|

|

|||||||

| Construction Equipment If it digs, pushes, hauls dirt "off road" post it here. |

|

|

|

Thread Tools | Display Modes |

|

#101

|

||||

|

||||

|

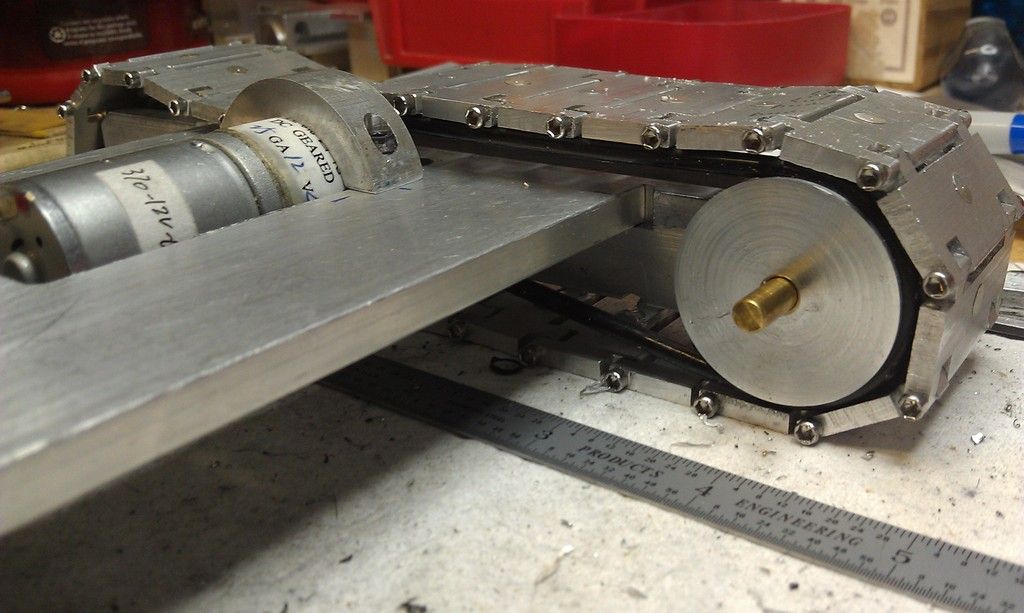

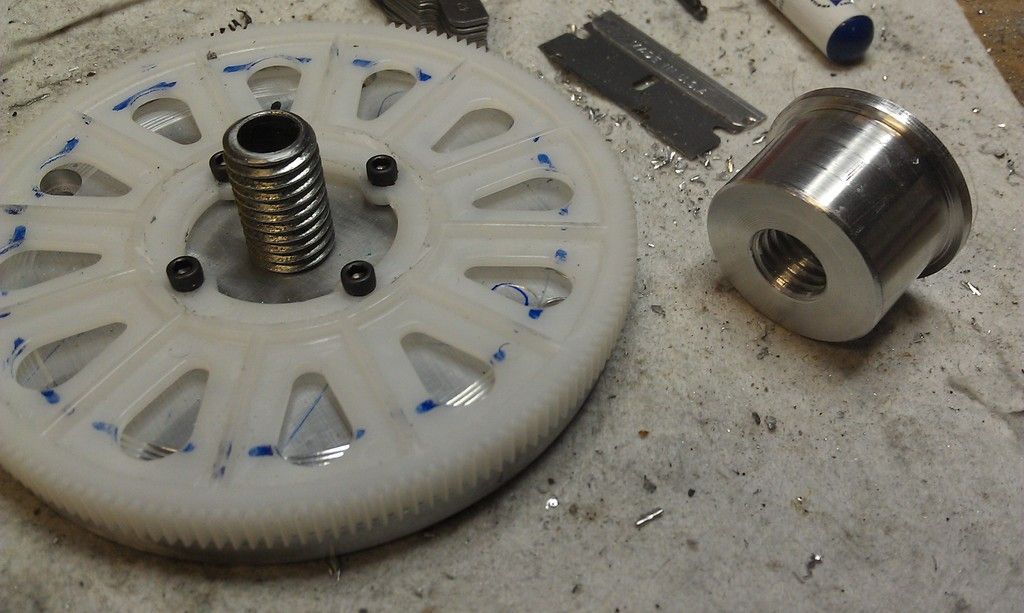

Pulleys and O ring. Need to finish the rollers now...

Jim |

|

#102

|

||||

|

||||

|

Hey Jim, Have you thought about powering the carbody through the center pin like the 1:1 machine? One motor bevel gear then make sliding jaw clutches to engage each track disengaged with a servo for steering.

|

|

#103

|

||||

|

||||

|

Steve, that sounds interesting, probably beyond my machining abilities, but interesting! I will have to find some pictures and drawings of that, I'm not sure I know exactly how it looks?

