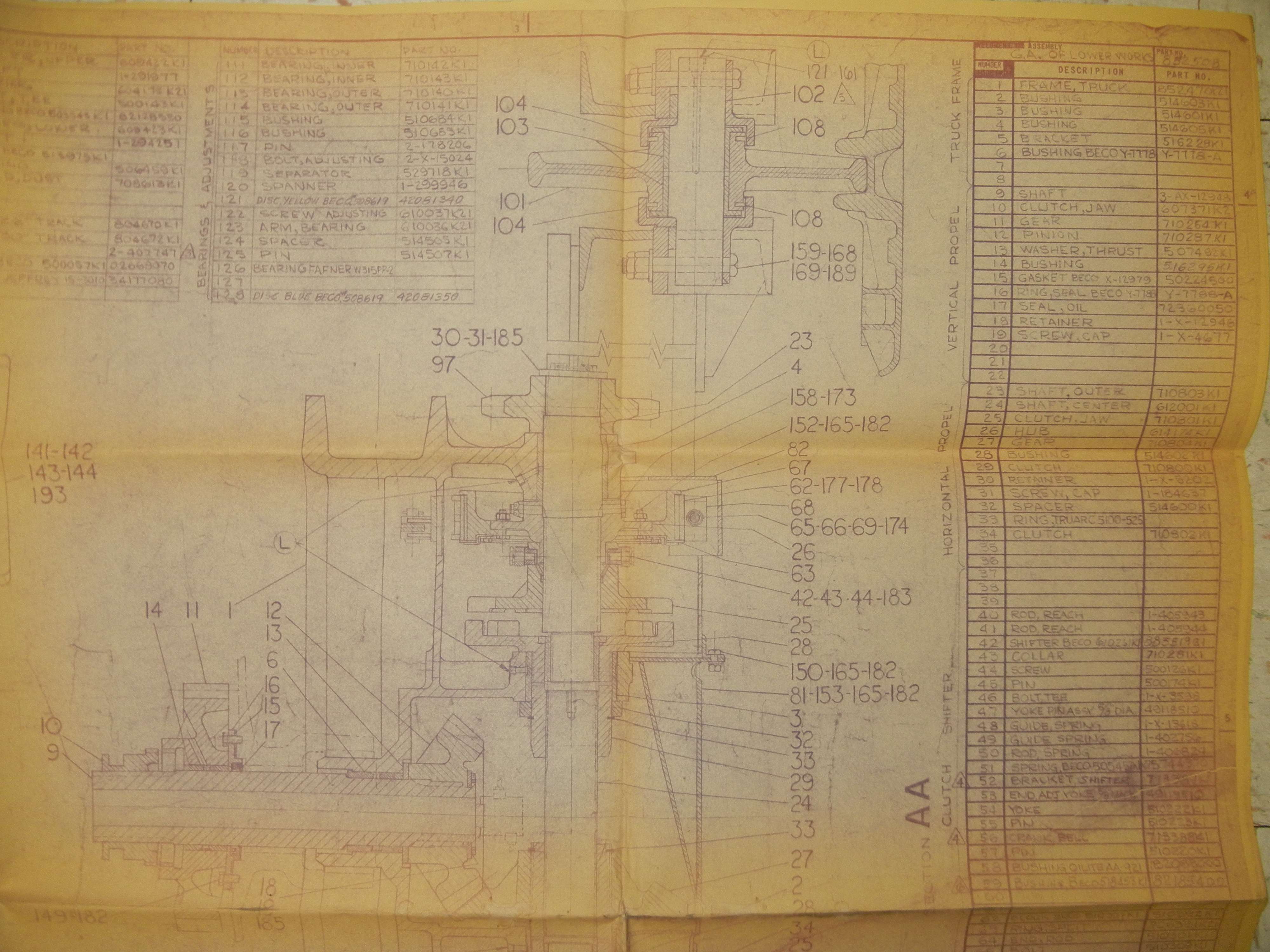

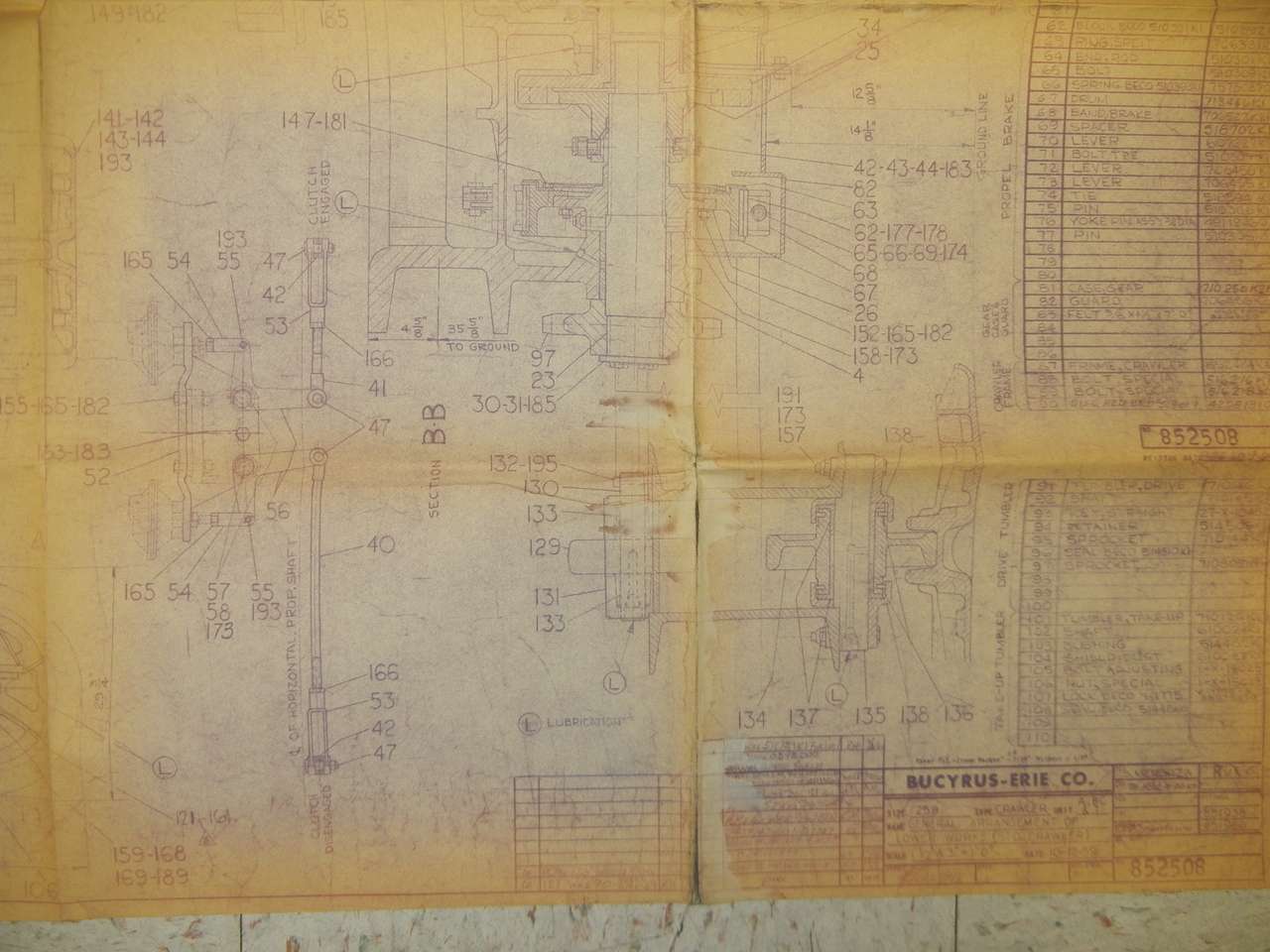

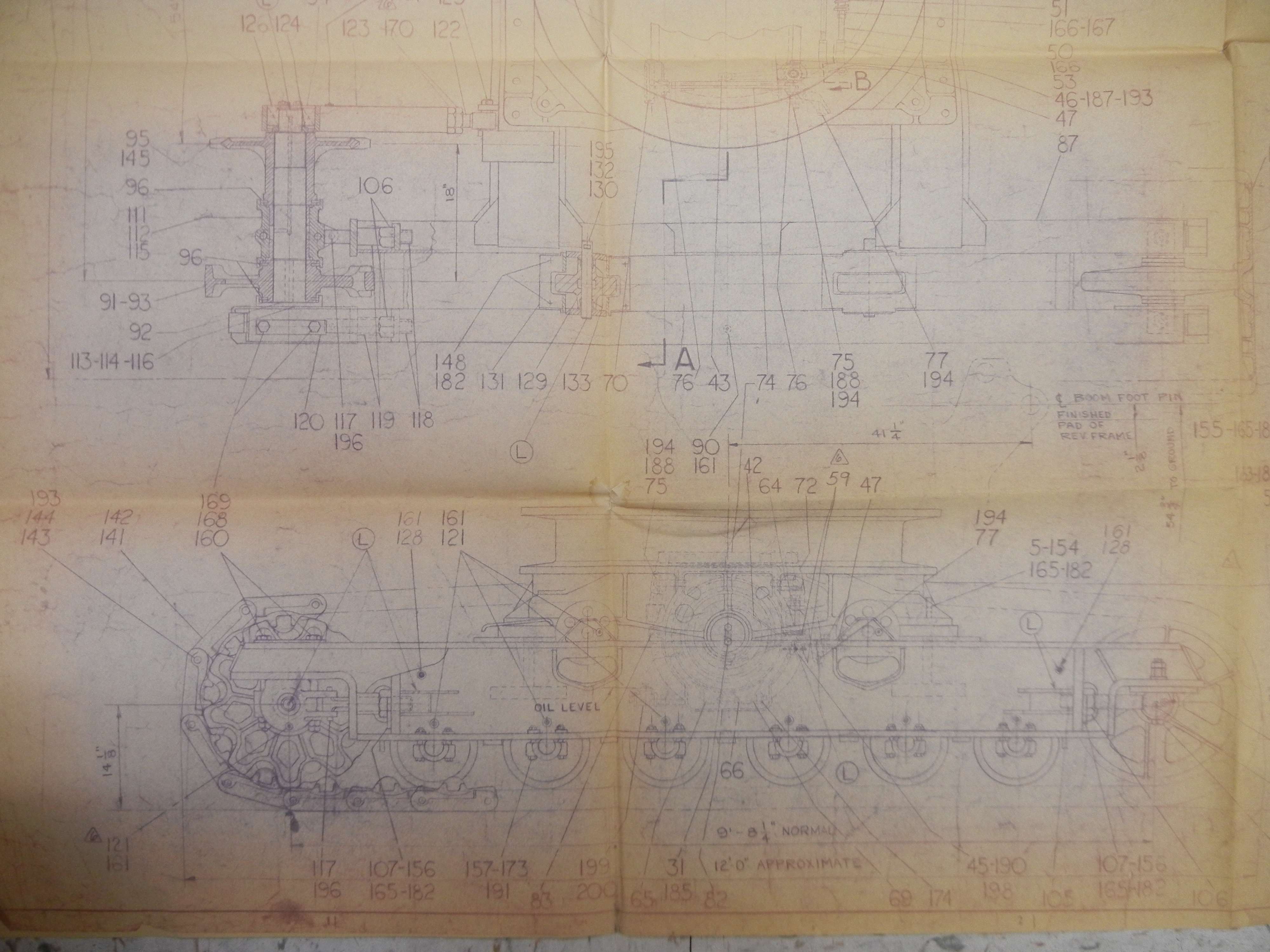

Here is what I have for the 25B. I don't have a parts book but I have a few operators and service manuals. They do contain a nice drawing of the carbody though. Hope this helps with the drawing tweaking.

|

|

#4

|

|||

|

|||

|

Much appreciated, tc1cat.

