|

|

#221

|

||||

|

||||

|

No, I'm starting the third section and hope to get it pretty much complete this weekend. I won't have the point sheave done so I'm going to just clamp a temporary one on.

|

|

#222

|

||||

|

||||

|

Steve,

Talk to Willy (customrcmodels) about your lighting. He uses some 5mm LEDs on his tanks and trucks that you can not look at as they are so bright. They make the stock Tamiya headlights look like candles! Looks like I will not be able to make the York, PA show next week  Was able to get new computer and software for my CNC Sherline mill at a very good price so all of my available funds went there instead. Hope to see your dragline next year if all goes well. Was able to get new computer and software for my CNC Sherline mill at a very good price so all of my available funds went there instead. Hope to see your dragline next year if all goes well.Lynn |

|

#223

|

||||

|

||||

|

Quote:

Sorry you can't make it. Let's see some pictures of your new mill set up. |

|

#224

|

|||

|

|||

|

Steve-this looks really great! Your patience will be rewarded!!

|

|

#225

|

||||

|

||||

|

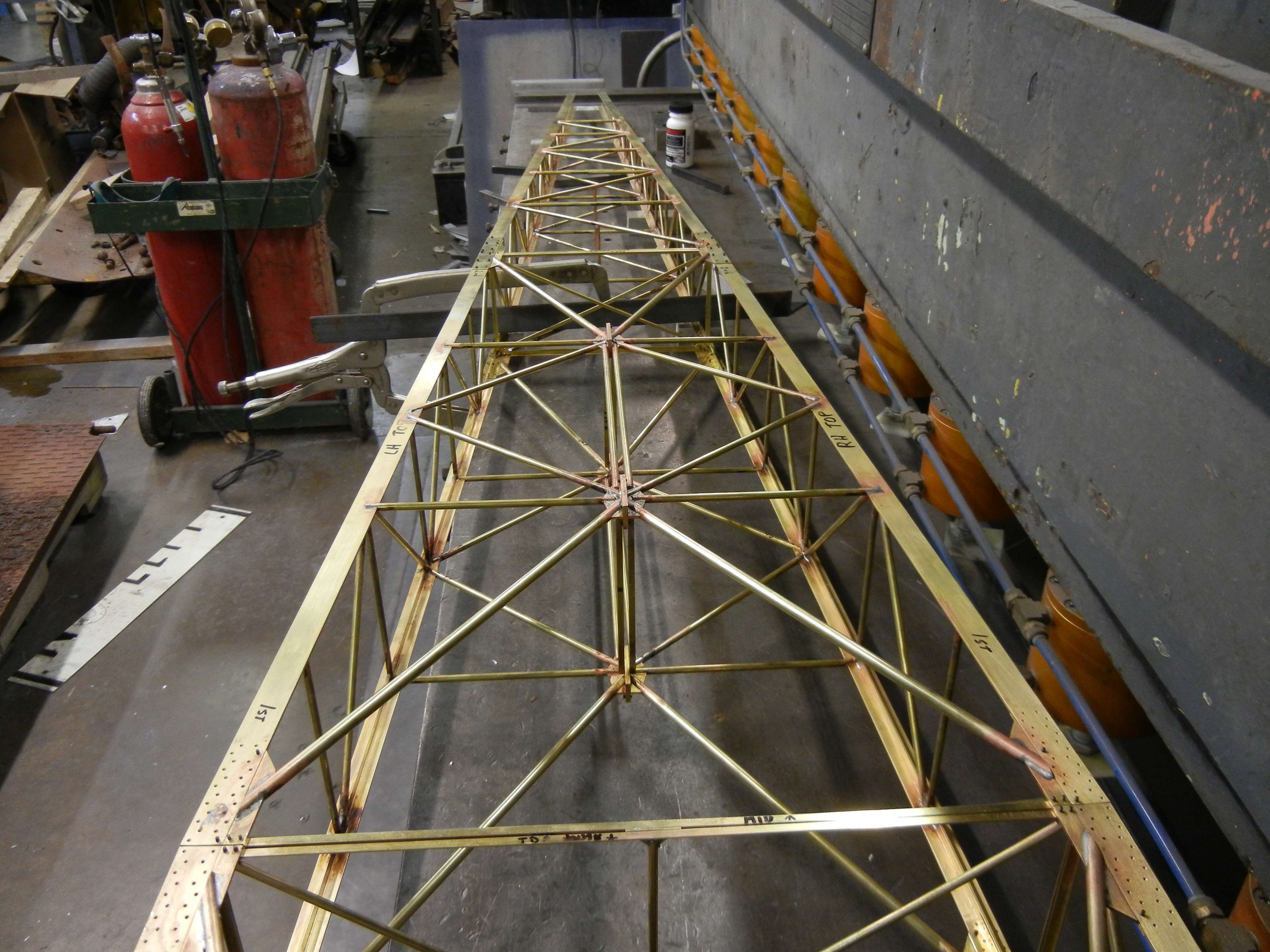

Thanks Tom, I am busy trying to get the 3rd section pretty much done this evening but got cut short from running out of oxygen on my torch. I have all the pieces made and about 3/4 of it is soldered together. I haven't started on the point yet but I'll still be putting a block of wood up there for the sheave temporally so we can run it this weekend.

|

|

#226

|

|||

|

|||

|

nice work i like all the detail jusy can't put it into words lol one day i will see your drag line model in person

__________________

I built this thing and have it working now what do I do with it? |

|

#227

|

|||

|

|||

|

Hey Steve, that's just amazing. If I only could see it in real life. That would be great.

How do you solder the 4 sides together without loosing any piece If the latice work while reheating? |

|

#228

|

||||

|

||||

|

td9clyde: Well who ever wants to brave the snow can see it this week end

Lorenzo, If you look closely at some of my previous posts you will see how the lattice is held together by notching the ends of the tubes. I can carefully pick the section up even without solder. Right now, I have to run down to the welding store this morning and get another bottle of Oxygen. |

|

#229

|

|||

|

|||

|

