|

|

|||||||

| Construction Equipment If it digs, pushes, hauls dirt "off road" post it here. |

|

|

|

Thread Tools | Display Modes |

|

#661

|

|||

|

|||

|

I love this build, ever thing about it shows your dedication to building an accurate scale representation of one incredible machine. I still cant believe that a machine like this exists in the real world a gigantic walking crane!!!!!! sounds like something George Lucas would come up with for one of his movies.

|

|

#662

|

||||

|

||||

|

Weather permitting I am going to go Jim. I'll know better next week.

|

|

#663

|

||||

|

||||

|

Quote:

Thanks for the interest in my build. Wish I could work on it more but time is limited due to running my business. |

|

#664

|

||||

|

||||

|

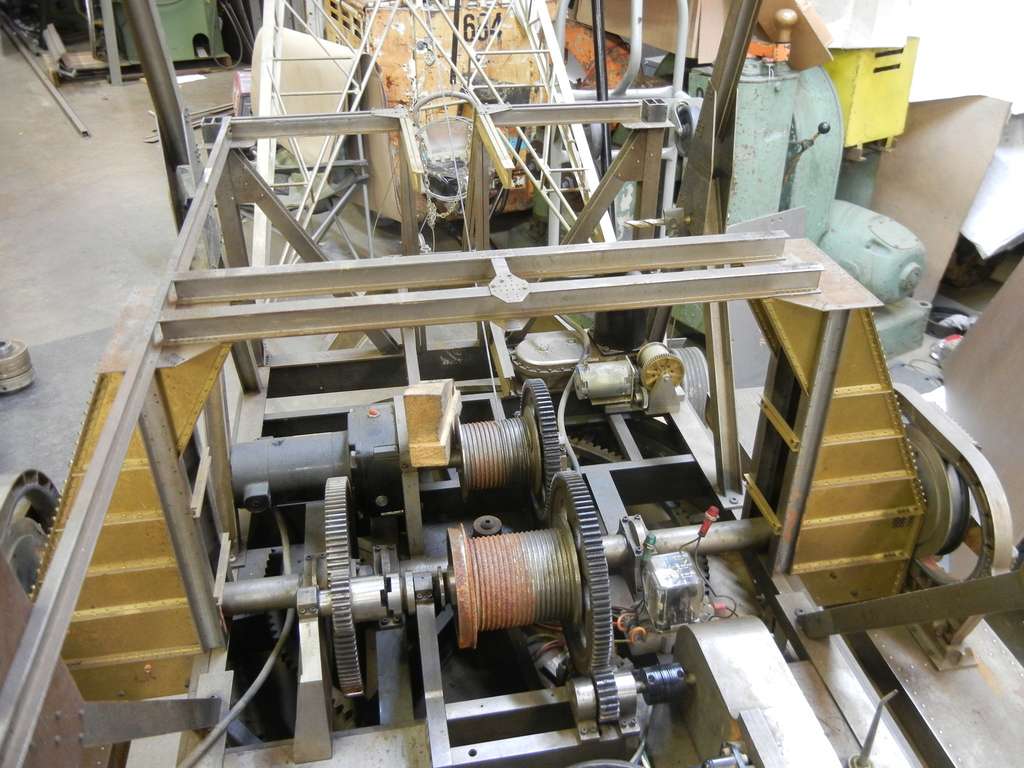

We got the 9W out of my trailer to get it ready for Cabin Fever Expo and I was surprised how bad it looked from the past few outings. Seems it rained every time I took it out or the humidity was so bad everything got rusty. I kept spraying the steel parts with WD40 over the years but obviously not on ALL areas.

I made the decision to dismantle the machine completely and do some much needed sandblasting and painting. I am also going to get the clutch working that shifts the drag mode to walking mode. Hopefully I can get the wiring done at the control console to make the shift.

|

|

#665

|

||||

|

||||

|

Wow, ya that really picked up some rust huh?!

Couple more years and we will have to blow it up at Brownsville and scrap it! |

|

#666

|

|||

|

|||

|

The rust never sleepes! Lucky you to find this out not a couple of days before show. I remember us having the discussion regarding paint or not. For shure, now the model will stand time and humidity better. My 463 scraper has been sitting in untemperated storage for some years now without any problem but it's painted of course.