Thanks Steve. There was a bit more info I was able to glean from those drawings. I'm finally starting to feel like the drawing is done and now all that's left is the actual building. It seems like with all the time I have into this so far the building will be the fast part  , but I know better than that. , but I know better than that.Got the fairlead pretty well nailed down.

|

|

#5

|

|||

|

|||

|

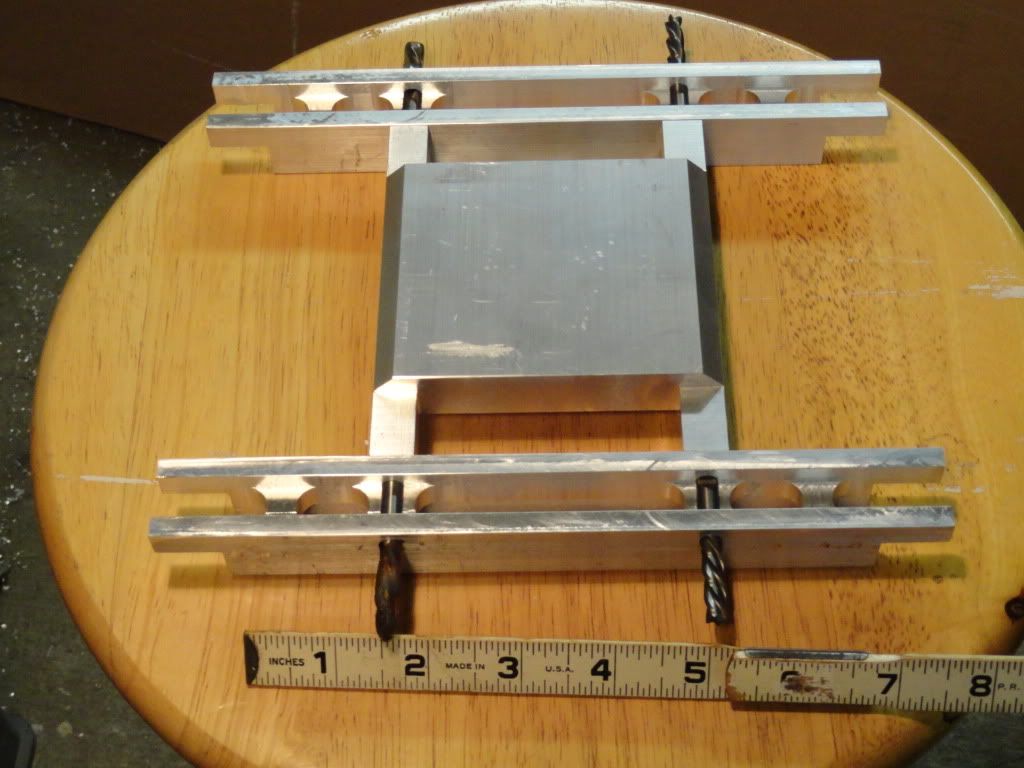

Today I got the track frames 75% completed. The one I made earlier I had to remake because I changed it so it was 1/8" longer and .100" shorter in height. I didn't get any pictures of making them but I clamped them in the vice side-by-side and then when it was time to turn them over I put some little C-clamps on then turned them twice without disturbing the alignment. The first frame I made a few weeks ago took me about 5 hours to do. Doing these two together took 7 and I still have another hour or so to go, but still faster than making them separately. Managed to break off a 2-56 tap in a hole but I should be able to cook it out with a home brew solution I found on another forum. I can't remember the recipe but I think it uses alum.