Steve are you using silver solder on the boom? If it was me I'd use 50 % silver solder so it would take the strain and the flex. Ed

|

|

#230

|

||||

|

||||

|

Quote:

http://www.harrisproductsgroup.com/~...IDGITSpec.ashx |

|

#231

|

||||

|

||||

|

Well I got the boom done enough to work and now I need to make a quickie point sheave and a eye bolt for the suspension cables

|

|

#232

|

||||

|

||||

|

Quote:

Also wicked picture there in your shop Monighan! Whats with the little cat hiding up on the shelf :P

__________________

Rc's are like pringles. You can't have just one!! my YouTube is - To view links or images in signatures your post count must be 10 or greater. You currently have 0 posts. Subscribe!! My Facebook - To view links or images in signatures your post count must be 10 or greater. You currently have 0 posts. |

|

#233

|

|||

|

|||

|

Steve-that looks FANTASTIC! I LIKE IT!!!

|

|

#234

|

|||

|

|||

|

Looks great. I get a kick of the Cat on the shelf everytime I see it!

__________________

Jeff |

|

#235

|

||||

|

||||

|

I tried the drag out some before we took the boom off and separated the top section for transport tomorrow. I noticed I'll need to add some counter weight. It may not walk very well because there may be too much weight on the nose of the tub preventing it from dragging along. I forgot to weigh the boom but I think it's around 25#

|

|

#236

|

|||

|

|||

|

nice job that thing is cool verry detailed makes my stuff look like matchbox toyslol

__________________

I built this thing and have it working now what do I do with it? |

|

#237

|

||||

|

||||

|

Here's a video of my machine walking down a steep grade Sunday. We had a time getting it up there on that pile Friday

http://www.youtube.com/user/Scentlessapprentice9 |

|

#238

|

||||

|

||||

|

Looking real nice!!

any pics or details on that CAT dozer up on the shelf????

__________________

"If you build it, they will come" East Coast Mini Truckers To view links or images in signatures your post count must be 10 or greater. You currently have 0 posts. |

|

#239

|

||||

|

||||

|

D1-Look under the 1:1 topics.

|

|

#240

|

|||

|

|||

|

Steve-that's a great video of the 9W walking down the pile. I could see you were having some problems but I was amazed that the model would walk down a hill that steep. Did you walk it up the hill to start digging? Also I liked your hoist drum brake.

|

|

| Currently Active Users Viewing This Thread: 19 (0 members and 19 guests) | |

|

|