Jim |

|

#104

|

||||

|

||||

|

Study my drawings I posted on the 25B build.

|

|

#105

|

|||

|

|||

|

I see you are making progress jim-You said you would have to raise the swing gear over this motor. Is that going to cause any problems? I like 9W's idea on the movements but that would require a lot of technical machining and this is a really small model. Are you up for that challenge?

I probably could not do that. I probably could not do that.

|

|

#106

|

||||

|

||||

|

Tom,

I made a round 1/4" plate to raise the swing gear just to get it up off the deck so the pinion had a bit of clearance. So, I think I can flatten the top of the motor clamp a bit and then I will make some braces that screw to the flat top frame to hold it all together, since the motors basically split the flat part in two parts. As long as it doesn't look like the body sits up too high I should be okay. It should actually improve the digging geometry for a drag bucket. I would love to do the central power scheme but you are right. It is just really small to make all that work. I am going to proceed with the current motor placement and try to work out the pads function . Still messing with tumblers and alignment issues. Jim |

|

#107

|

|||

|

|||

|

Jim-seems like you have a good plan. Will the O-rings for the drive belt have enough grip? Aren't those track pads fun!!!

|

|

#108

|

||||

|

||||

|

Tom,

If I don't know for sure on the O rings. My master plan is simple pulleys and O rings just until I get the pads working the way they should/need to. Then convert from O rings to that small plastick Chain and sprockets. I have some steel roller chain but I think it is too big to look or function well and I think plastic would probably work okay as long as the pads and tumblers are working right. I need to put the RT back on the mill and make some more tumblers. I don't have a combination that works to my satisfaction yet.  Jim |