|

|

#667

|

||||

|

||||

|

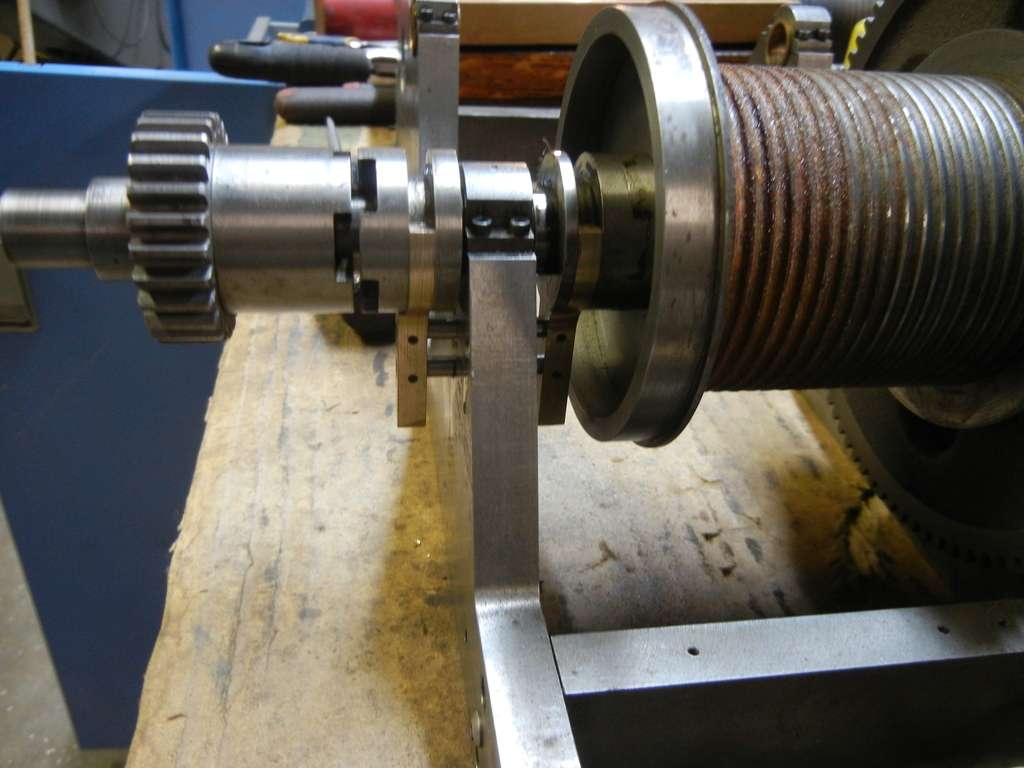

After several hours over the past three weeks I'm making some headway.

Here are the shifting forks needed to shift from drag mode to walking mode. I needed to do this for quite some time. I just needed an excuse to tear down the machine.  Here they are fitted into the main machinery frame. I am still working on a method to fit a servo to make the shift. I also need to make a brake band to keep the drag drum from unwinding when the clutch is moved over to the walking clutch.

|

|

#668

|

||||

|

||||

|

Now that everything is torn down on the main frame and tub. I cleaned and primed them.

Dirty Tub  Added some sheet to the bottom of the ballast compartments finally.  Primed and ready for some reassembly.

|

|

#669

|

||||

|

||||

|

Wow, you better wear a name tag so we can find you now! Not gonna recognize the new dragline!

jim jim

|

|

#670

|

|||

|

|||

|

It sure is a shame that all that rust came on and you had to tear it all apart. IT is hard enough to put it together the first tome with out doing it the second time. Ed

|

|

#671

|

||||

|

||||

|

I knew it would have to be done someday Ed. I never put all of the screws in it because it would take too long to put them in and remove them when the time comes. It also costs a few bucks just to buy all the alloy socket head cap screws. I have a couple thousand on order right now at $.07 each.

|

|

#672

|

||||

|

||||

|

Here are some more pictures of the I beam frame coming together. I spent about 28-30hrs putting this much together. Every hole had to be re-tapped to make sure the 0-80 screws go in easily. My thumbs and fingers get cramped up doing all those.

Finally...Paint

|

|

#673

|

||||

|

||||

|

Looks nice!

Kerst |

|

#674

|

|||

|

|||

|

Looking good! The rust is irritating but it's good motivation, ain't it?

|

|

#675

|

||||

|

||||

|

That's looking awesome! Paint really helps, and having all the fasteners takes the detail way up.

I wonder if some removable lexan body work might help with future rust when running it at outdoor shows. Either leave it clear, or light fog paint so it's just translucent and doesn't hide the workings |

|

#676

|

||||

|

||||

|

Thanks Kerst. See you in a week.

Quote:

Quote:

|

|

#677

|

||||

|

||||

will you be doing any weathering and ageing to the inside and outside makeing it look old and used that would be so cool will you be doing any weathering and ageing to the inside and outside makeing it look old and used that would be so cool

|

|

#678

|

||||

|

||||

|

Jackvan, i thought he just took care of the weathering. It got blasted and painted.

Then you could really have fun with doing: Clear or translucent skins, solid colors brand new paint job, solid colors weathered like the day you saw it dismantled... make them interchangable. That's such a cool machine, where ever you look there's always something else you hadn't noticed before. |

|

#679

|

||||

|

||||

|

A Masive undertake to overhaul. I have to sit down when i look what's going on.