|

|

#6

|

|||

|

|||

|

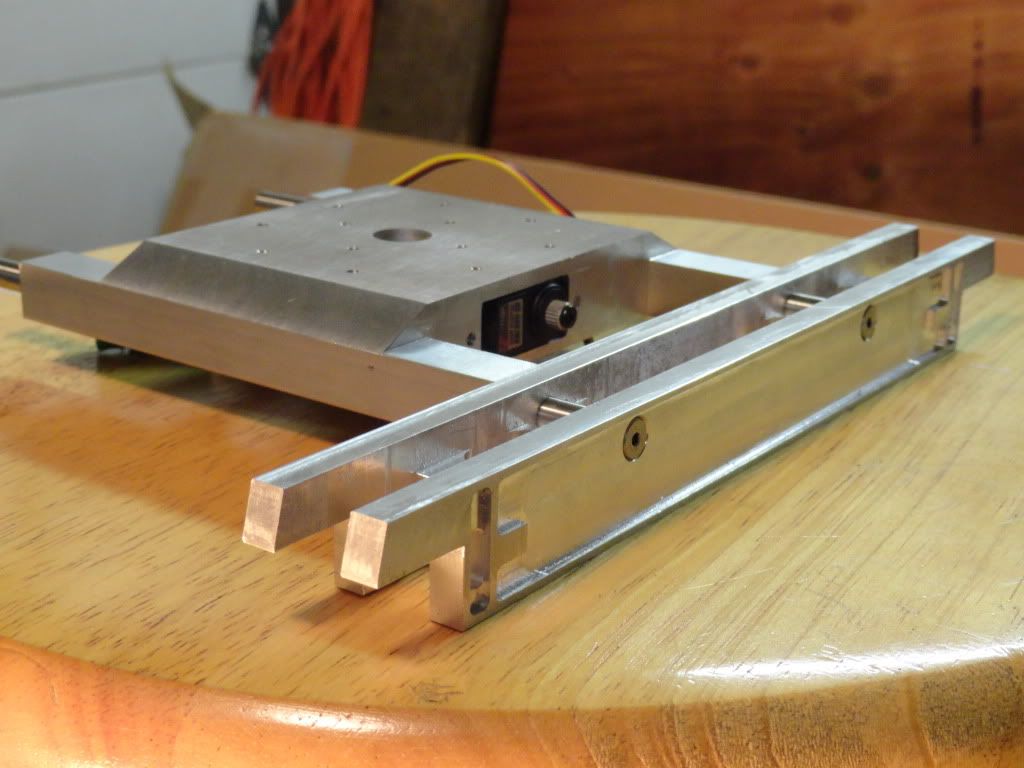

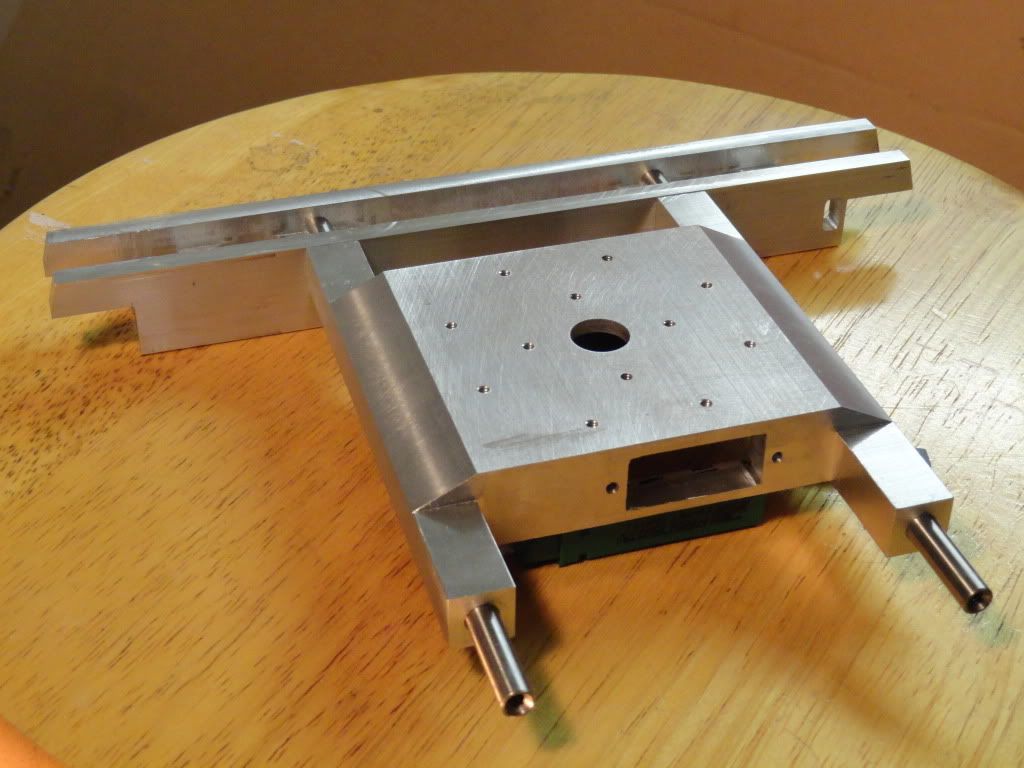

Almost finished with the carbody and track frames. This week I was working close enough to home to get a couple hours in the evenings. Sure is nice!

