|

|

|||||||

| Construction Equipment If it digs, pushes, hauls dirt "off road" post it here. |

|

|

|

Thread Tools | Display Modes |

|

#1

|

|||

|

|||

|

Tonight, I started a Conversion of the small caterpillar, D4 I think it is.

|

|

#2

|

|||

|

|||

|

Once my Email quits lagging, & I can get them to show up in my INBOX, so I can upload them to flilcker, I'll post up a few pics.

I CAN'T take credit for the inspiration on this build. Jug has done it & posted it on his YouTube page. I liked the idea. I wanted to use Micro Servo's for it, but was having a problem finding a part that would connect the micro servo to the track sprockets. Since I couldn't source the parts I wanted, I ran with his idea. I will deviating slightly from his build in the way the sprockets mount to the motor......That is, once the parts FINALLY arrive on the SLOW boat from China. |

|

#3

|

|||

|

|||

|

FINALLY, they showed up in my Email. Here's a few pics of the build so far

20170809_234213 by Anthony Kalnoski, on Flickr 20170809_234213 by Anthony Kalnoski, on Flickr 20170809_234244 by Anthony Kalnoski, on Flickr 20170809_234244 by Anthony Kalnoski, on Flickr

|

|

#4

|

|||

|

|||

|

|

|

#5

|

||||

|

||||

|

I think thats a D5, and looks like a good start.

You may want to shim the gearbox shafts, some have too much play and the gear mesh is inconsistant.

__________________

What do ya mean "Cars are neither Trucks or Construction"? It's still scale, and i play fairly well with others, most of the time... |

|

#6

|

|||

|

|||

|

Quote:

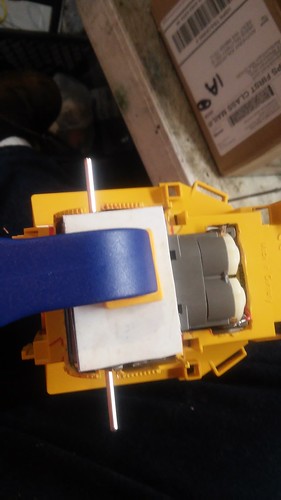

I wish I would have saw that BEFORE I did what I done on Thursday morning. I wish I would have saw that BEFORE I did what I done on Thursday morning.  Thinking I would be slick, & try & dust/dirt proof the gearbox a bit, I did this little mod. Thinking I would be slick, & try & dust/dirt proof the gearbox a bit, I did this little mod.  20170810_051457 by Anthony Kalnoski, on Flickr 20170810_051457 by Anthony Kalnoski, on Flickr 20170810_051447 by Anthony Kalnoski, on Flickr 20170810_051447 by Anthony Kalnoski, on FlickrIn addition to dirt proofing it a bit, my thought was, it'd give the inner workings a SAFE place to lay, WITHOUT risk of getting caught in the gearbox. In hindsight, I'm sure I SHOULD  have completed the build & tested it prior to doing it. have completed the build & tested it prior to doing it.

|

|

#7

|

|||

|

|||

|

Those are the only pics I have of it. The glue has since dried, & the clamps are removed.

|

|

#8

|

|||

|

|||

|

Rain delays this weekend at work, left me with some spare time this weekend. I did a bit on the Cat.

Added a bit of weight, about 6OZ to it, mounted the blade servo, & affixed the track sprockets to the Tamiya gearbox.  20170813_013849 by Anthony Kalnoski, on Flickr 20170813_013849 by Anthony Kalnoski, on Flickr 20170813_034818 by Anthony Kalnoski, on Flickr 20170813_034818 by Anthony Kalnoski, on FlickrThe bolts I had that were lengthy enough were WAY TOO LONG. I used them, cut them off after installation, & filed them flat with the adapter.  20170813_035955 by Anthony Kalnoski, on Flickr 20170813_035955 by Anthony Kalnoski, on FlickrSince I had the gloves on to work with the epoxy, I decided to drill a hole in a fishing weight. It was an 8OZ weight, with a bit trimmed off of it. I guestimate it's about 6OZ left on it.  20170813_032420 by Anthony Kalnoski, on Flickr 20170813_032420 by Anthony Kalnoski, on FlickrThe sides of the dozer modified so the redneck lifting mechanism for the blade can do it's thing. YEAH, I KNOW, I went a bit overboard hogging out the holes in it. I had some leftover scraps of plastic laying around. I glued them into the excess opening. I forgot to take snaps of it.  20170814_023921 by Anthony Kalnoski, on Flickr 20170814_023921 by Anthony Kalnoski, on FlickrThe metal gear micro servo installed  20170814_030713 by Anthony Kalnoski, on Flickr 20170814_030713 by Anthony Kalnoski, on Flickr

|

|

#9

|

|||

|

|||

|

Just a few more mods to do on the tracks, & then it'll be time to test it out. I know being plastic if WON't be durable, or powerful enough to push much of anything, but it'll still be fun.