It's a True Masterpiece. Carry on Please. We help you unload carefully

|

|

#680

|

||||

|

||||

|

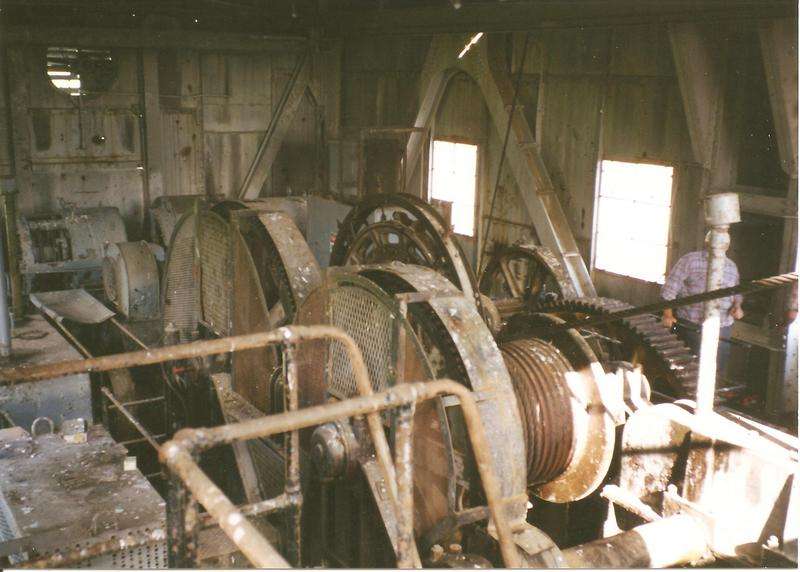

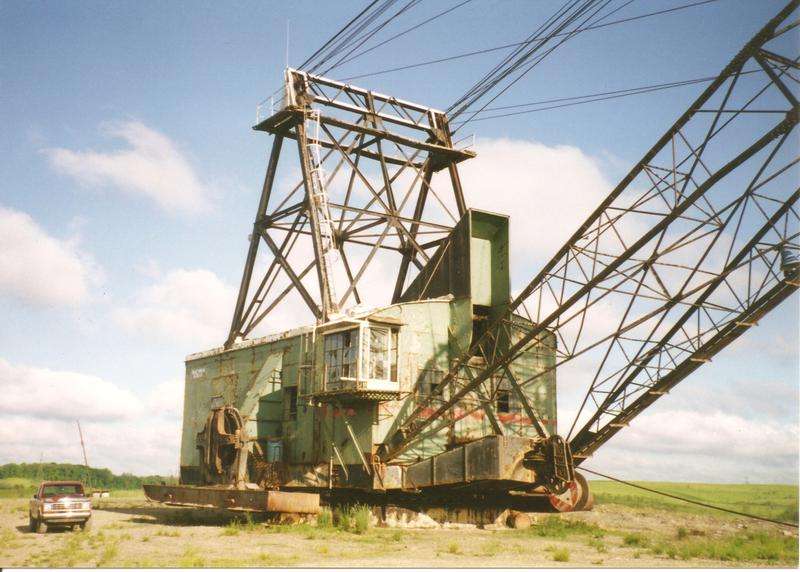

Quote:

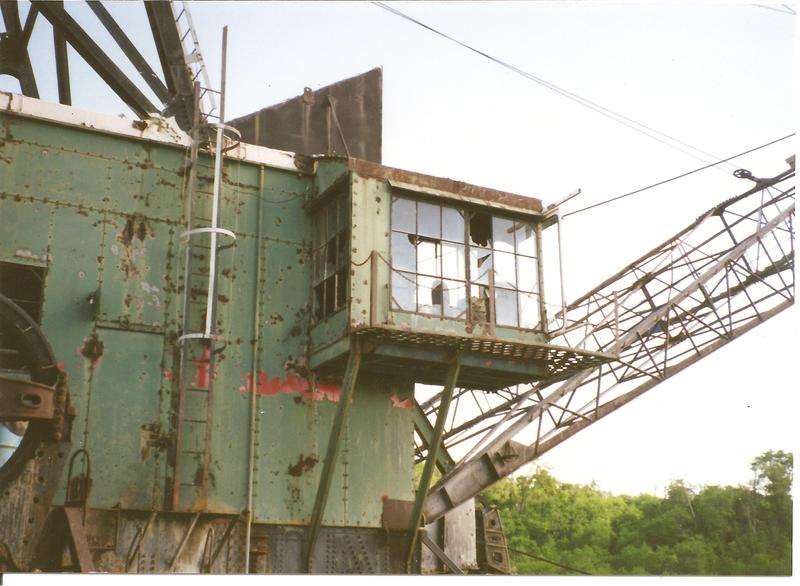

Here is an example of a heavily weathered relic   Here is my machine the day the scrappers started cutting her up. I originally wanted to make the house the light green with black boom ect. But now I'll be painting it Grey with the dark Green boom ect.    Here is the paint scheme I will be doing on the interior. Green machinery grey I beams. |

|

| Currently Active Users Viewing This Thread: 3 (0 members and 3 guests) | |

|

|