|

#109

|

||||

|

||||

|

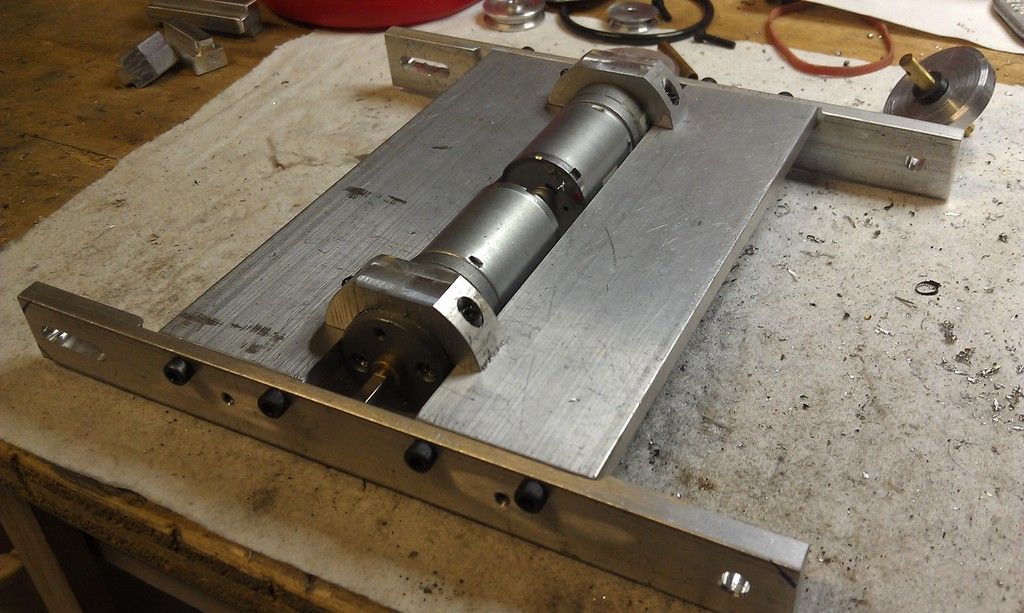

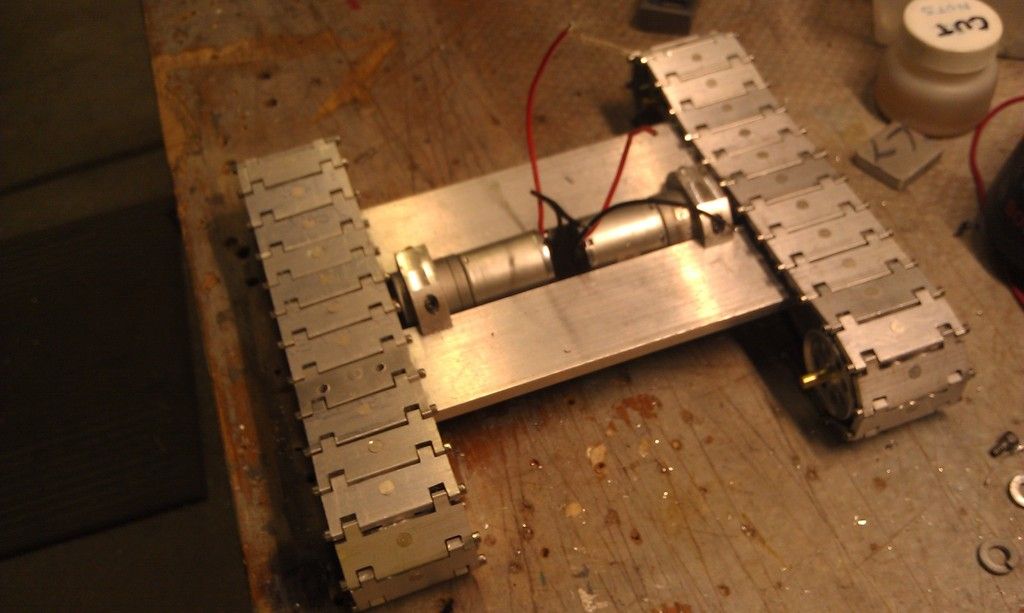

Got the top plate split so I could mount both motors. Ended up making new smaller drive pulleys just cause they would fit better and the speed reduction will be good. Still haven't made a decision on how to make rollers or solid rails in order to help maintain alignment. I should get that started now, gona want to see if this thing is going to move on its own!

Jim |

|

#110

|

||||

|

||||

|

That's lookin really beefy and tough. Kool

|

|

#111

|

||||

|

||||

|

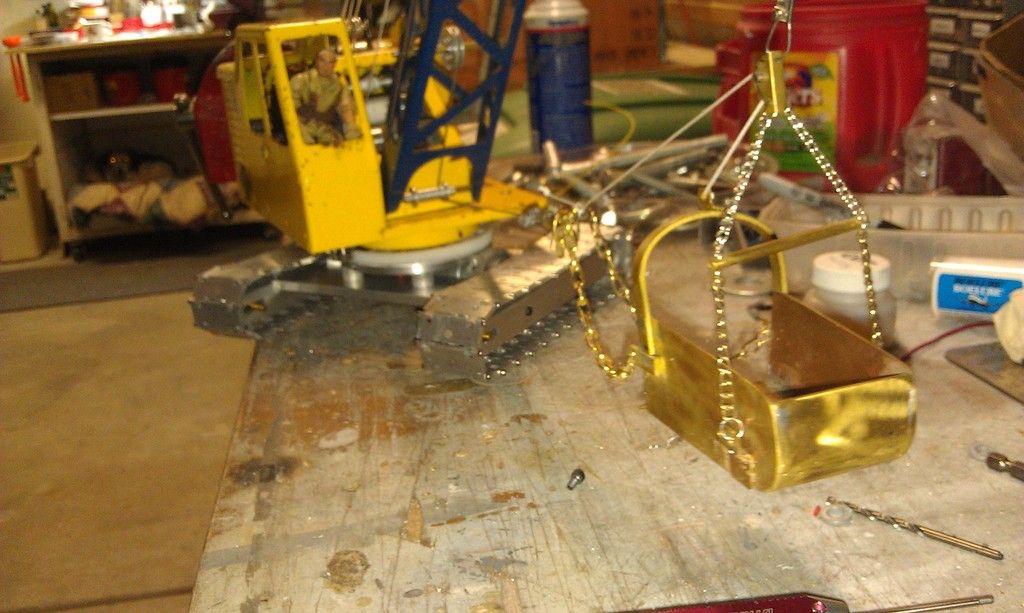

Wow, that looks really good! Love the old school tracks.

__________________

Jarrett |

|

#112

|

|||

|

|||

|

great job you have done there so far it is coming along quiet well keep up the good work

__________________

Steve |

|

#113

|

||||

|

||||

|

Thanks for the nice comments guys!