|

|

#10

|

|||

|

|||

|

A quick note about the lead weight. If you plan to drill a fishing weight, as I did, & it's pure lead, be prepared for a LOT of work. I'd get about 2 seconds of the drill working in the lead, then I'd have to spend 10-25 seconds cleaning the drill bit. The lead clogs up the bits. It DOESN'T spit out in ribbons like other metals do.

|

|

#11

|

||||

|

||||

|

Looks like it's coming along well.

Watch some videos, bruder conversions are pretty capible, even though it's plastic. Lead likes some thin lube and a slow feed rate so it spits little flakes off the bit, and pulling out to clear chips a lot.

__________________

What do ya mean "Cars are neither Trucks or Construction"? It's still scale, and i play fairly well with others, most of the time... |

|

#12

|

|||

|

|||

|

I just received a d5 conversion from small haul on youtube. This is one bad little dude, not only will it push dirt but it will also cut in. It is a very capable machine and affordable.

|

|

#13

|

|||

|

|||

|

I'm glad to hear that. I was worried that being plastic it may not do so well.

|

|

#14

|

|||

|

|||

|

I've many questions about yours. Are the tracks still the stock Bruder kind? Is the cab interior still in it? What size battery pack is it running? Is/was any weight(s) added to it when it was converted?

|

|

#15

|

|||

|

|||

|

Yes tracks are stock bruder, they actually provide way more traction than i thought they would. Cab interior is still in, 2300 mah nimh pack, It was stuffed with as much weight as he could fit, It weighs around 5 pounds.

|

|

#16

|

|||

|

|||

|

Do you have pictures of how & where the battery mounts in it? I'm struggling trying to figure out how to put the battery pack in it, while including the cab interior.

|

|

#17

|

|||

|

|||

|

I don't know how it is mounted inside it came RTR, And i probably wont take it apart until I have too. Look up "small haul" on youtube, he has a bunch of videos and I'm sure you can find what you need.

|

|

#18

|

|||

|

|||

|

After looking at a few of his vids, I found the info for his builds. There's an internal RECHARGEABLE battery pack in his

I LIKE that idea. I LIKE that idea.

|

|

#19

|

|||

|

|||

|

After working Thursday, & then finding out we're working Friday NIGHT, I stayed up all night to get my self acquainted with night shift AGAIN! I had a LOT of time to work on the littel dozer.

I found a PROBLEM with where I mounted the blade control rod. I SHOULD have ended the bolt between the 2 side of the blade arm, & NOT ran completly through it.  20170817_225951 by Anthony Kalnoski, on Flickr 20170817_225951 by Anthony Kalnoski, on FlickrIt SHOULD have ended where the knife blade is, & has since been re-located.  20170817_225345 by Anthony Kalnoski, on Flickr 20170817_225345 by Anthony Kalnoski, on FlickrI cemented the blade pivots where the knife blade is, to prevent it from moving while working  20170817_225400 by Anthony Kalnoski, on Flickr 20170817_225400 by Anthony Kalnoski, on FlickrEach drive sprocket got TEN screws placed into them between every OTHER tooth.  20170817_205810 by Anthony Kalnoski, on Flickr 20170817_205810 by Anthony Kalnoski, on FlickrNOTE: DON'T do like I did! Before I reinstalled EVERYTHING onto the tracks, I adjusted the slack in the track by lengthening the distance the screws stuck out form the sprocket. Once I re-assembled the track guides, the tracks were too tight. |

|

#20

|

|||

|

|||

|

I somewhat flattened a 20Ooz teardrop shaped fishing weight. I plan to trim it to shape, & place it in the dozer for more added weigh. I still have bugs to work out with it. Once my Email quits lagging, I'll post the vid of it. The video ISN'T a very long video, & doesn't show the quirks I have yet to work out with this little dozer.

|

|

| Currently Active Users Viewing This Thread: 1 (0 members and 1 guests) | |

|

|