|

|

|||||||

| General Discussion A place to post off topic discussions. |

|

|

|

Thread Tools | Display Modes |

|

#1

|

||||

|

||||

|

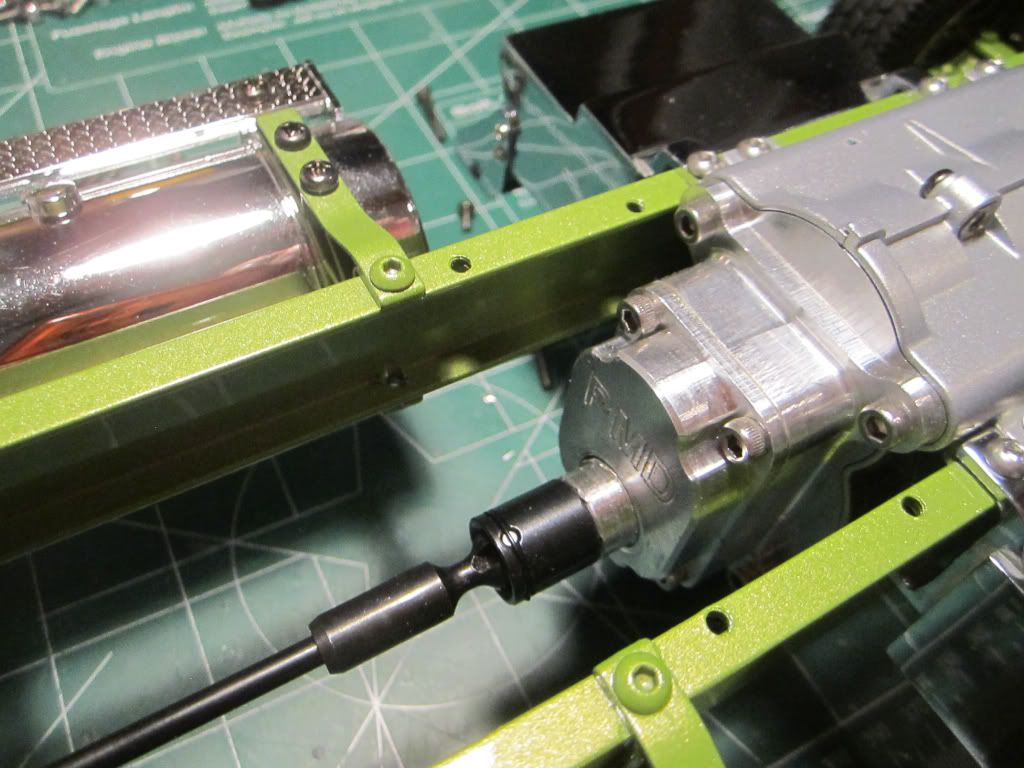

Hey has anyone ever had this happen, I just noticed it on one of my pics. It has not even ran yet! Any thoughts on repair or just get a new back case. Liquid steel epoxy?

Arrgggg [IMG]  [/IMG] [/IMG][IMG]  [/IMG] [/IMG]

|

|

#2

|

|||

|

|||

|

I would call up Ric after u send an e-mail with the pics.

|

|

#3

|

||||

|

||||

|

I'm sure Ric will make it right for you Keith. The sad part is the postal system and the time lost waiting for parts

kinda puts the build on hold eh? kinda puts the build on hold eh?Mario |

|

#4

|

||||

|

||||

|

Is that the bearing we can see, behind the driveshaft yoke, or part of the box which broke off? It's got some vise looking marks on it too. I'm sure Ric will hook you up with a new one.

__________________

Nathan |

|

#5

|

||||

|

||||

|

Keith - your first line of communication should be with the vendor - not spittin nails to the general public. Ric will clear this up with you.

Does your drive line have enough slide distance? There really shouldn't be any pressure on that case to pull the bearing out. I can't tell - but I hope you don't have a fixed length drive shaft between your axel and the transfer case. Izzy |

|

#6

|

||||

|

||||

|

Yeah, I'm going to call Ric on Monday and send a pic to him.