I started mounting the swing gear on top of the frame. With any luck I will have the crane in place and digging dirt by the end of the weekend. I need to make and mount the round adapter bushing to the inside of the cab. Pictures in a few hours... Oh, and I ordered some plastic chain, sprockets, bevel gears and stuff from servo city. I think I am going to need to learn how to make two small sprockets. Jim Last edited by Rvjimd; 07-11-2015 at 09:29 AM. |

|

#114

|

||||

|

||||

|

looking good Jim ..quite a challenge and not your typical build ...your working through some pretty difficult challenges ..If you have a rotory table / Drill press you should be able to make your own spockets ..I did make my own for the Dozer.. A bit of math and you probably knew already though ...your circumference should match your pitch ..10 tooth x .25 pitch = 2.5 circumference

so diameter would be 2.5 divided 3.14 = .796 .Thats where you would drill your 10 holes Overall sproket diameter would be bigger ..dont remember how many turns it took for one rotation of the RT but im sure you would figure it out from there..I did have to touch up a few of the teeth with a dremel though I started out with with a 3x3 square .2 thick aluminum plate ..scroled the diameter of the circumference ..drilled the center and used a bolt and nut through the center hole to mount in the RT .Once the holes were drilled i cut out the sprockets with a band saw ..hope this helps you out a little |

|

#115

|

||||

|

||||

|

Lou,

Thanks for the tips. My parts might be here Monday so I can see how stuff fits. If I'm lucky I might be able to use what I ordered.  Got a bit more done today. Actually took some video trying to dig wet sand but it sticks in the bucket so bad it wasn't worth posting. Besides, I don't have the tracks moving yet anyhow  I just wanted to see how it looked digging, sitting on the new undercarriage! I just wanted to see how it looked digging, sitting on the new undercarriage! These are shots of the threaded bushing that inserts into the hole in the cab. The hollow stud is an old 1/2-13 bolt that I bored to run the wires from the slip ring.     Maybe I can dry out some sand Sunday and post a digging video... Jim |

|

#116

|

||||

|

||||

|

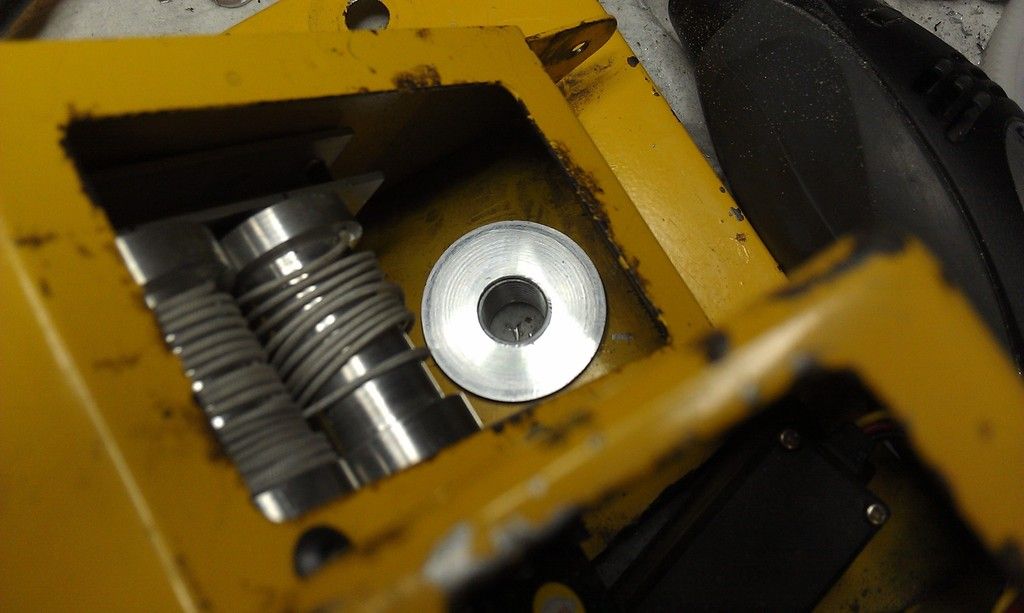

Some more pics...

It looks SO much better all rigged with a bucket on it!   I took one motor apart to match drill mounting holes (which I ended up NOT using  ) this is a "how the heck does this sucker go back together" photo. ) this is a "how the heck does this sucker go back together" photo.  This shot is too close to really see the setup. This is where I clamped the cab down to the mill table and used a fly cutter to enlarge the pivot hole.  Jim |

|

#117

|

|||

|

|||

|

Your making good progress jim. You should be moving dirt soon. You may not be thinking about this now but are you planning to R/C the truck that this dragline goes on? That's a good idea to still use the truck and the crawlers.

|

|

#118

|

||||

|

||||

|

Tom,

My original plan was to motorized the truck and swap the crane from one to the other. I had to cut the big hole for the crawler slew but I can mod the truck bed to make that work. I actually bought a second entire truck crane just like the first so I don't know what I might do with them both now... Jim |

|

#119

|

|||

|

|||

|

fantastic job

|

|

#120

|

|||

|

|||

|

That bucket looks great!. Well, so does everything else.

|

|

| Currently Active Users Viewing This Thread: 3 (0 members and 3 guests) | |

|

|