Hopefully those screw heads will be a little less conspicuous when everything gets painted. That's the best and easiest way I came up with to hold the track frames on the dead axles.

|

|

#7

|

|||

|

|||

|

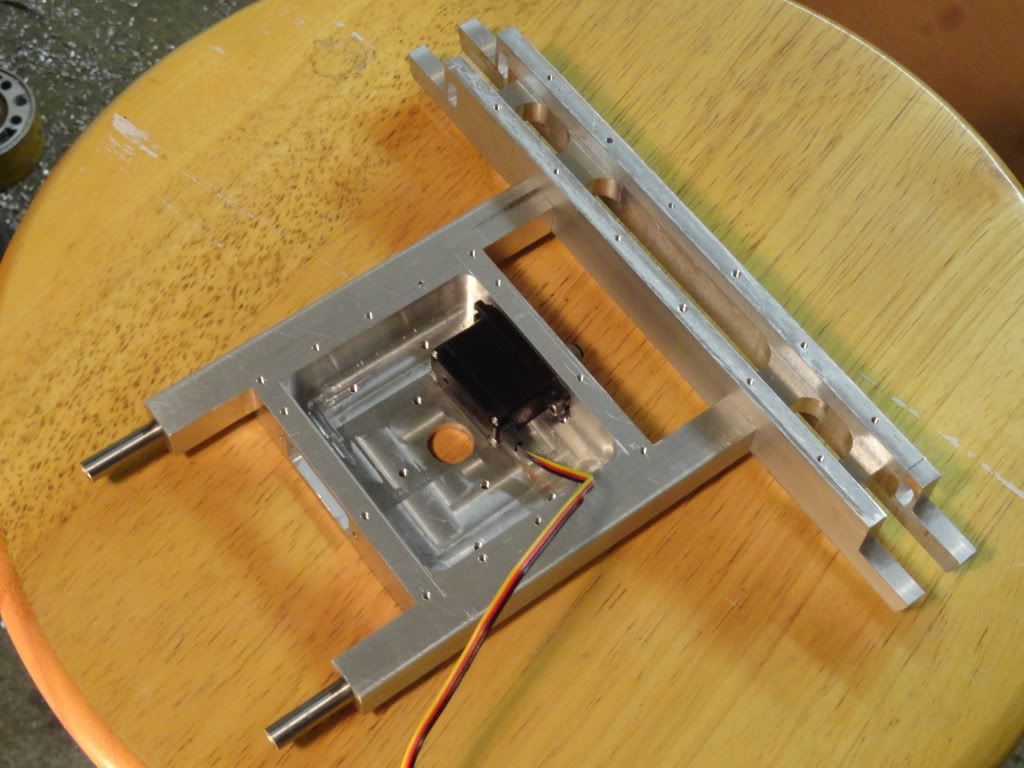

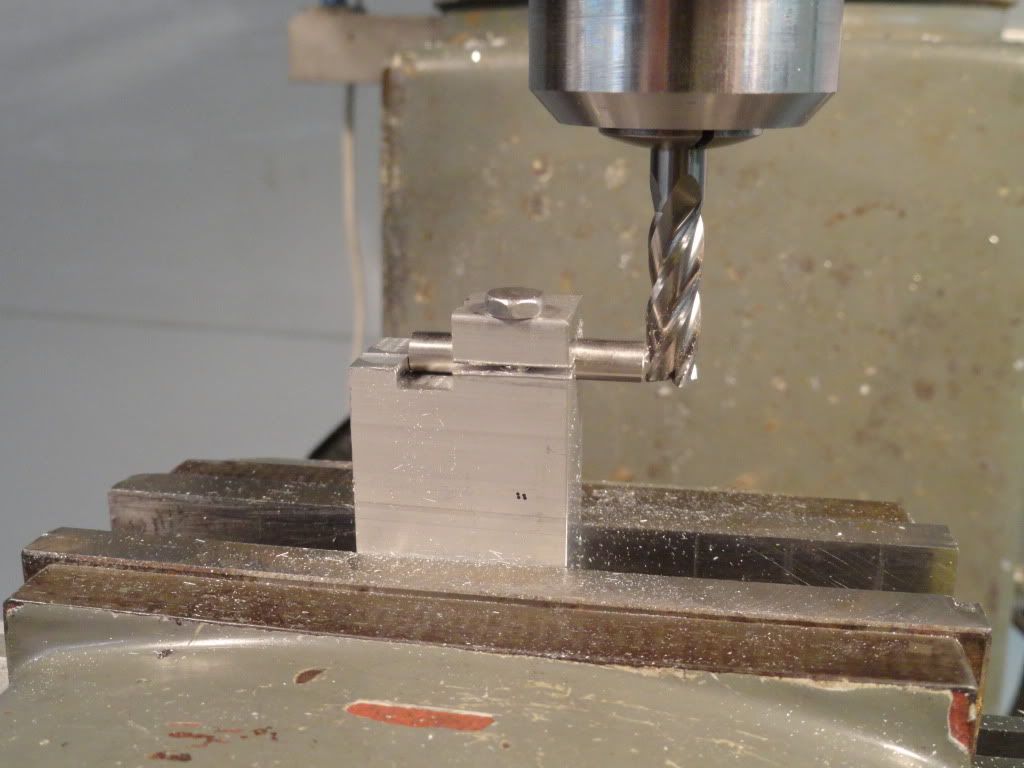

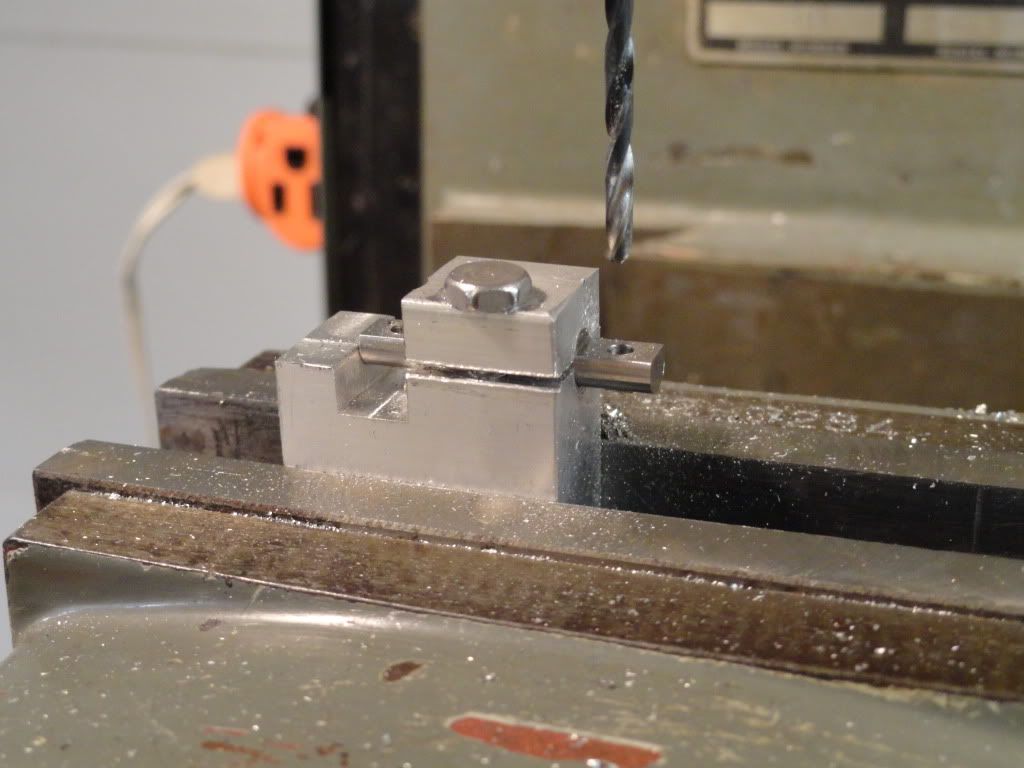

Jigs. I love 'em and I don't like making them. But often they're the only way to go. I made the track roller shafts the other day.

Next time I'll make the stop on the left side of the jig the same height as the flats on the shaft. That way they'll be easier to square up when I drill the holes.  And a batch of more or less identical shafts.   And I got started on the machinery deck. Kind of goofed up on it though. I got ahead of myself and milled the recess for the servo on the wrong side. But since everything is symmetrical I can flip it over and countersink the holes on the other side. Those are the bolt holes for the side frames for the machinery.

|

|

| Currently Active Users Viewing This Thread: 1 (0 members and 1 guests) | |

|

|