Quote:

Quote:

Quote:

The drive shaft has about 3/8" of slide, but it is between two fixed points. The 4:1 and a frame mounted carrier bearing. The second drive shaft between the carrier bearing and first axle is also adjustable. The bearing is still in place in the housing, it's the housing itself that is broke. |

|

#7

|

||||

|

||||

|

hmm looking at the machine marks , I'm wondering how that was made

the face milling marks go right through where the bearing boss is the face milling marks go right through where the bearing boss is

__________________

RIP FreddyGearDrive 2-12-59/12-19-11 To view links or images in signatures your post count must be 10 or greater. You currently have 0 posts. |

|

#8

|

||||

|

||||

|

Quote:

Ric should be able to take care of you, that def looks like a defect in the casing itself, not from the driveshaft or coupler. Keep us updated --Dan

__________________

To view links or images in signatures your post count must be 10 or greater. You currently have 0 posts. Last edited by scalelover; 02-09-2013 at 09:44 PM. |

|

#9

|

||||

|

||||

|

Quote:

Quote:

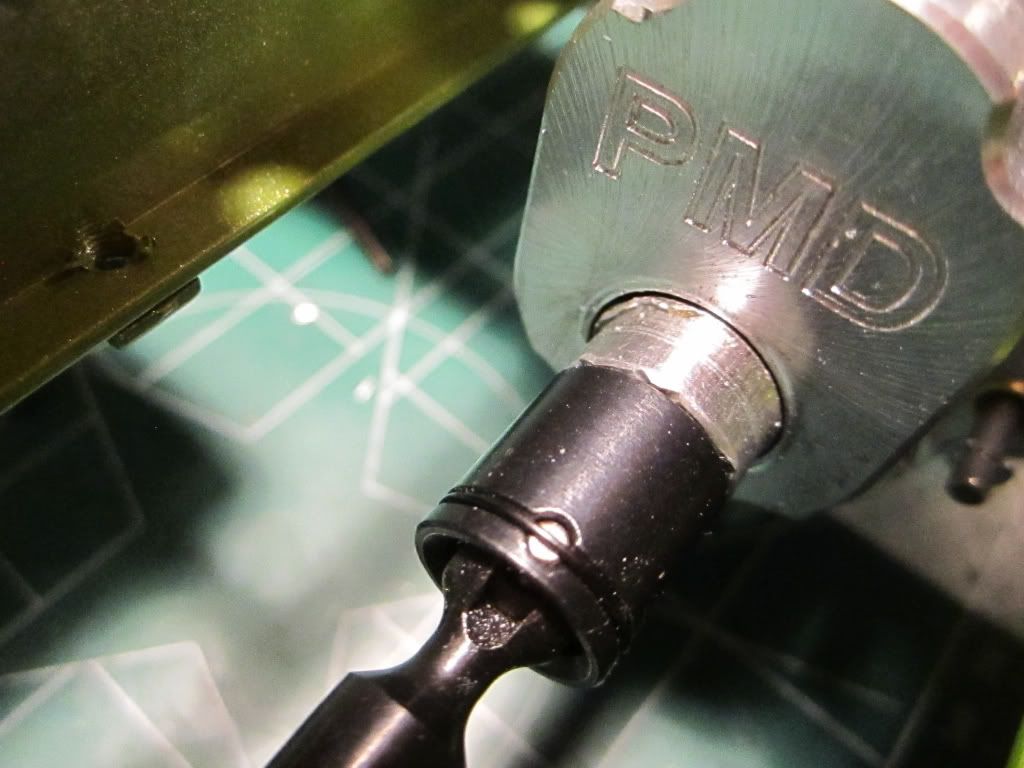

Ric is a great guy and his products are industry standard, I have met him a few times and have spoke to him more times in the past few months than I can count. Ric has always took the time to discuss, explain or just talk with or about anything I was purchasing from him. Here are a few closer shots of it apart for the machinist out there, I will talk to Ric on Monday but my first question is still does anyone think I can repair this without machining? [IMG]  [/IMG] [/IMG][IMG]  [/IMG] [/IMG][IMG]  [/IMG] [/IMG]

|

|

#10

|

||||

|

||||

|

Kaf, I wasn't trying to say it was a badly designed part I was just wondering how he did the final machining. Te first pics it was hard to see the full radius of the bearing and it looked as if he may have gone right into the cap or just machined straight down around it. With the angled pics I can see a lot better how it was done and it makes sense because you can see how it was machined around the bearing cap, and not straight down or right into it.

As for repairing it, IMO I'd say it probably wouldn't hold up unless its welded. The side load from the output spinning and the force (even though its not a lot) that's put on the bearing is prob enough that any type of epoxy or aluminum weld putty may hold up for a short period, but it would probably just rip apart again. If your really good at welding you could do that and it would be fine as long as its lined up accurately.but again being such a small piece that won't be an easy task to do.i don't really see any other way myself, maybe a more seasoned machinist would know better. --Dan

__________________

To view links or images in signatures your post count must be 10 or greater. You currently have 0 posts. Last edited by scalelover; 02-10-2013 at 10:37 AM. |

|

#11

|

||||

|

||||

|

Quote:

Thanks for the input. I appreciate it. |

|

#12

|

||||

|

||||

|

OK this final pick says a lot - they just took a little too much away from the bearing cap - a nice fillet would have been prime. Un fortunately the bearing is actaly outside the case for the most part. - I suppose you could take a new plate, machine in a countersink to hold the bearing and then bolt to the outer of the existing housing - in all it would look like crap though.

I think Dn's idea of welding ot back together is best - really thin material though - it would be difficult even for an experienced welder. I know this sounds bad - but what about some 2 part epoxy like JB weld - you could pretty much lay a nice fillet around the housing and the bearing cup. Izzy |

|

#13

|

||||

|

||||

|

It's definitely a defect. Simply put, the milling process removed to much material around the boss. I wouldn't even try fixing it. Just be honest and show Ric the photos. I'm sure he'll take care of you.

Welding or JB weld is not going to be the answer. Even if you do pull that off, the shaft alignment could easily be off, and that will cause other problems.

__________________

Nathan |

|

#14

|

||||

|

||||

|

I'm gona stick my neck out here and my $.02 now that I see better pics I see a small design flaw. To much material is removed from the bearing bore on the out side of the case . could be fixed real easy withe a simple tool change in the machining process with a .125" radi around the bearing bore or don't go so deep on the counter bore . I wouldn't trust any glues or welding in that area it's to critical for alignment . send for a replacement .

__________________

RIP FreddyGearDrive 2-12-59/12-19-11 To view links or images in signatures your post count must be 10 or greater. You currently have 0 posts. |

|

#15

|

||||

|

||||

|

I'm pretty sure that welding it would just warp the bearing bore and it would no longer fit without remachining it. Much easier to get a new piece in my opinion.

|

|

#16

|

||||

|

||||

|

Welding is def a last option because its such a critical alignment and so thin you'd have to be a super experienced welder to get it aligned correctly and not burn through it.

As IH said earlier I think it was machined to thin as well but didn't want to put my neck out there, seeing as I'm still a novice machinist compared to him but if he says so then I'd have to agree, for the reasons I mentioned in the earlier post about the force that's put on it. it id not a ton but enough that I'd have left a thicker base area right at the plate itself if not the entire bearing cap to avoid fatiguing the metal. --Dan

__________________

To view links or images in signatures your post count must be 10 or greater. You currently have 0 posts. |

|

#17

|

||||

|

||||

|

Definitely a defect in machining, just as Steve described it -> free replacement shipping included, nothing but!!!

Let us know how it turns out for you.

__________________

Sharing knowledge is one thing that defies basic arithmetic logic --- the more you share, the more you get! Joe |

|

#18

|

|||||

|

|||||

|

Quote:

Quote:

Quote:

Quote:

Quote:

|

|

#19

|

||||

|

||||

|

I just spoke to Ric and as everyone said, no problem. Send it in and he will replace it as soon as he gets new cases. Thanks again for everyone's input.

|

|

| Currently Active Users Viewing This Thread: 1 (0 members and 1 guests) | |

|

|